Device for eliminating wall surface coating

A technology for removing devices and coatings, applied in construction and building construction, etc., can solve the problems of loose overall structure, damage to the surface of the wall, and no collection of dust and debris, so as to improve the clean environment, reduce the work intensity, The effect of ideal balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] First of all, what the applicant needs to explain is: in the following description, all concepts related to orientation, such as left and right, are for the position status shown in the illustration, so this should not be interpreted as a limitation to the solution of the present invention; Secondly, the embodiment is only one of the best implementation modes recommended by the applicant, so it should not be regarded as unique and limit the solution of the present invention.

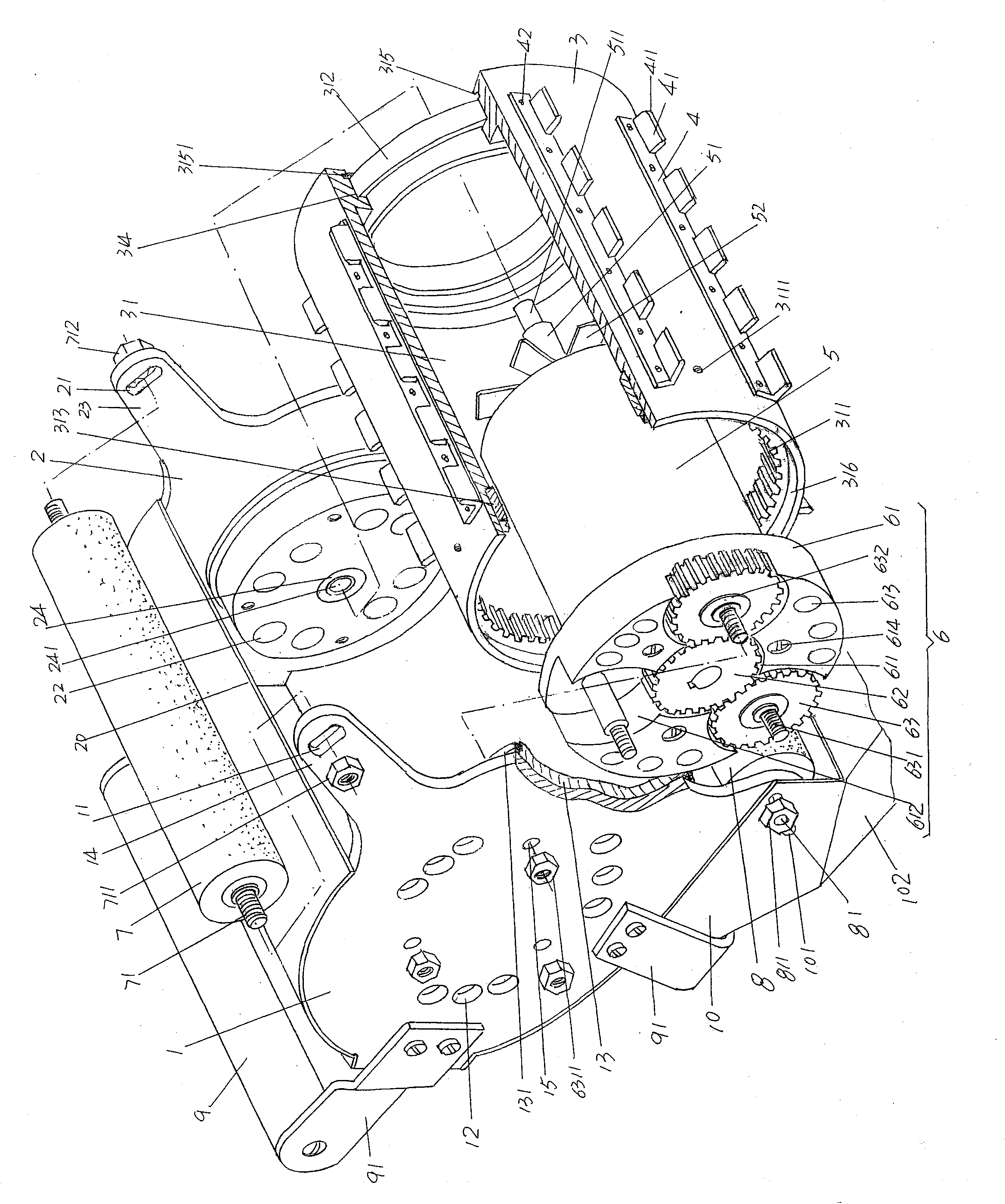

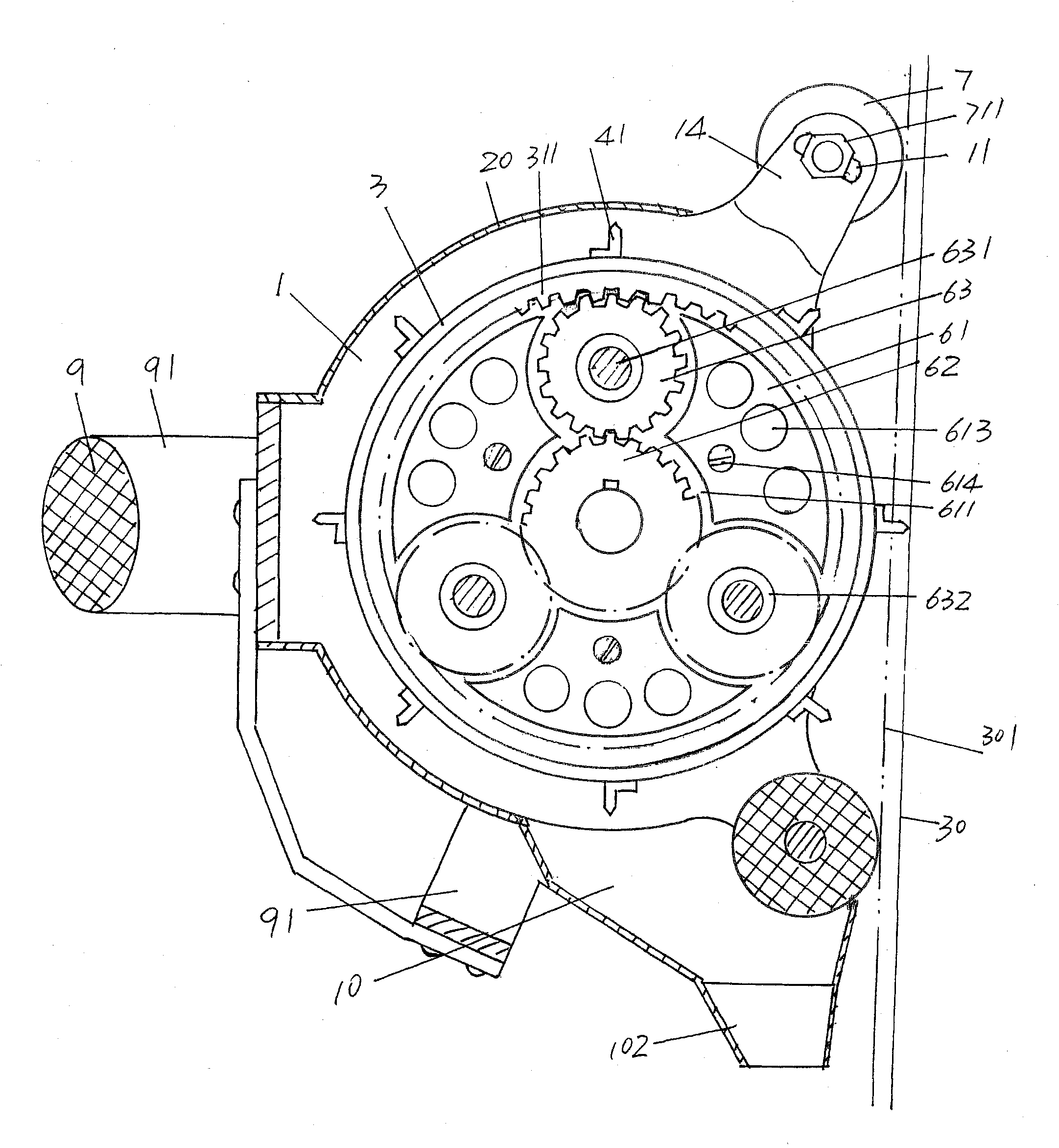

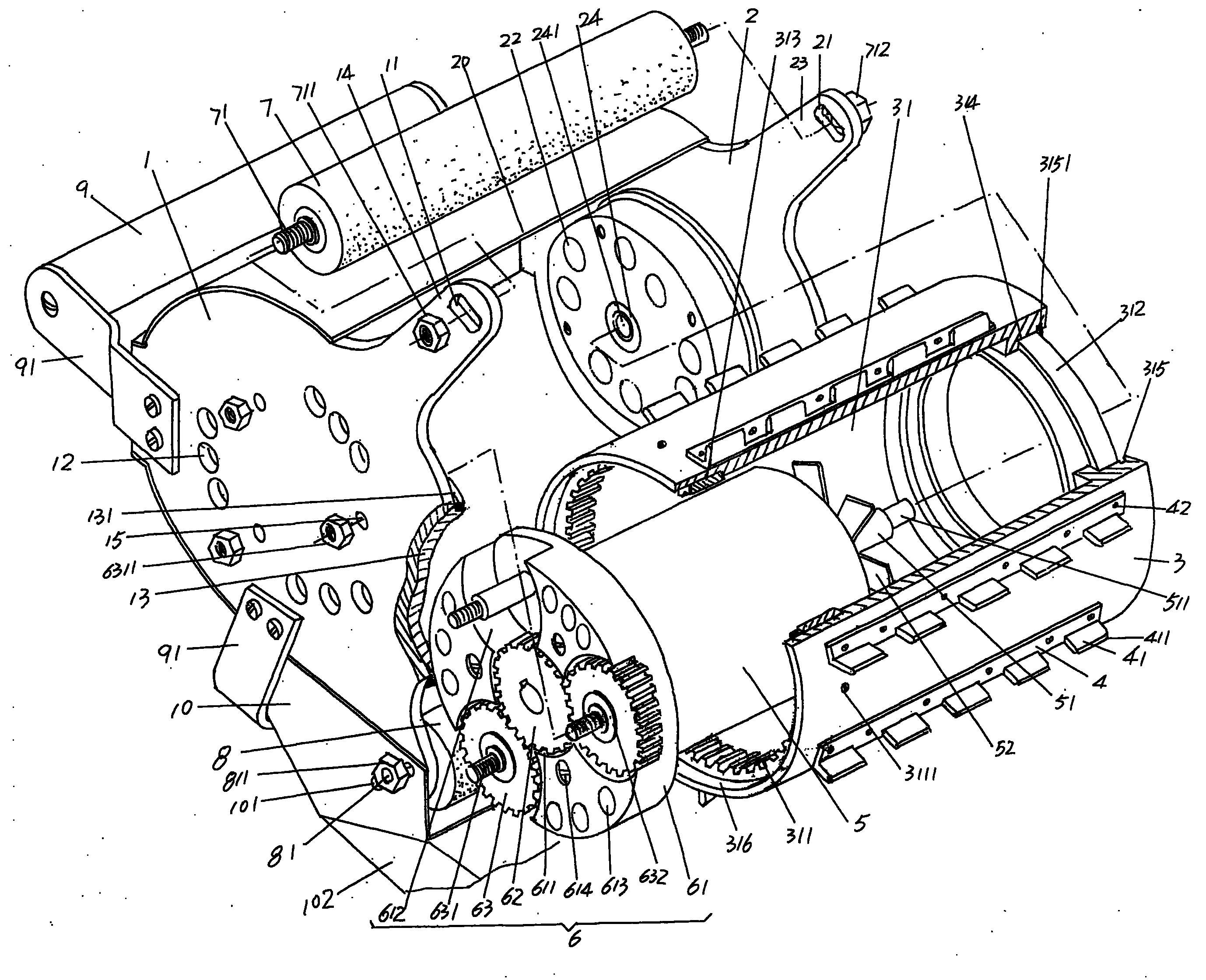

[0026] please see figure 1, the first and second support plates 1 and 2 which are set facing each other and have the same shape and size are provided, and the upper and lower parts of the first support plate 1 each extend a first support plate guide roller seat 14 in a narrow form, And the upper and lower parts of the second bracket plate 2 also extend a second bracket plate guide roller seat 23 in a narrow form. The concept of narrowing here is like the relationship between the auricle and the ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com