Film-pressing roller assembly of thin film processing assembly line

An assembly line and lamination roller technology, which is applied to the cleaning method using tools, removing smoke and dust, and flat products, etc., can solve the problems of decreased production efficiency and qualified rate, film surface indentation, insufficient support of the mounting plate, etc. Comprehensive, weight-preventing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

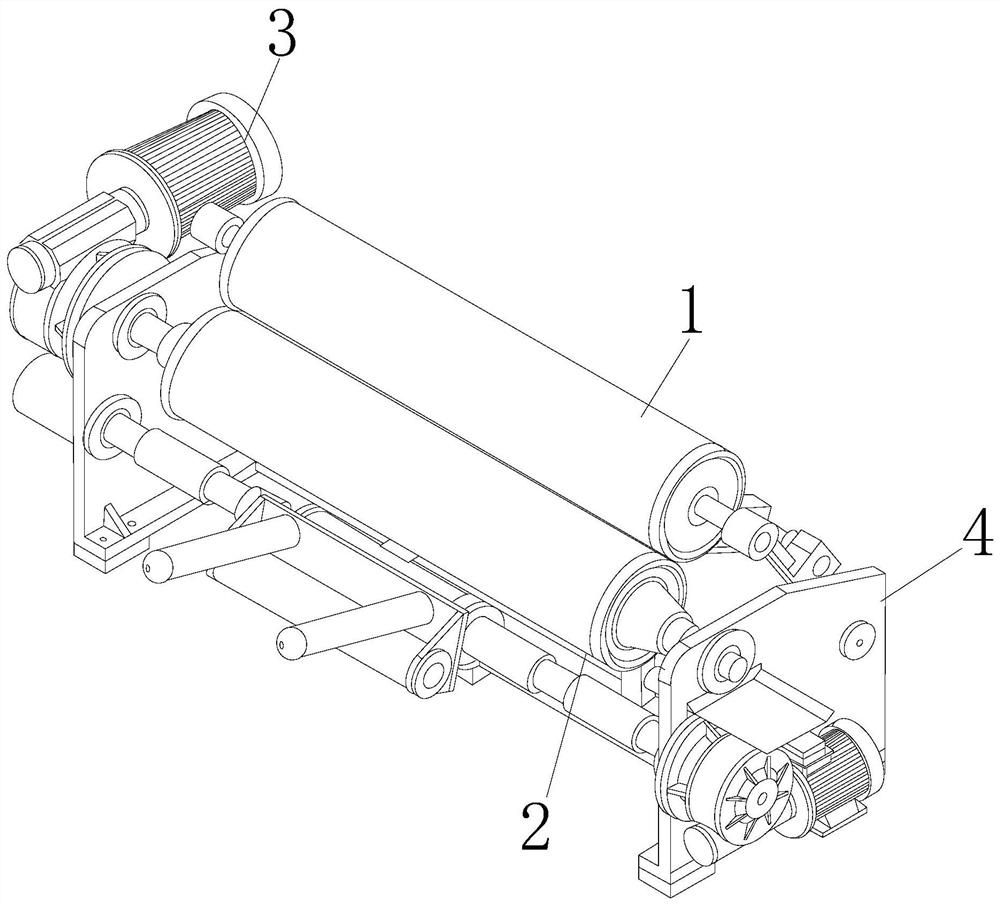

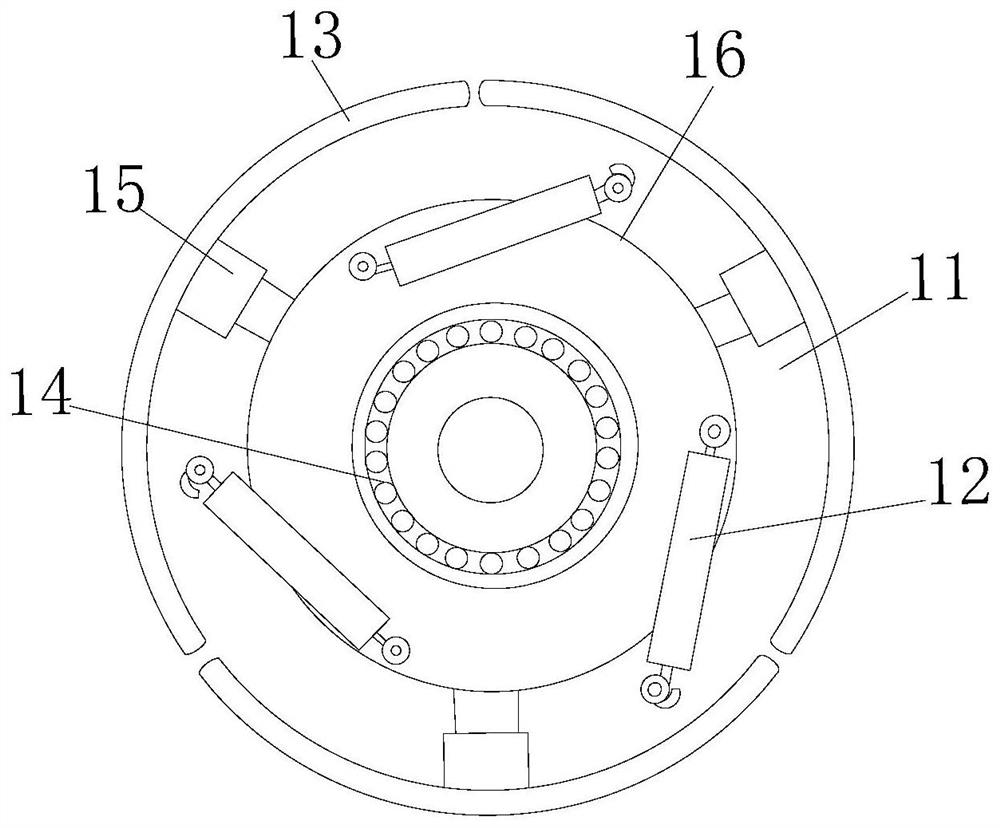

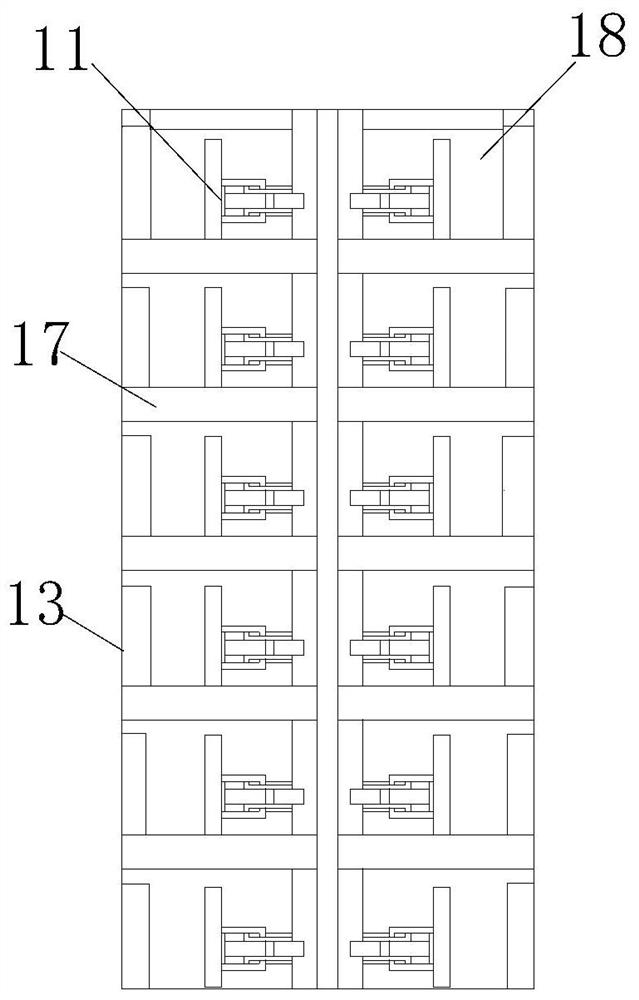

[0034] like Figure 1-Figure 6As shown, the present invention provides a lamination roller assembly of a film processing line, the structure of which includes a roller 1, a scraper structure 2, a frame 3, and a motor 4, and the inside of the frame 3 is equipped with a roller 1, A scraper structure 2 is provided below the roller 1, and the signal output end of the motor 4 is electrically connected to the connection end of the roller 1. The interior of the roller 1 mainly includes a support device 11, an elastic member 12, an installation Plate 13, bearing 14, connector 15, turntable 16, the support device 11 is installed under the turntable 16, and the turntable 16 and the turntable 16 are connected by buckling through the elastic member 12, and the bearing 14 is fixedly installed on the turntable 16 One end of the connector 15 is fixedly connected to the mounting plate 13, and the other end is clamped to the bayonet outside the circumference of the turntable 16. A partition 17...

Embodiment 2

[0036] like Figure 7-Figure 10 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. As a further improvement of the present invention, the scraper structure 2 mainly includes a scraper 21, an ash receiving port 22, an opening assembly 23, a collector Ash tube 24, positioning rod 25, fixed rod 26, control shaft 27, the scraper 21 is in contact with the arc-shaped surface of the roller 1, and its tip opening is provided with an ash-connecting port 22, and the ash-connecting port 22 is connected to One end of the ash collecting pipe 24, the opening assembly 23 is fixedly connected to the inner side of the scraper 21, the fixed rods 26 cooperate with each other through the control shaft 27, and the two ends of the positioning rod 25 are fixed on the fixed rod 26 by bolt connection, The opening assembly 23 is provided with a spring 231, a chute 232, a locking ball 233, and a curved rod 234. The spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com