Manufacturing method for freeze-drying seafood

A freeze-dried and seafood technology, applied in the preservation of meat/fish, food preservation, bivalve processing, etc., can solve the problem of uneven quality of freeze-dried seafood products, inclusion of impurities and harmful microorganisms, and inconsistent smell and taste Unsatisfactory and other problems, to achieve the effect of enhancing the preservation effect, enhancing the freeze-drying effect, and improving the health degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

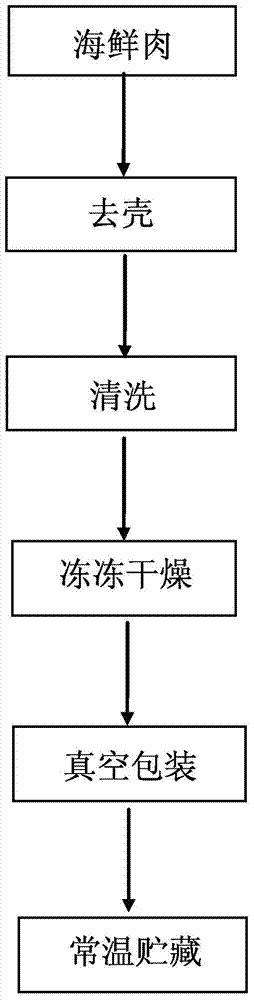

[0036] figure 1 An implementation form according to the present invention is shown, which includes:

[0037] Step 1. Buy live shellfish;

[0038] Step 2, removing the shell of the live shellfish and retaining the shellfish meat of the live shellfish;

[0039] Step 3, cleaning the shellfish to remove impurities and residual broken shells;

[0040] Step 4, dividing the shellfish into multiple plates, loading 5kg shellfish in each plate, and using a vacuum freeze dryer to freeze-dry the shellfish, specifically:

[0041]a. Place the shellfish in the cold east warehouse of the vacuum freeze dryer, check the vacuum pump oil gauge of the vacuum freeze dryer, make the oil in the vacuum pump oil gauge clear and not viscous, and the oil level is at the oil level. Mirror center position; detect whether there is oil in the compressor of the vacuum freeze dryer, if there is no oil, add oil to the compressor, open the refrigeration valve of the vacuum freeze dryer, the high and low press...

Embodiment 2

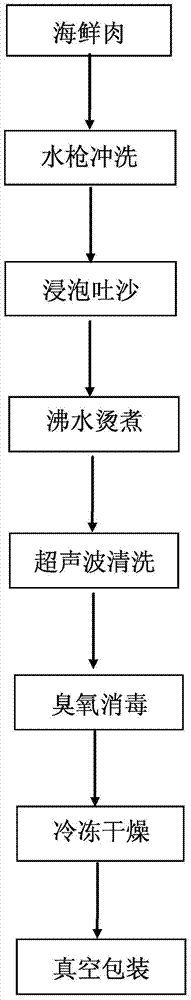

[0047] figure 2 Another implementation form according to the present invention is shown, which includes:

[0048] Step 1, buy two live shellfish with tightly closed shells, wherein the weight of the selected live shellfish is 100-150g, wherein, the live shellfish selected in this embodiment are oysters, mussels, snails, pearl snails, red snails, One or more of shellfish such as car snails, abalone or scallops, but the method disclosed in the present invention is not limited to the species listed in this embodiment;

[0049] Take seawater, add activated carbon to seawater, boil for 2-3 minutes, filter out activated carbon, cool to 30°C, add distilled water, citric acid and potassium permanganate to seawater to obtain the first cleaning solution, wherein the mass ratio of seawater to activated carbon is 1:7, the mass ratio of seawater, citric acid and potassium permanganate in the first cleaning solution is 100:3:0.1;

[0050] Step 2: Use a high-pressure water gun to spray th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com