CARP optimizing and cleaning device

A cleaning device, polyurethane technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of easy wear of blades, poor cleaning effect, easy damage to belts, etc., to ensure cleaning angle and wear resistance , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

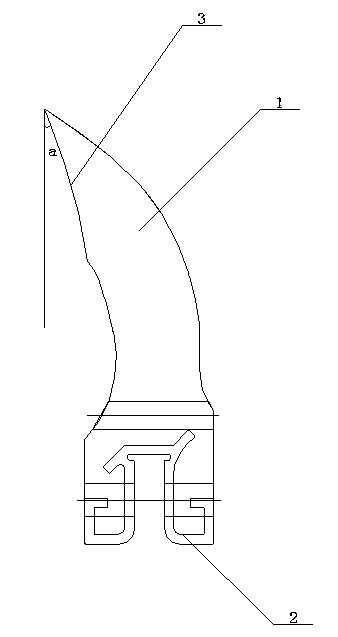

[0009] see figure 1 , This specific embodiment adopts the following technical scheme: it includes a polyurethane blade 1, an aluminum alloy insert 2, and the polyurethane blade 1 is embedded in the aluminum alloy insert 2.

[0010] The inner surface of the upper end of the polyurethane blade 1 is provided with an inclined contact surface 1-1, and the angle a between the contact surface 1-1 and the vertical line is 20°-30°.

[0011] According to this specific embodiment, the shape and size of the blade are designed through the difference according to the friction coefficient between the blade and the belt, the material properties of itself and the characteristics of the conveyed material, so as to ensure the contact area and cleaning angle of the cleaner, and can more comprehensively clean the Remove the material on the belt; the blade of the selected polyurethane material ensures the wear resistance of the blade and the service life of the blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com