Patents

Literature

60results about How to "Improve snow performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

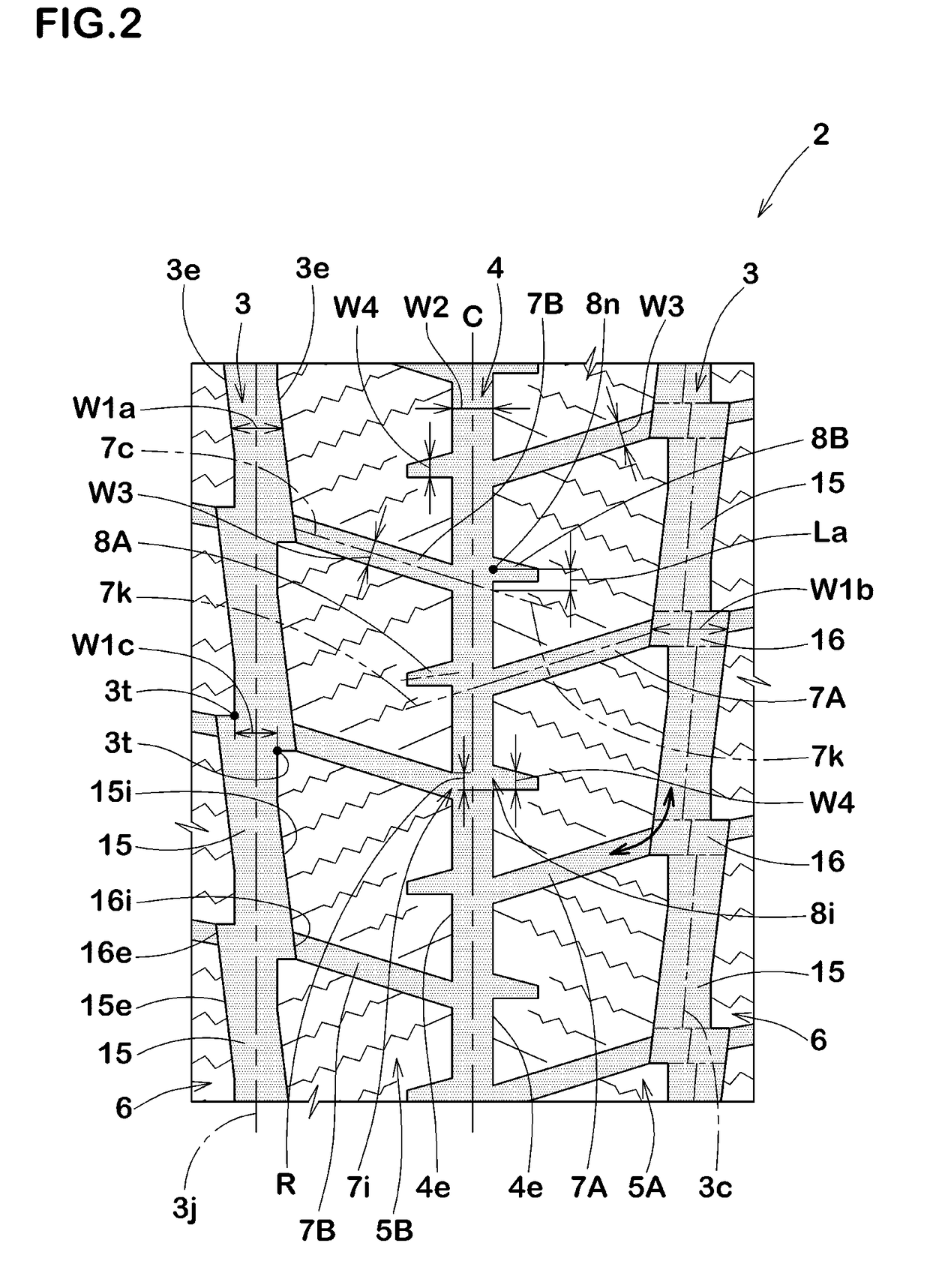

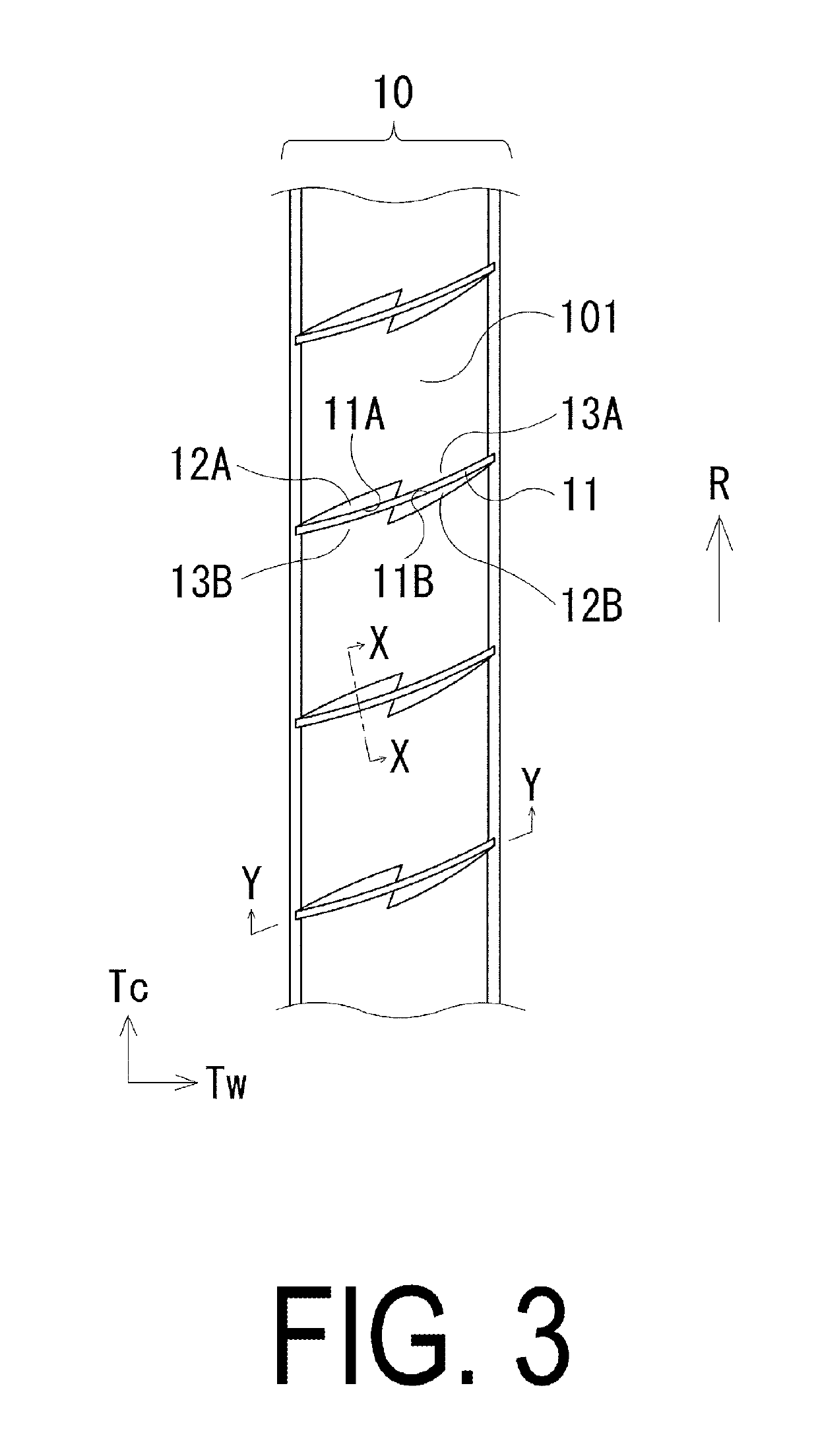

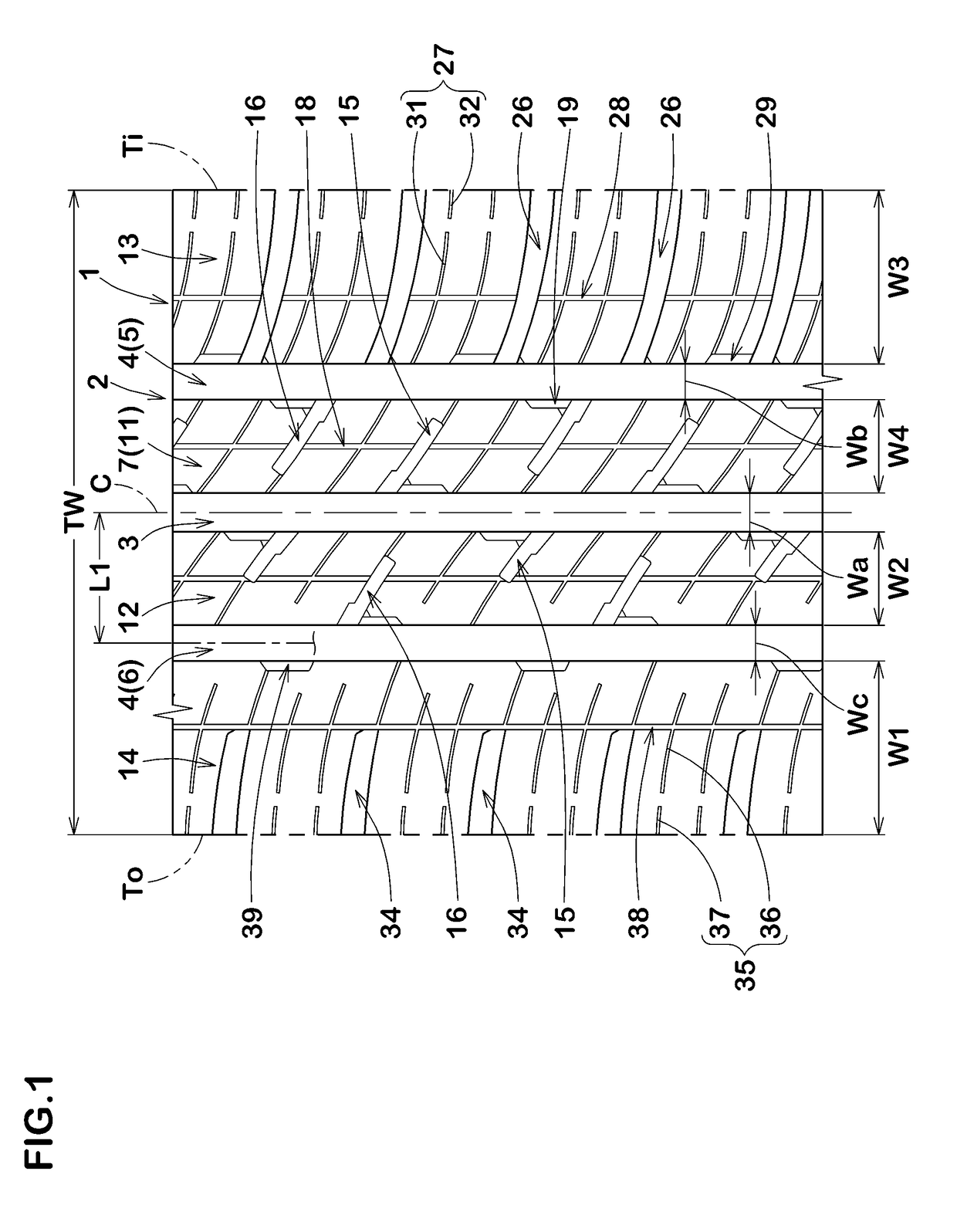

Pneumatic tire

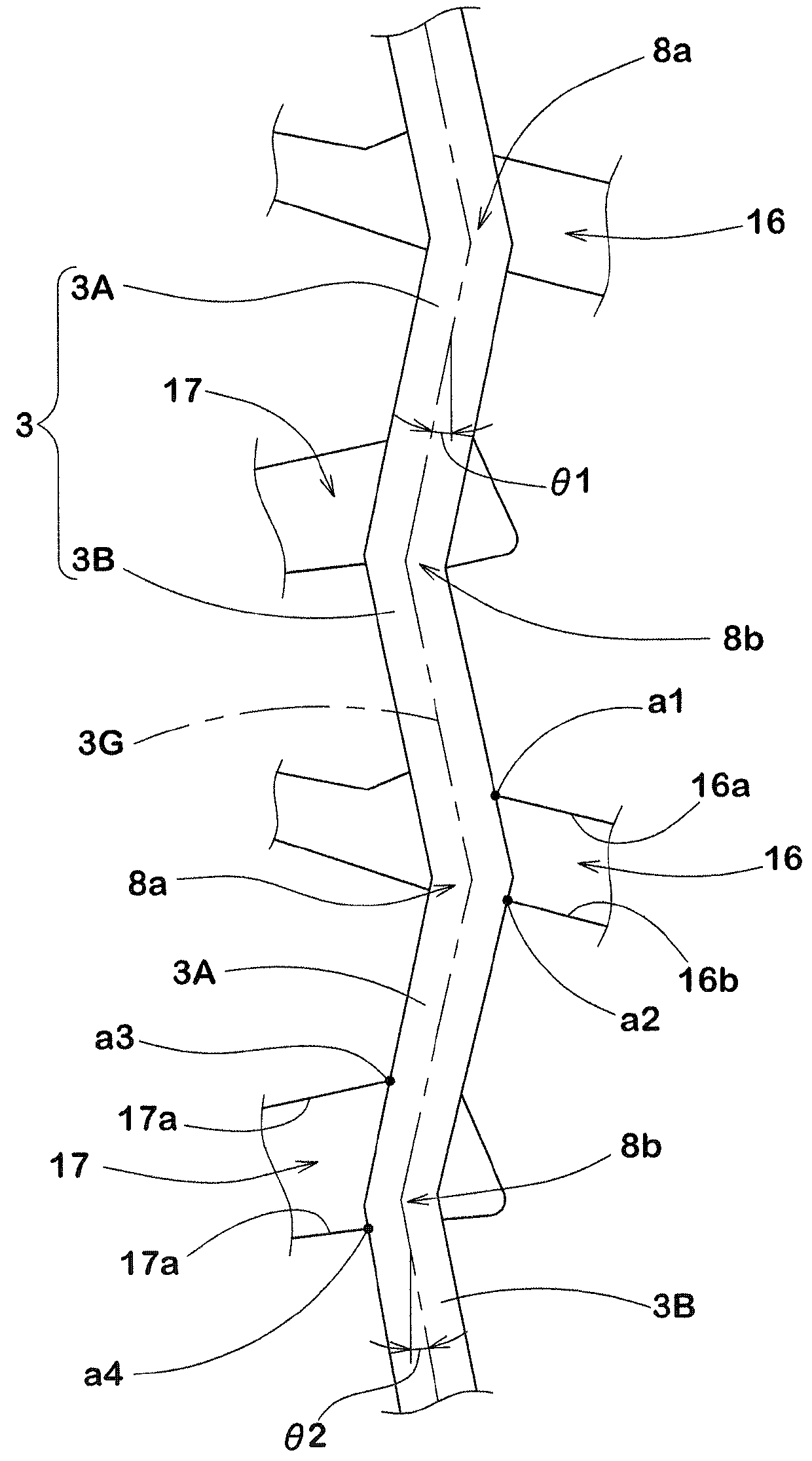

ActiveUS20130248068A1Improve snow performanceImprove steering stabilityTyre tread bands/patternsNon-skid devicesStructural engineeringTread

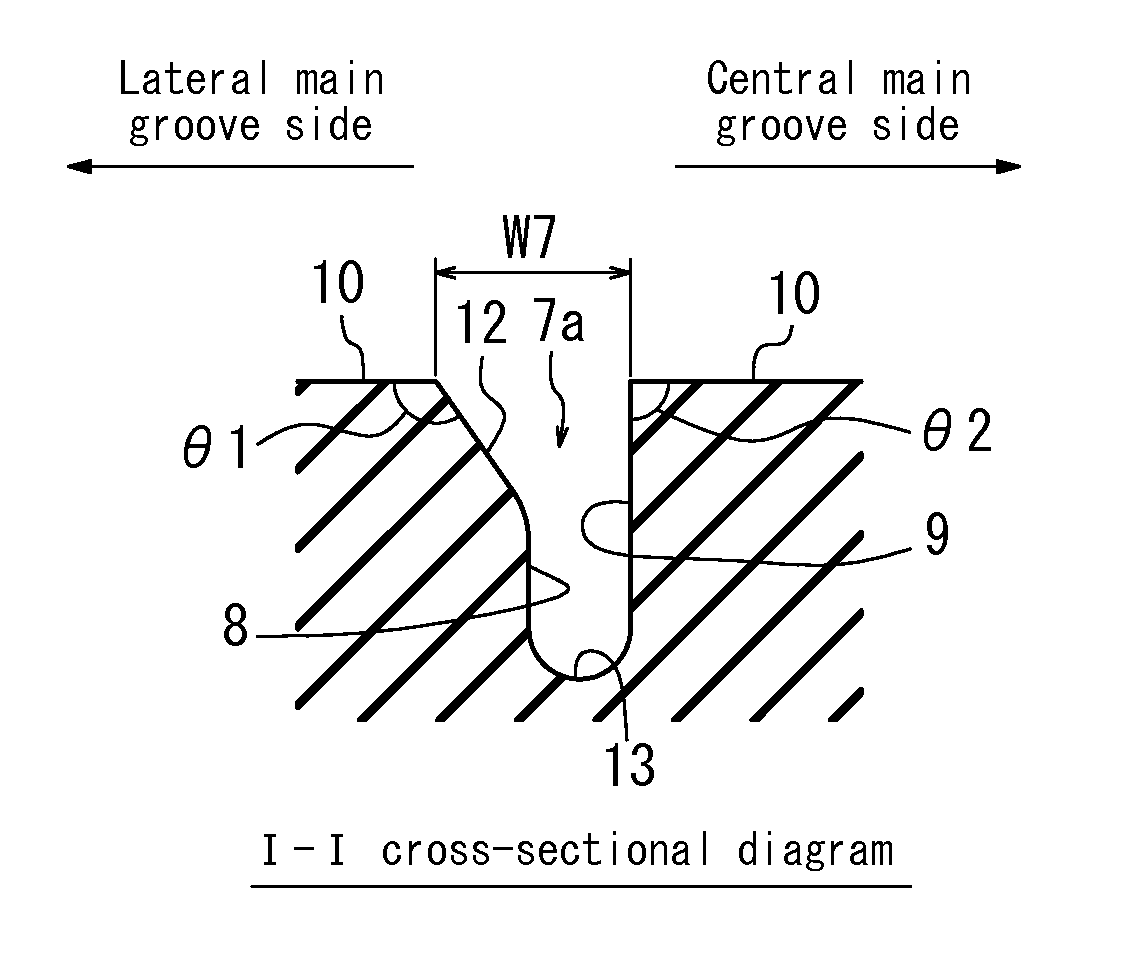

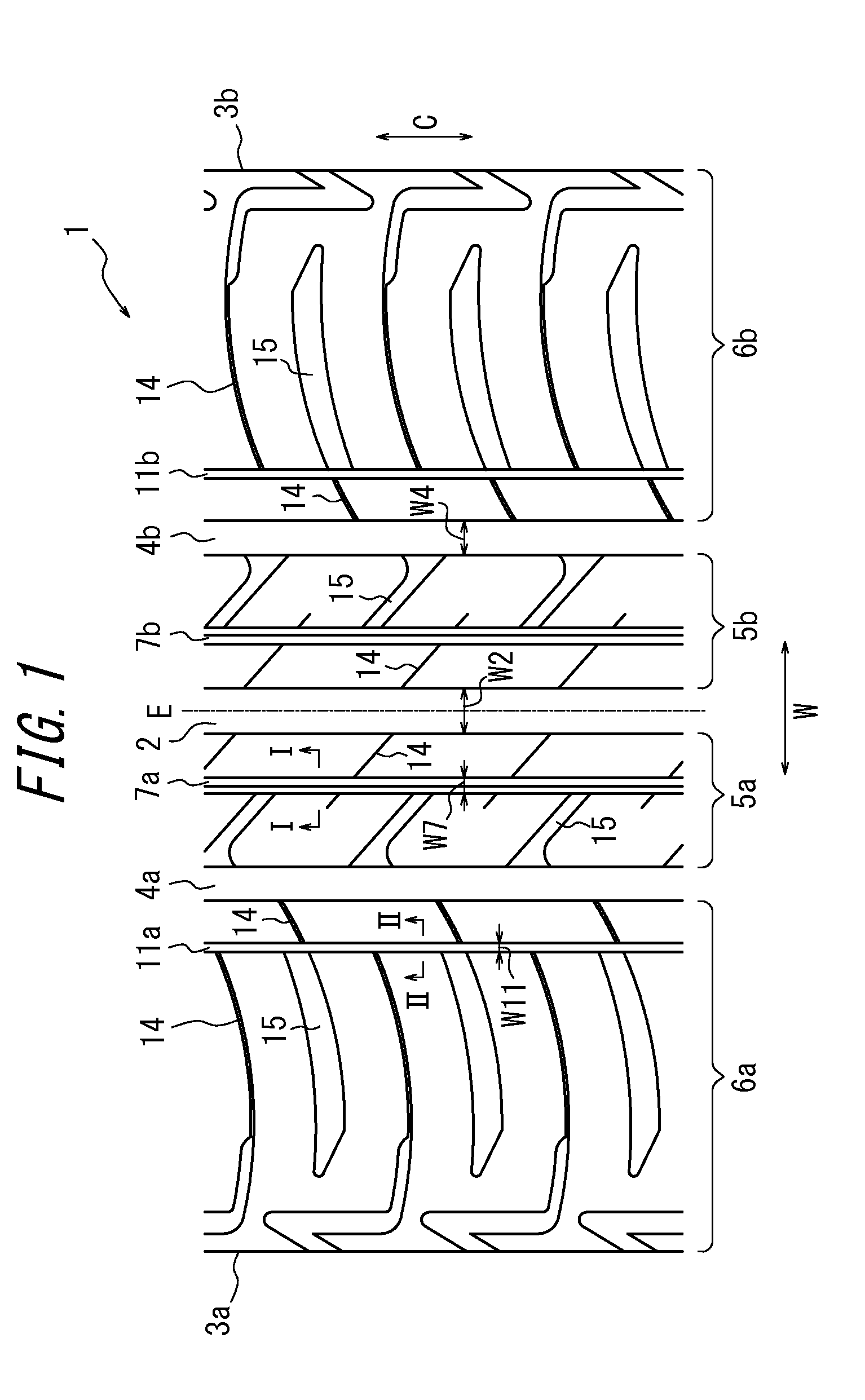

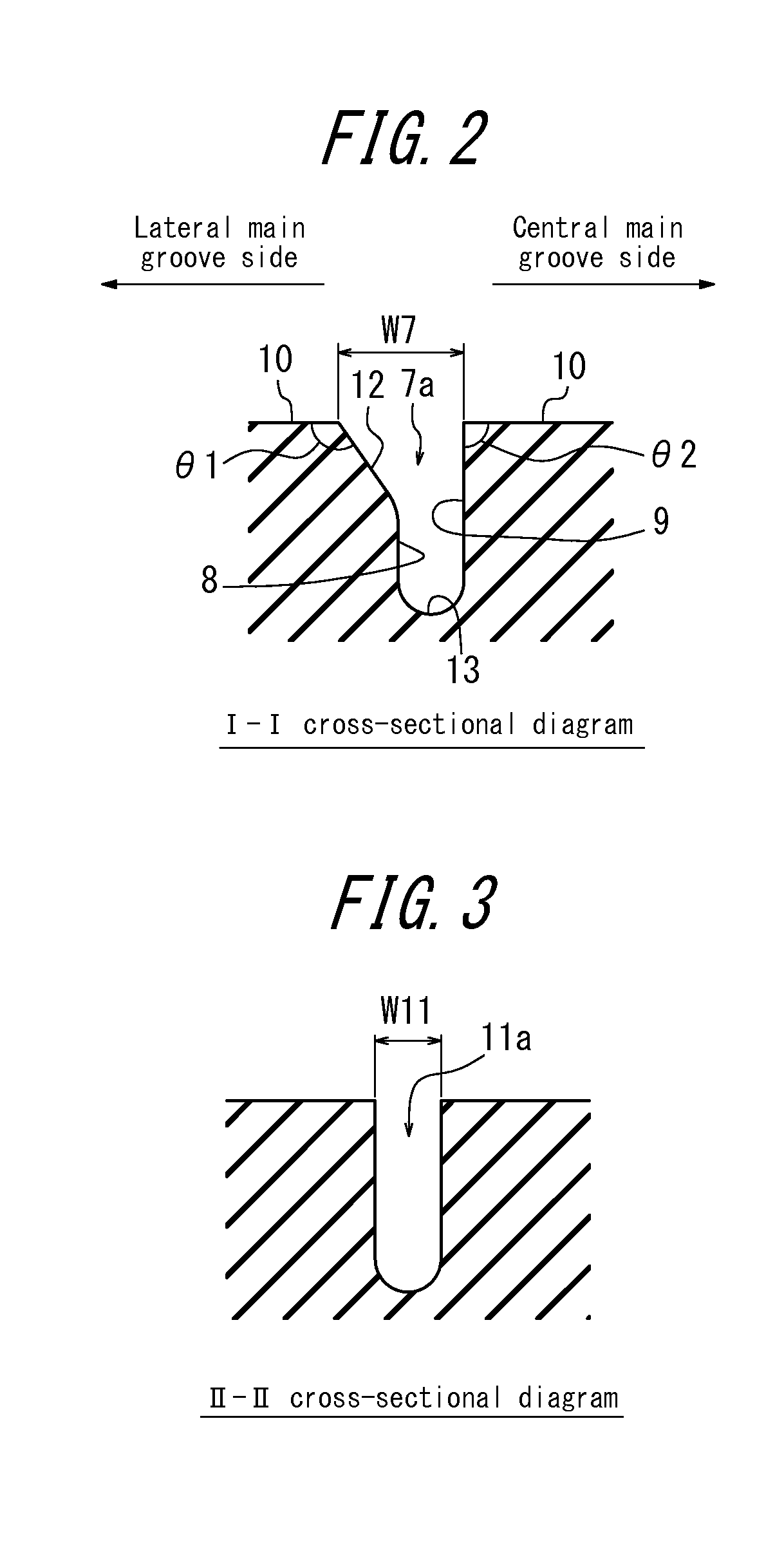

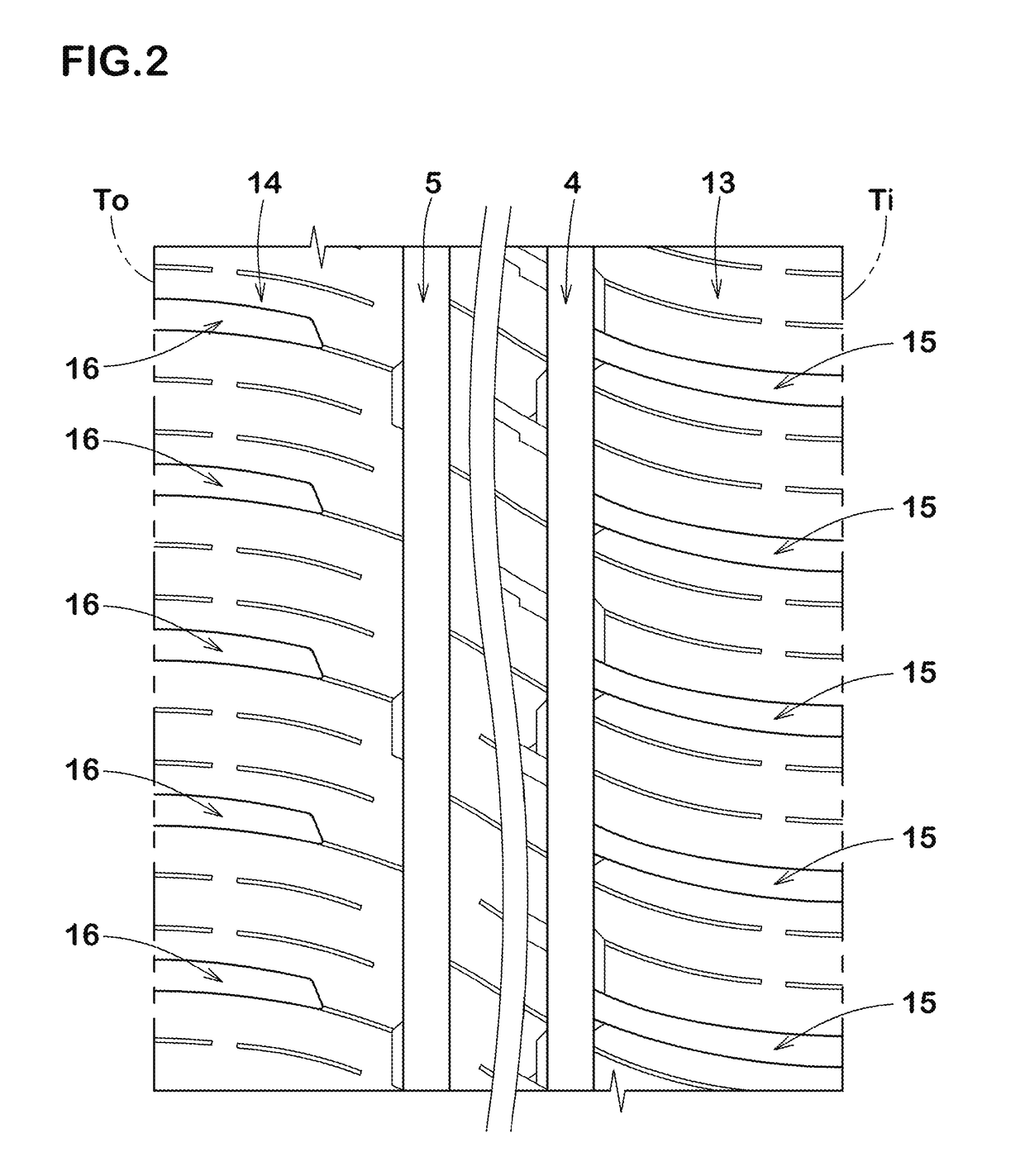

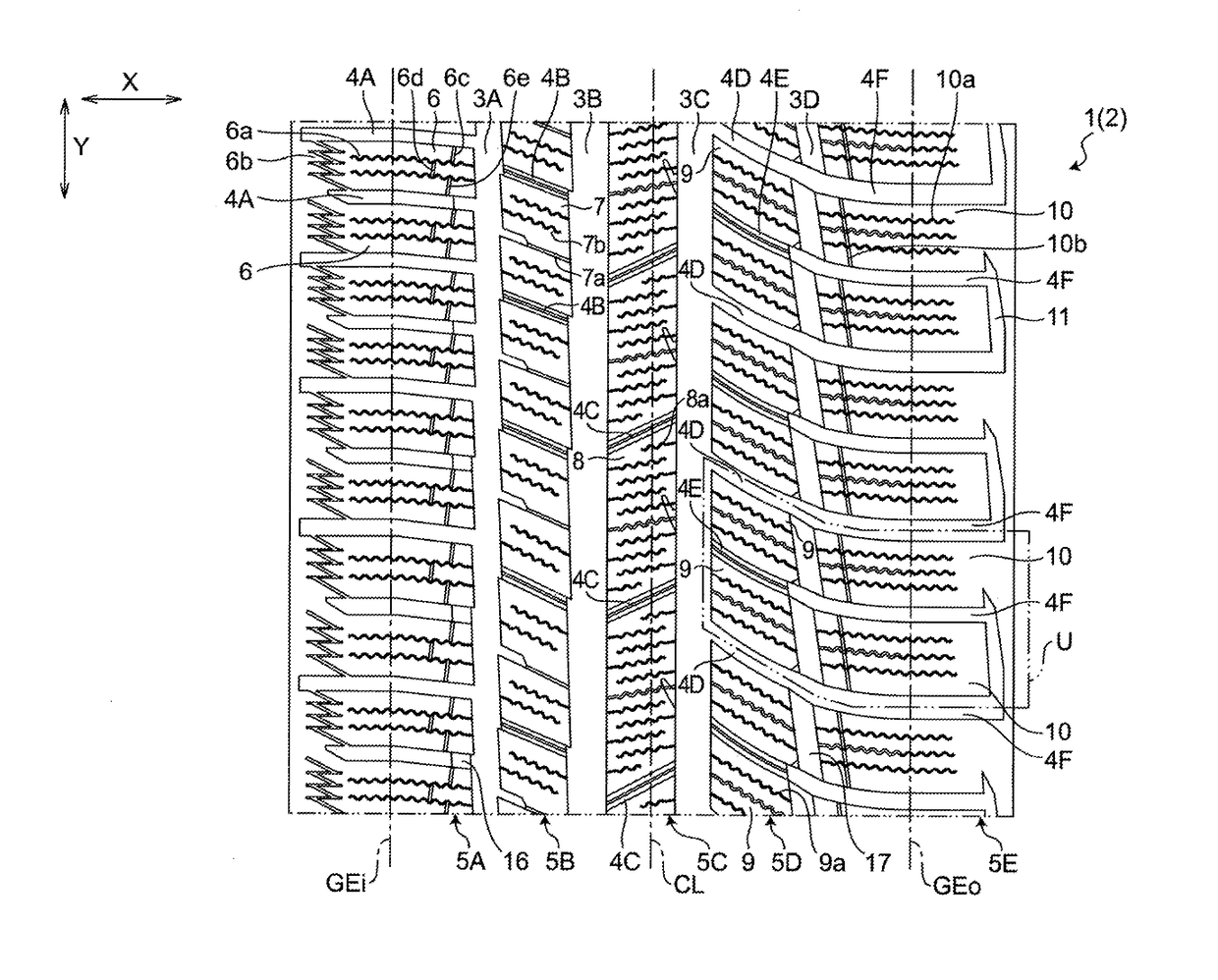

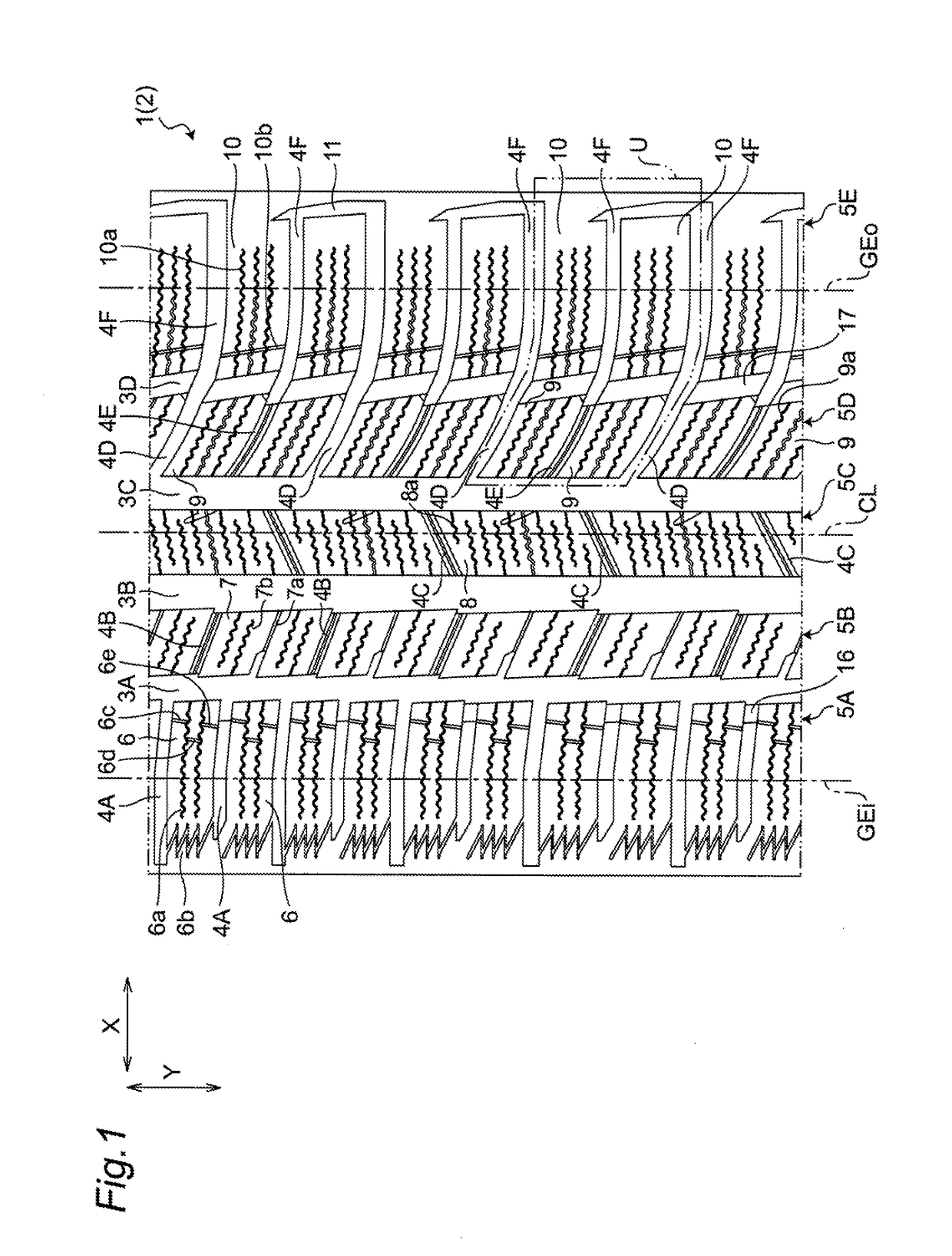

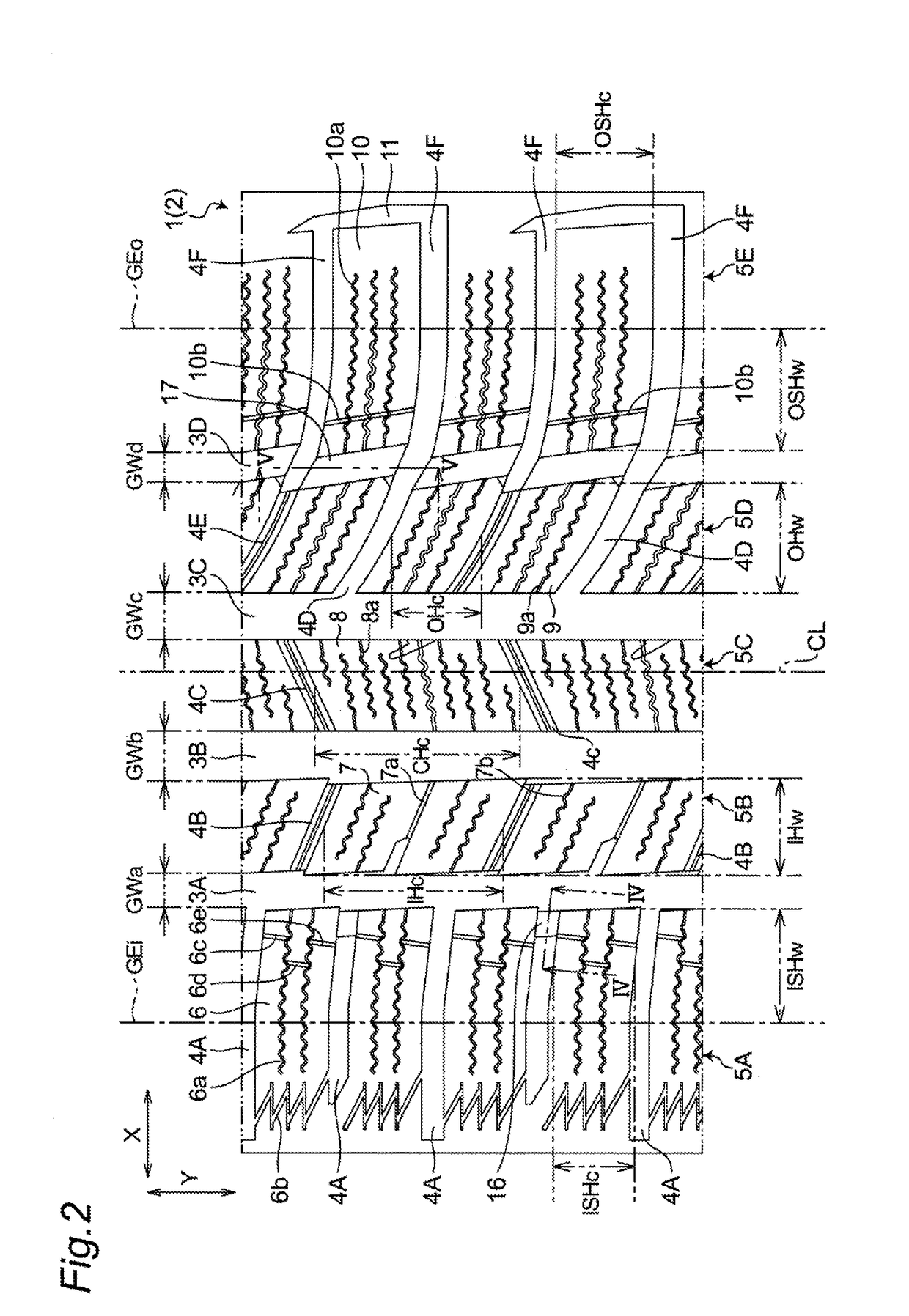

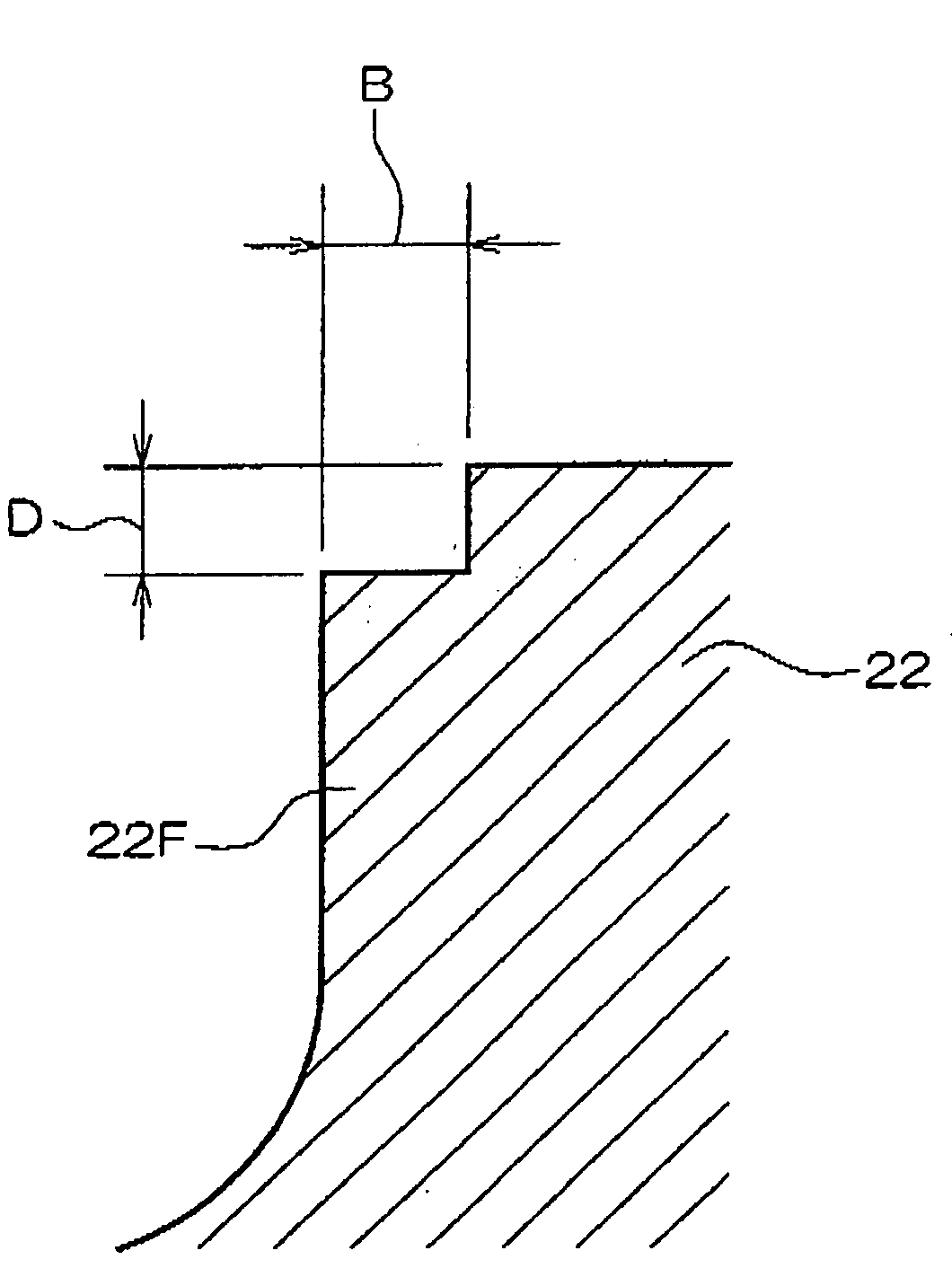

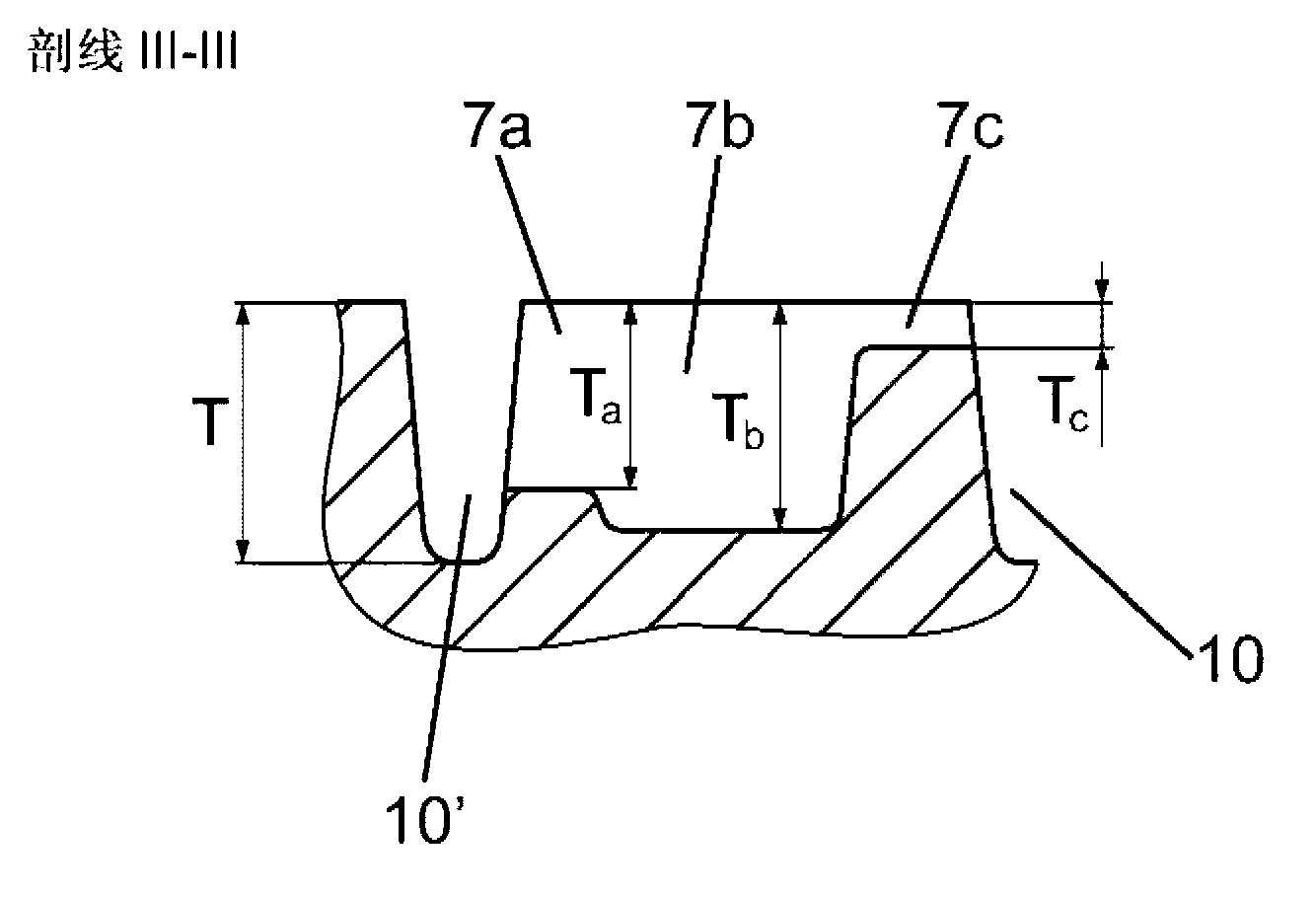

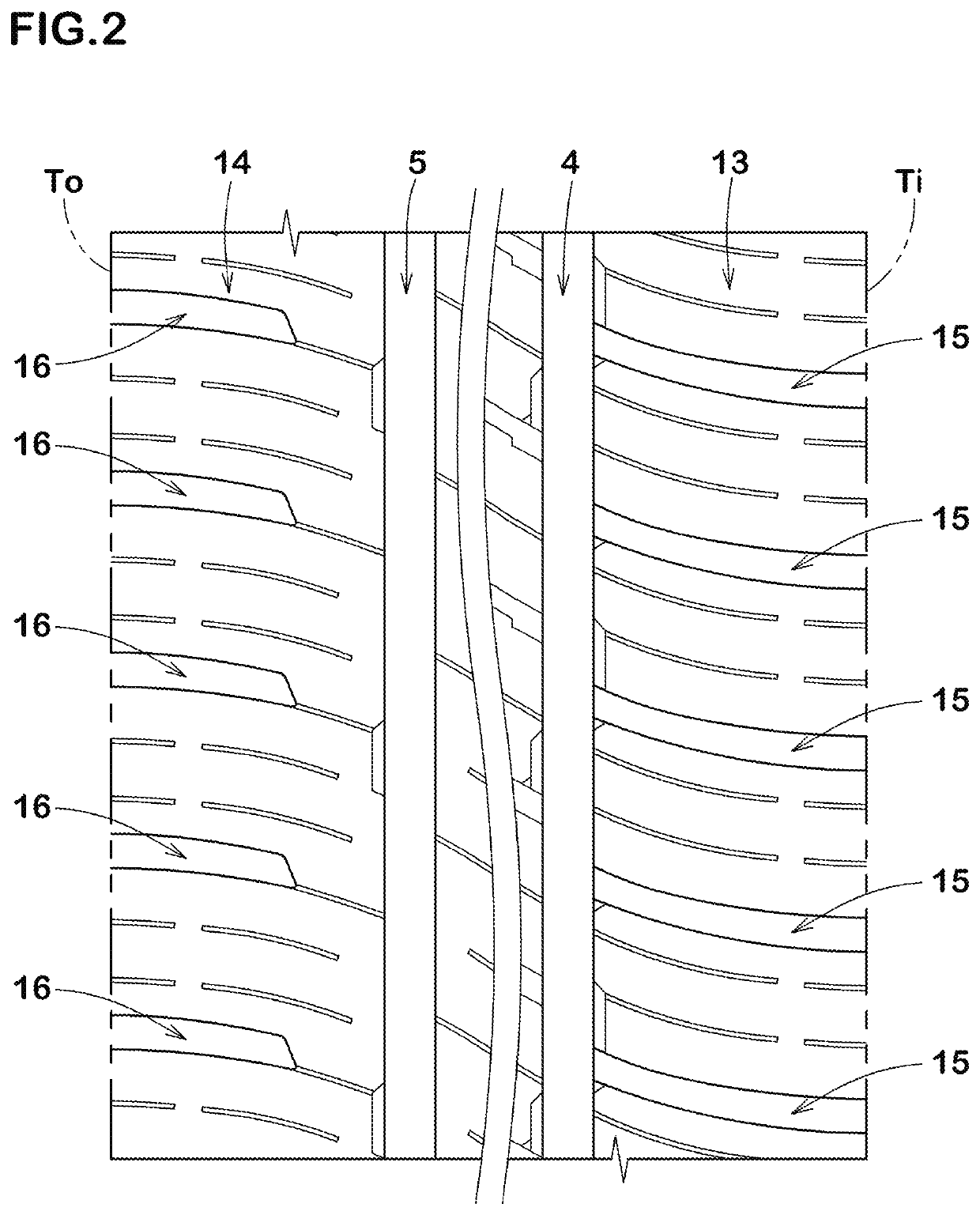

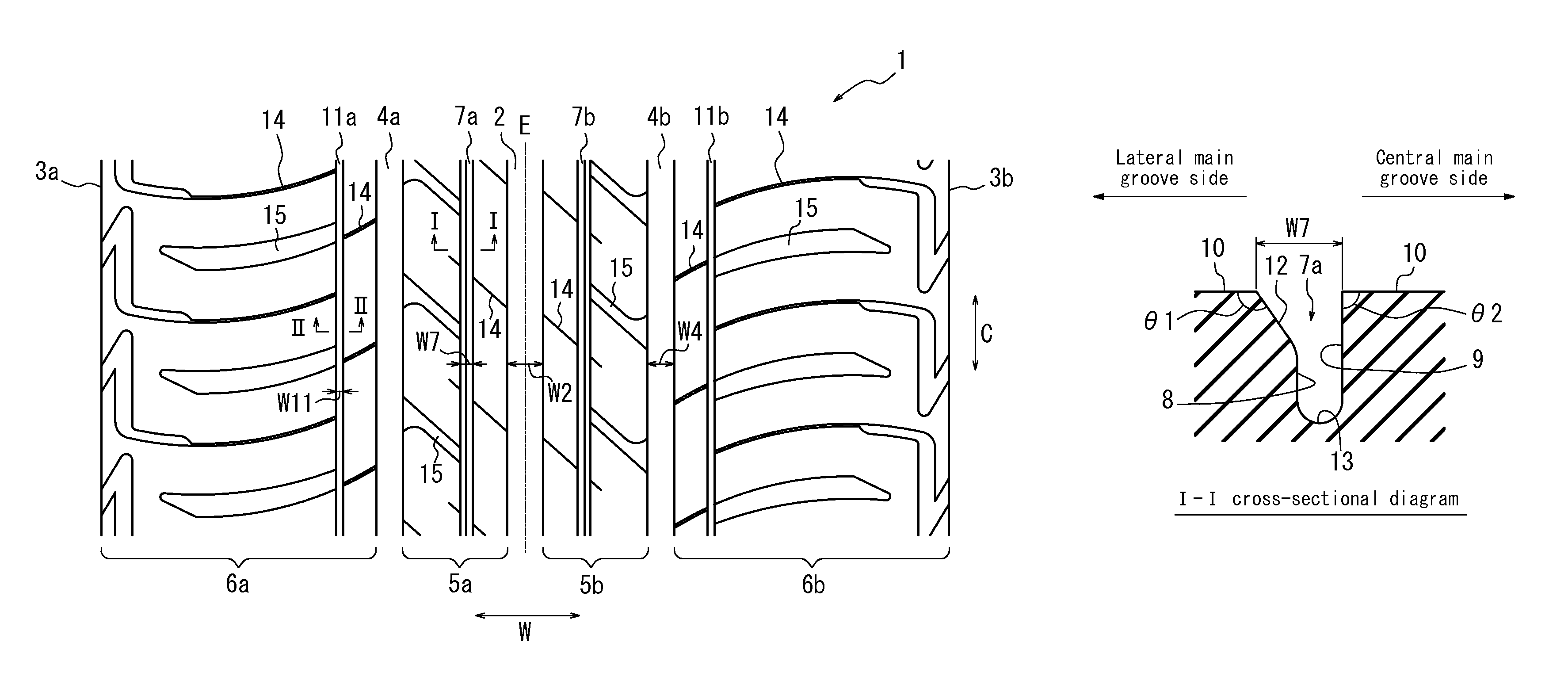

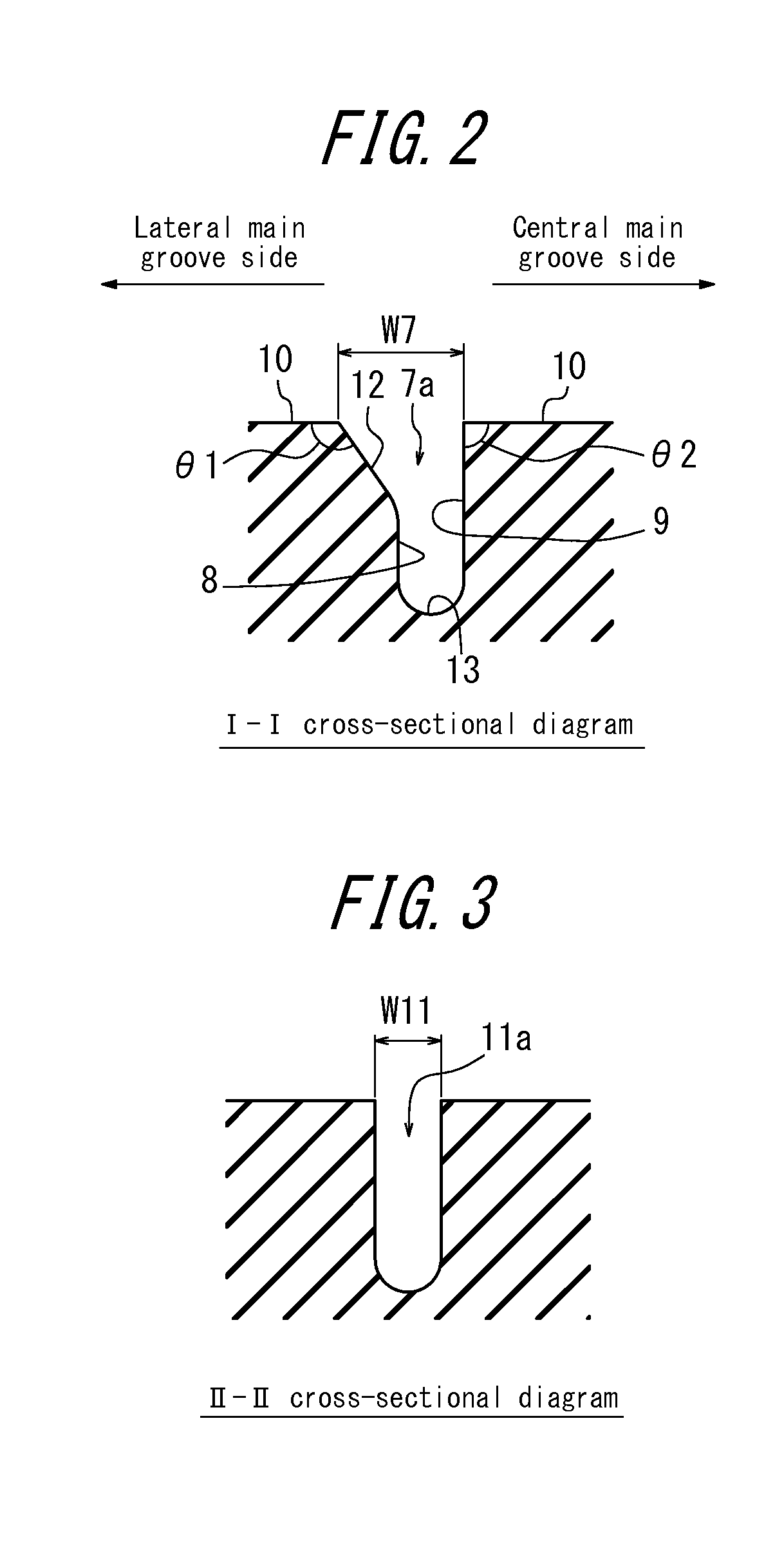

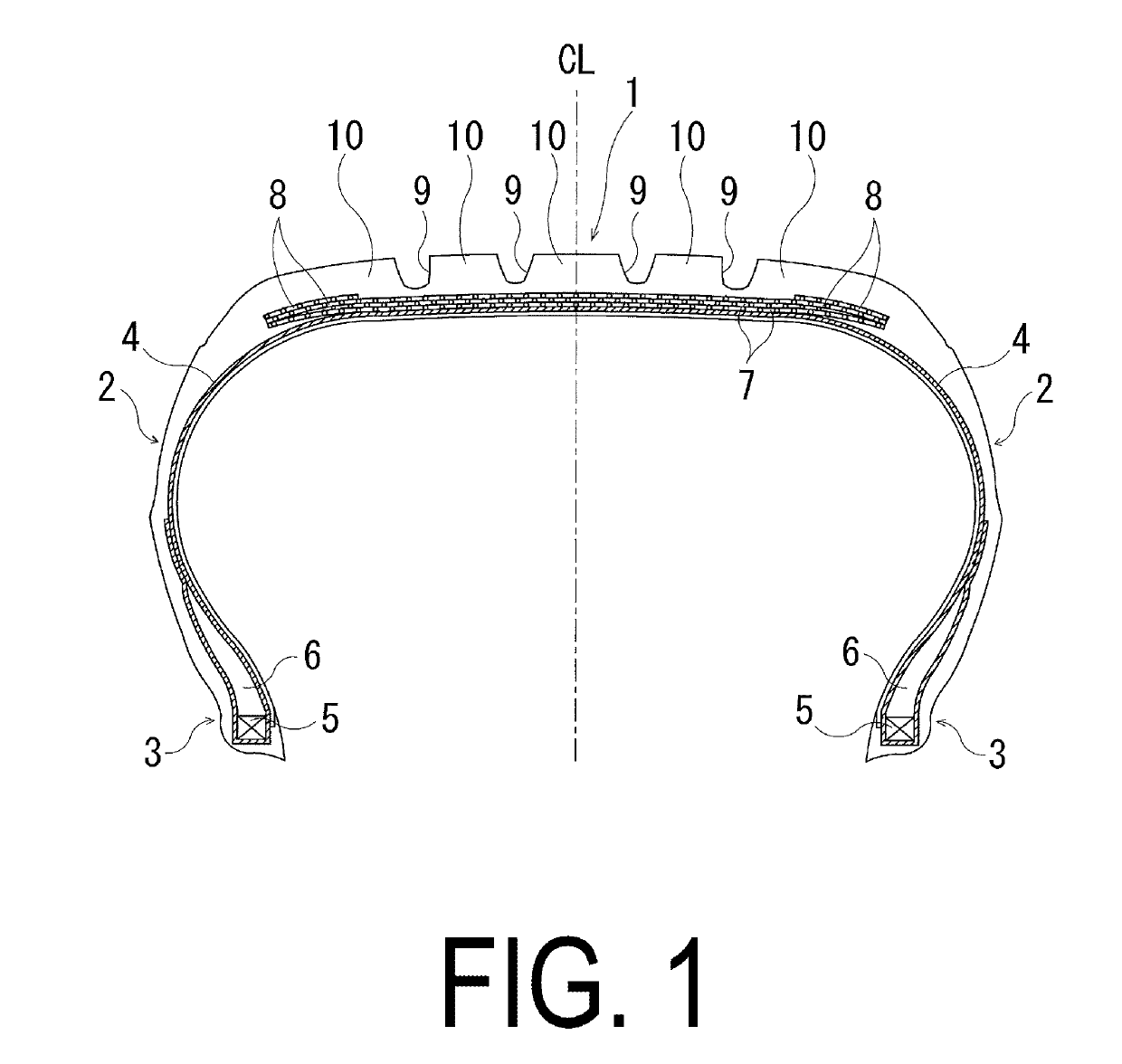

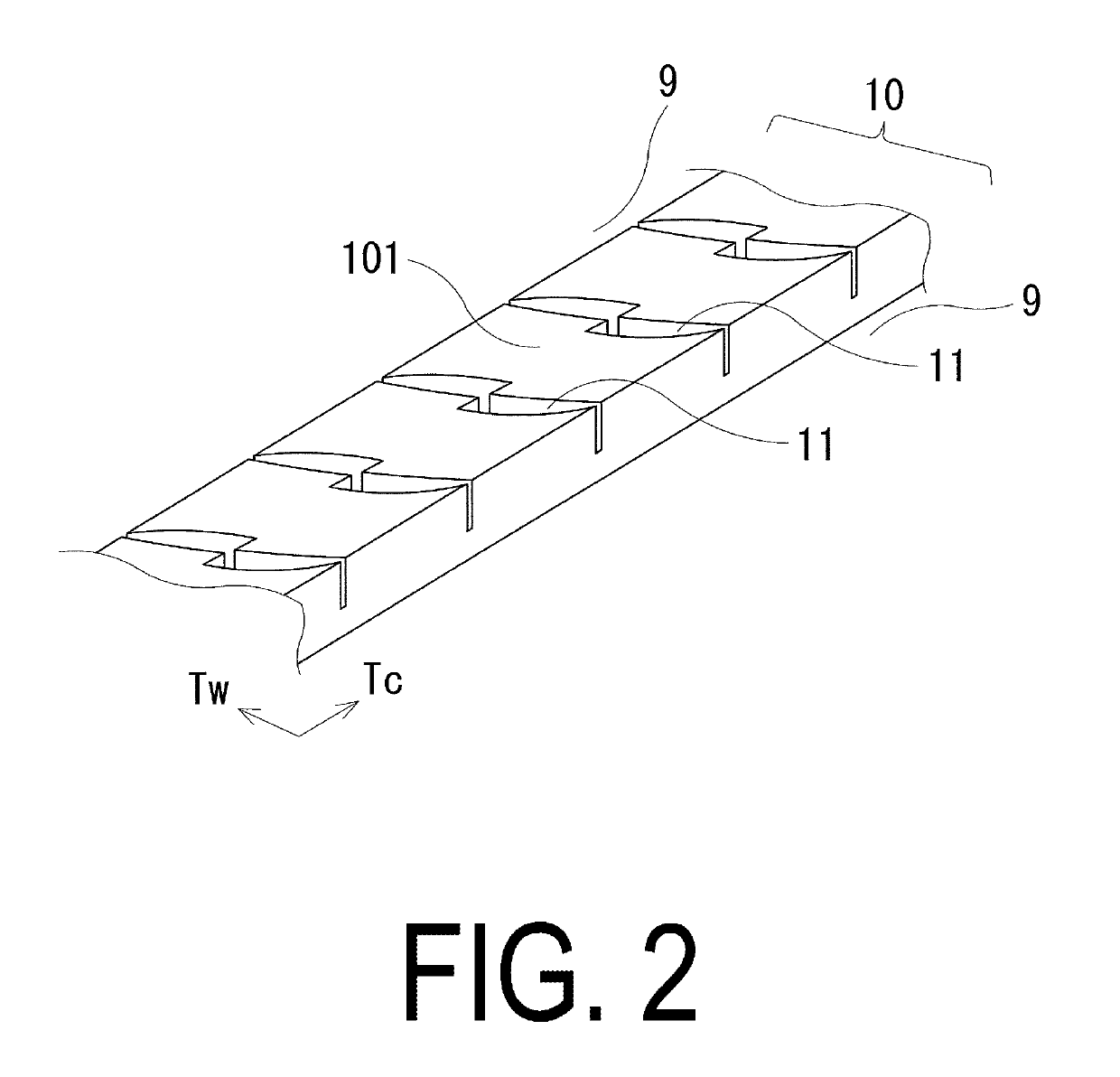

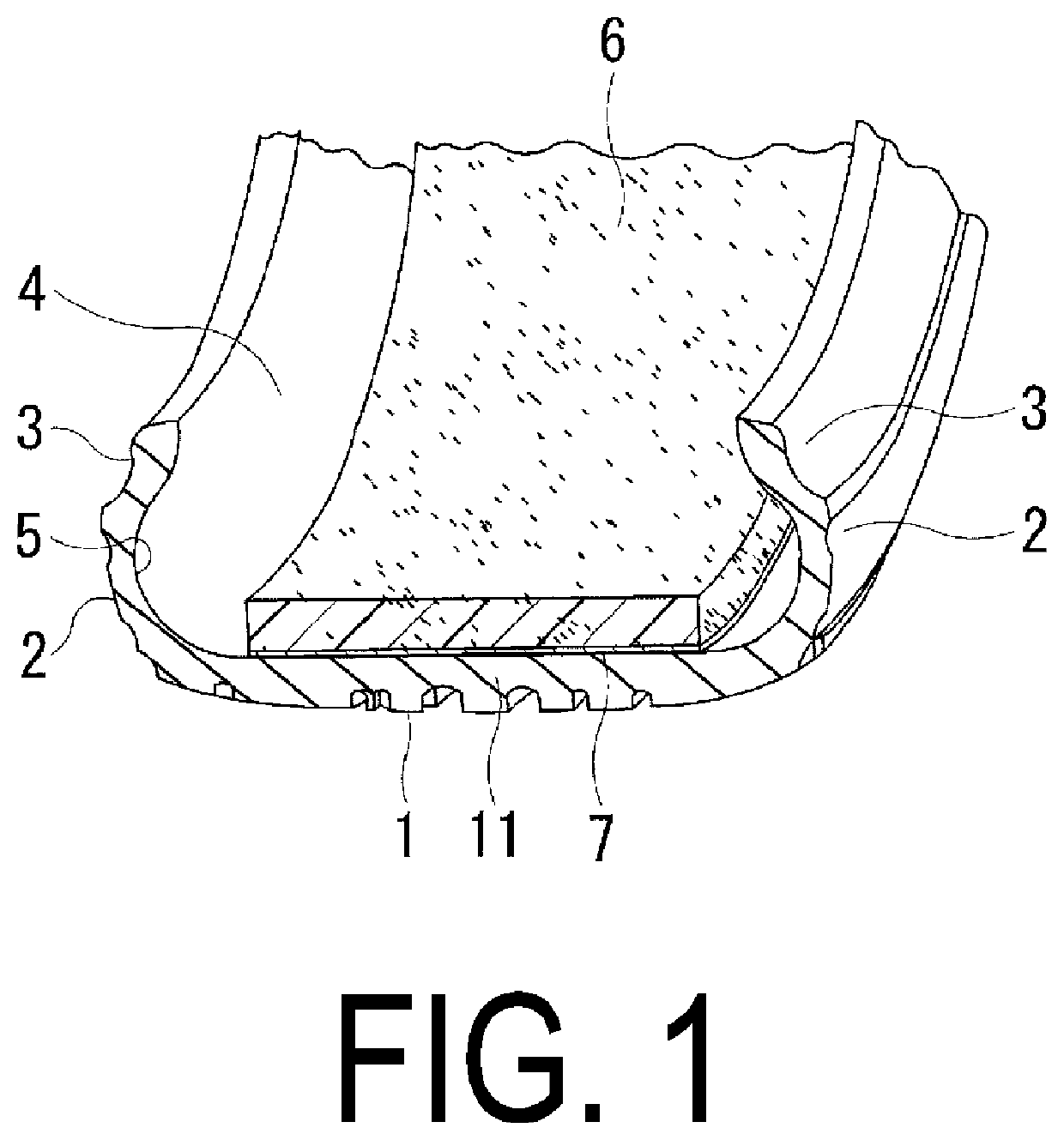

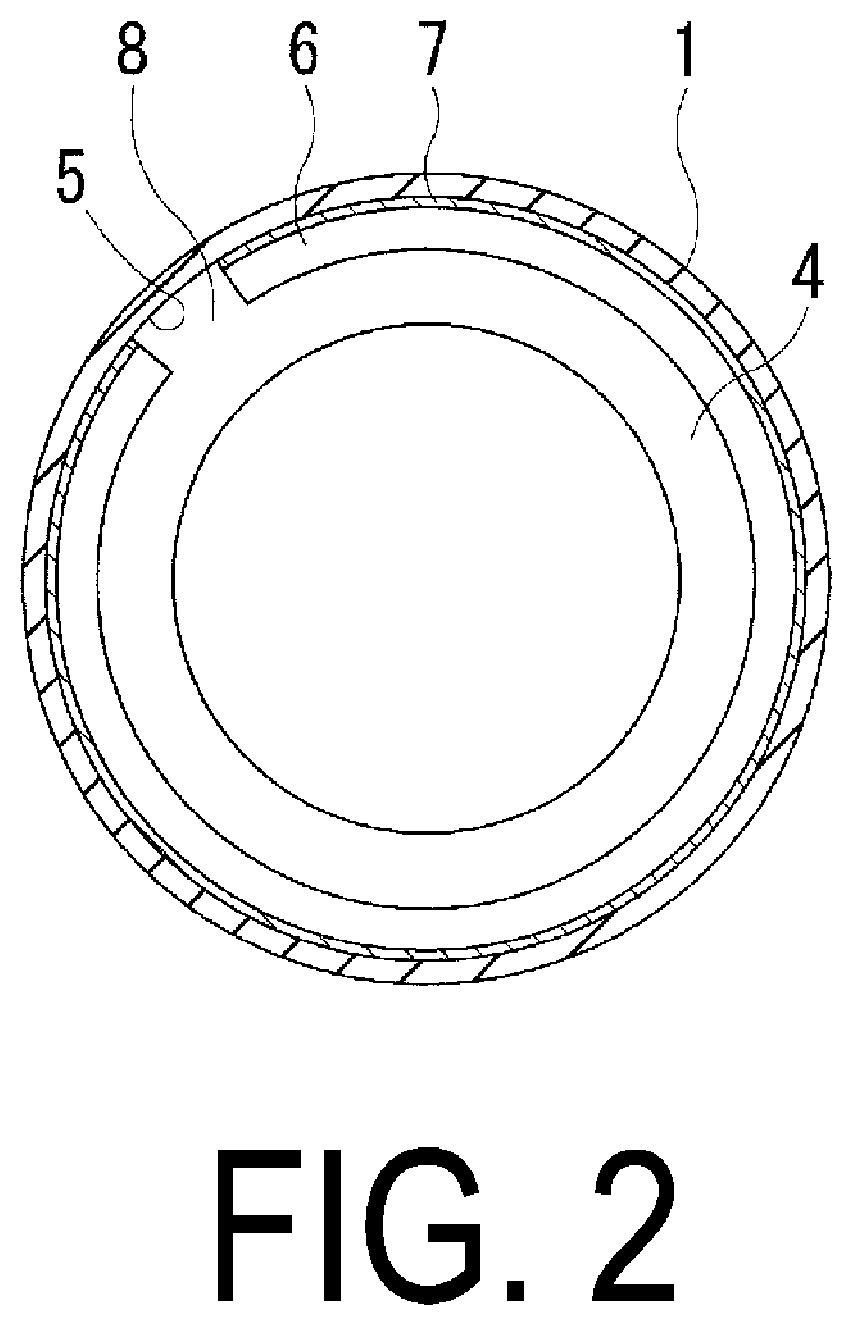

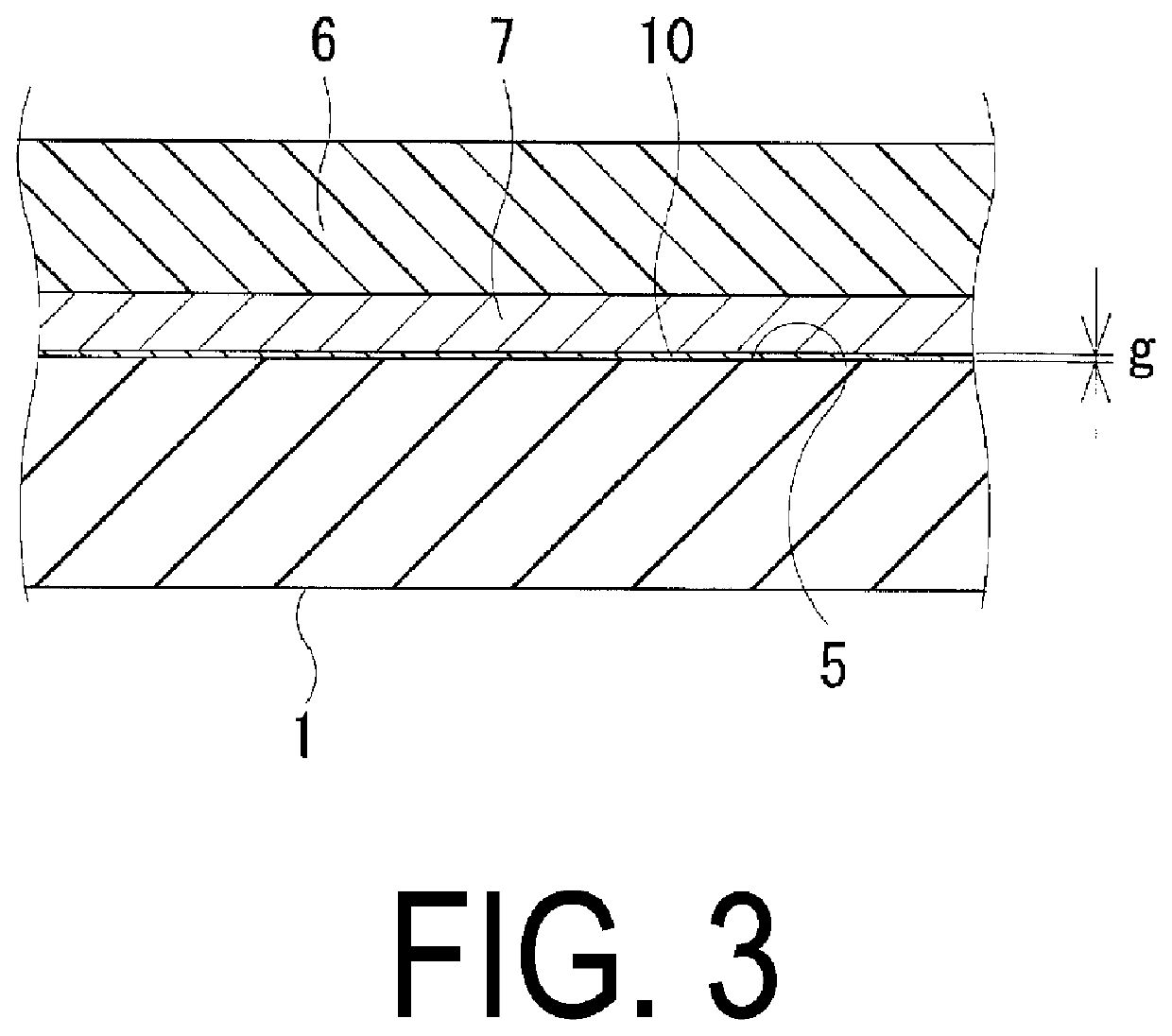

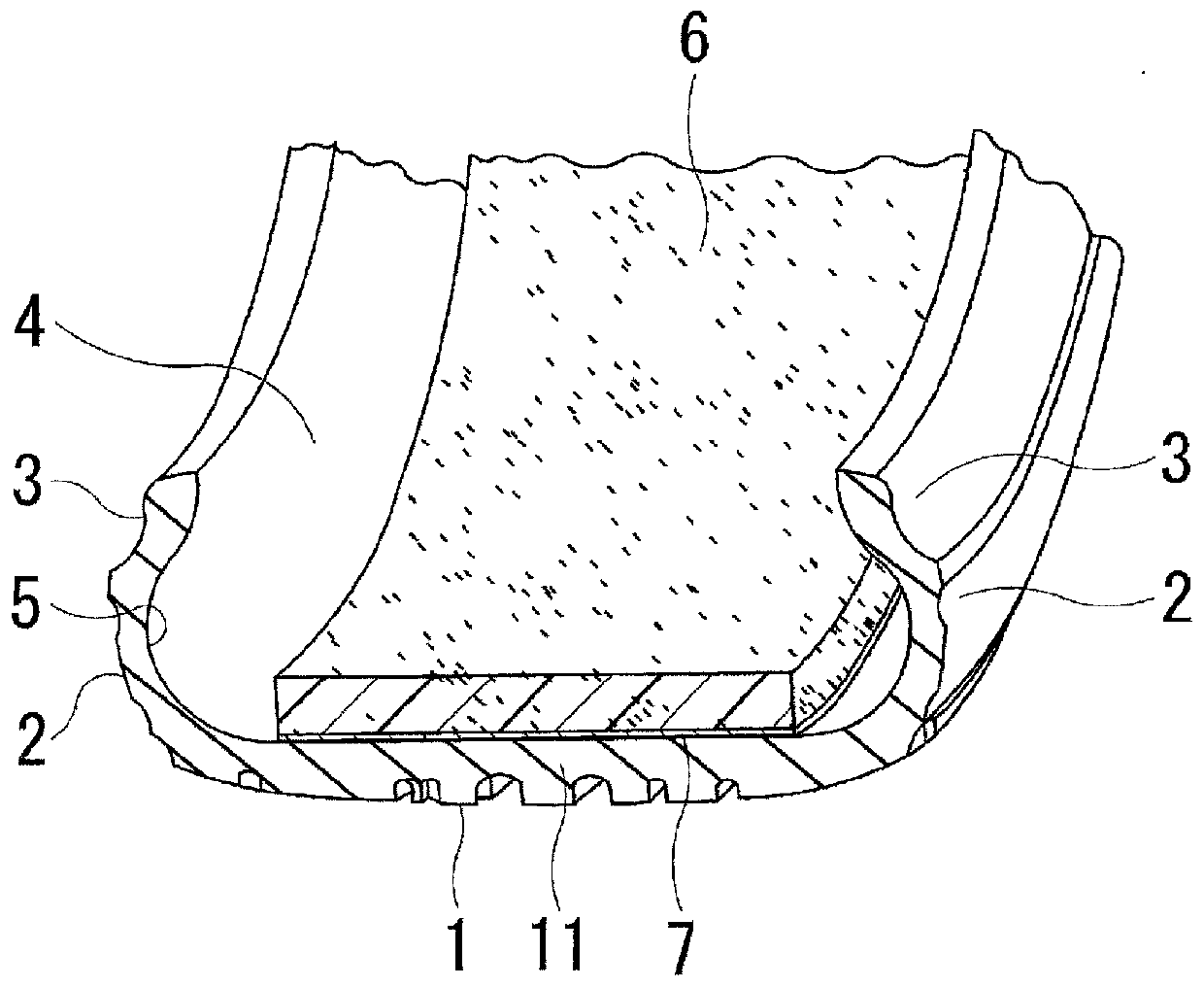

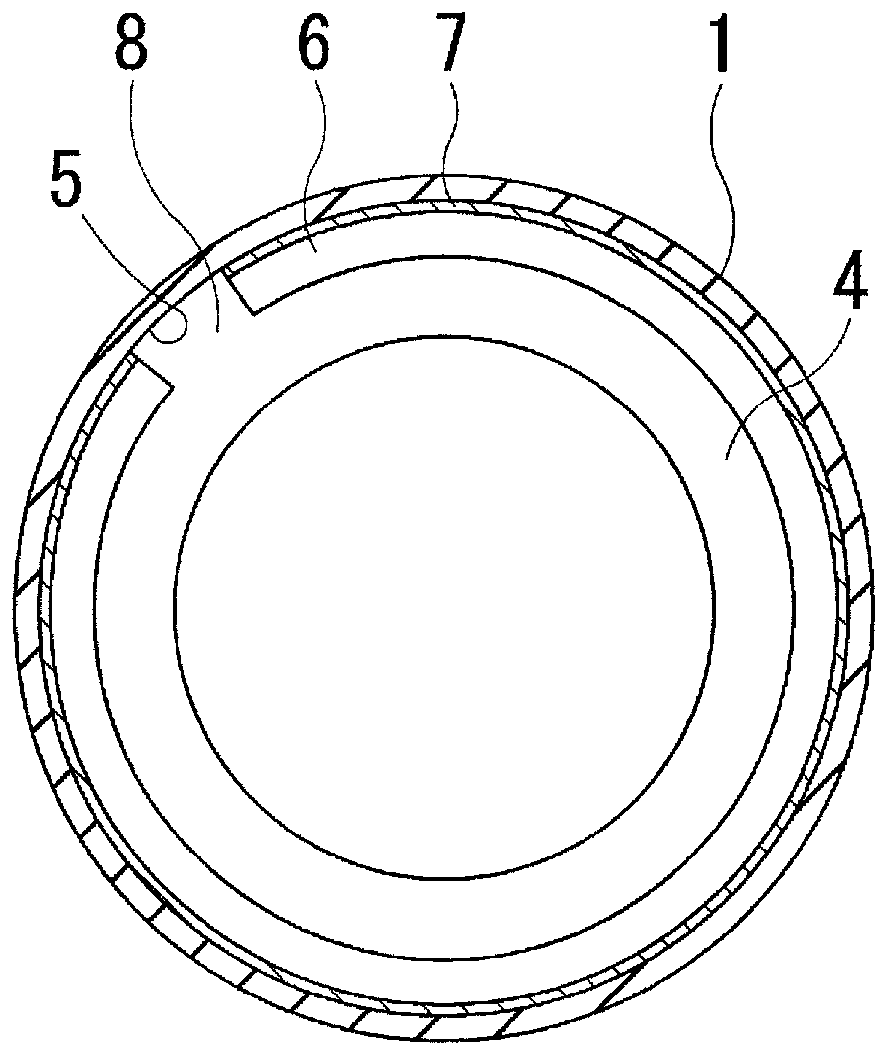

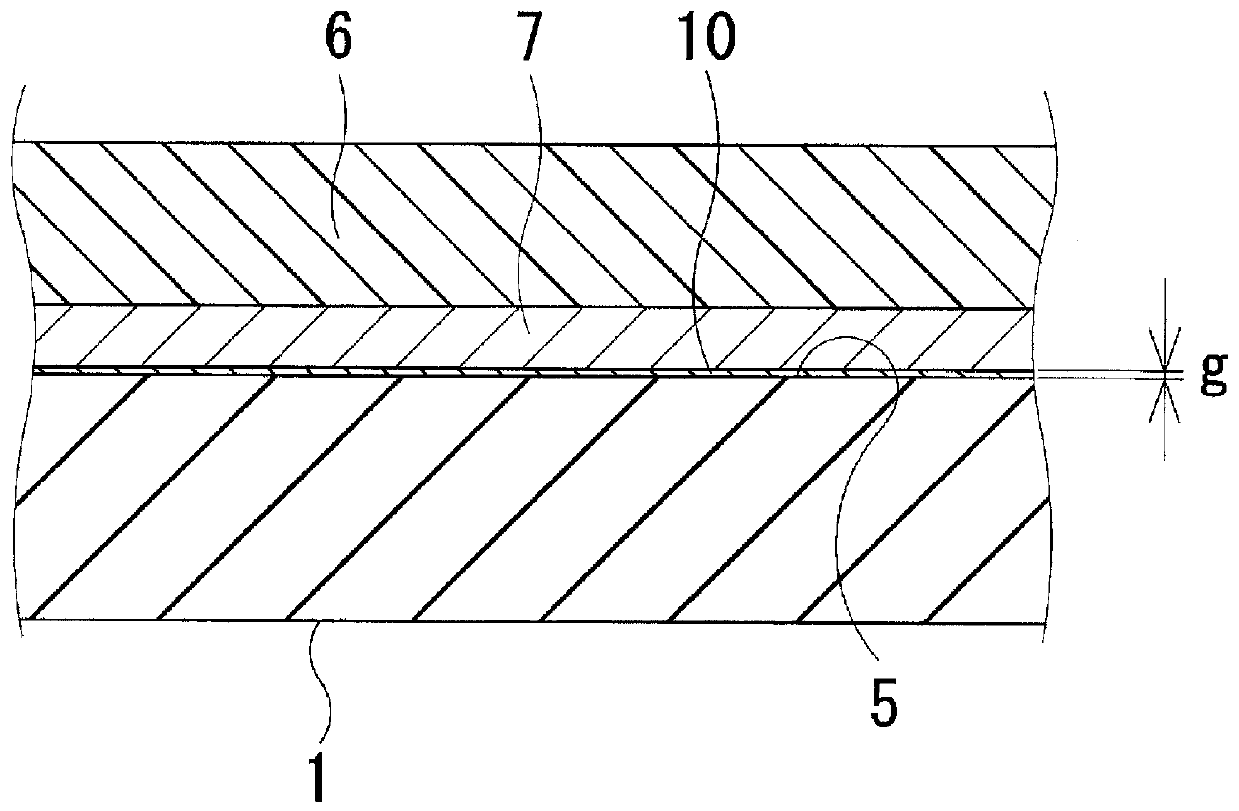

On the surface of a tread portion (1), one central main groove (2) extends in a tire circumferential direction (C) at a pattern center, and a pair of outer main grooves (4a, 4b) extend in the tire circumferential direction (C) each at a position between the central main groove (2) and a respective one of two tread ends (3a, 3b). The central main groove (2) and the outer main grooves (4a, 4b) define central land portions (5a, 5b), and the outer main grooves (4a, 4b) and the tread ends (3a, 3b) define outer land portions (6a, 6b). Among the central land portions (5a, 5b) and the outer land portions (6a, 6b), first circumferential narrow grooves (7a, 7b) are provided only in the central land portions (5a, 5b), extend in the tire circumferential direction (C), have a narrower opening width and a shallower depth than those of the central main groove (2), and have a first groove wall (8) on the side of the outer main groove (4a, 4b) and a second groove wall (9) on the side of the central main groove (2) such that an intersection angle (θ1) between a tread surface (10) and the first groove wall (8) is larger than an intersection angle (θ2) between the tread surface (10) and the second groove wall (9).

Owner:BRIDGESTONE CORP

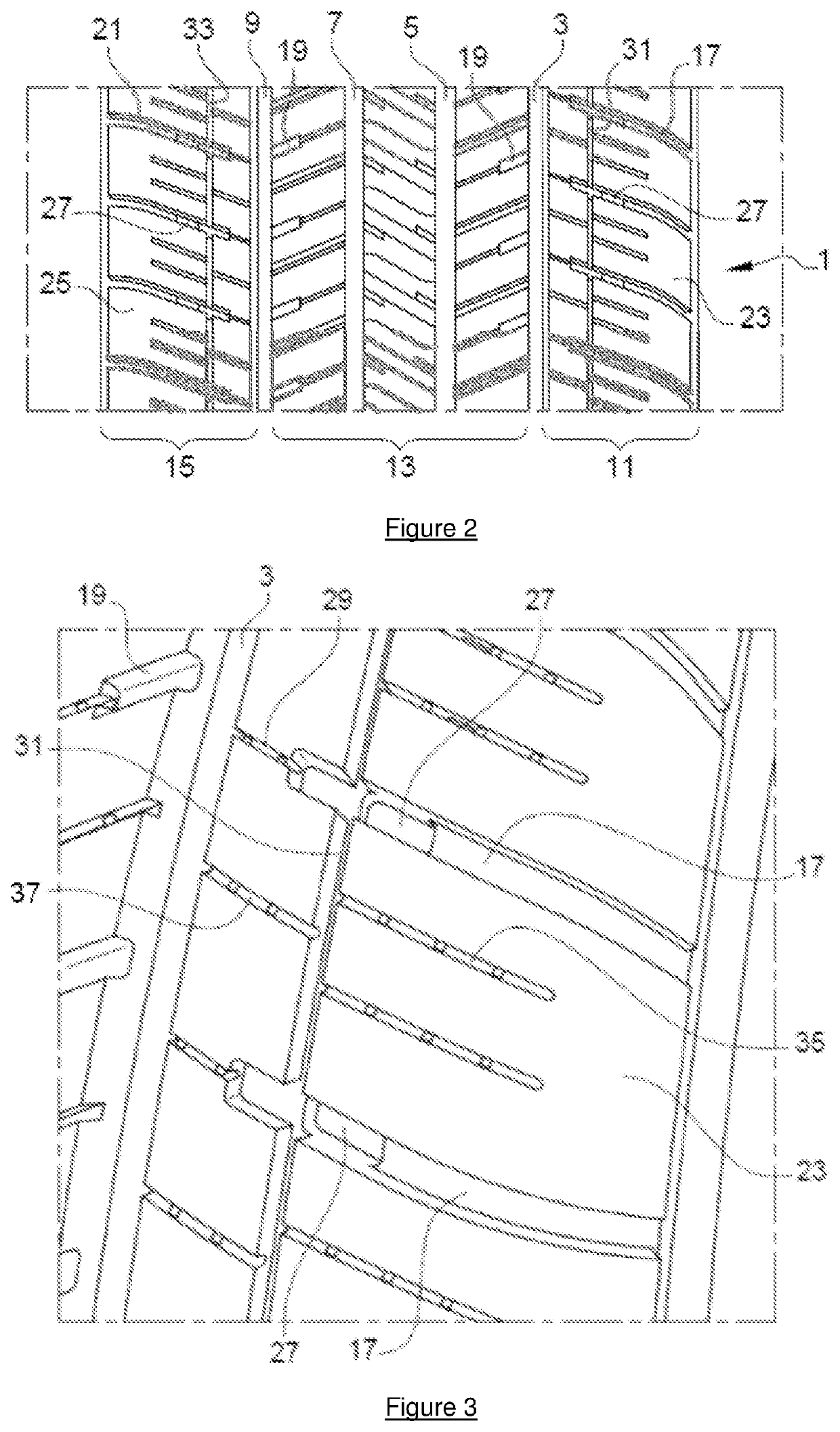

Pneumatic tyre

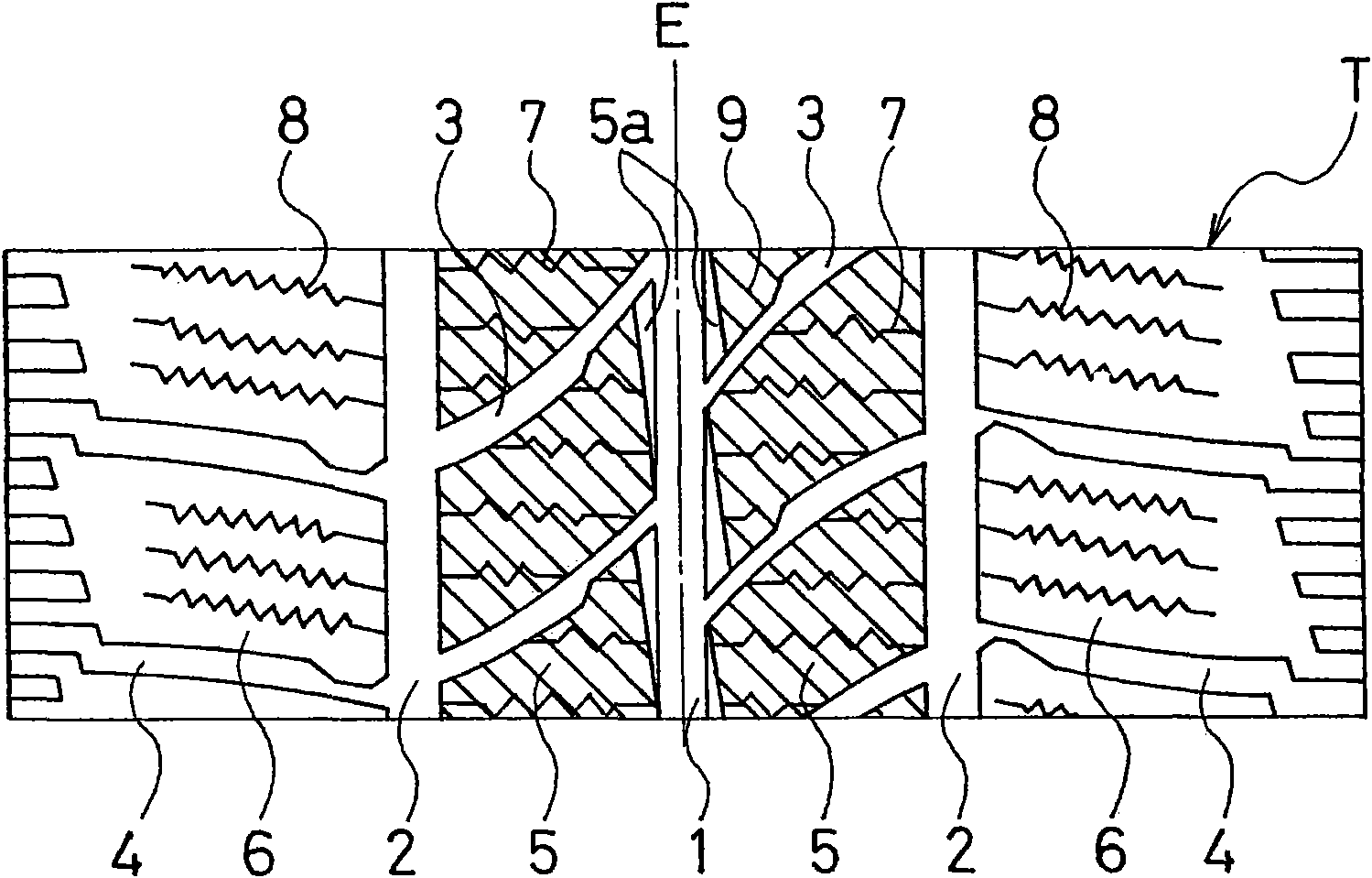

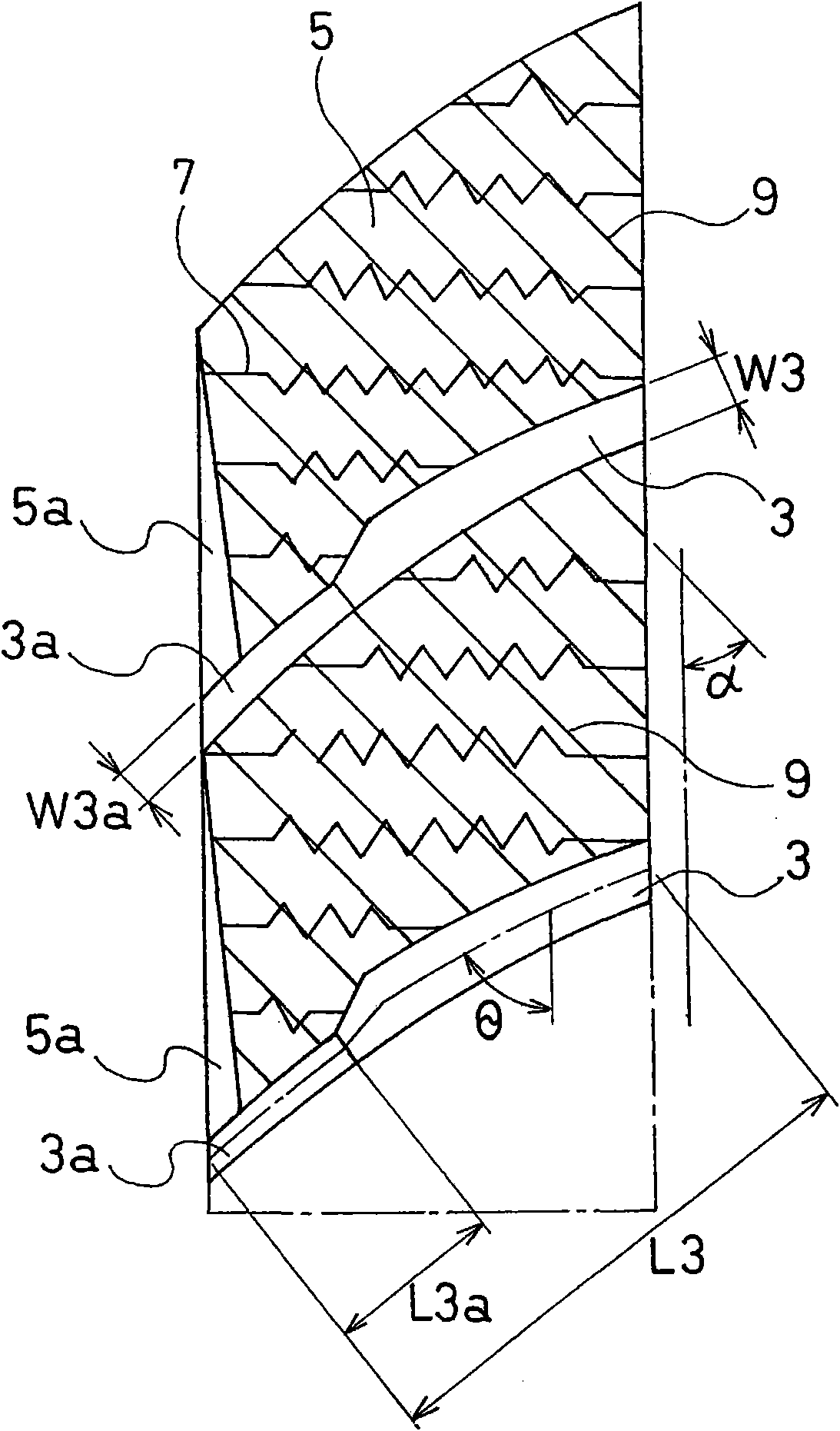

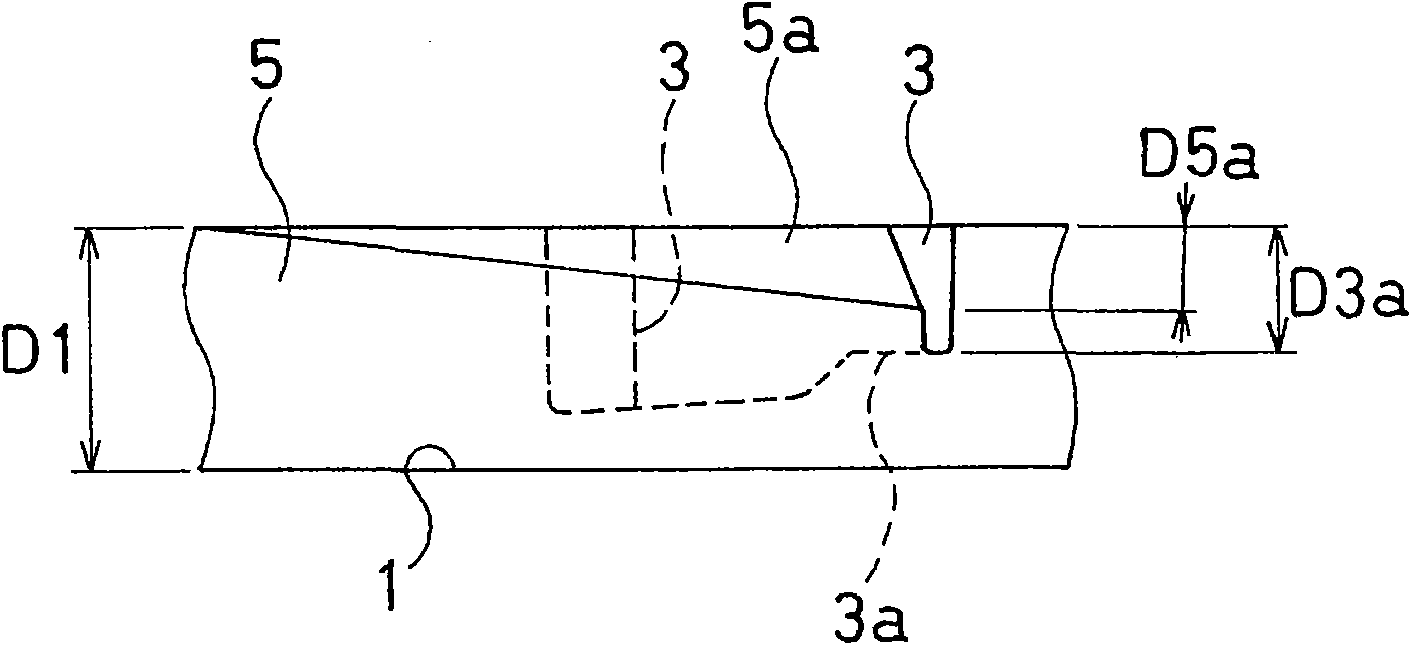

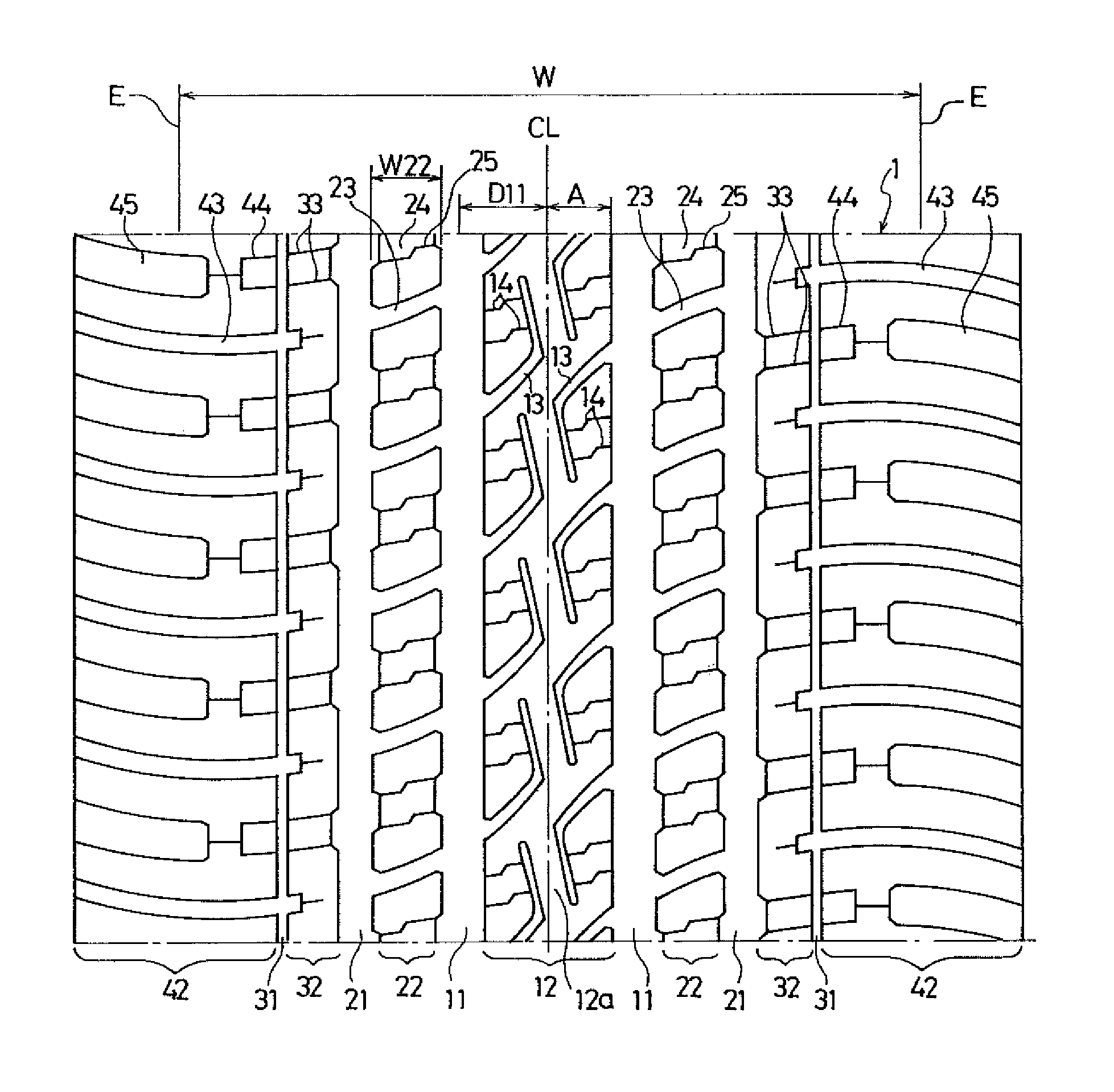

The invention relates to a pneumatic tyre. At least three main grooves (1,2) extending towards the perimeter of the tyre and a plurality of horizontal grooves (3) extending towards the width direction of the tyre and communicating between the main grooves are mounted on a tyre tread part (T) and a plurality of pattern blocks (5) are divided using the main grooves (1,2) and the horizontal grooves (3), characterized in that: a central main groove (1) on a tyre equator (E) is formed into a straight line shape and the horizontal groove (3) is arranged and inclined by 40-60degree relative to the tyre perimeter and an ascending part (3a) is formed at the part of the horizontal groove (3) communicated with the central main groove (1) to make the groove width and the groove depth of the horizontal groove (3) proportionally change and the groove depth (D3a) of the horizontal groove (3) is 40-60% of the groove depth (D1) of the central main groove (1) and the minimum groove width (W3a) of the horizontal groove (3) is 30-50% of the maximum groove width (W3). The pneumatic tyre well keeps the wet road and simultaneously improves the operation stability during driving on the snow road and the dry road.

Owner:THE YOKOHAMA RUBBER CO LTD

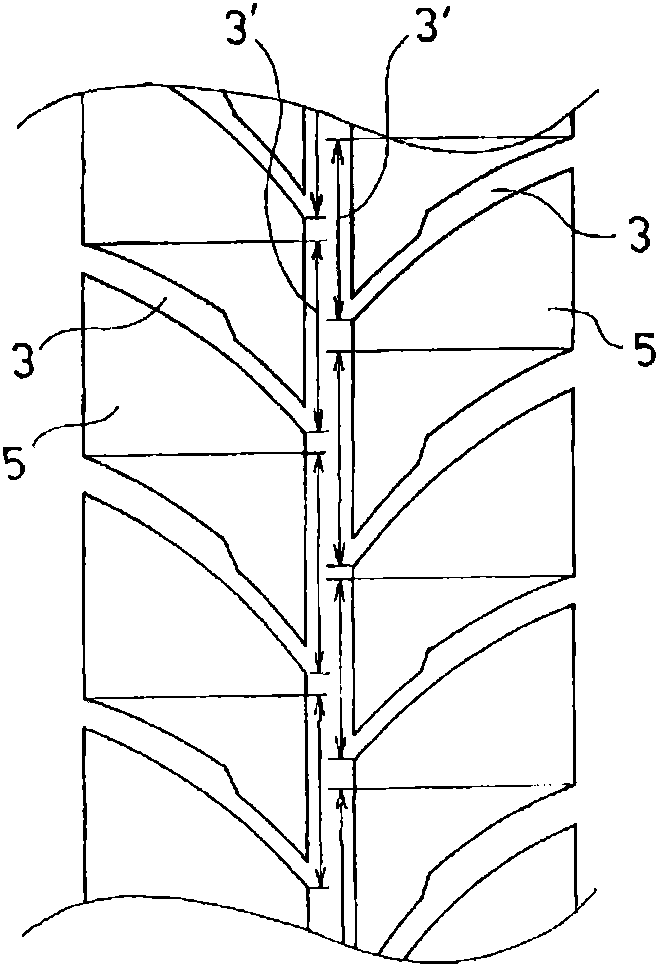

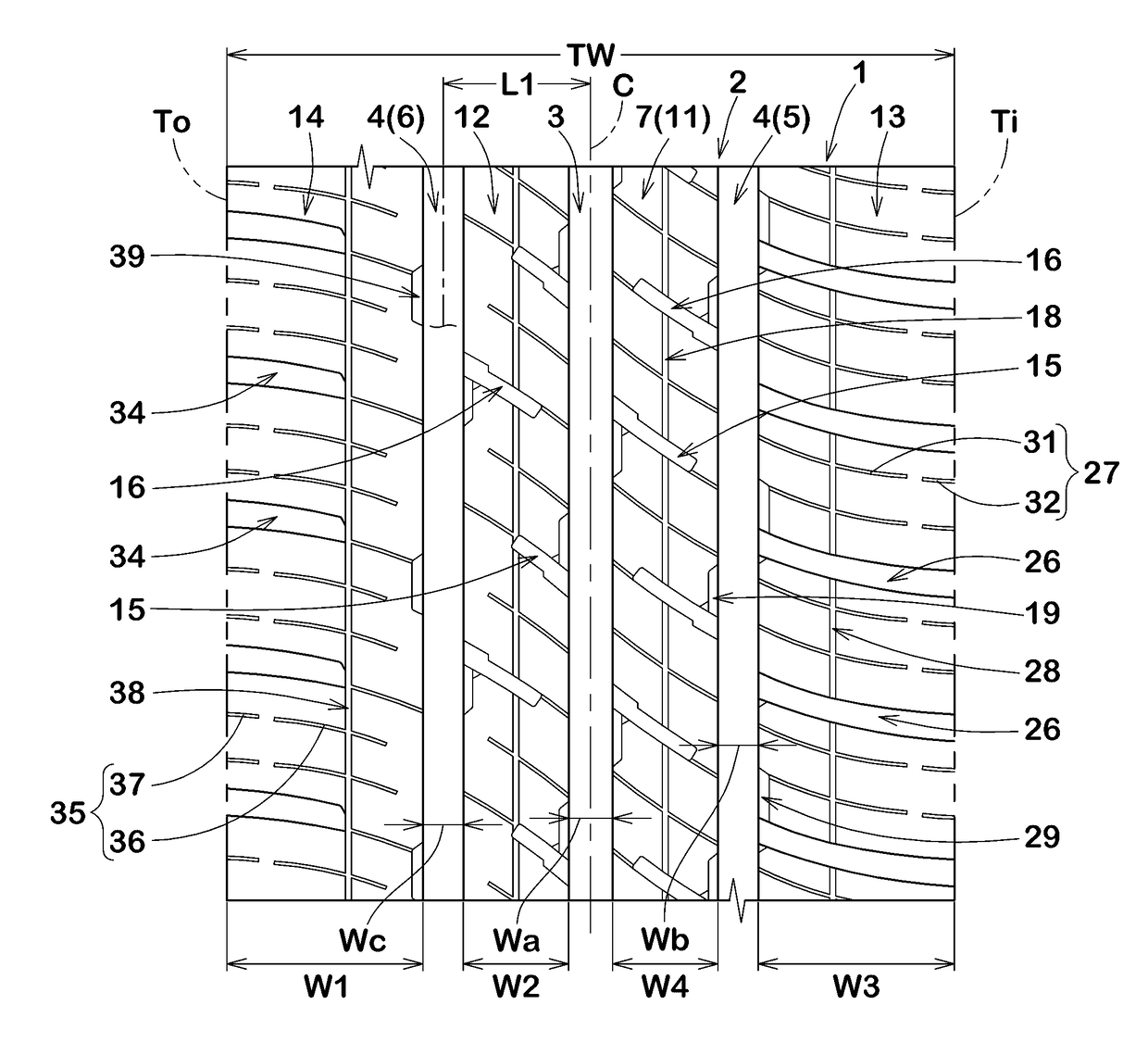

Pneumatic tire

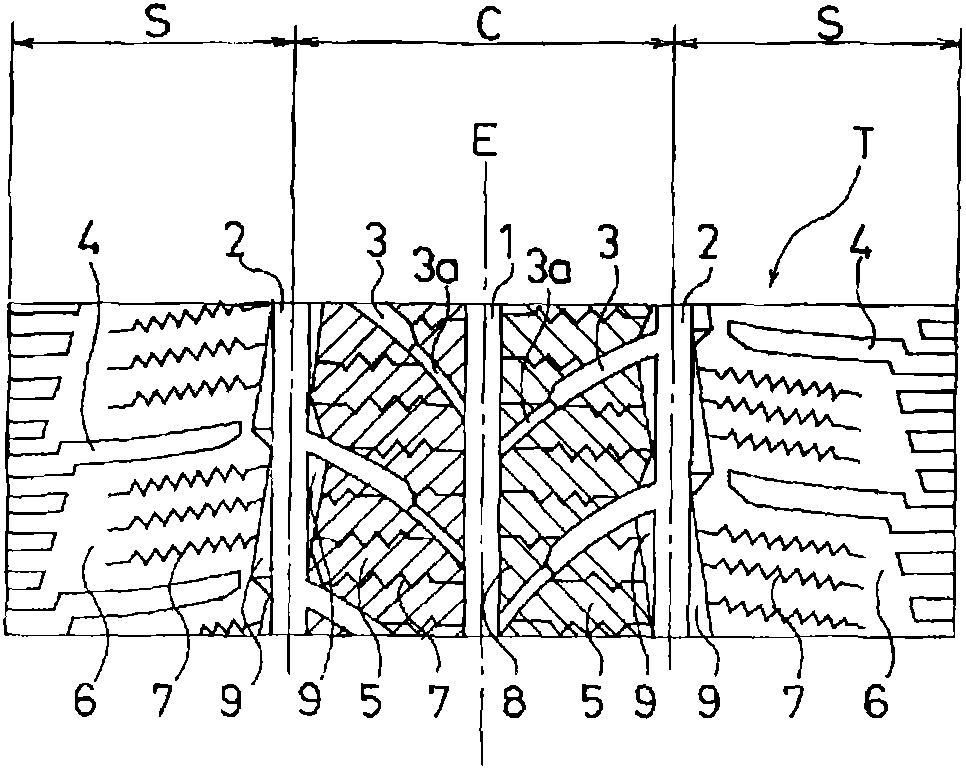

ActiveCN102310723AImprove wetting performanceImprove snow performanceSpecial tyresTyre tread bands/patternsAcute angleTransverse groove

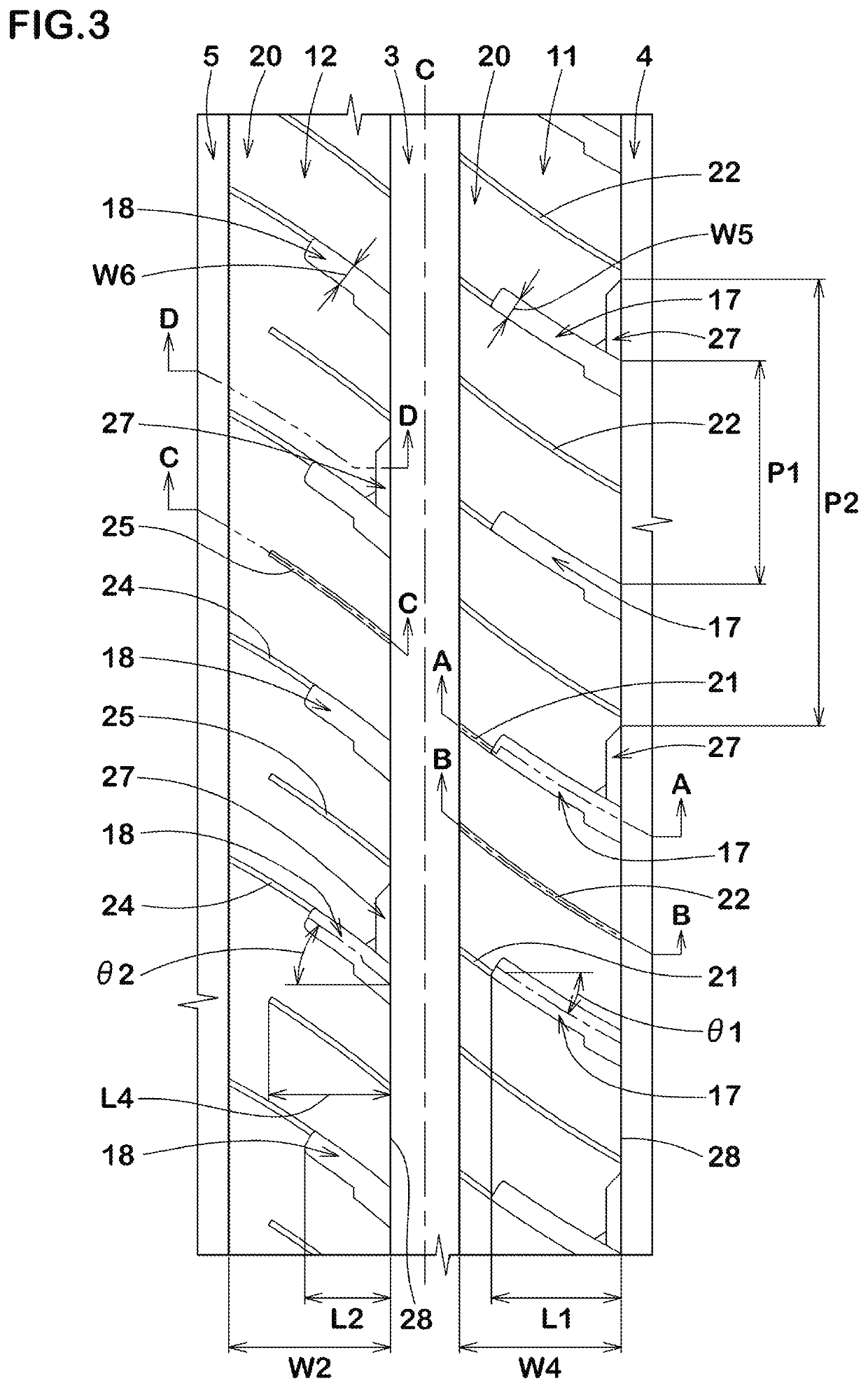

The invention provides a pneumatic tire, which has directional patterns and achieves improved wet performance, snow performance and nonuniform wear resistance. The central portion (C) of the pneumatic tire is divided into multiple pattern blocks (5) via a central main groove (1), outer main grooves (2) and transverse grooves (3). Meanwhile, the strip-shaped patterns (5) at the tire shoulder portion (S) is provided with shoulder pattern grooves (4). The patterns of the pneumatic tire are directional patterns. The transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and is reversely inclined relative to the tire equator, wherein the central inclined angle Theta1 of the transverse grooves (3) is an acute angle. Meanwhile, the transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and the tire circumferential direction in a staggered manner such that the circumferential portion (3') formed by upward projection of the transverse grooves (3) in the tire circumferential direction is provided at the periphery of the tire. In addition, sipes (7) are provided at the pattern blocks (5) and the strip-shaped patterns (6).

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20160121659A1Improve snow performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire includes a tread portion provided with a circumferentially and continuously extending zigzag shoulder main groove located adjacent to a tread edge to define a shoulder portion axially outward of the shoulder main groove and a central lateral groove extending axially inwardly from the shoulder main groove. The shoulder portion includes a top surface having an axially inner edge facing the shoulder main groove and a sidewall extending radially inwardly from the inner edge. The sidewall of the shoulder portion is provided with a shoulder dent portion dented axially outwardly from the shoulder main groove. The central lateral groove is located so that an extended portion in which the central lateral groove is extended axially outwardly overlaps with the shoulder dent portion at least partially.

Owner:SUMITOMO RUBBER IND LTD

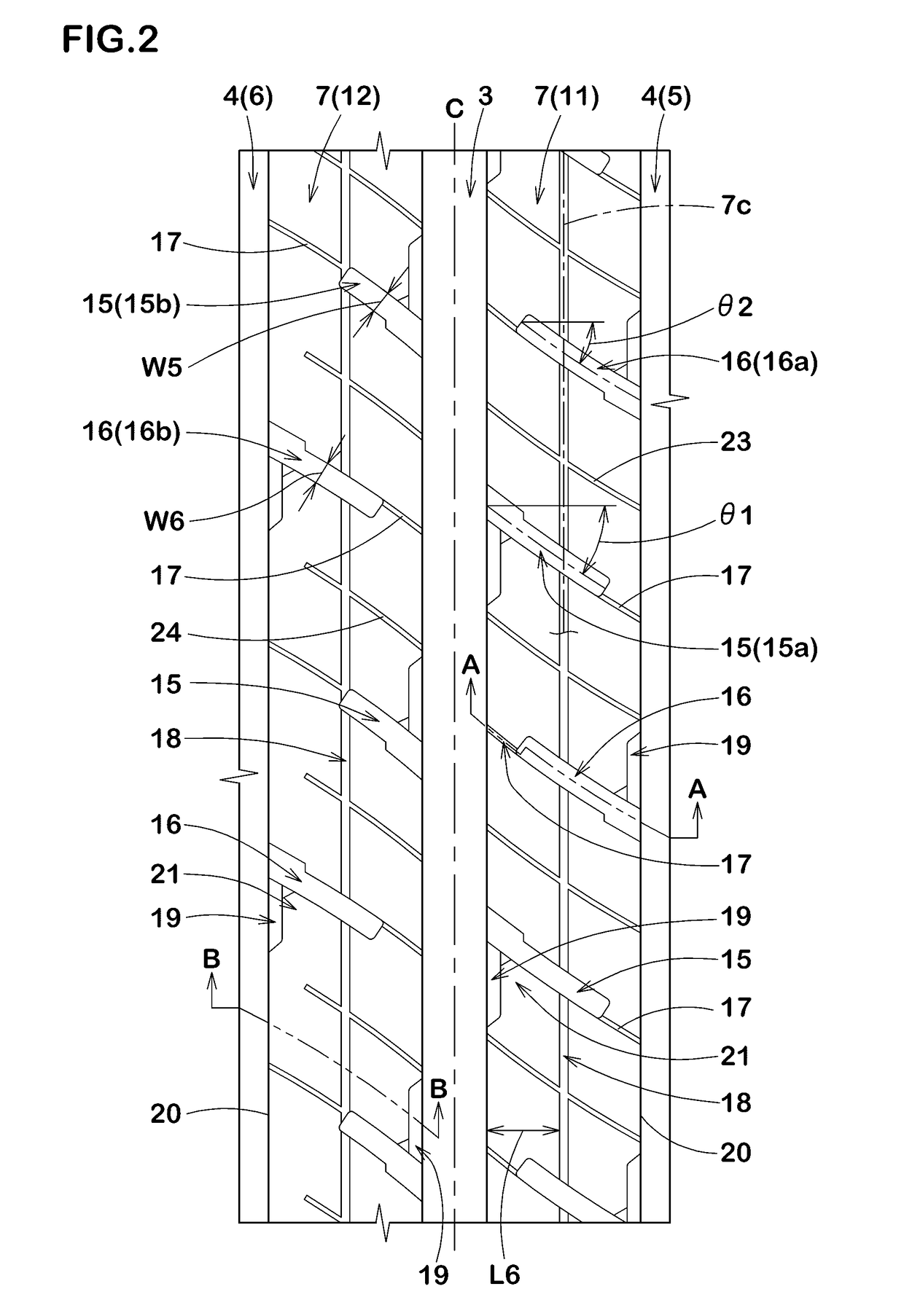

Pneumatic tire

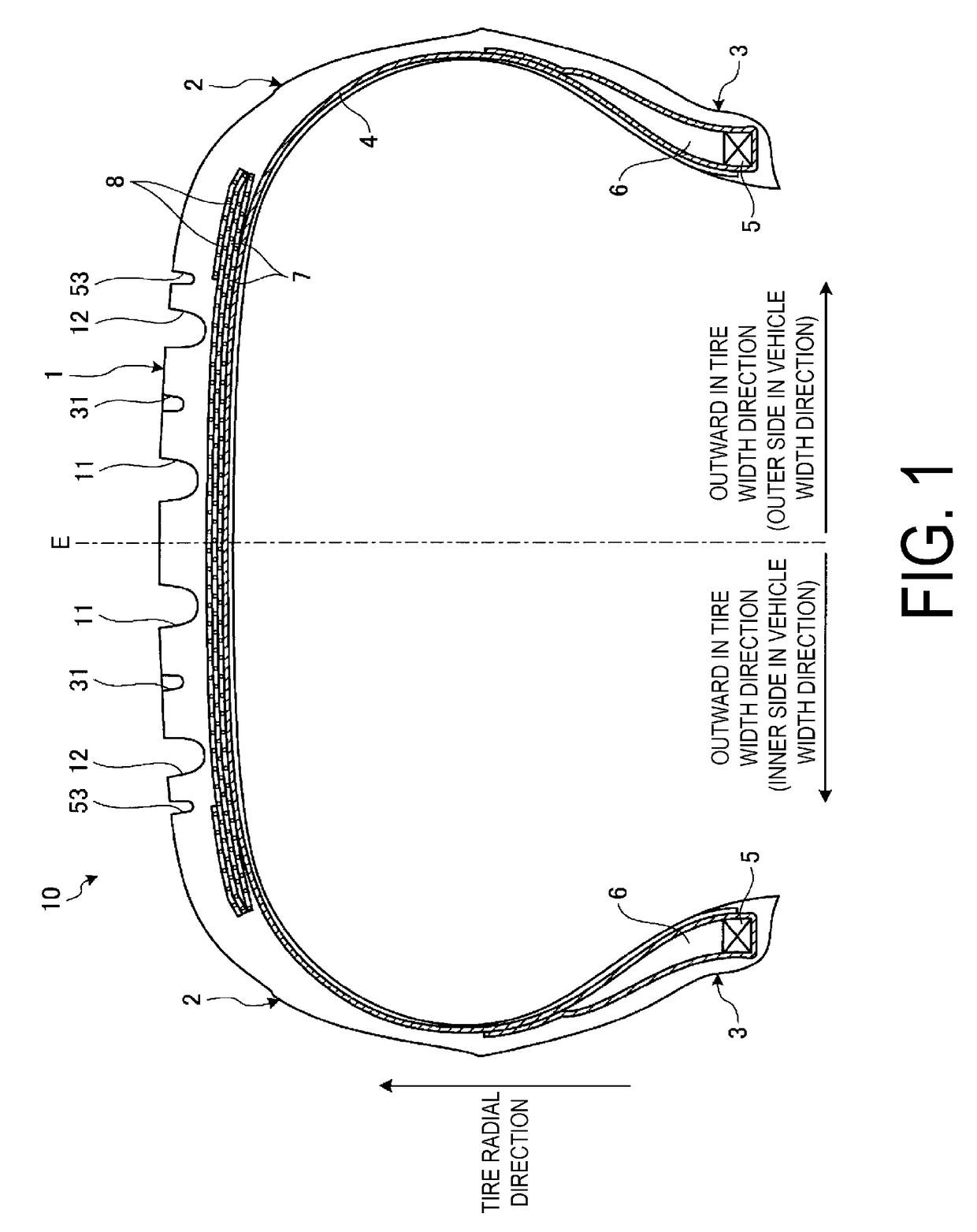

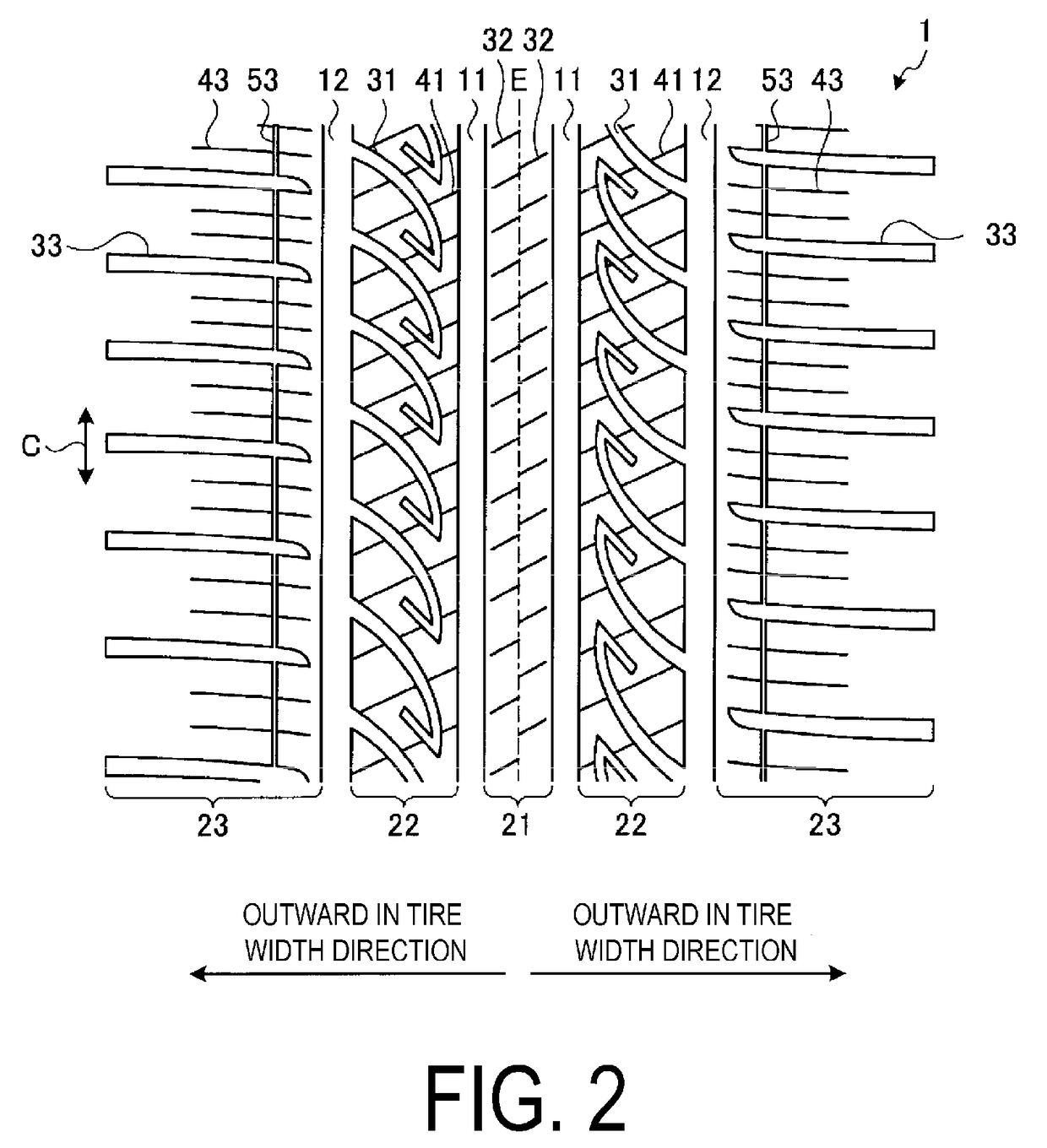

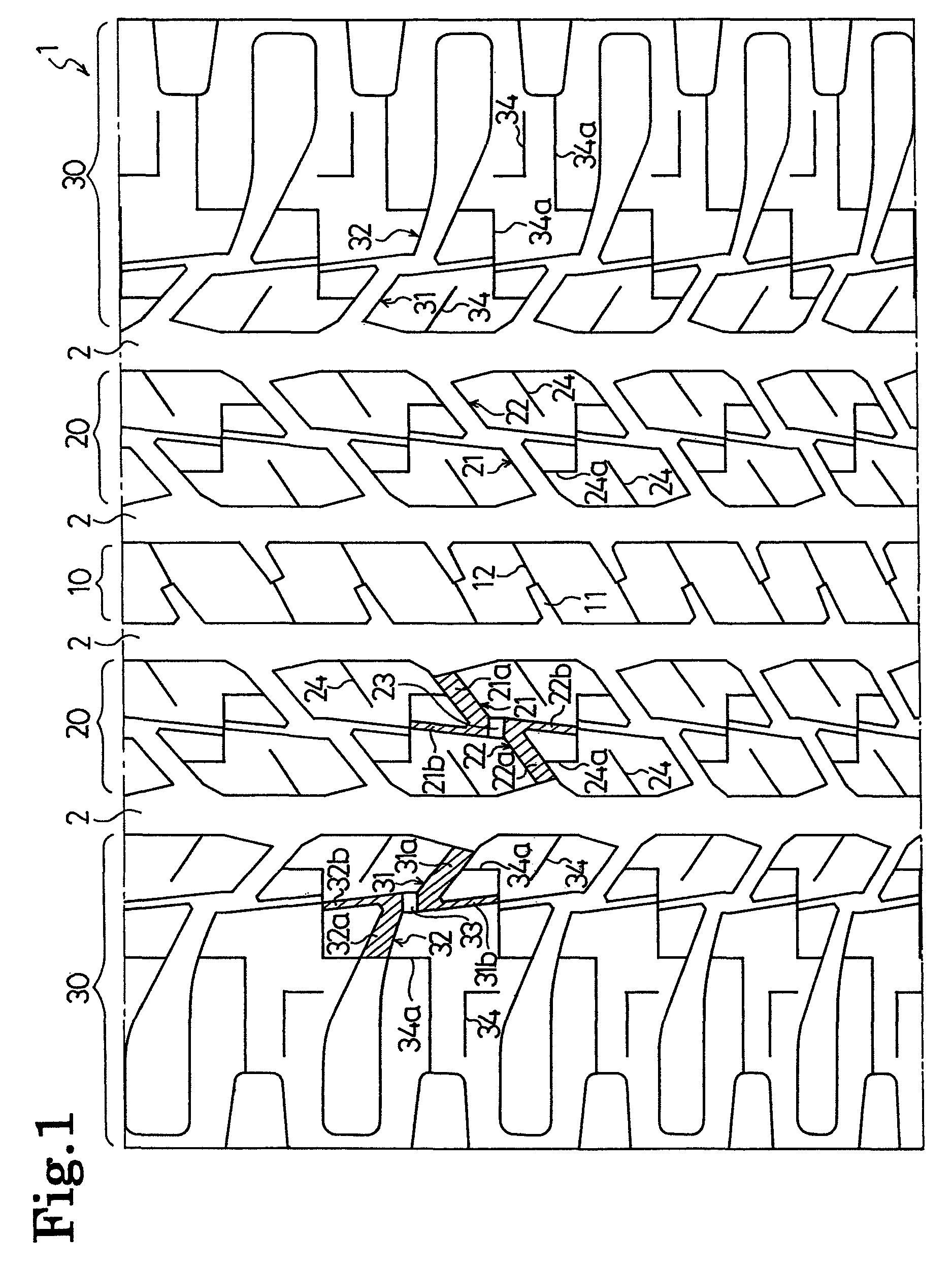

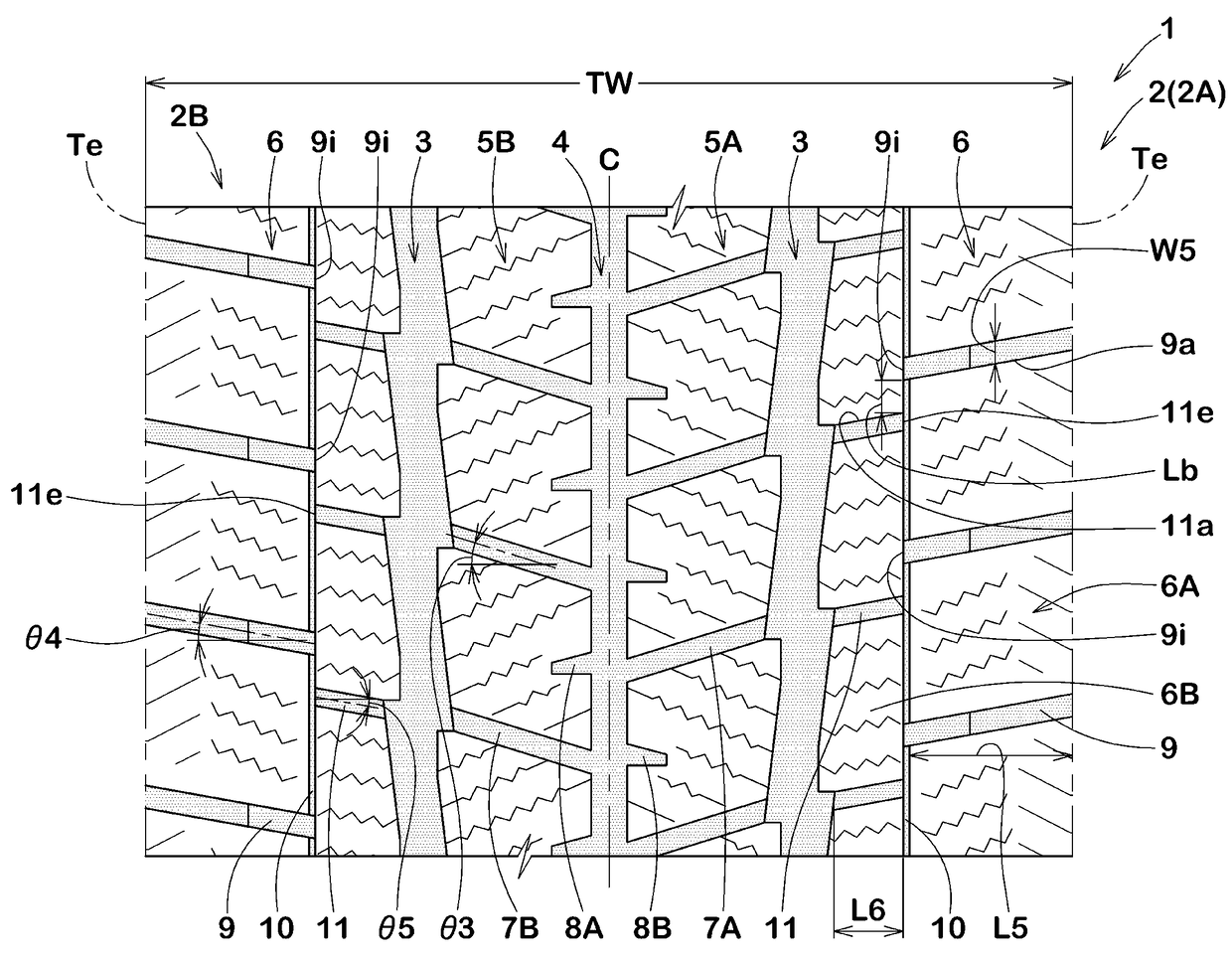

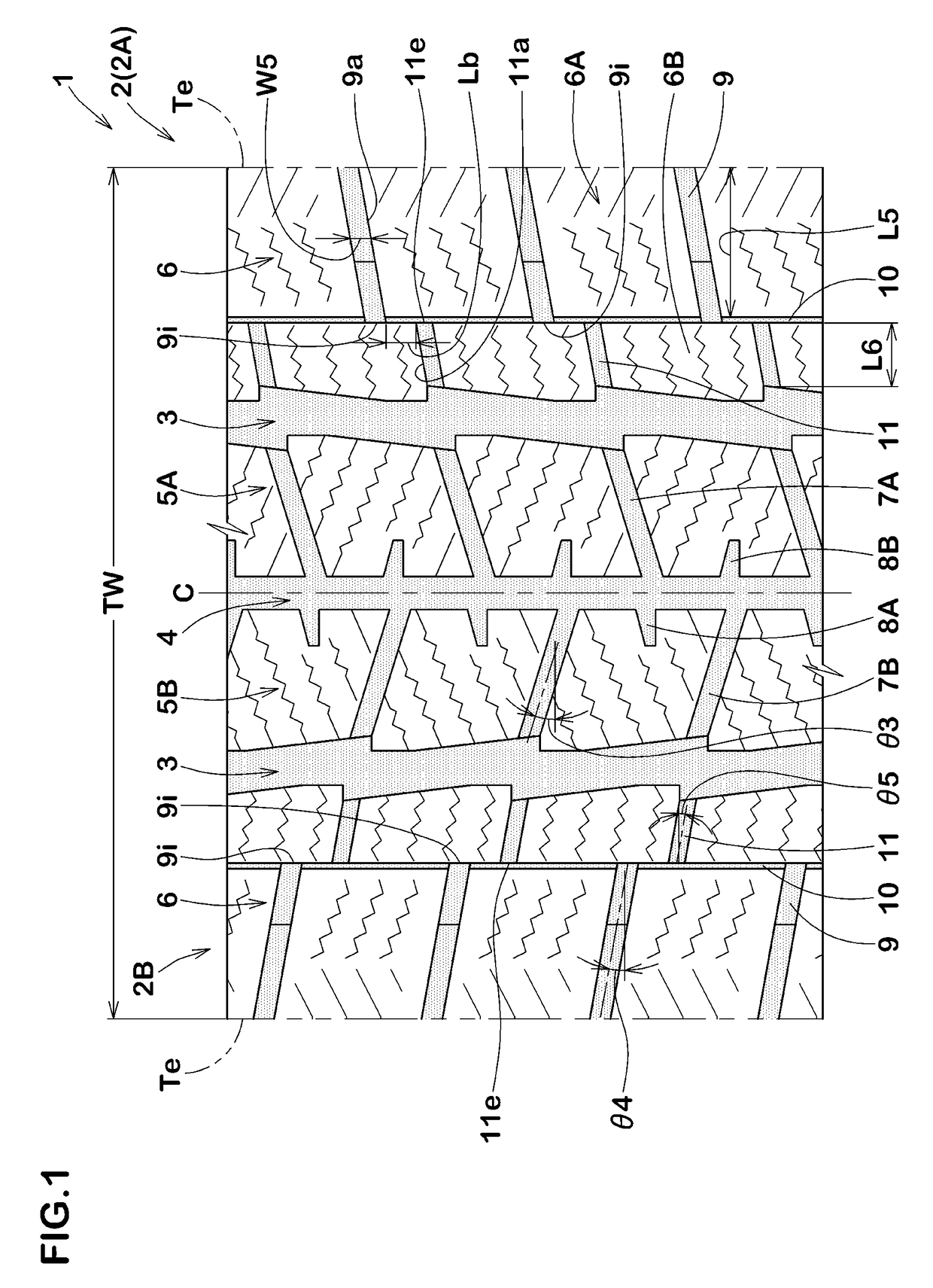

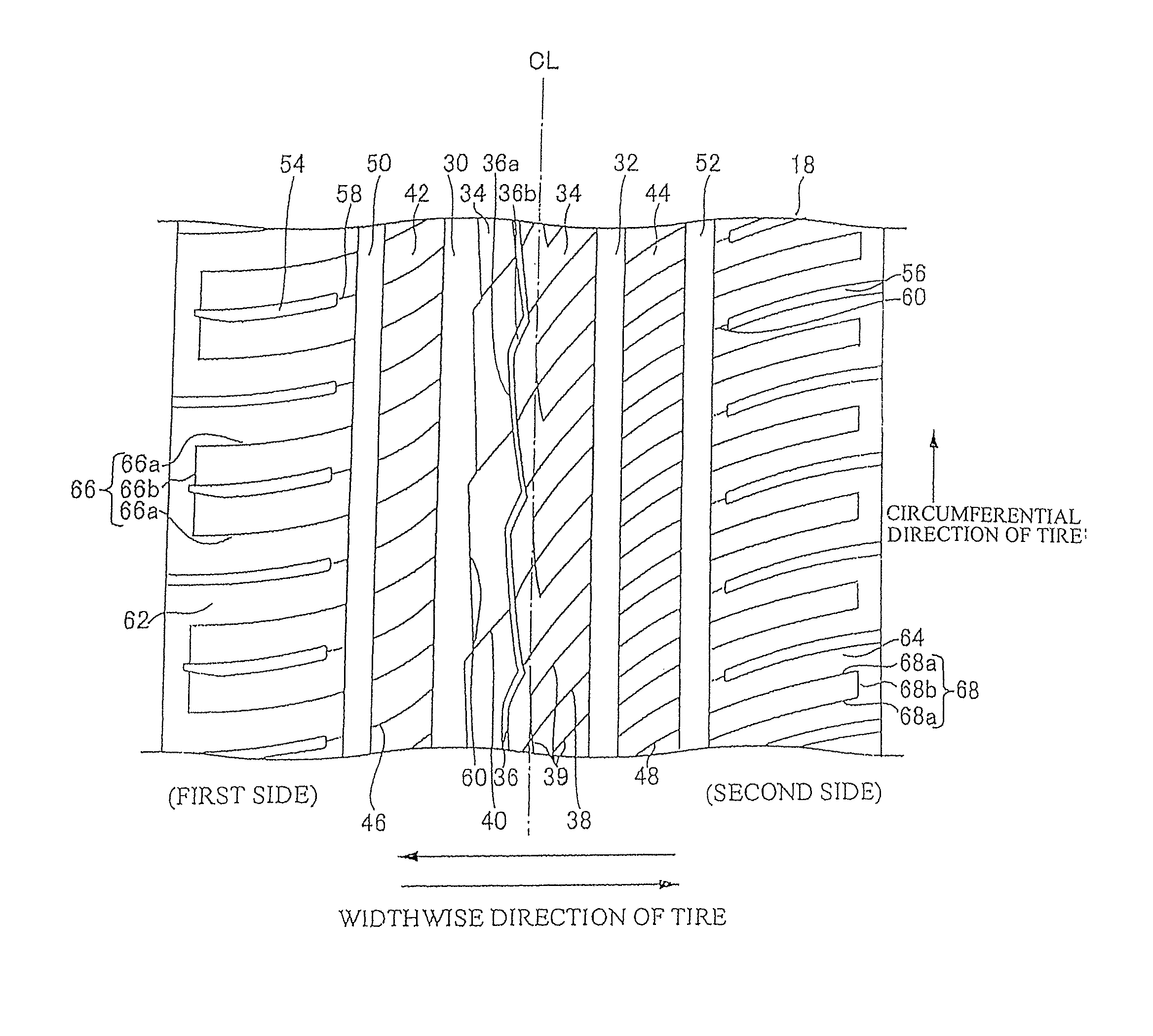

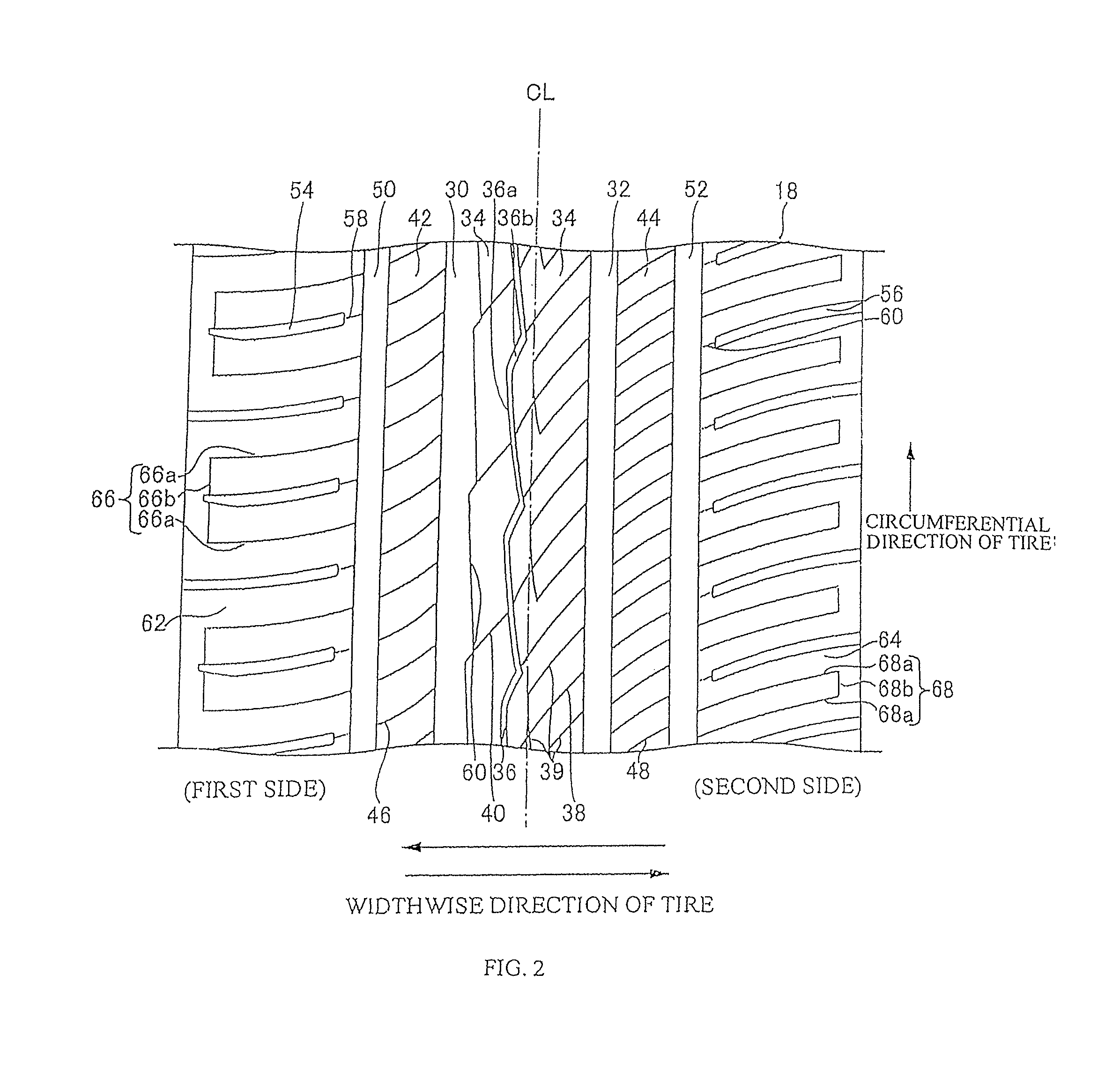

InactiveUS20090101260A1Improve snow performanceWorsening its pattern noiseTyre tread bands/patternsNon-skid devicesGround contactEngineering

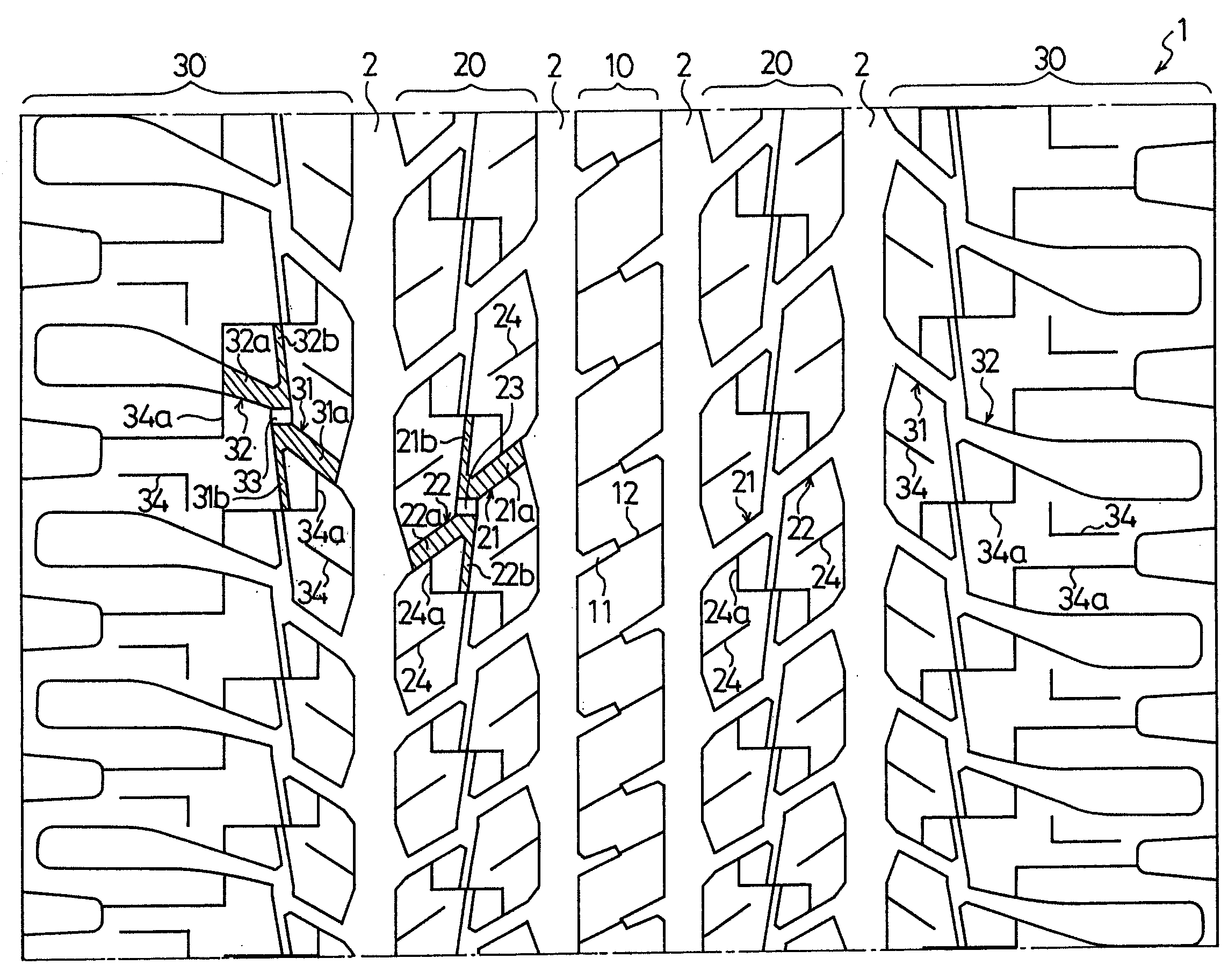

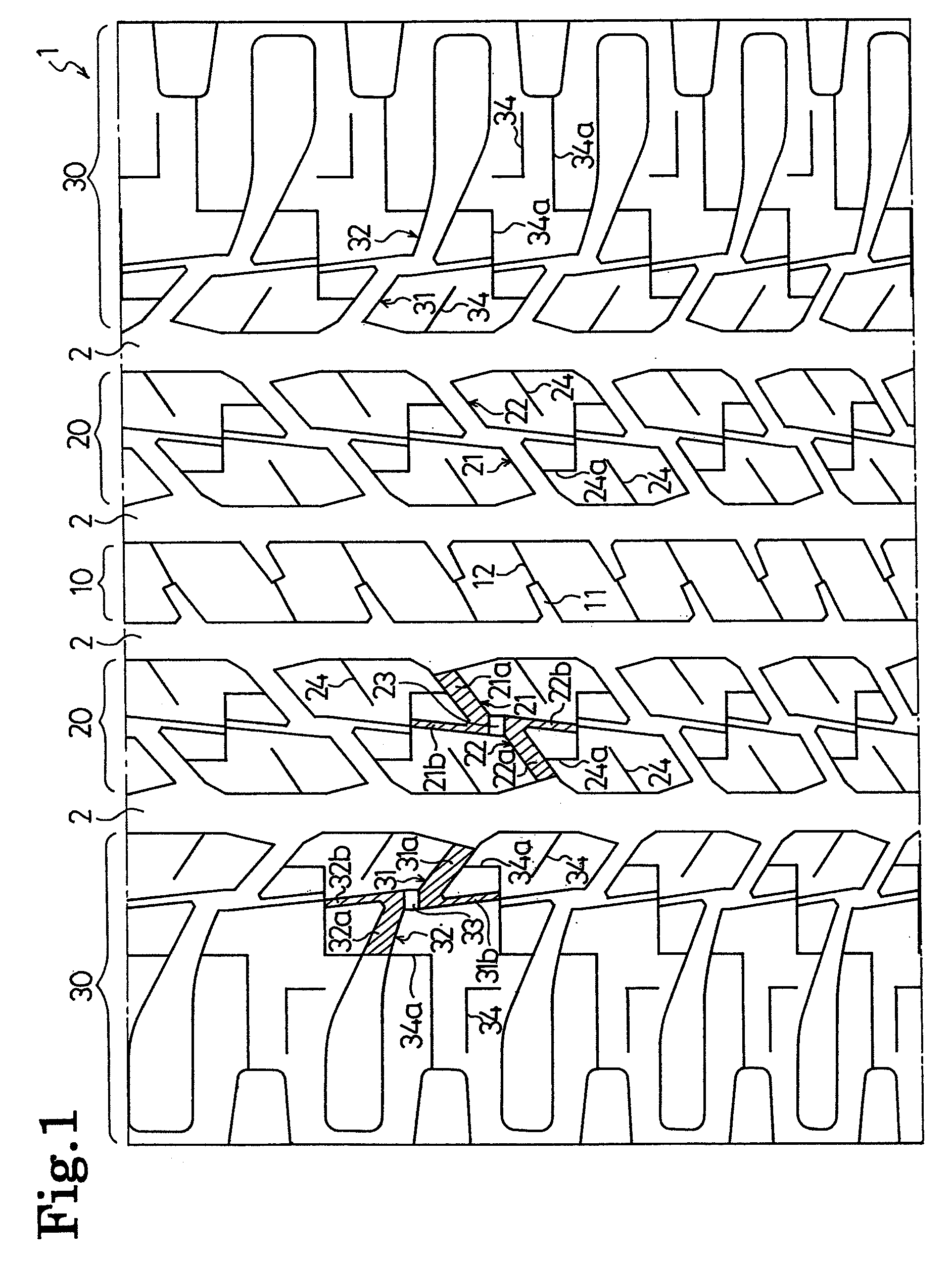

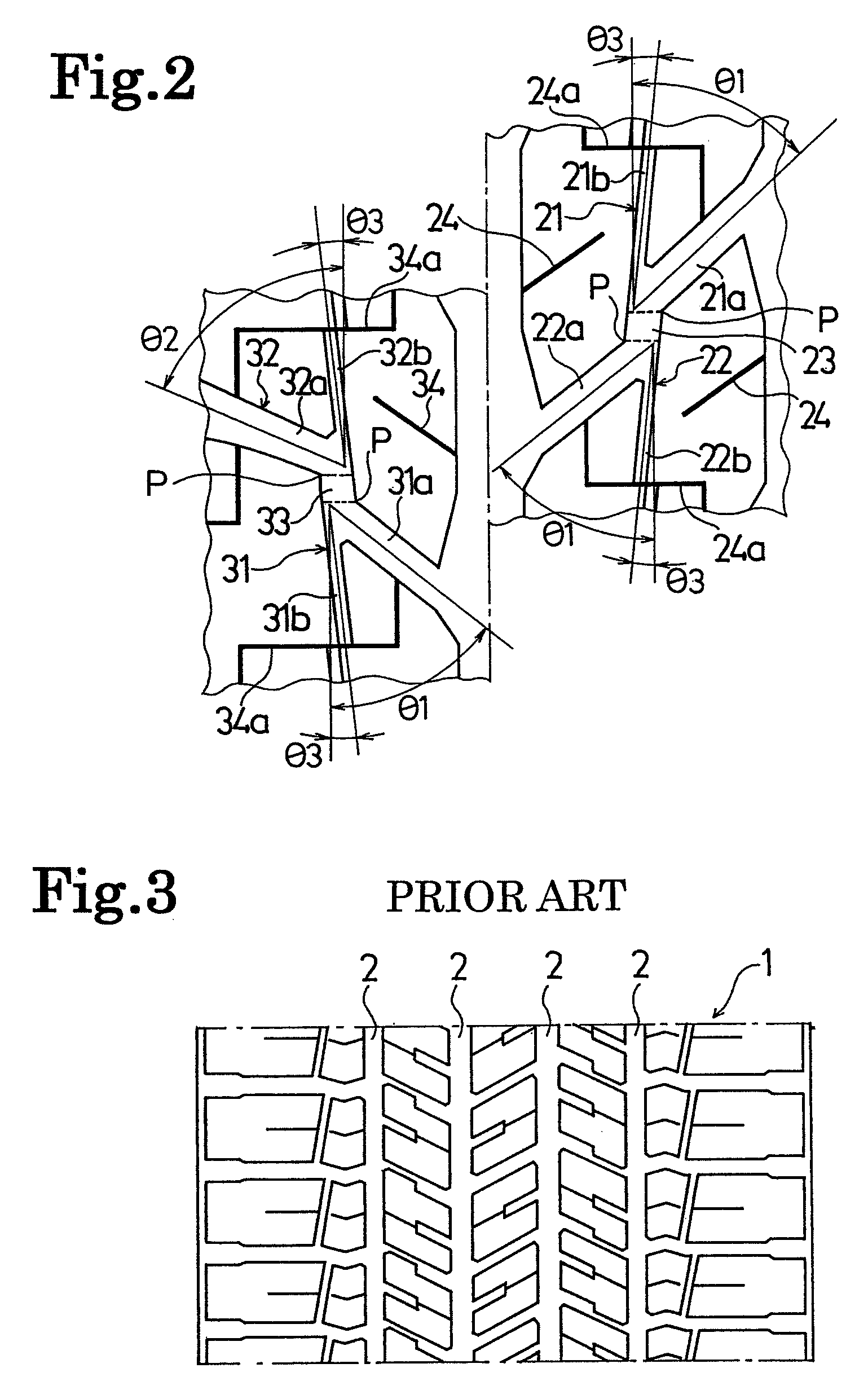

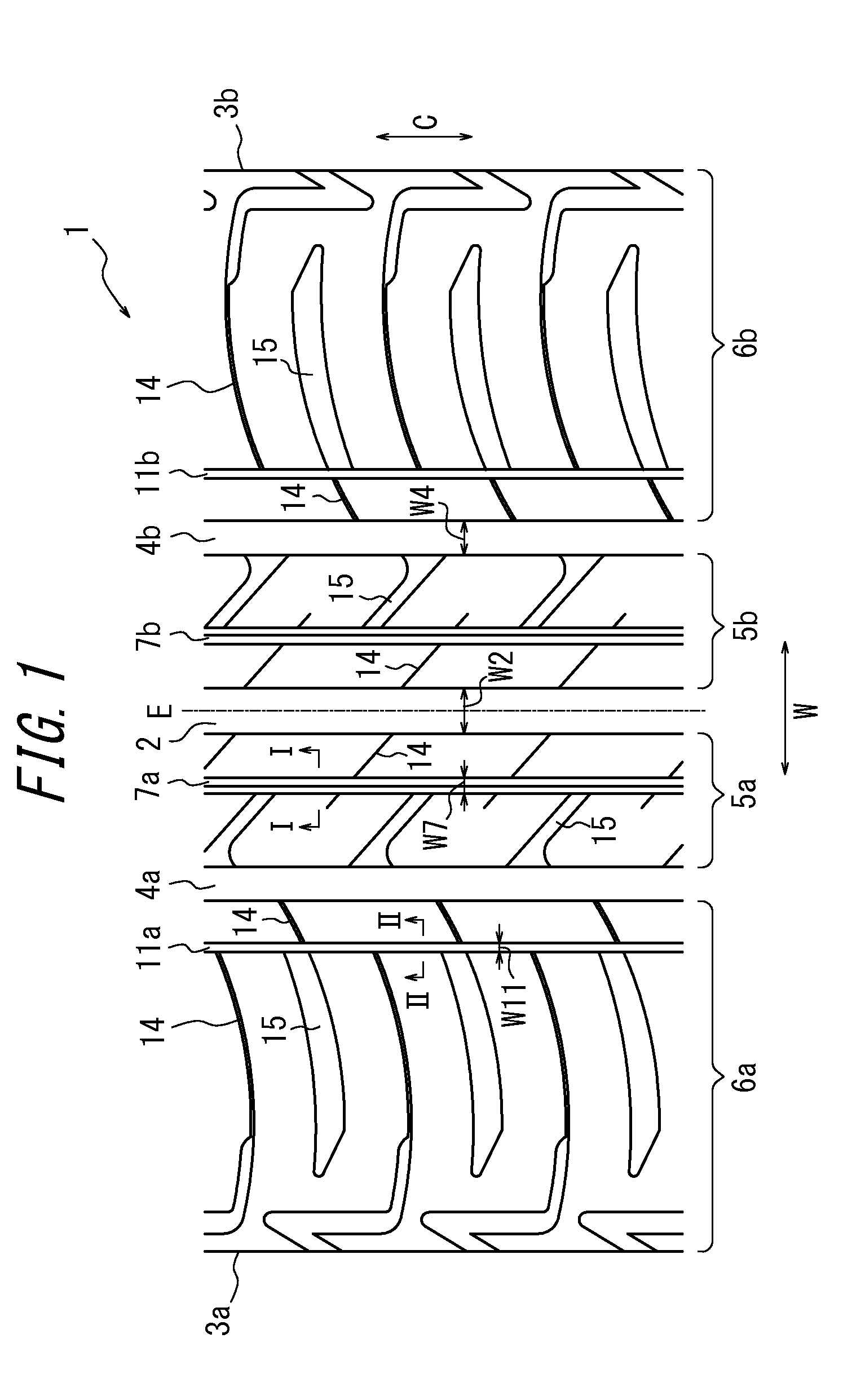

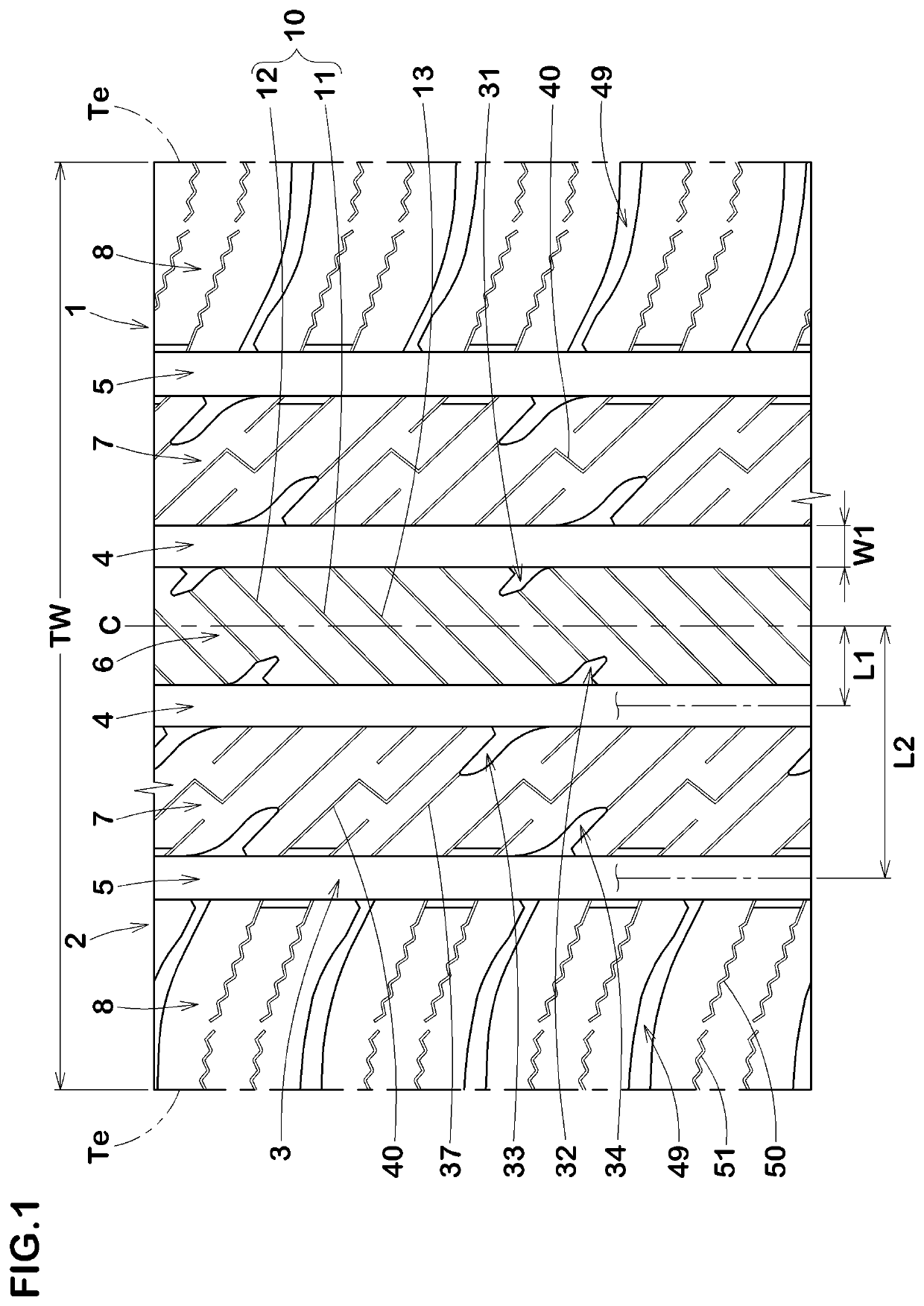

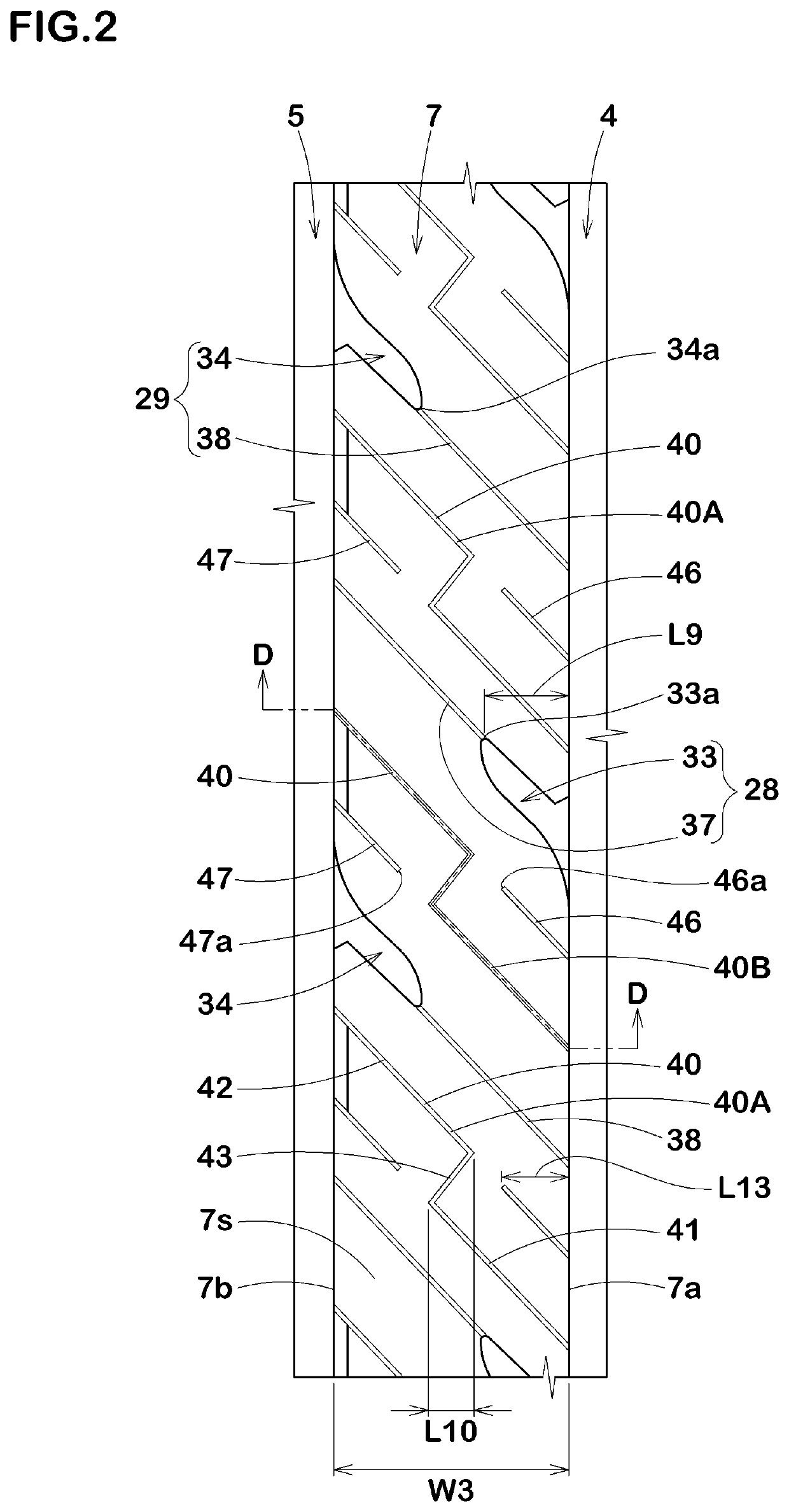

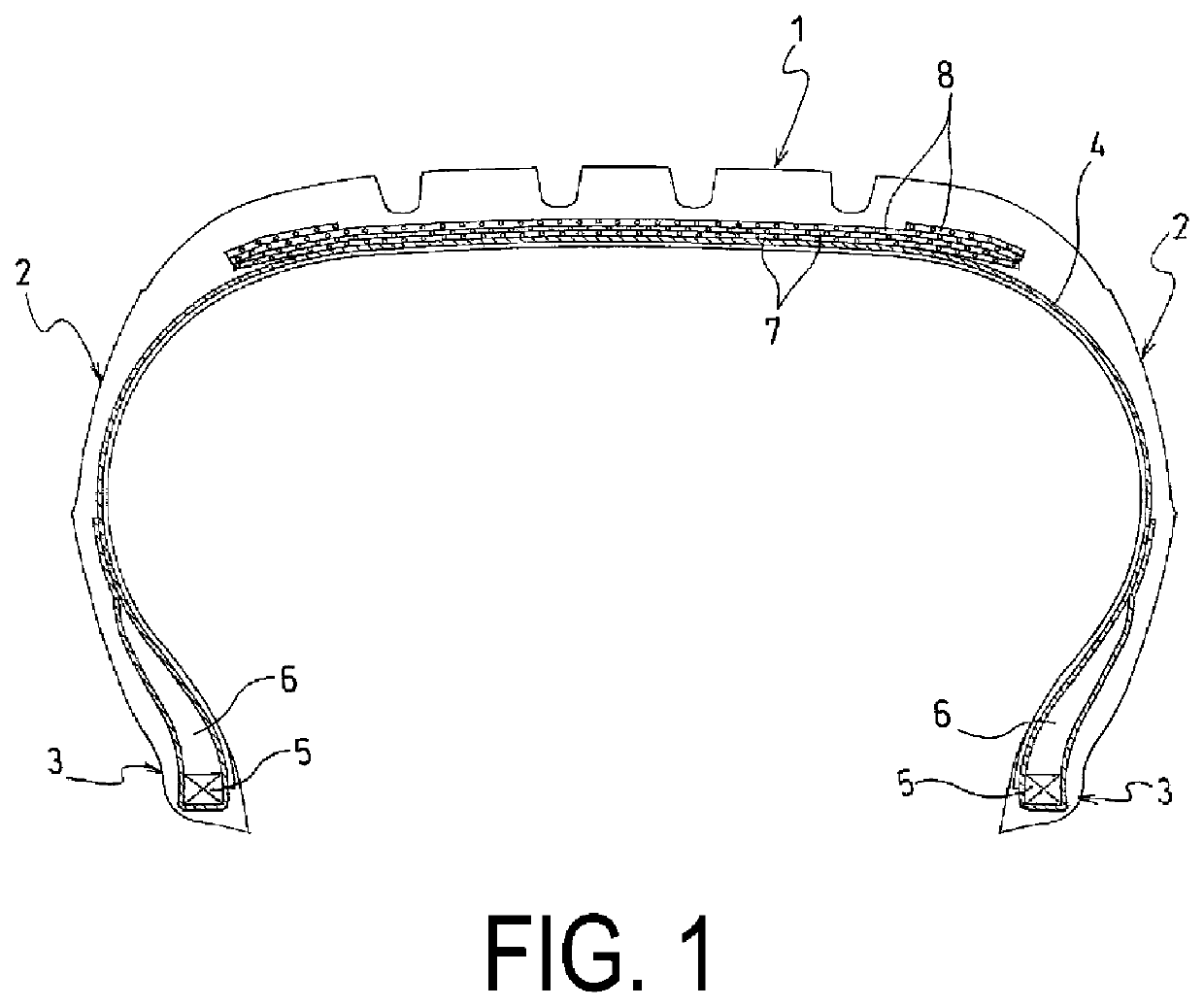

Provided is a pneumatic tire which is capable of securing a driving stability on dry road surfaces and concurrently of improving snow performance without worsening its pattern noise. The pneumatic tire includes four main grooves each extending in its tread part in a tire circumferential direction, and the four main grooves partition the tread part into: a center land part; paired intermediate land parts located with the center land part being interposed in between; and paired shoulder land parts located with the center land part and the paired intermediate land parts being interposed in between. Each of the intermediate land parts and the shoulder land parts includes multiple V-shaped grooves each configured of: a thick groove part extending in a tire width direction; and a thin groove part extending in the tire circumferential direction. The V-shaped grooves are arranged in a way that each paired V-shaped grooves are opposed to each other in the tire circumferential direction with a connecting groove part being interposed between vertices of the respective paired V-shaped grooves. Each thick groove part communicates with the main grooves or the outside of a ground contacting area. Each thin groove part terminates within the land part.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveCN101554829AReduce noiseImprove snow performanceTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire capable of attaining both a reduction in tire noise and an improvement in on-snow performance and, having a feature in terms of a pattern. Wherein, on groove walls on both sides forming the at least three circumferential grooves, first inclined walls inclined by an inclination angle of 5 to 20 degrees with respect to the tire circumferential direction and second inclined walls inclined by an inclination angle of 0 to 45 degrees with respect to a tire width direction are provided so as to be successively connected in the tire circumferential direction so that positions of groove ends in the tire width direction vary in the tire circumferential direction. Connecting portions between the first inclined walls and the second inclined walls are bent in a V-shape in a plan view of the tread pattern. A length of the first inclined walls is larger than a length of the second inclined walls, every two of the first inclined walls on both sides of each of the second inclined wall have a step amount of 1.5 to 5.0 mm in the tire width direction. Three to five pairs of the first inclined walls and the second inclined walls adjacent to each other areprovided for one tread pattern.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

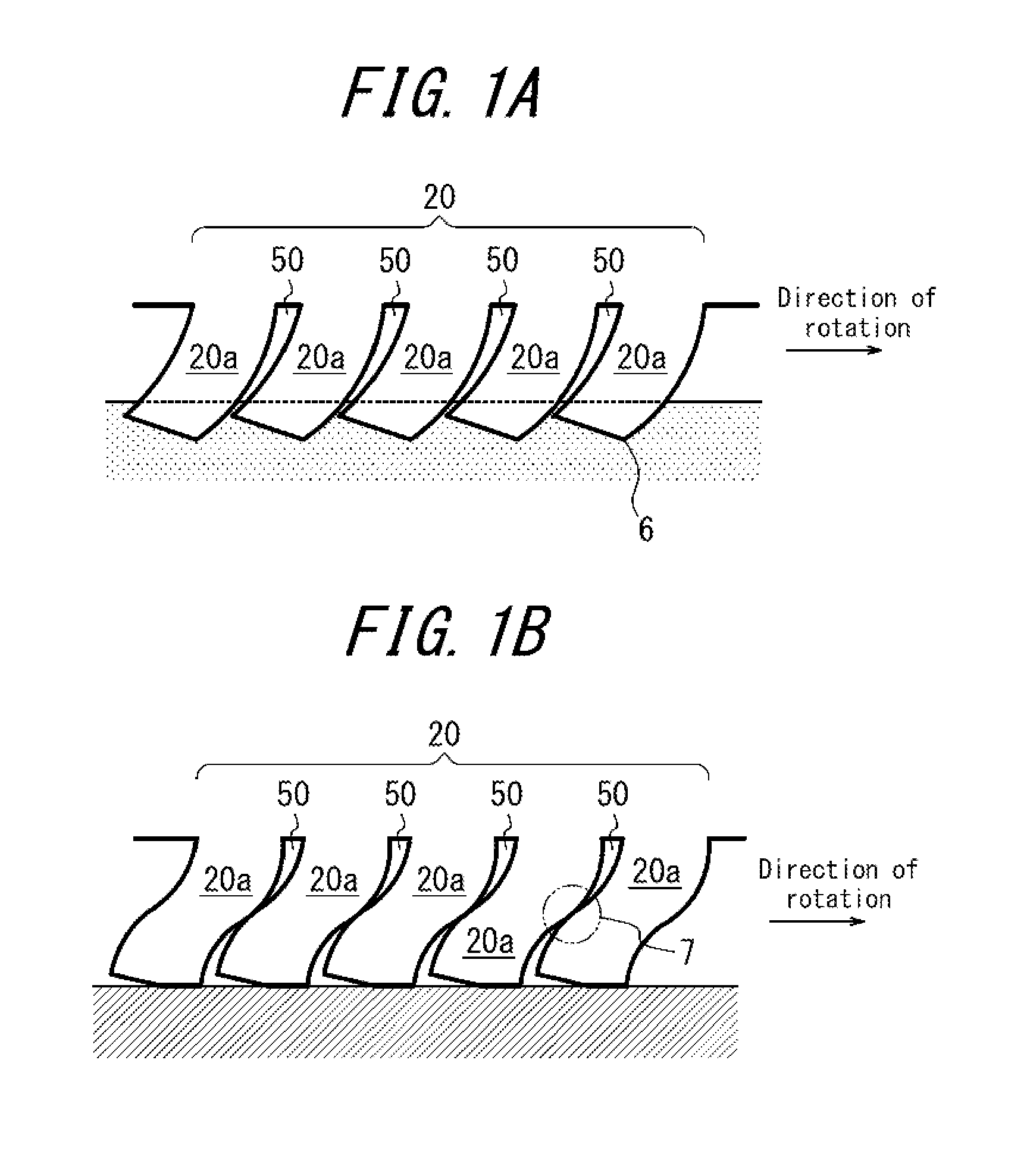

InactiveUS20110277895A1Good mud scooping actionGreat tractionOff-road vehicle tyresTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire has a shoulder land portion including a tread edge and a plurality of lateral grooves which are open to an outer wall of the shoulder land portion in a tread surface. One end in a tire circumferential direction of the outer wall is positioned on an inner side in a tire width direction with respect to another end between the lateral grooves which are adjacent to each other. A vacancy communicating with the lateral groove from the one end of the outer wall is formed so as to face the outer wall. A pawl portion protruding in the tire circumferential direction is provided in a wall surface of the lateral groove which is close to the other end of the outer wall. A height of the pawl portion from a bottom of the lateral groove is gradually decreased toward a leading end.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

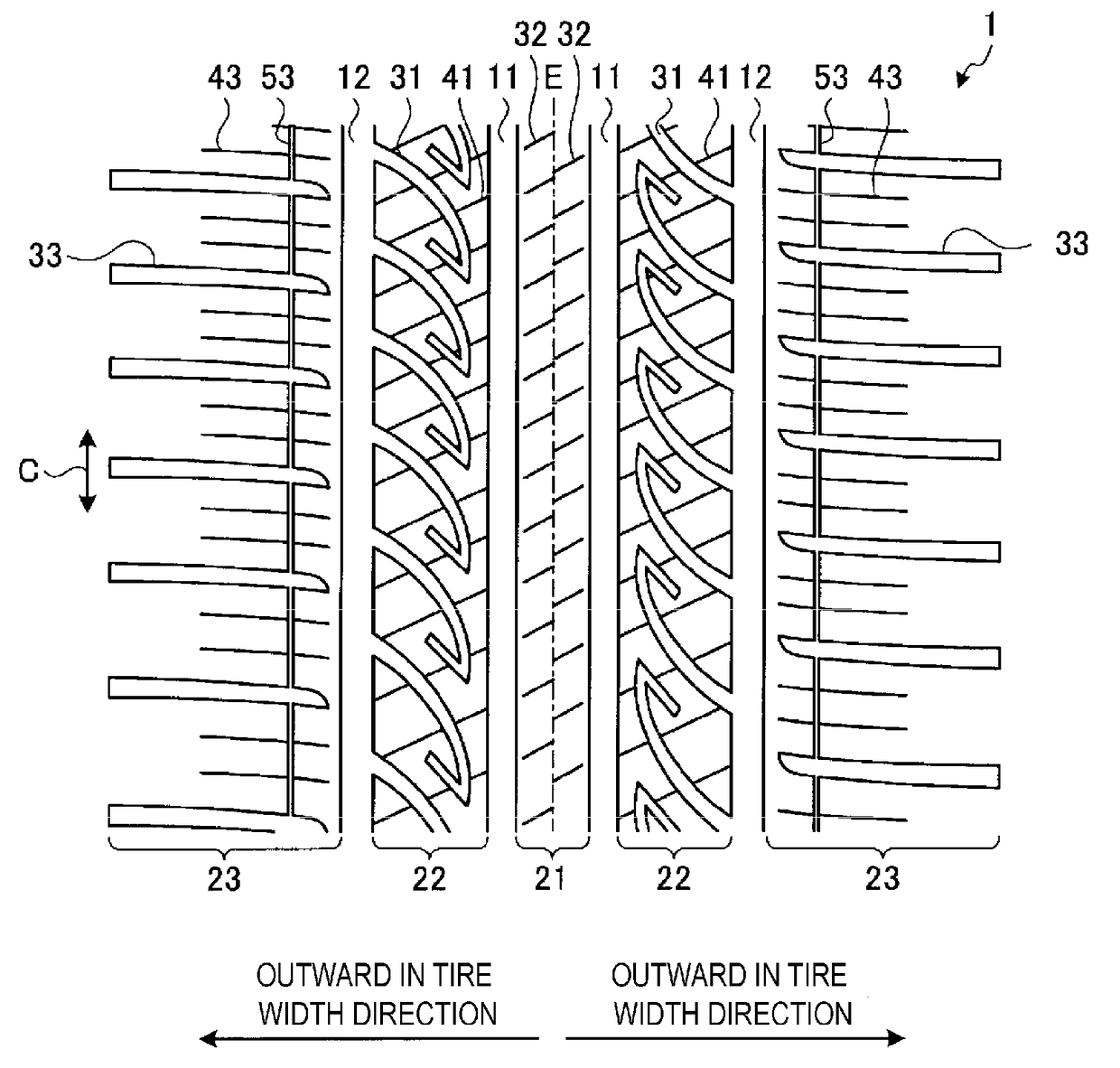

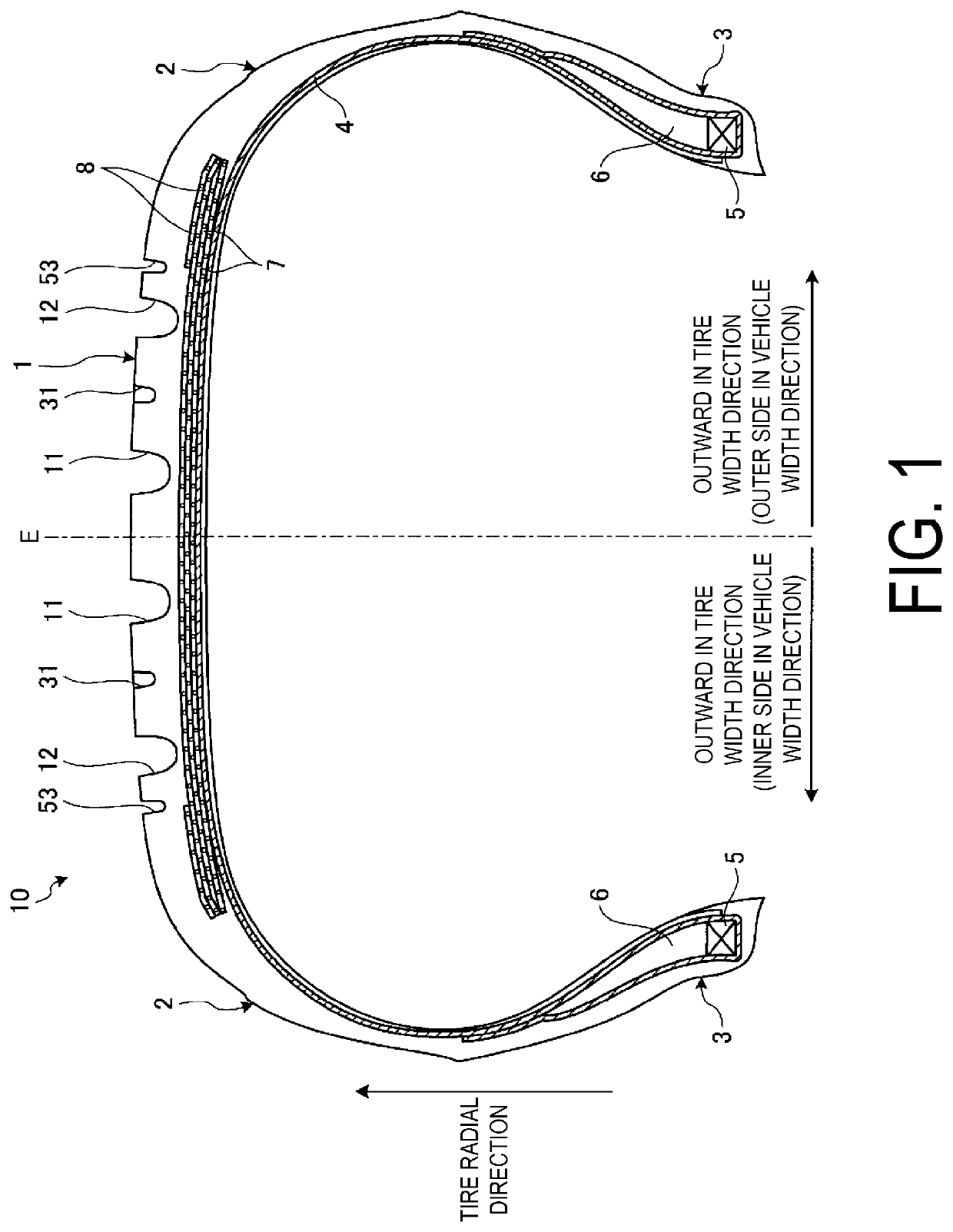

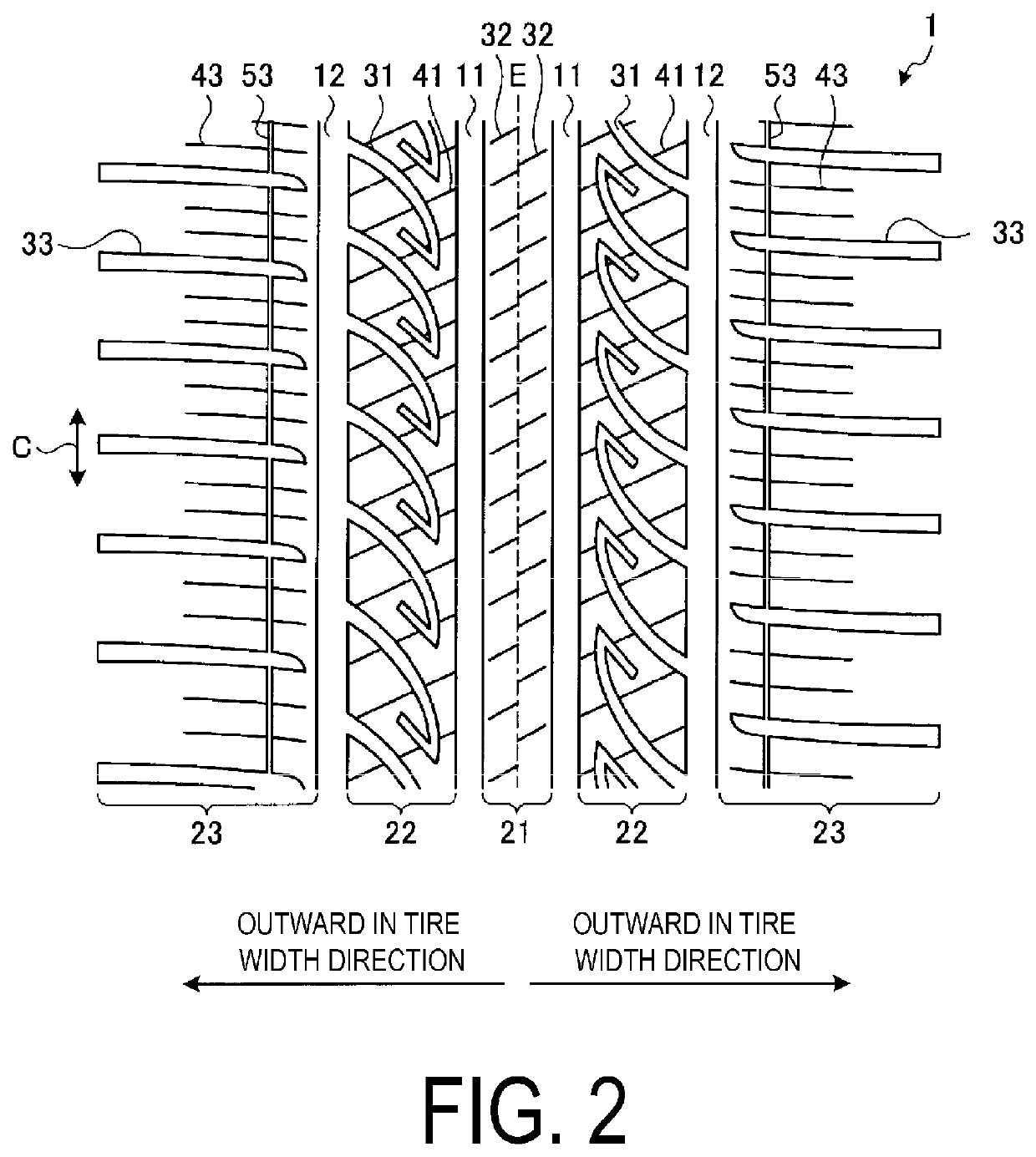

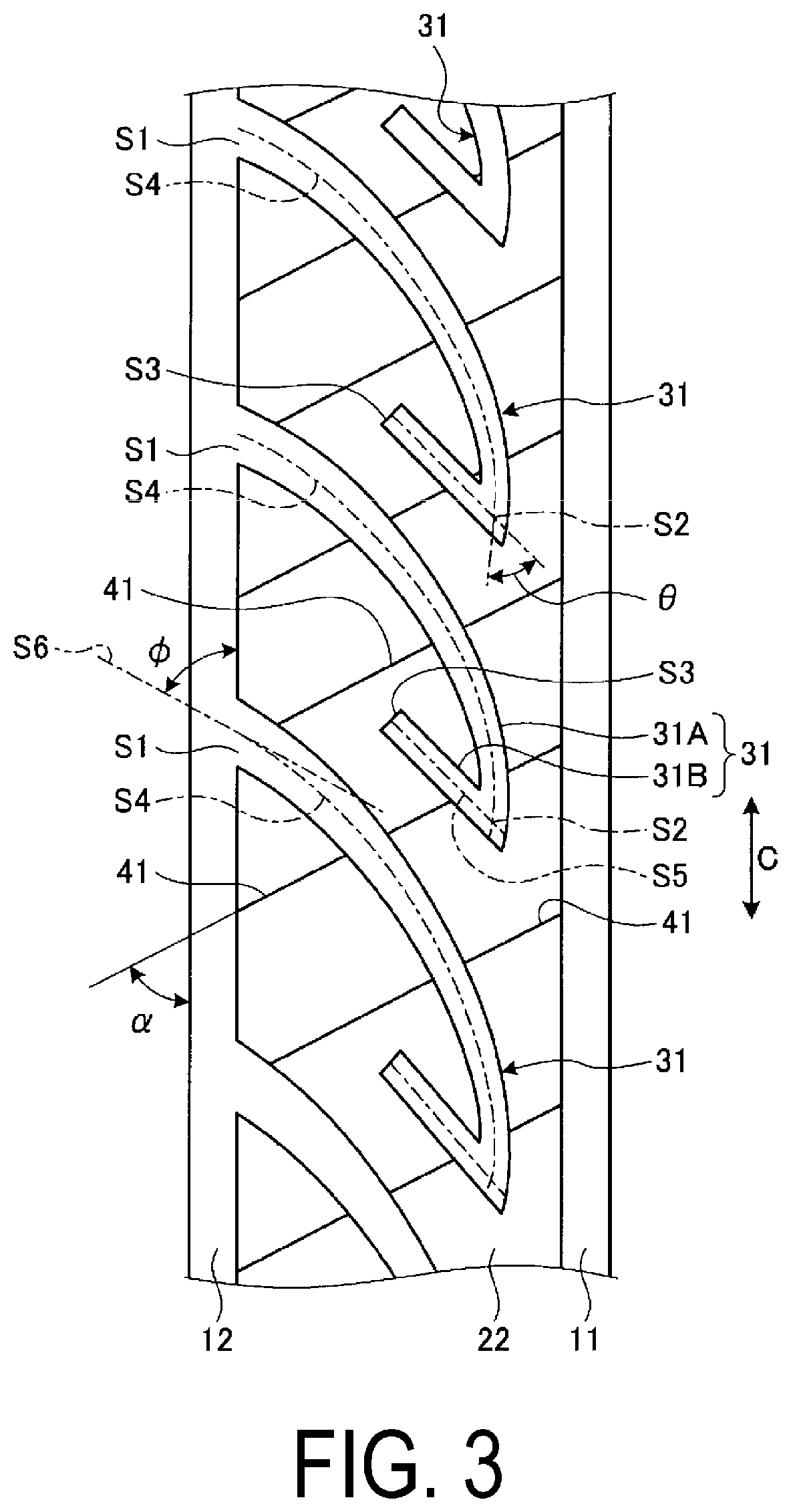

InactiveUS20110005653A1Improve rigidityImprove driving stabilityTyre tread bands/patternsNon-skid devicesGround contactCurve shape

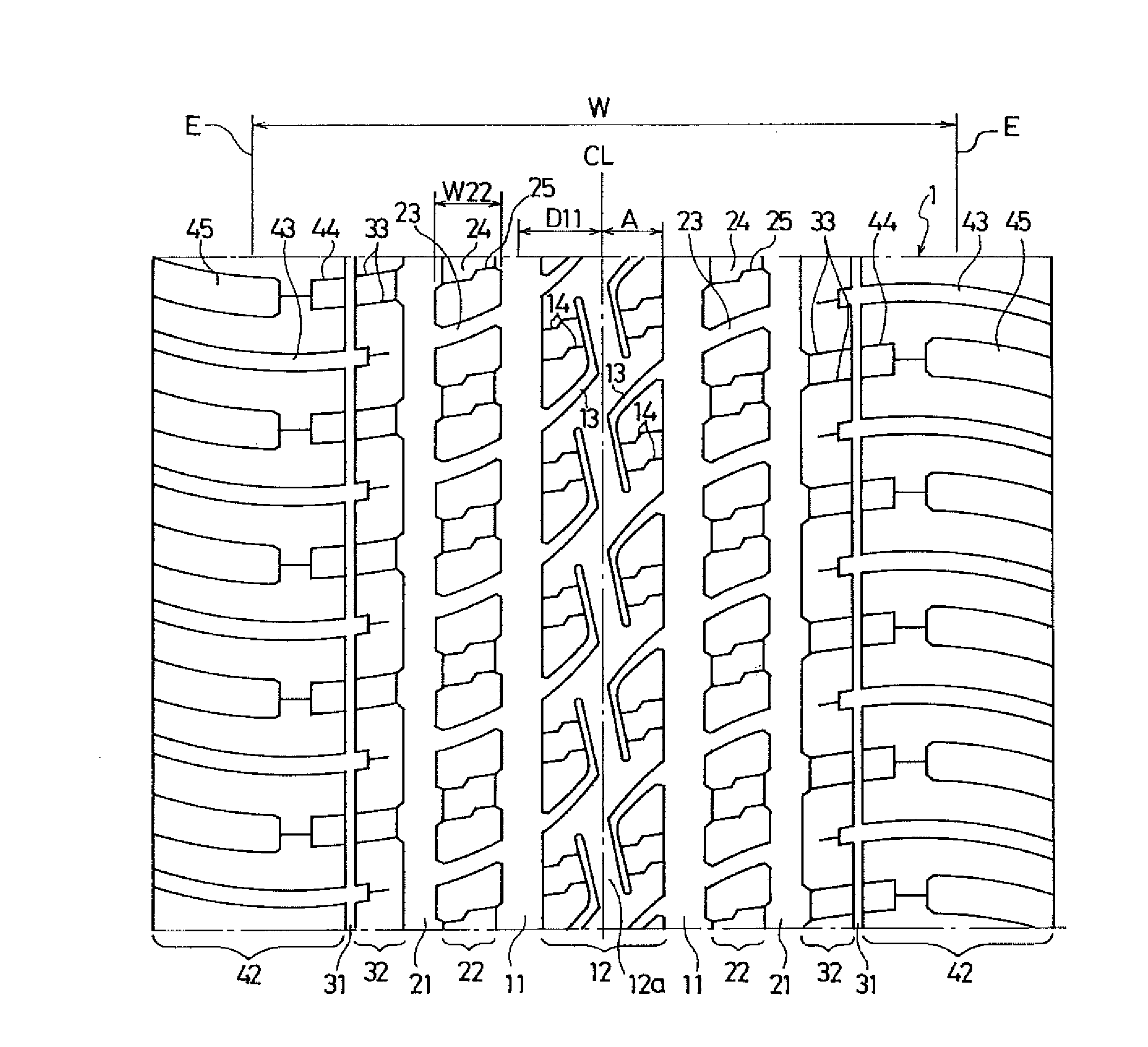

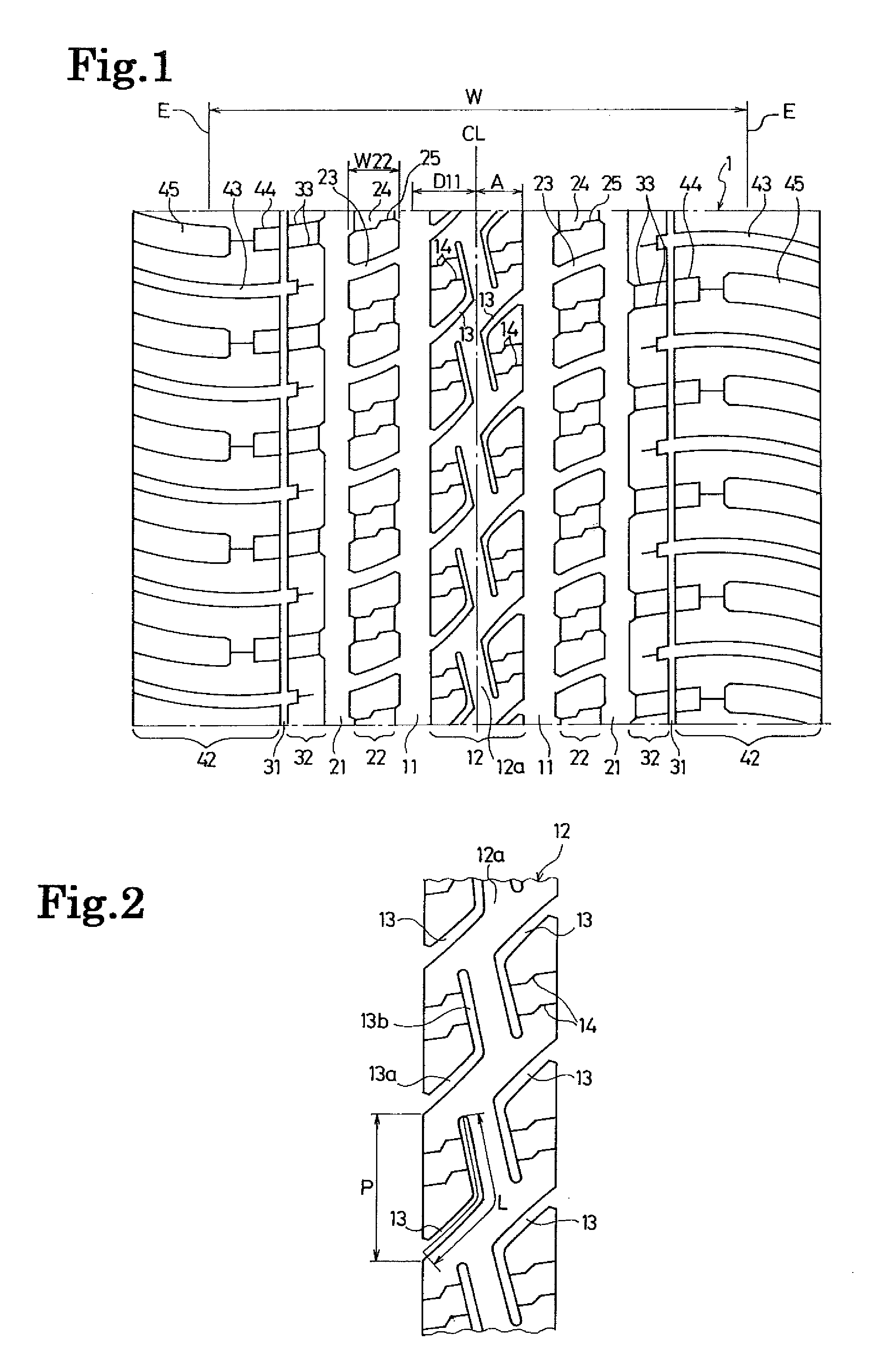

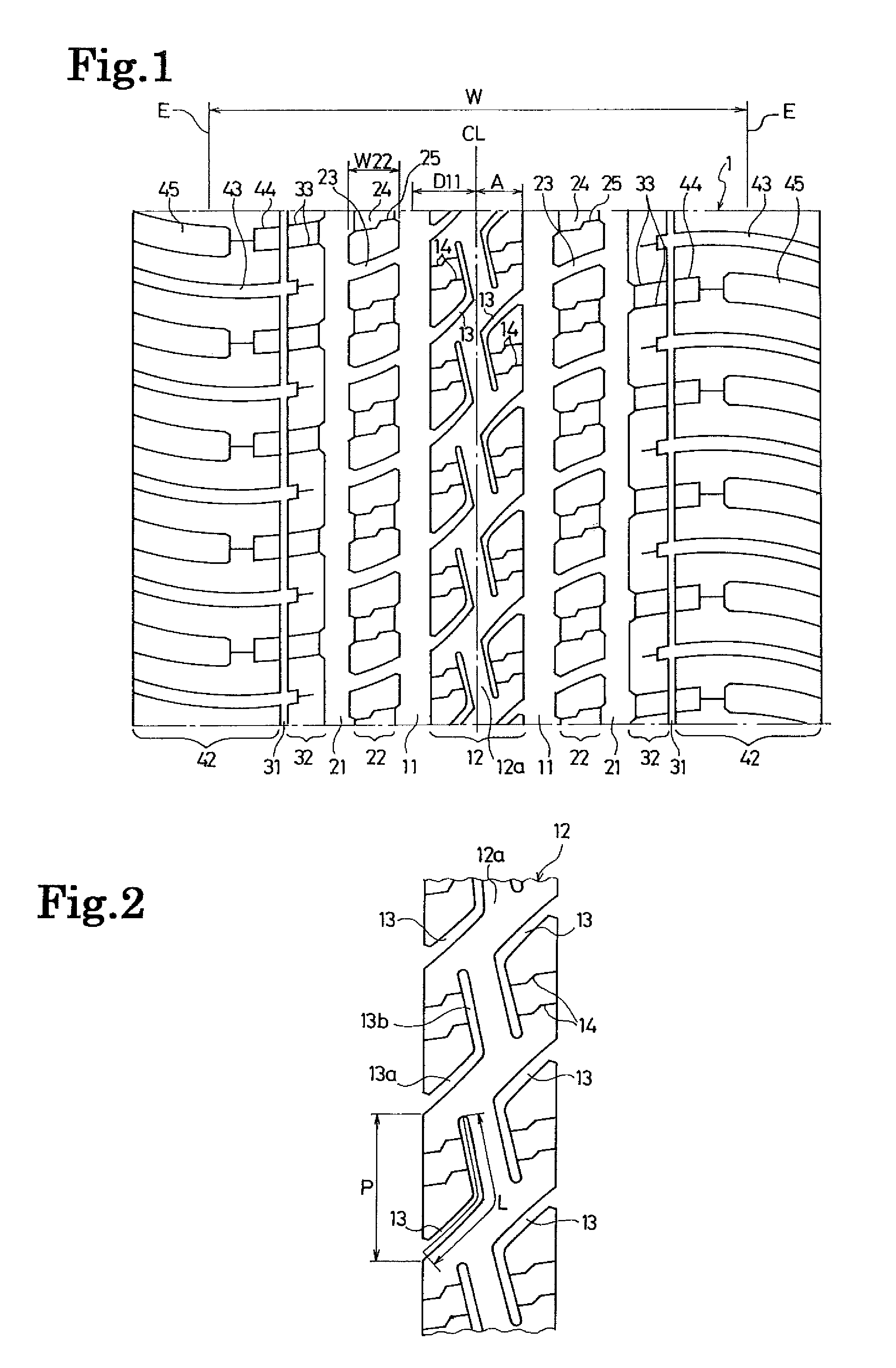

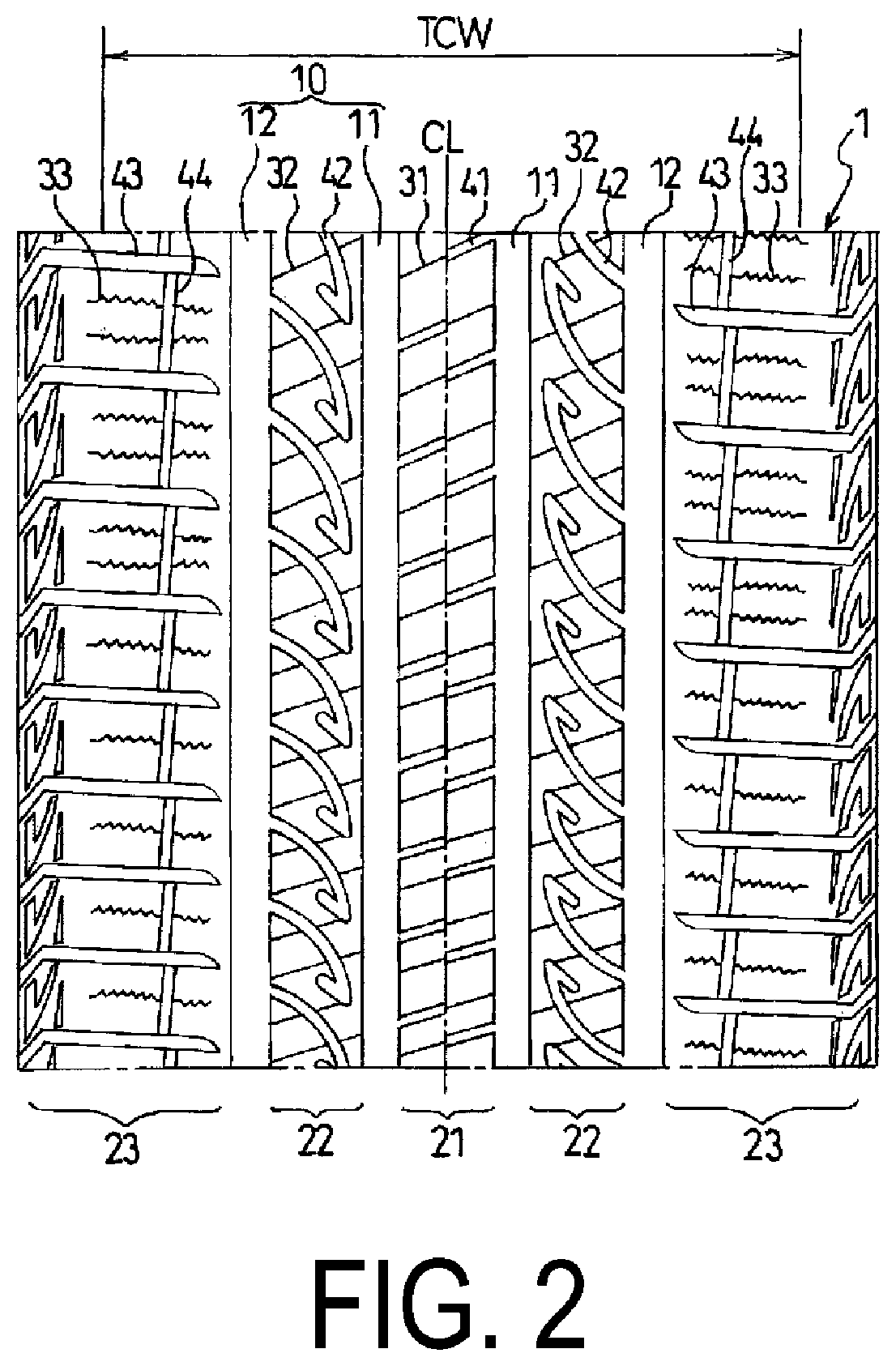

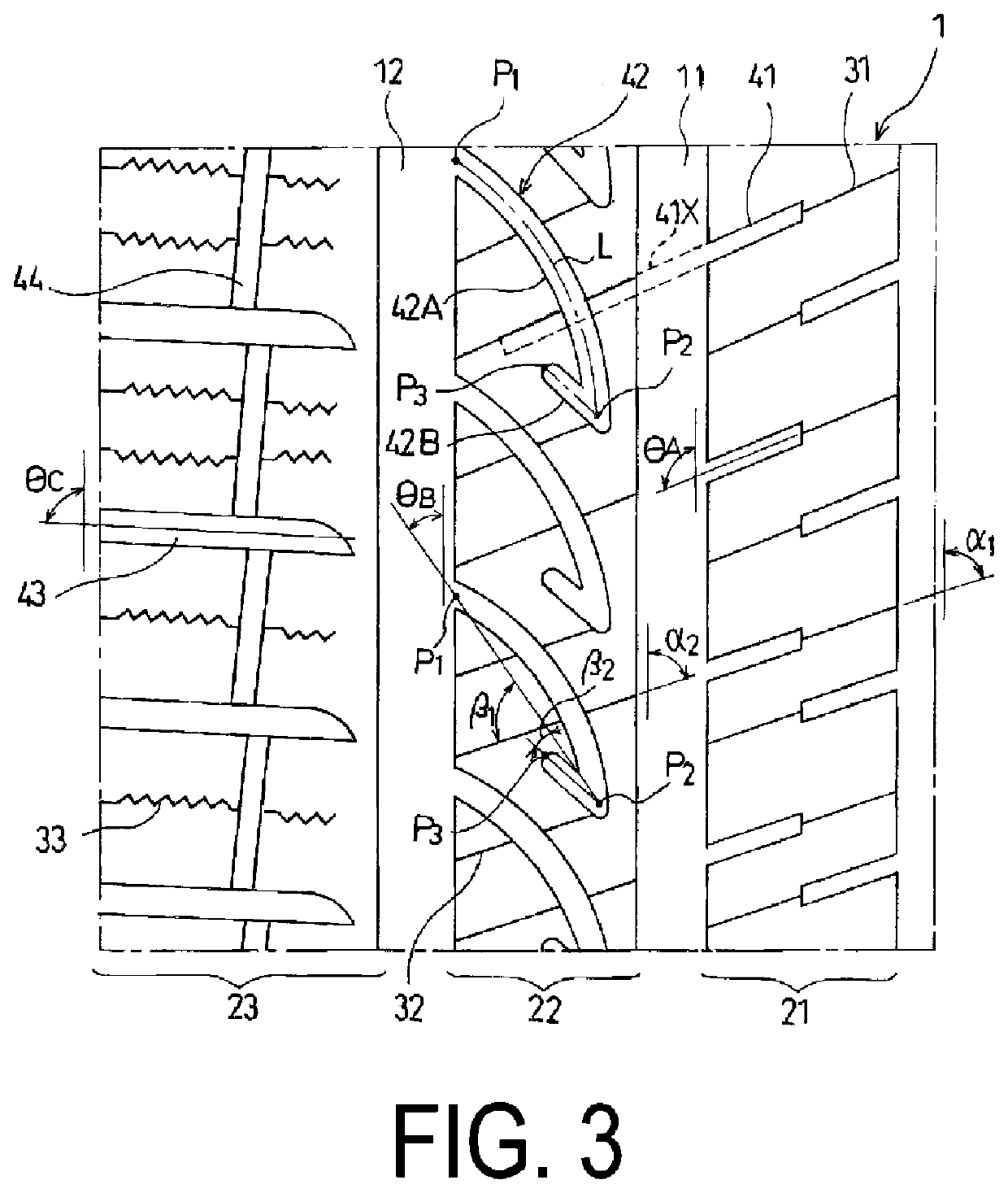

A pneumatic tire is configured such that: paired first main grooves extending in a tire circumferential direction are provided on the two sides of a tire equator line in a tread portion, respectively; a distance between a center position of each first main groove and the tire equator line is set at 8% to 20% of a ground contact width W; a first land portion is defined between these first main grooves; multiple sub-grooves each having a curved shape are formed in each of both edge portions of the first land portion at intervals in the tire circumferential direction; one end of each sub-groove is opened to the corresponding first main groove, and the other end of the sub-groove is terminated inside the first land portion; a rib portion continuously extending in the tire circumferential direction is formed in an area of the first land portion on the tire equator line; and a relation between a length (L) of a center line of each sub-groove and a pitch length (P) of the sub-grooves in the tire circumferential direction satisfies 1.1×P≰L≰2.0×P.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

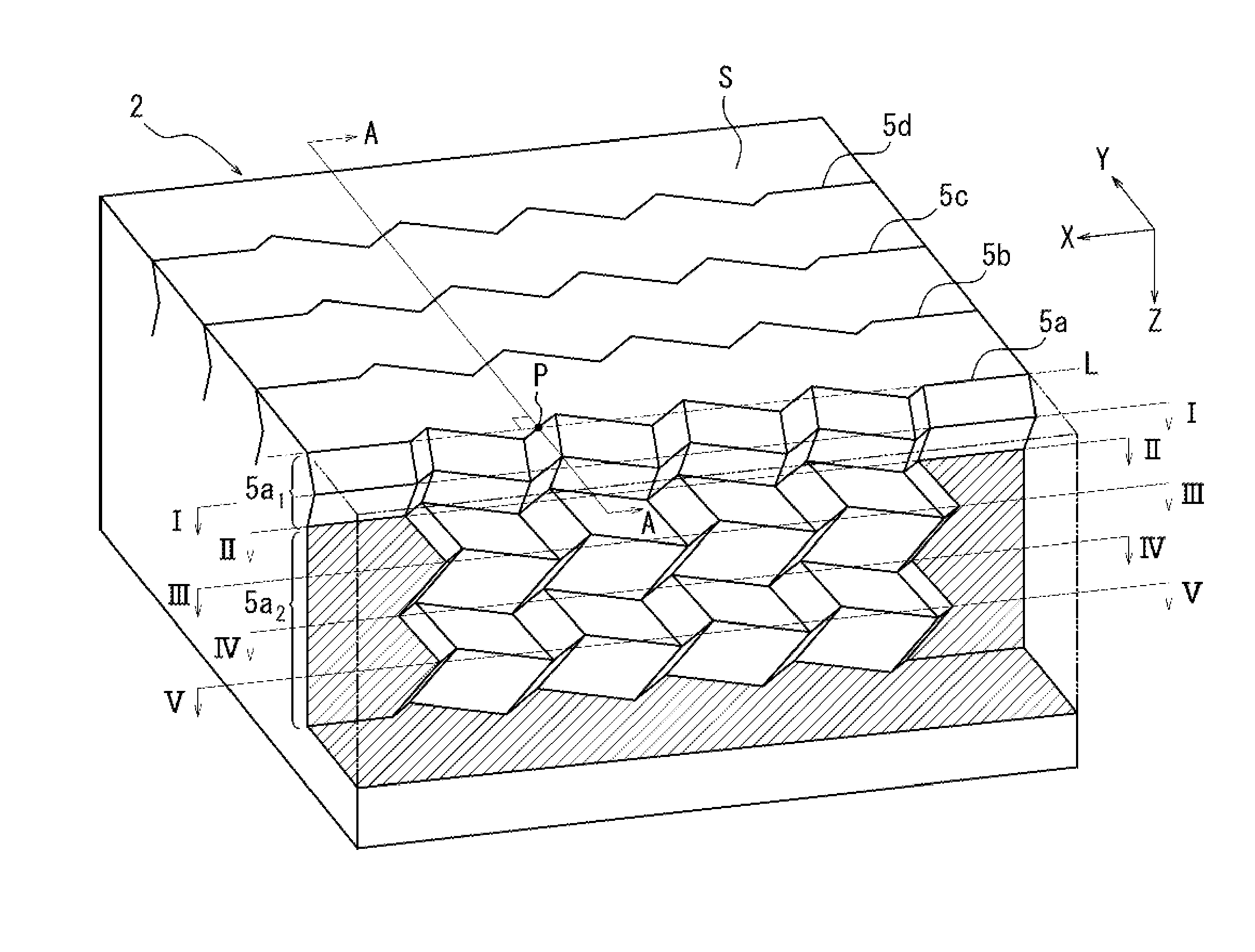

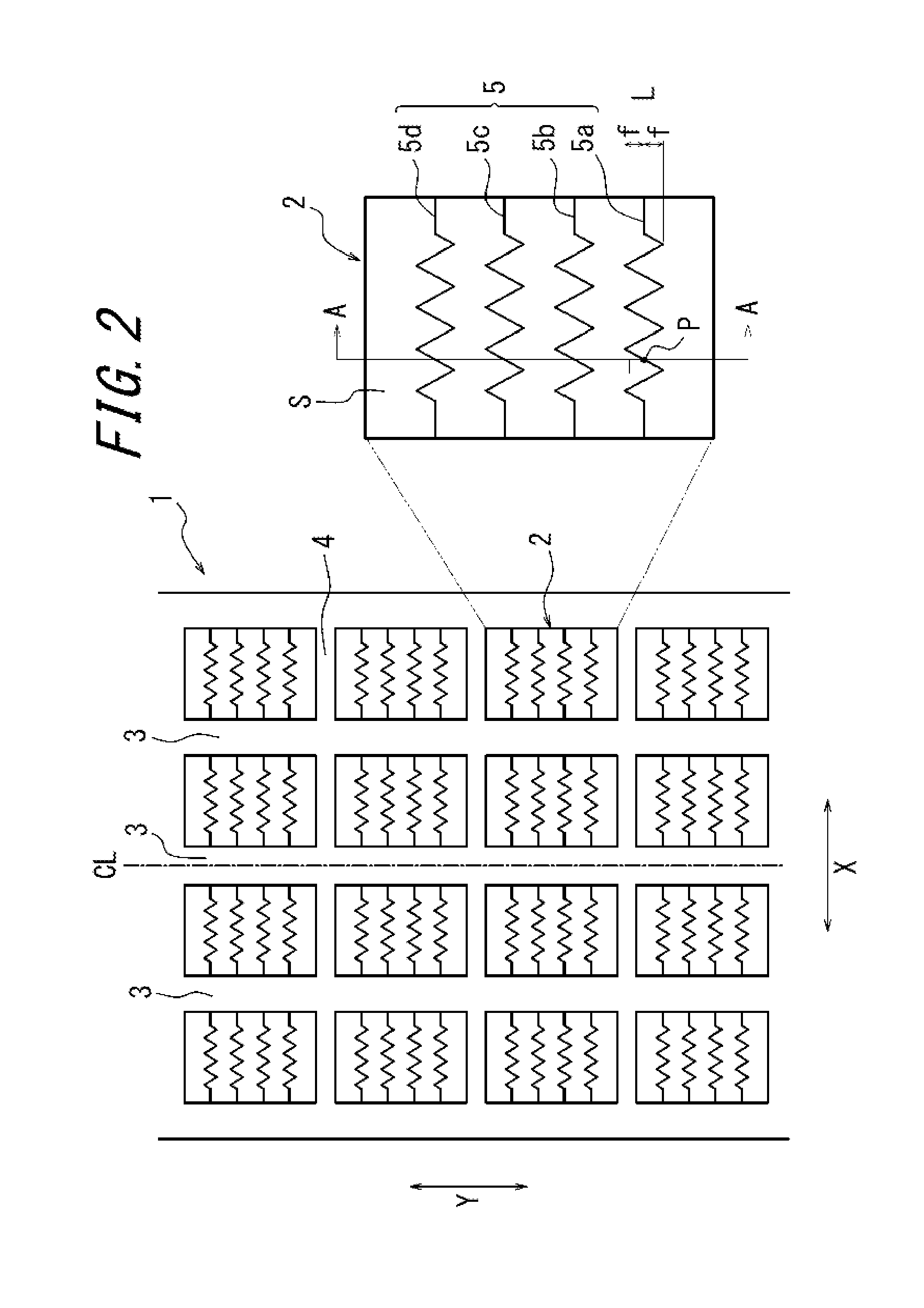

ActiveUS20140299245A1Keep dryImprove wetting performanceTyre tread bands/patternsNon-skid devicesEngineeringDepth direction

Provided is a pneumatic tire including a land portion provided with a sipe, which is capable of simultaneously providing snow performance, dry performance, and wet performance all at high level in a single land portion. The pneumatic tire includes a land portion 2 on a tread portion. The land portion 2 is provided with a sipe 5 having amplitude in a tire circumferential direction and extending in a tire width direction. In a depth direction extending from a land portion surface S toward an inner side in a tire radial direction, sipe 5 includes: a land portion's surface-side part 5a1 bent toward tire circumferential direction from land portion surface S; and a land portion's bottom-side part 5a2 bent in a direction different from a direction of land portion's surface-side part 5a1 or bent toward tire circumferential direction by a displacement different from a displacement of land portion's surface-side part 5a1.

Owner:BRIDGESTONE CORP

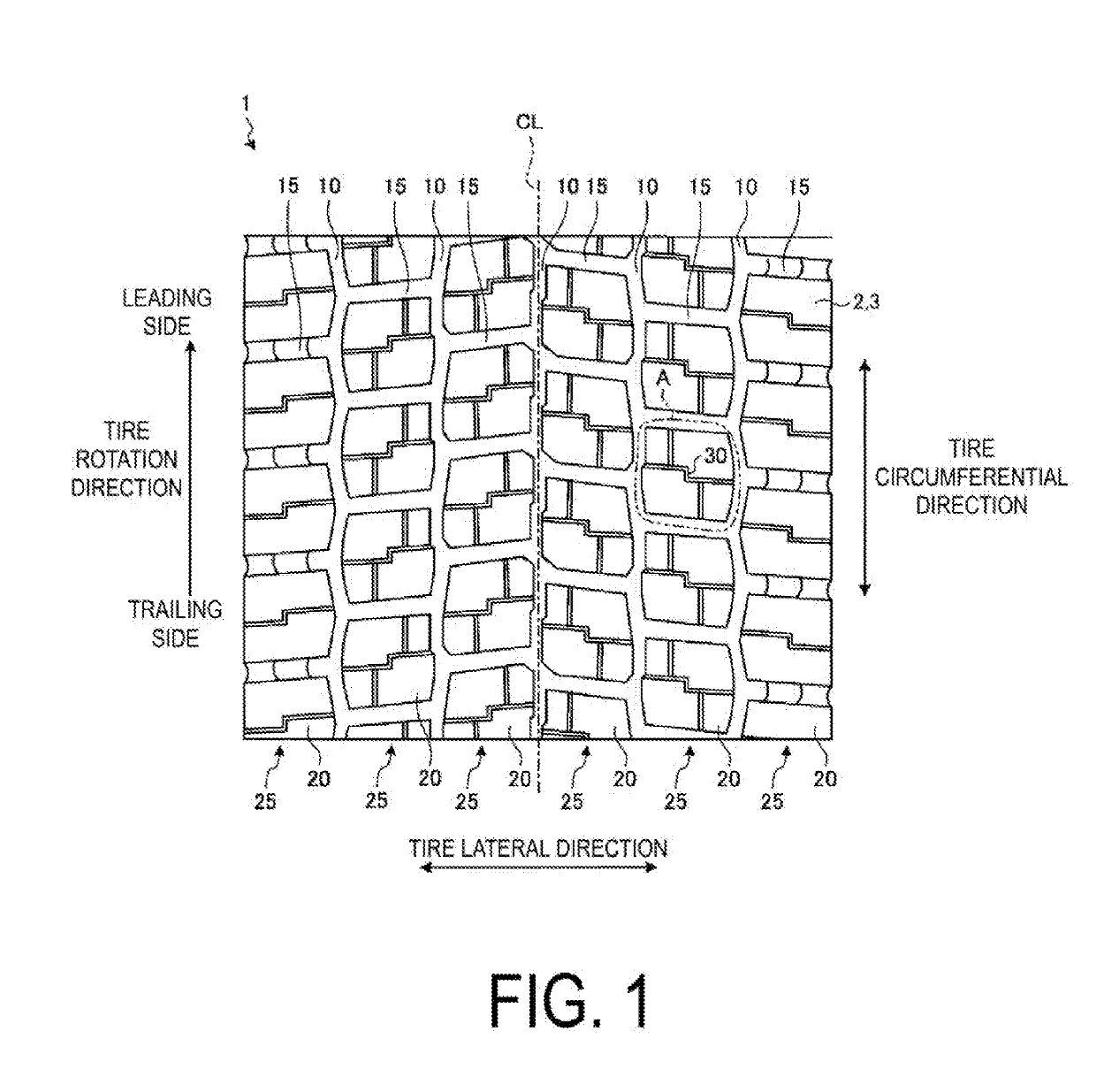

Tire

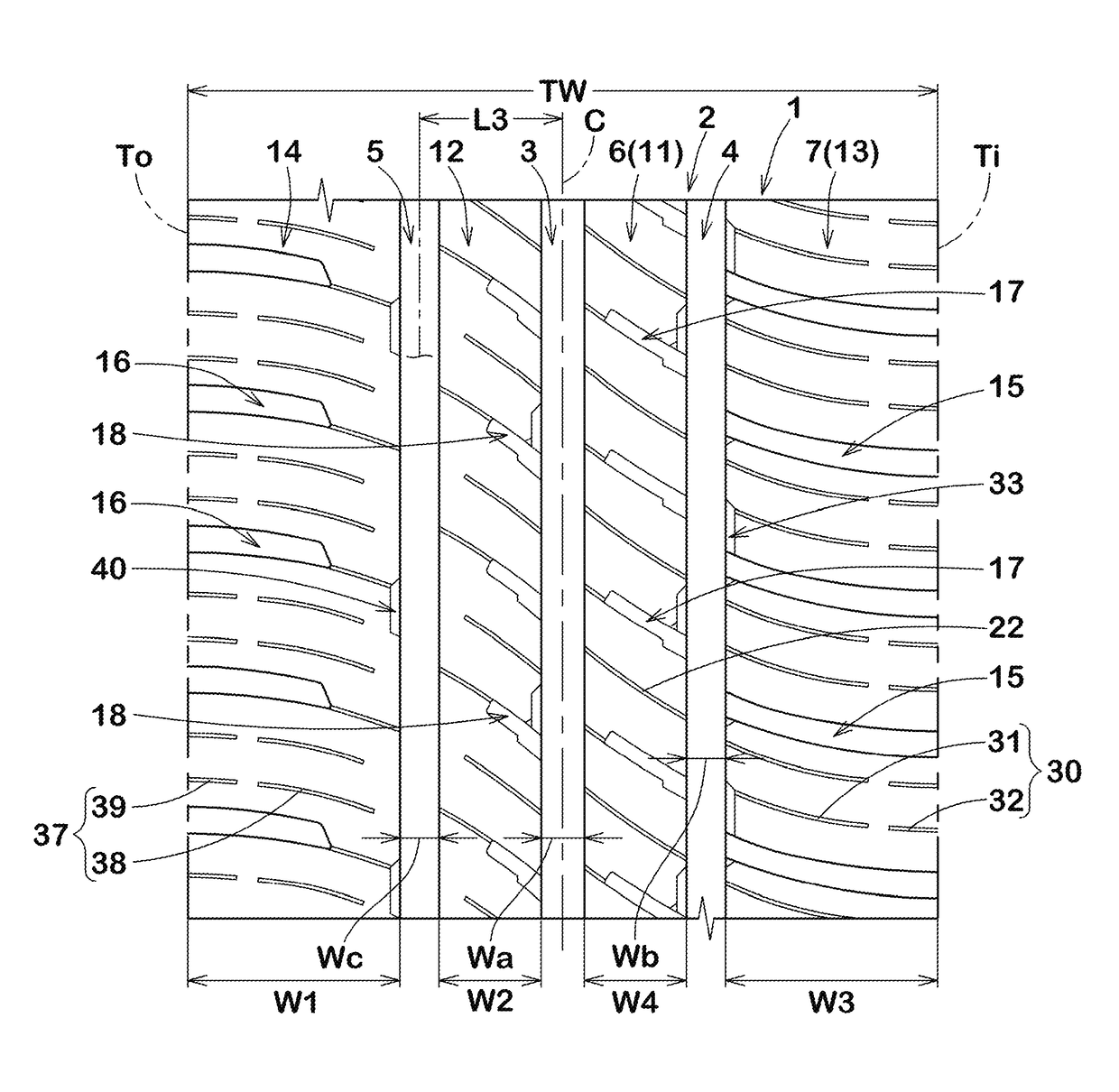

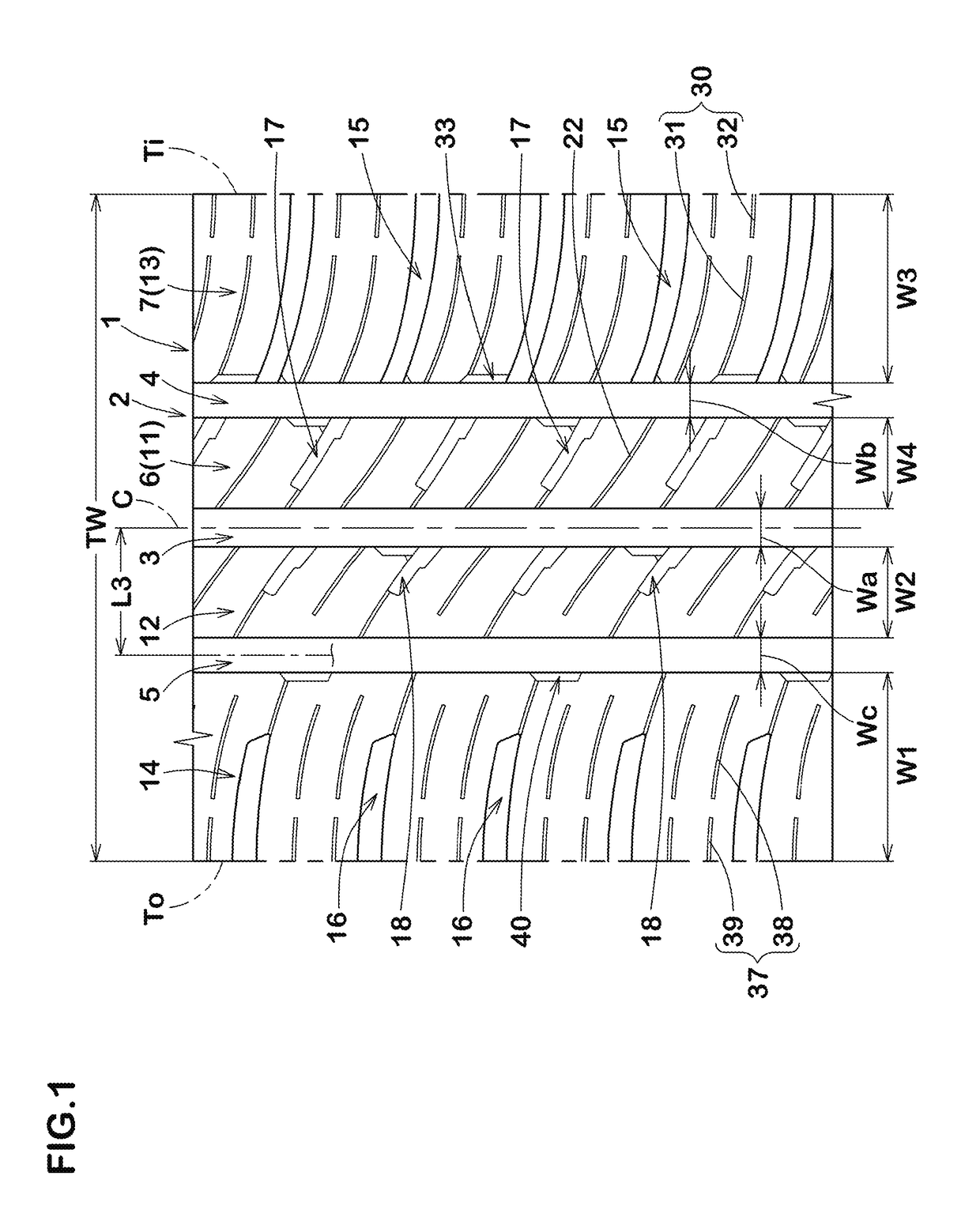

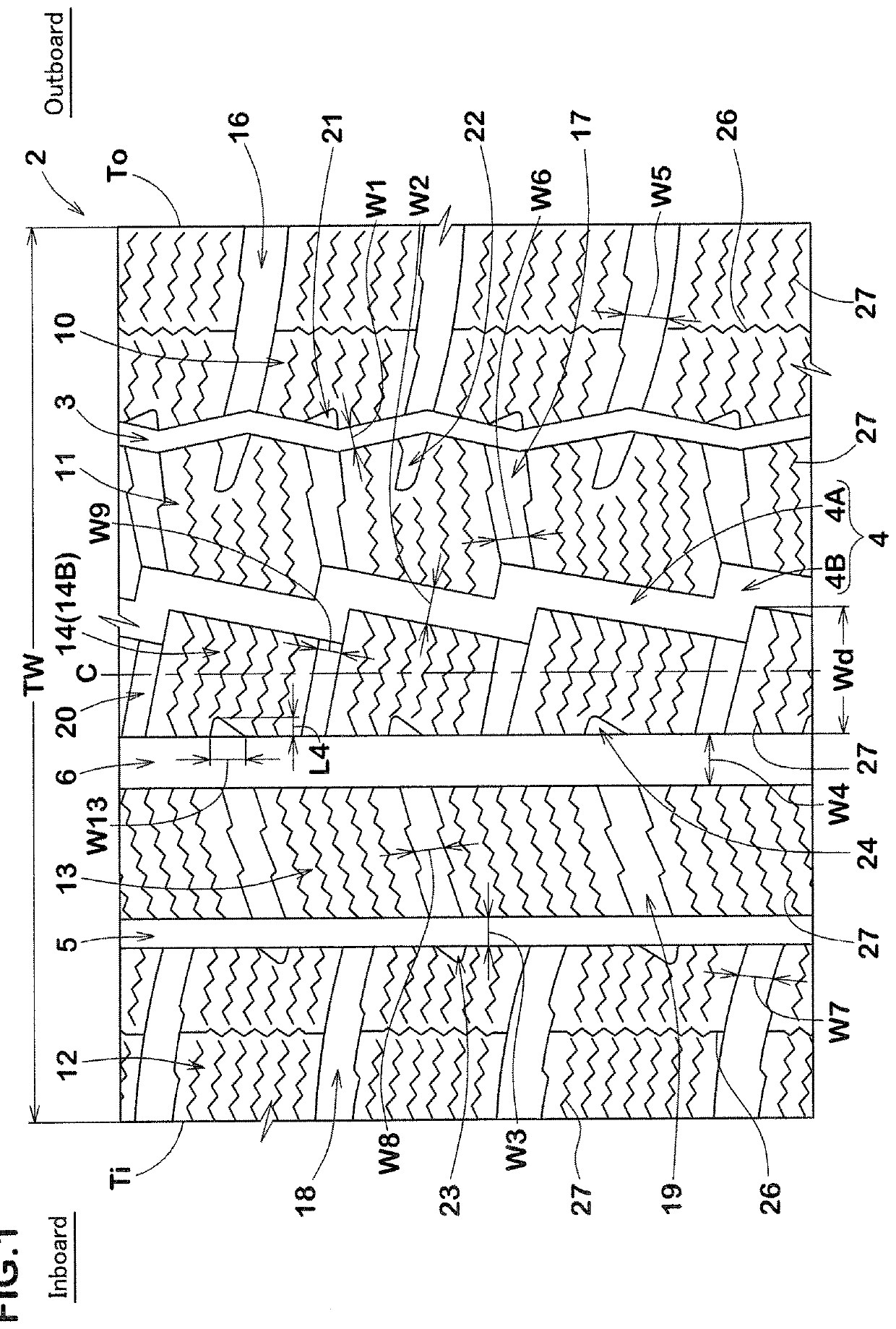

ActiveUS20180319219A1Improve snow performanceMaintaining steering stabilityInflatable tyresTyre tread bands/patternsTreadAerospace engineering

A tire tread is provided with a crown main groove, and outboard and inboard shoulder main grooves to divide the tread portion into an outboard crown land portion, an inboard crown land portion, an outboard shoulder land portion and an inboard shoulder land portion. The inboard shoulder land portion is provided with inboard shoulder lateral grooves connecting an inboard tread edge and the inboard shoulder main groove. The outboard shoulder land portion is provided with outboard shoulder lateral grooves extending axially inwardly from an outboard tread edge and terminating within the outboard shoulder land portion. The inboard crown land portion is provided with inboard crown lateral grooves extending from the inboard shoulder main groove and terminating within the inboard crown land portion. The outboard crown land portion is provided with outboard crown lateral grooves extending from the crown main groove and terminating within the outboard crown land portion.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20170096034A1High independenceReduce stiffnessTyre tread bands/patternsGroove widthEngineering

Owner:TOYO TIRE & RUBBER CO LTD

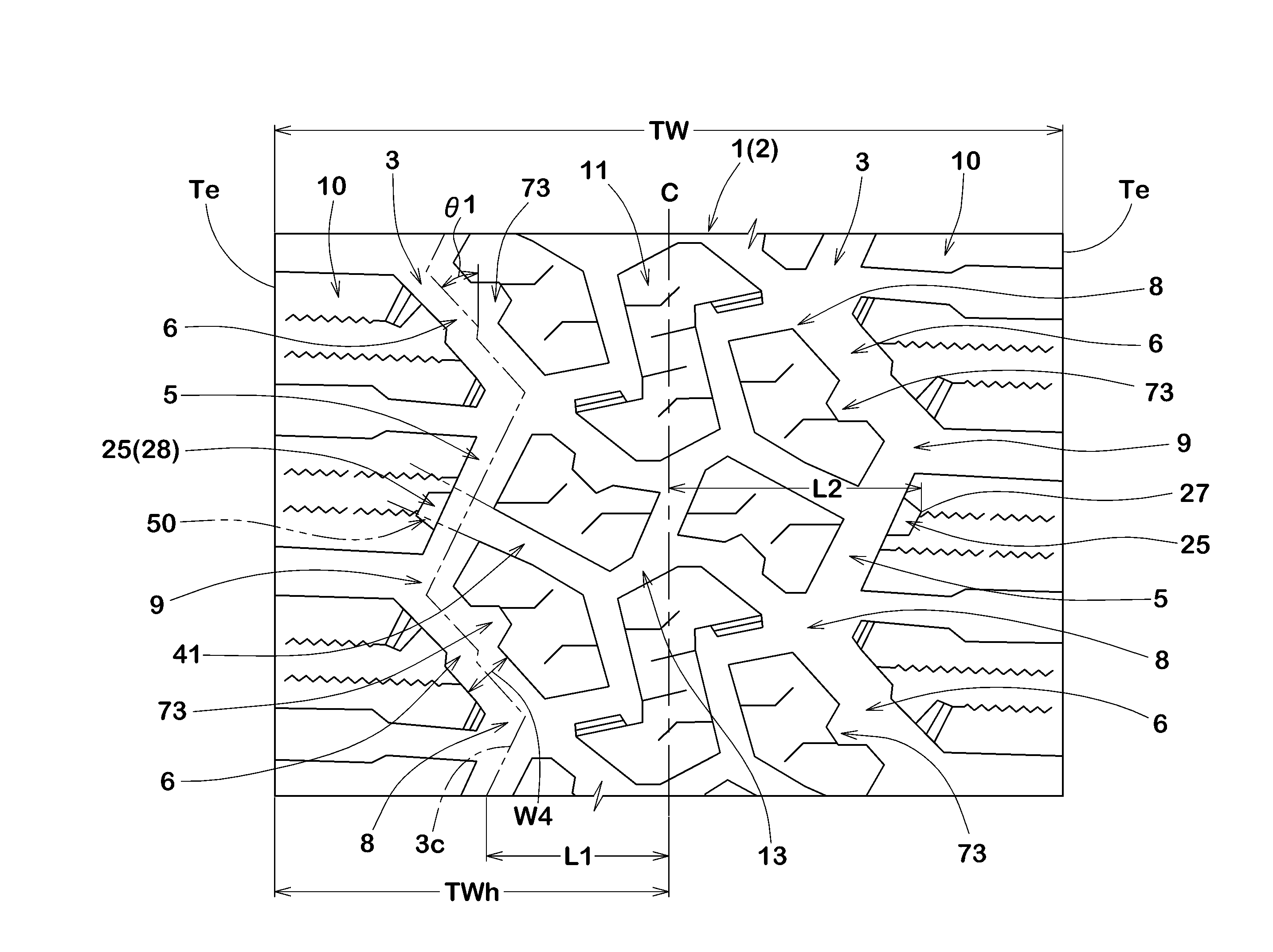

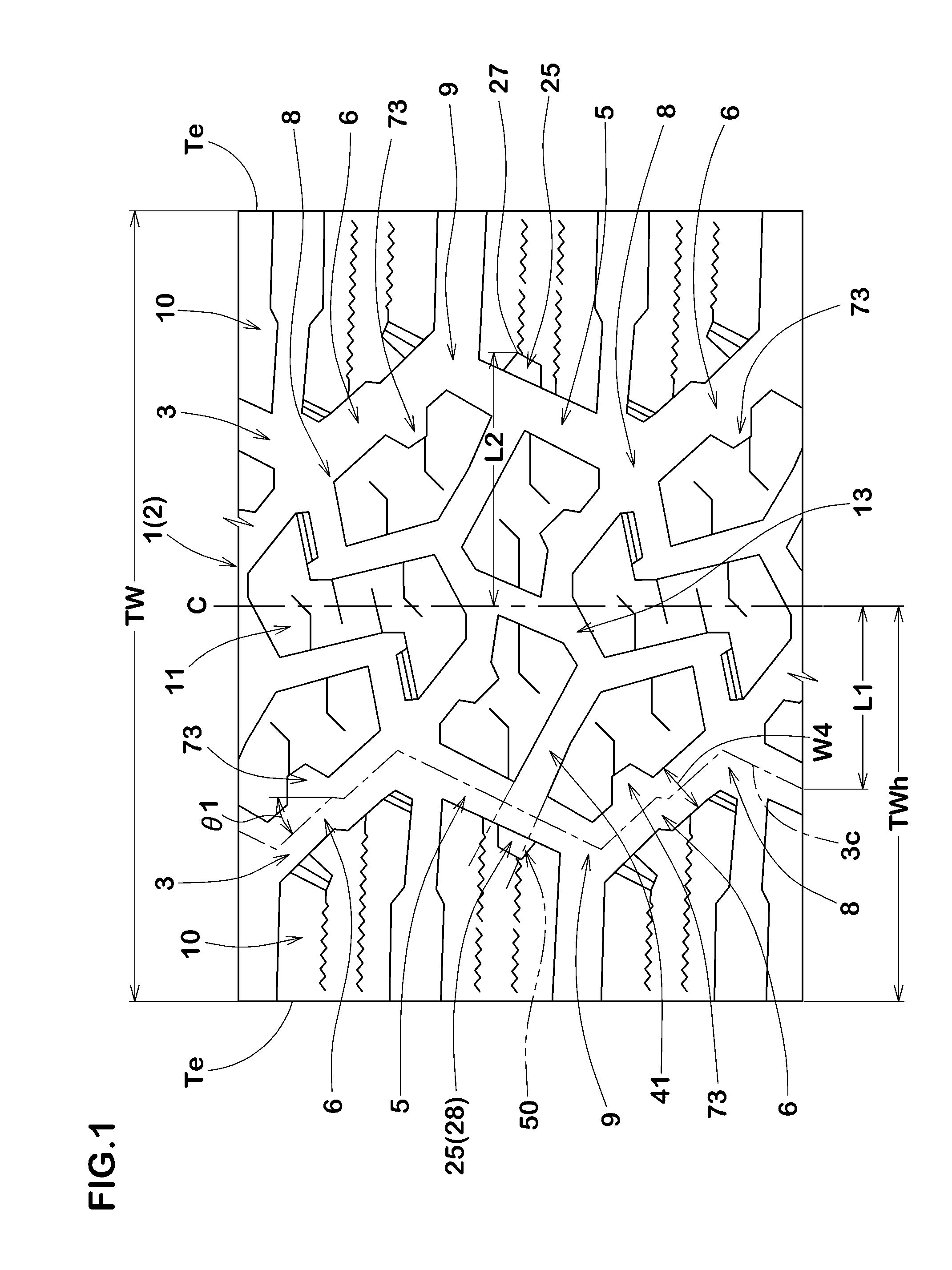

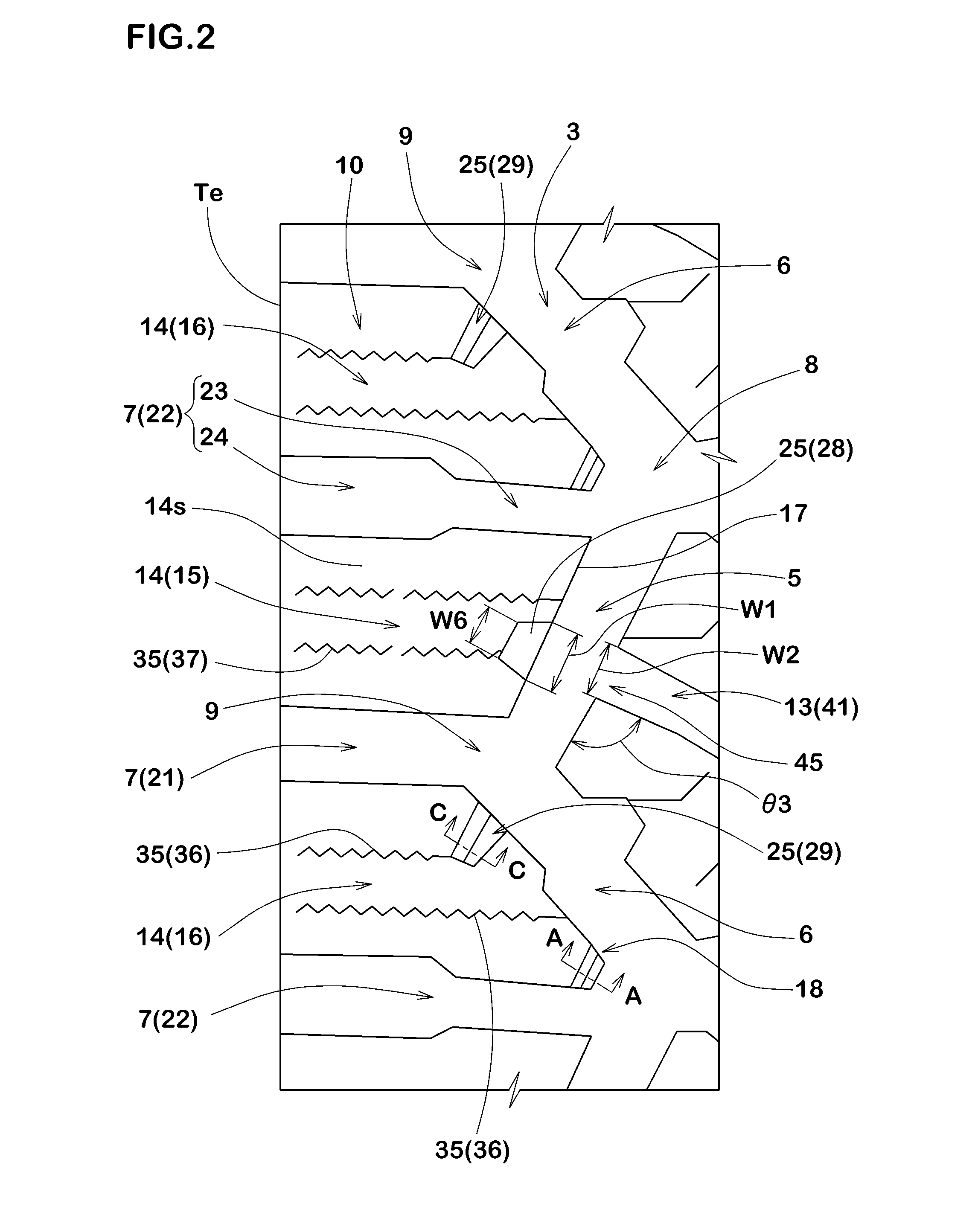

Pneumatic Tire

ActiveUS20170190222A1Improve snow performanceImprove wettabilityTyre tread bands/patternsEngineering

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveUS8522845B2Worsening its pattern noiseDrive stabilityTyre tread bands/patternsNon-skid devicesGround contactEngineering

Provided is a pneumatic tire which is capable of securing a driving stability on dry road surfaces and concurrently of improving snow performance without worsening its pattern noise. The pneumatic tire includes four main grooves each extending in its tread part in a tire circumferential direction, and the four main grooves partition the tread part into: a center land part; paired intermediate land parts located with the center land part being interposed in between; and paired shoulder land parts located with the center land part and the paired intermediate land parts being interposed in between. Each of the intermediate land parts and the shoulder land parts includes multiple V-shaped grooves each configured of: a thick groove part extending in a tire width direction; and a thin groove part extending in the tire circumferential direction. The V-shaped grooves are arranged in a way that each paired V-shaped grooves are opposed to each other in the tire circumferential direction with a connecting groove part being interposed between vertices of the respective paired V-shaped grooves. Each thick groove part communicates with the main grooves or the outside of a ground contacting area. Each thin groove part terminates within the land part.

Owner:THE YOKOHAMA RUBBER CO LTD

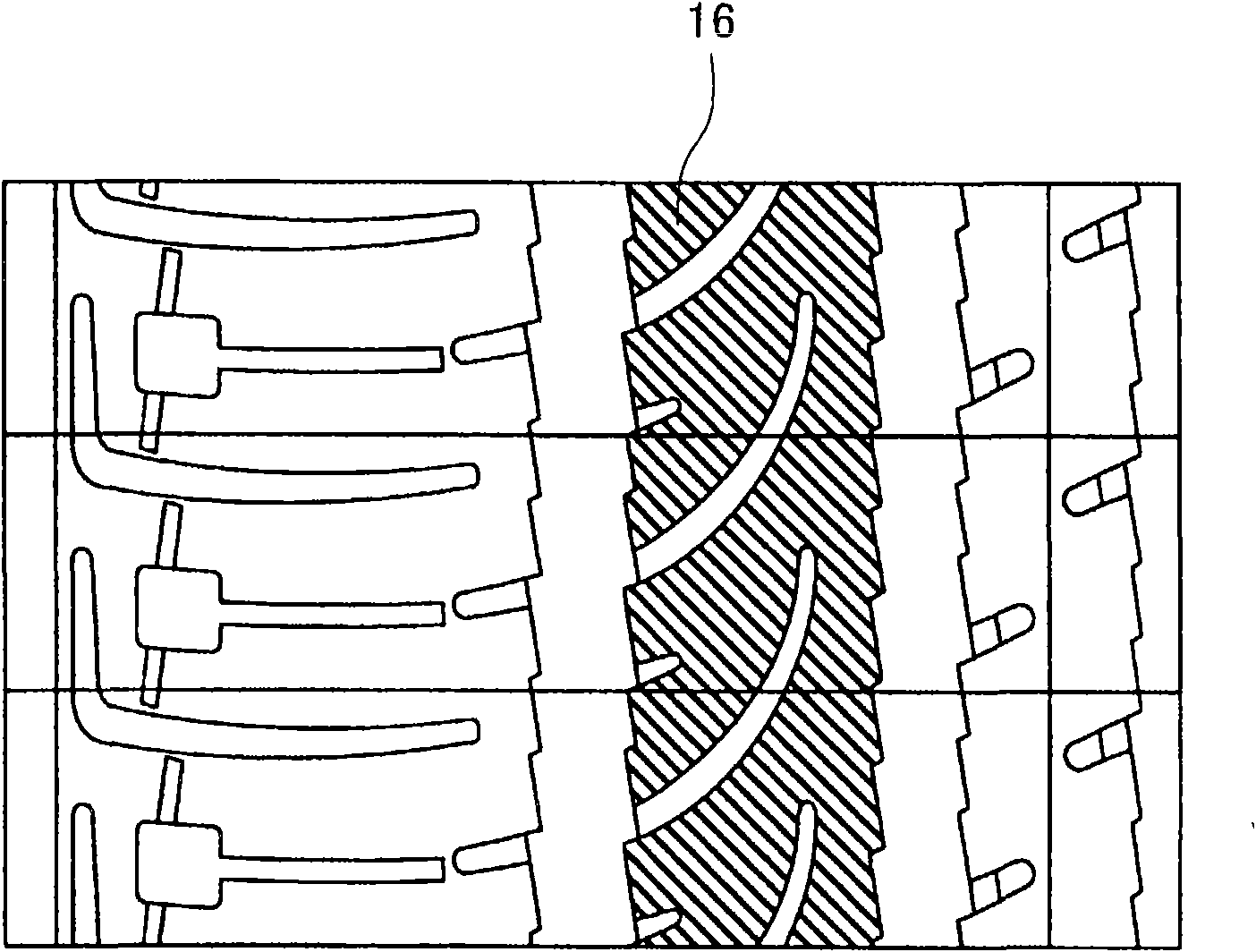

Pneumatic Tire

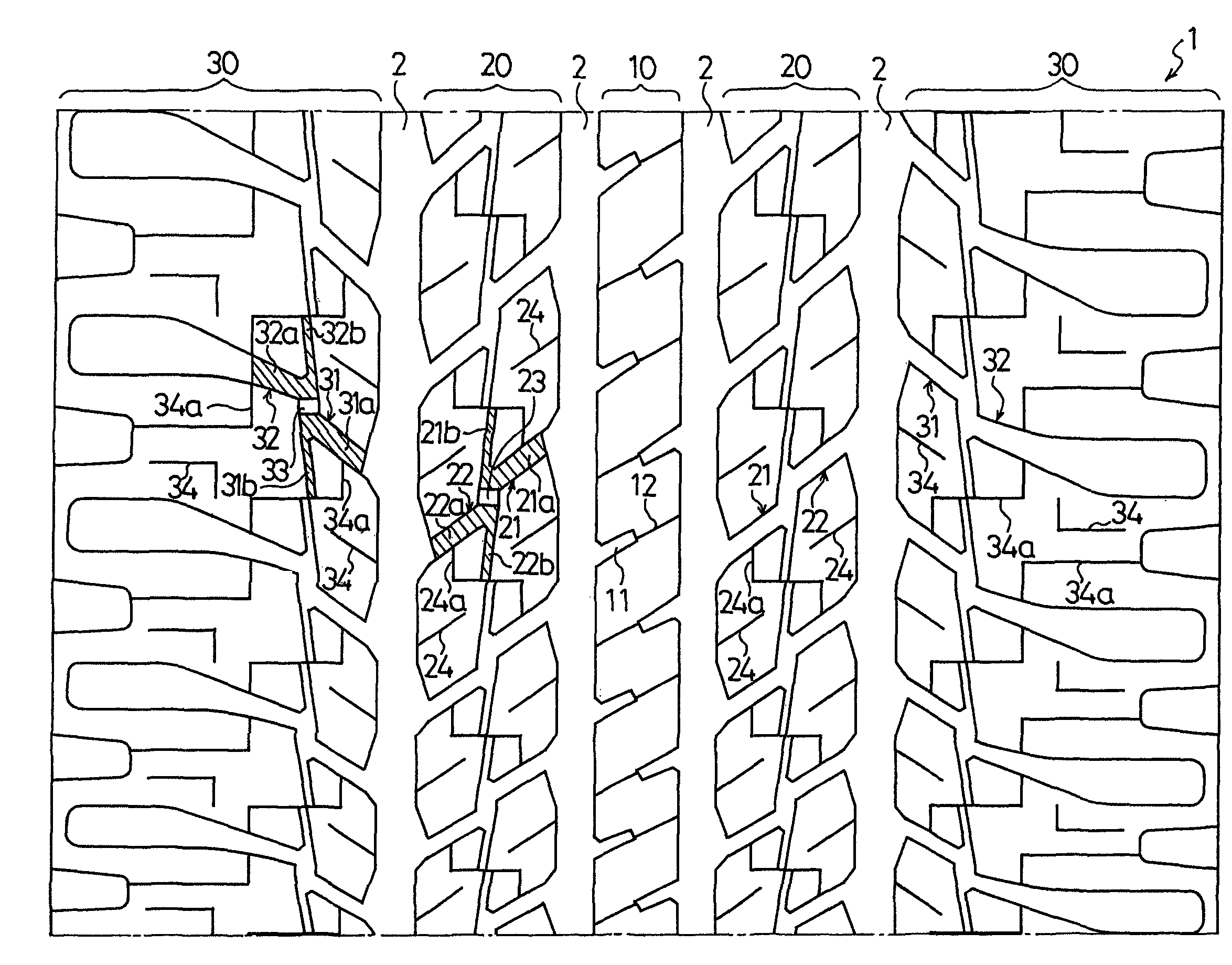

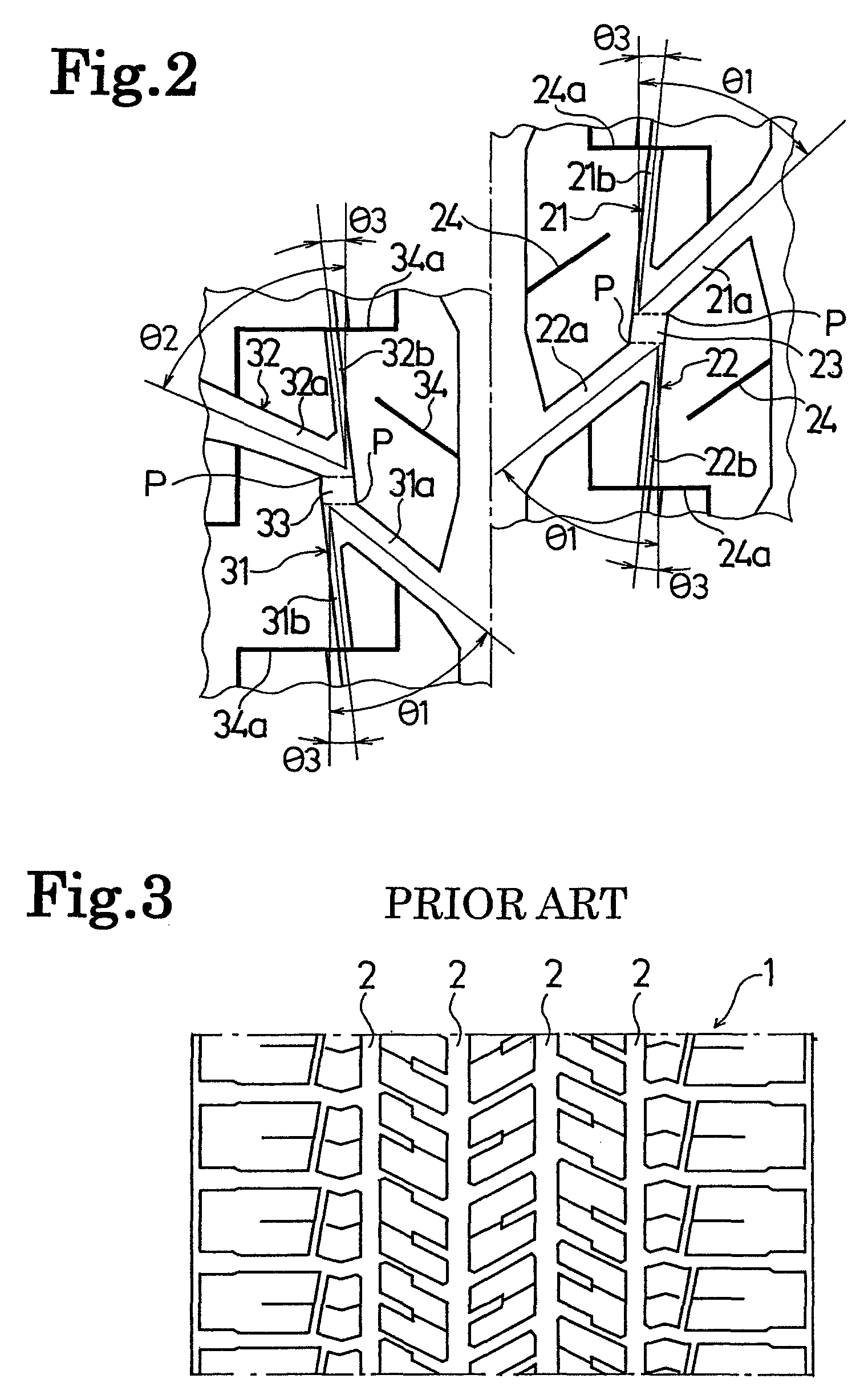

InactiveUS20080257467A1Improve snow performanceTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

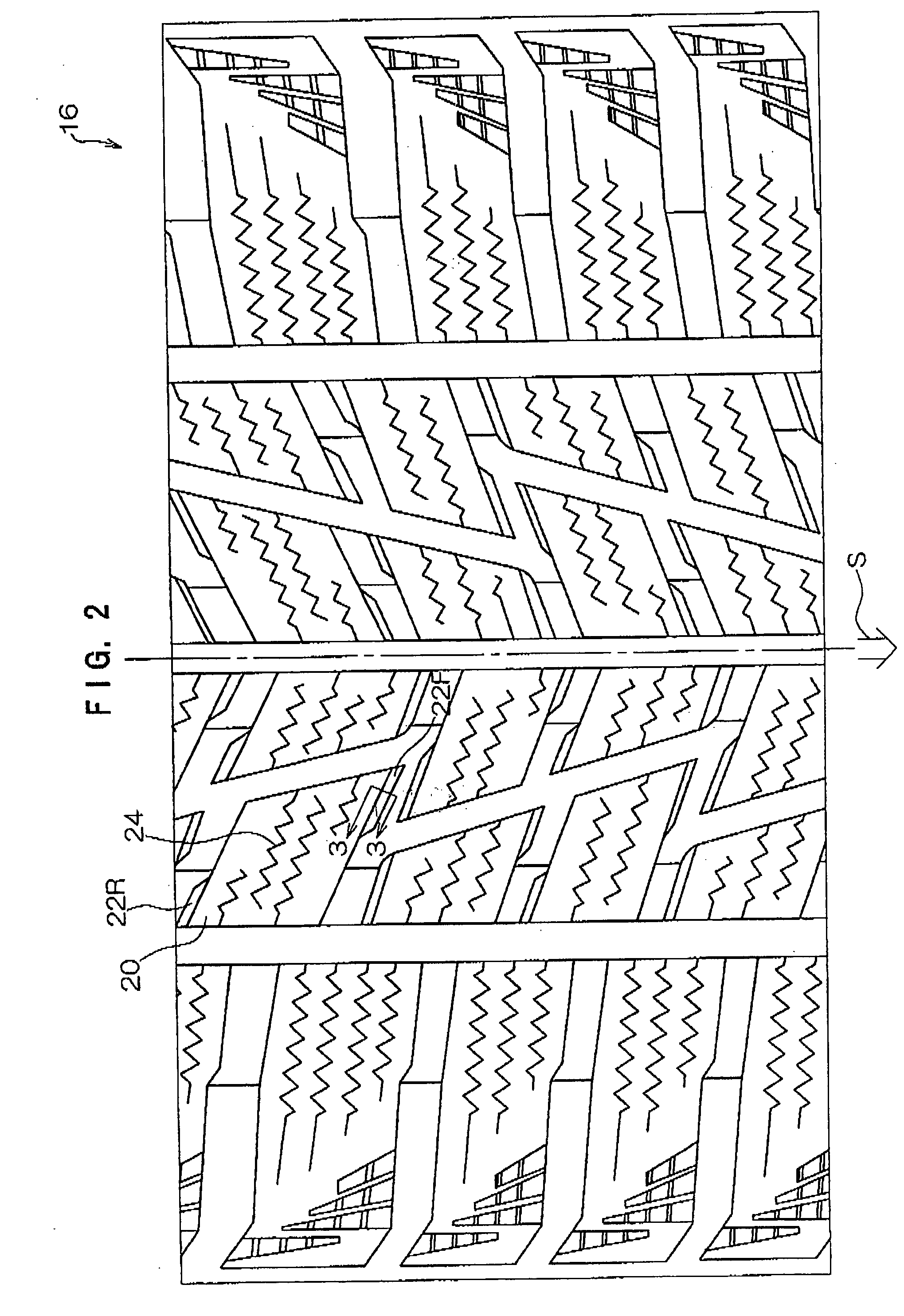

[Subject] To provide a pneumatic tire whose snow performance is improved without affecting its dry performance.[Measures for Addressing the Subject] Step portions 22F and 22R that are continuous so as to protrude respectively from step-in sides and kick-out sides of each of blocks 20 configuring a tread portion 16 are disposed in a pneumatic tire, and the step portions 22 are disposed in a staggered manner in the tread portion 16. Thus, even when the step portions 22 are disposed, the rigidity of the blocks 20 does not decline that much and dry performance is not affected that much. Further, snow performance can be improved by the edge pressure of the step portions 22.

Owner:BRIDGESTONE CORP

Pneumatic tire

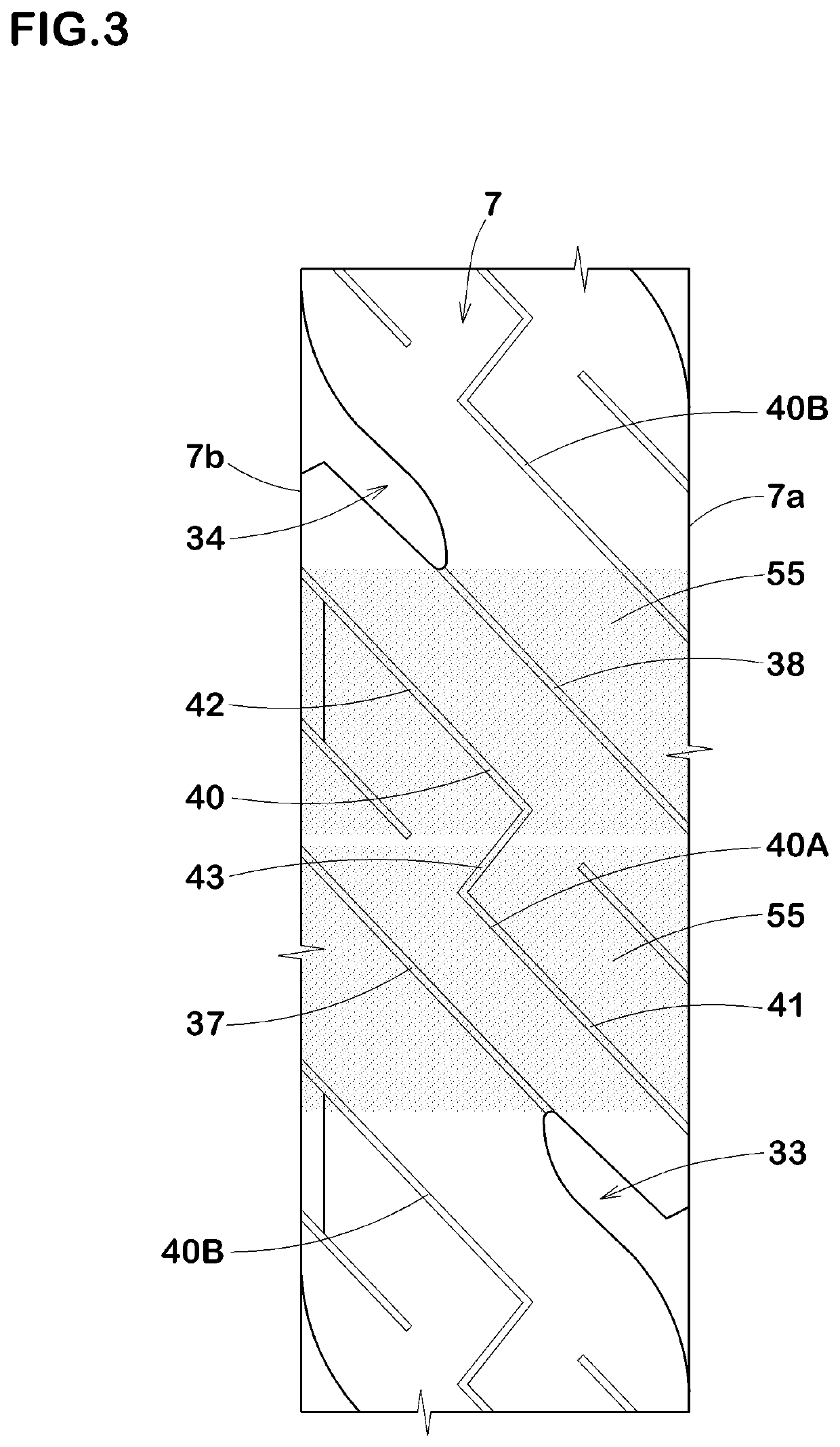

Provided is a pneumatic tire having high snow road performance. Provided is a pneumatic tire, the direction of mounting of which to a vehicle is specified. A tread section has formed therein an outer shoulder main groove which extends in a zigzag pattern, an outer middle main groove, outer shoulder lateral grooves, and outer middle lateral grooves. As a result, outer shoulder lands and outer middle lands are formed on the tread section. The outer shoulder lands are provided with outer shoulder lug grooves, and the outer middle lands are provided with outer middle lug grooves. The outer shoulder lateral grooves and the outer middle lug grooves are smoothly connected through the outer shoulder main groove. The outer middle lateral grooves and the outer shoulder lug grooves are smoothly connected through the outer shoulder main groove.

Owner:SUMITOMO RUBBER IND LTD

Tire

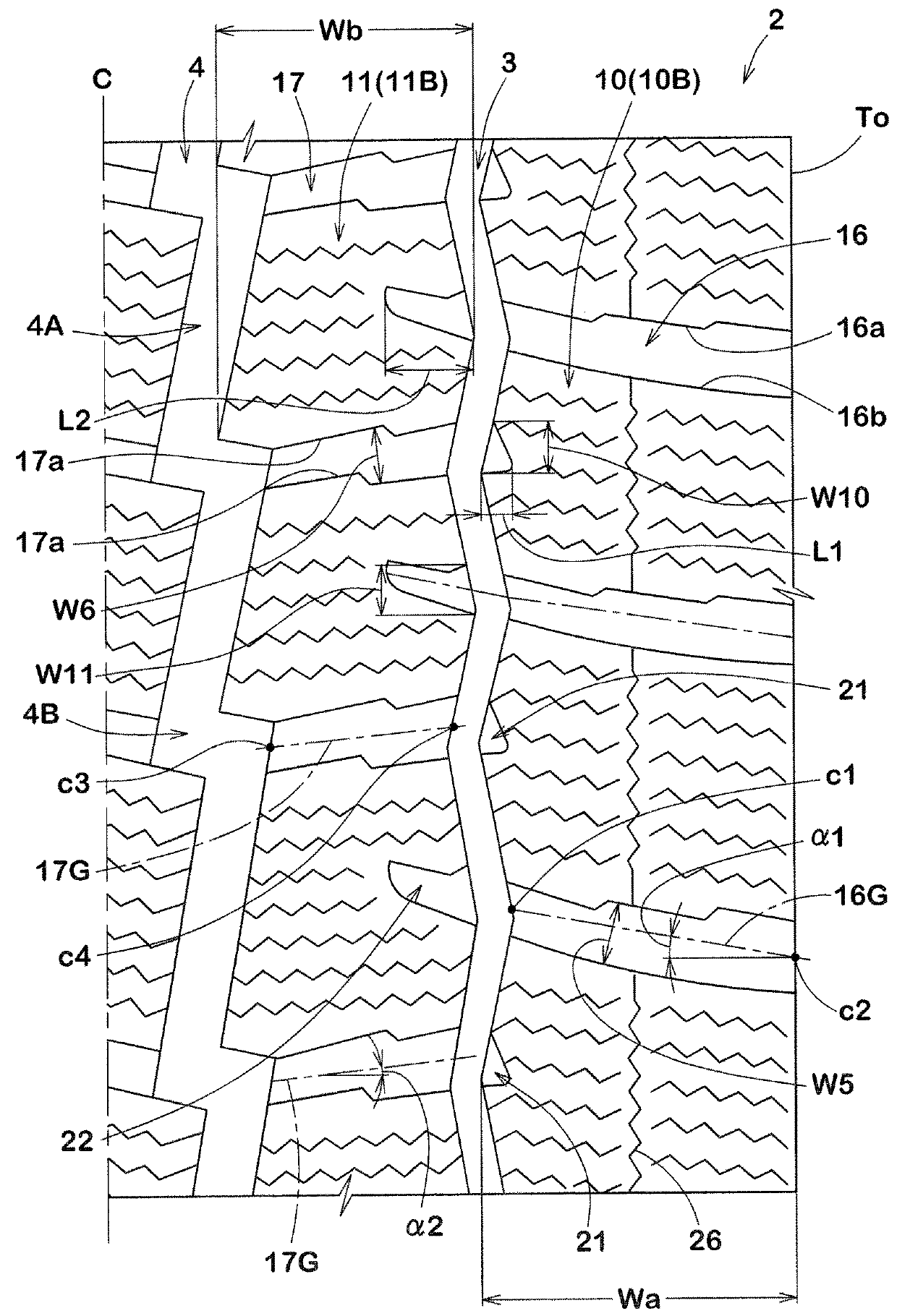

ActiveUS20170144488A1Improve snow performanceImprove wetting performanceTyre tread bands/patternsRolling resistance optimizationEngineeringTread

A tire includes a tread portion provided with at least one circumferentially and continuously extending shoulder main groove and at least one circumferentially and continuously extending crown main groove. The at least one crown main groove extends in a straight manner in a tire circumferential direction. The at least one shoulder main groove includes narrow segments inclined at angles with respect to the tire circumferential direction and wide segments each having widths greater than widths of the narrow segments. The narrow segments and the wide segments are arranged alternately in the tire circumferential direction so as to form a zigzag groove shape, wherein the widths of the narrow segments are in a range of from 5% to 7% of a tread width.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic Tire

PendingUS20190118581A1Improve performance on iceImprove snow performanceHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

A pneumatic tire includes a tread surface, a plurality of circumferential main grooves formed on the tread surface and extending in a tire circumference direction, a plurality of lug grooves formed on the tread surface and extending in a tire lateral direction, a plurality of blocks defined by the lug grooves on both sides in the tire circumferential direction and by the circumferential main grooves on at least one end in the tire lateral direction, and narrow grooves formed in the blocks. The narrow grooves include a plurality of bent portions as well as a circumferential narrow groove extending in the tire circumference direction and a lateral narrow groove extending in the tire lateral direction. The lateral narrow groove and the circumferential narrow groove are configured so that at least one thereof is provided in a plurality and includes a plurality of intersection points where the one intersects the other.

Owner:YOKOHAMA RUBBER CO LTD

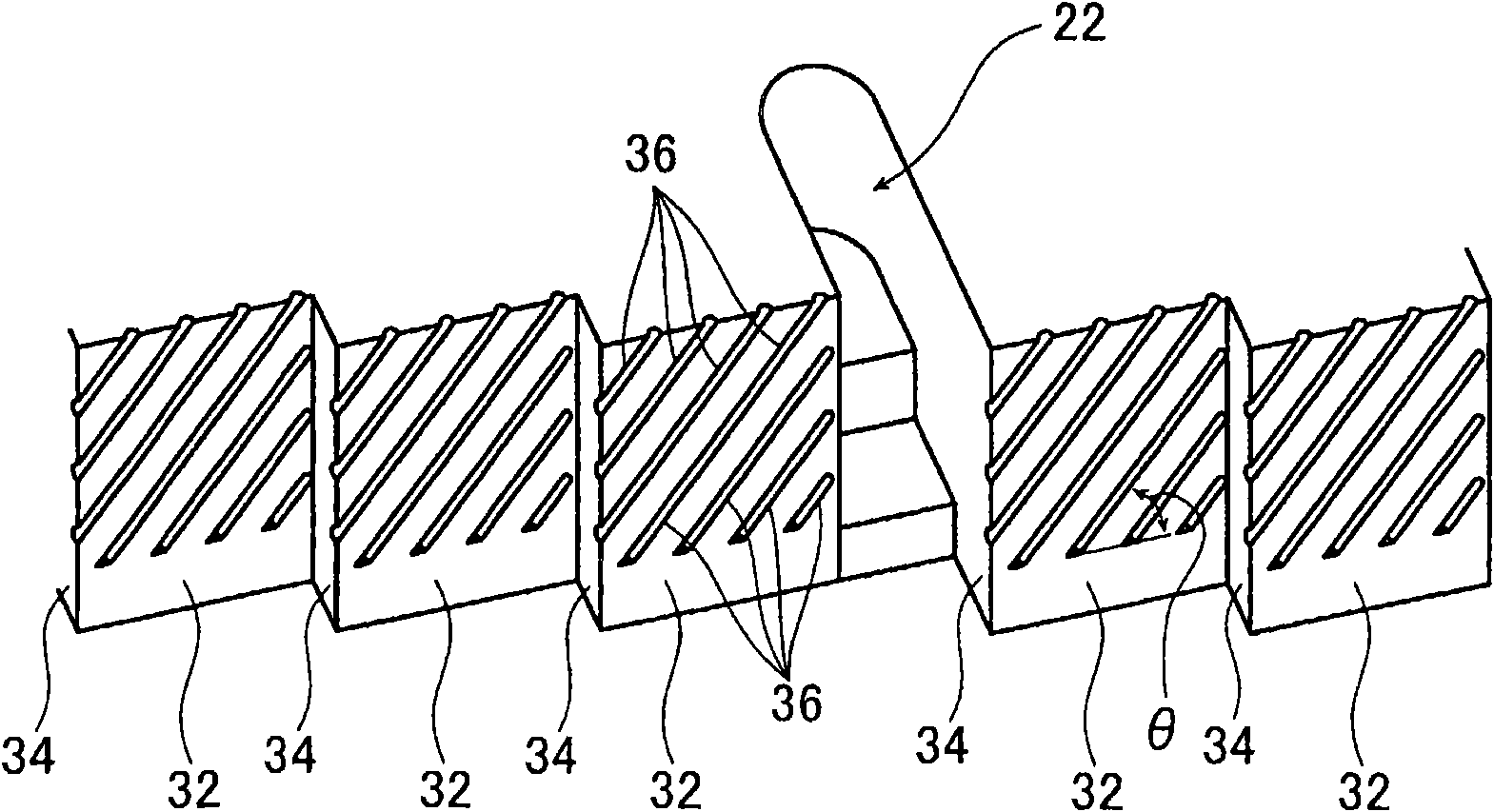

Vehicle tires

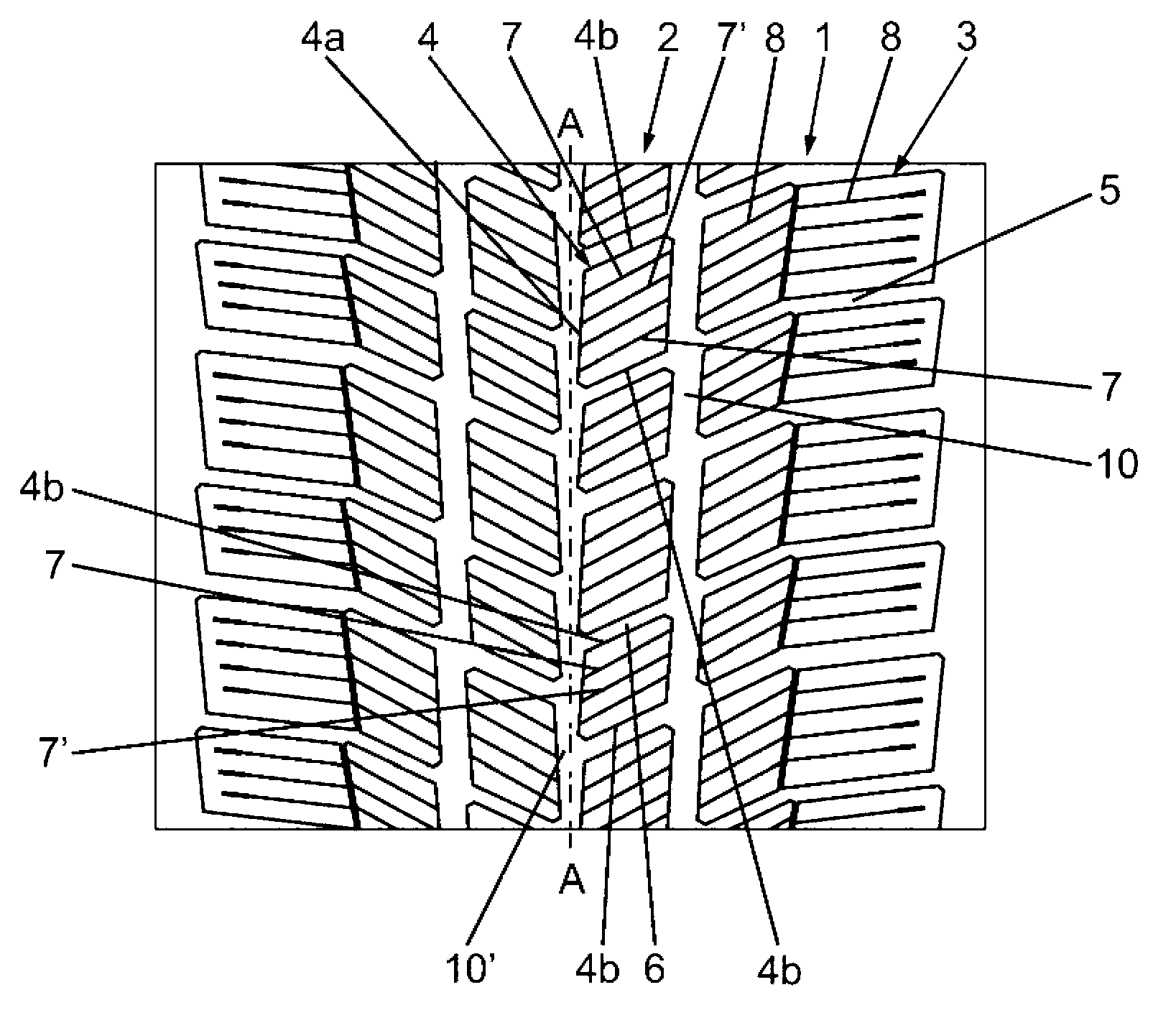

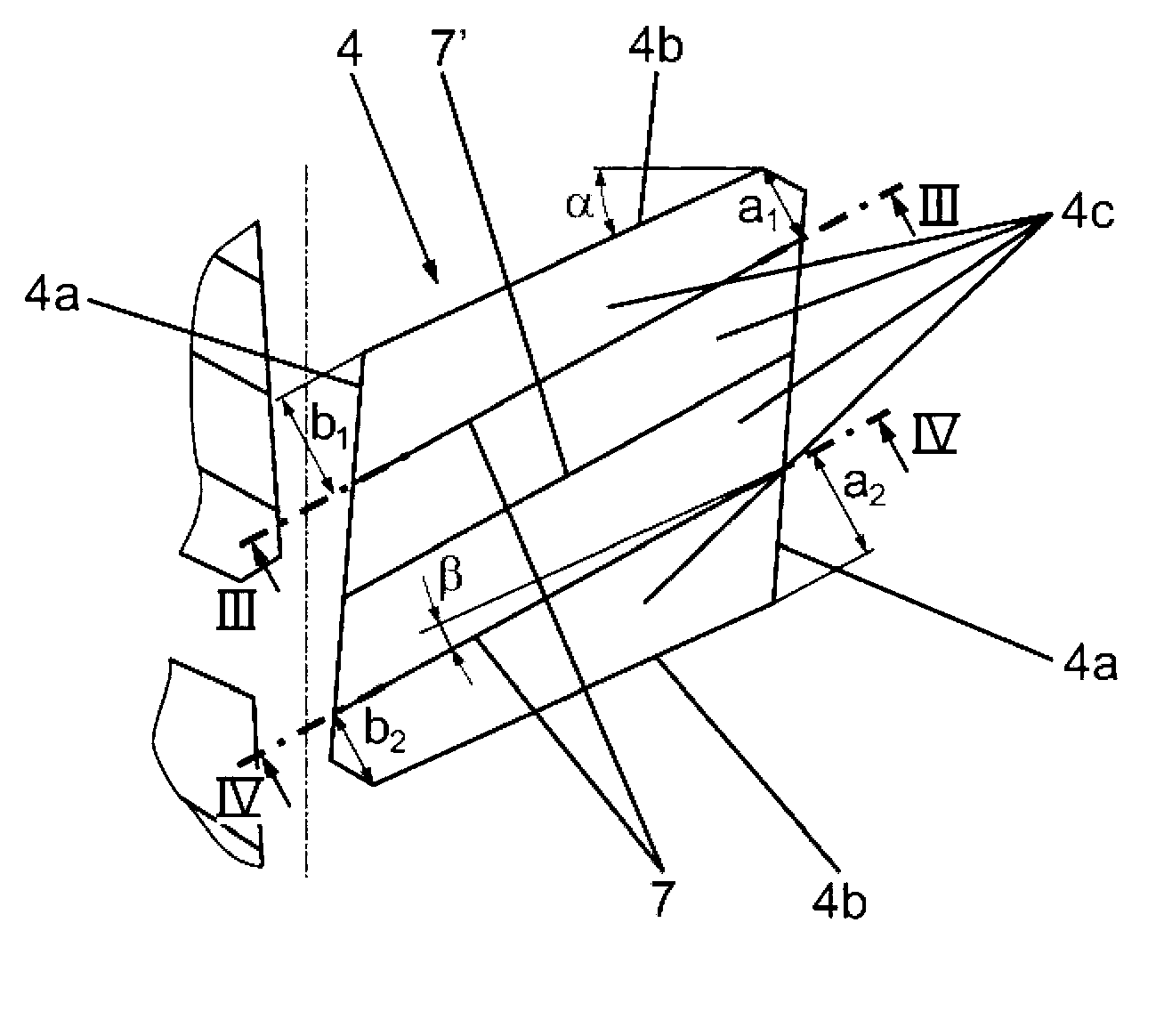

ActiveCN103221236AImprove winter performanceImprove snow performanceTyre tread bands/patternsTransverse grooveAcute angle

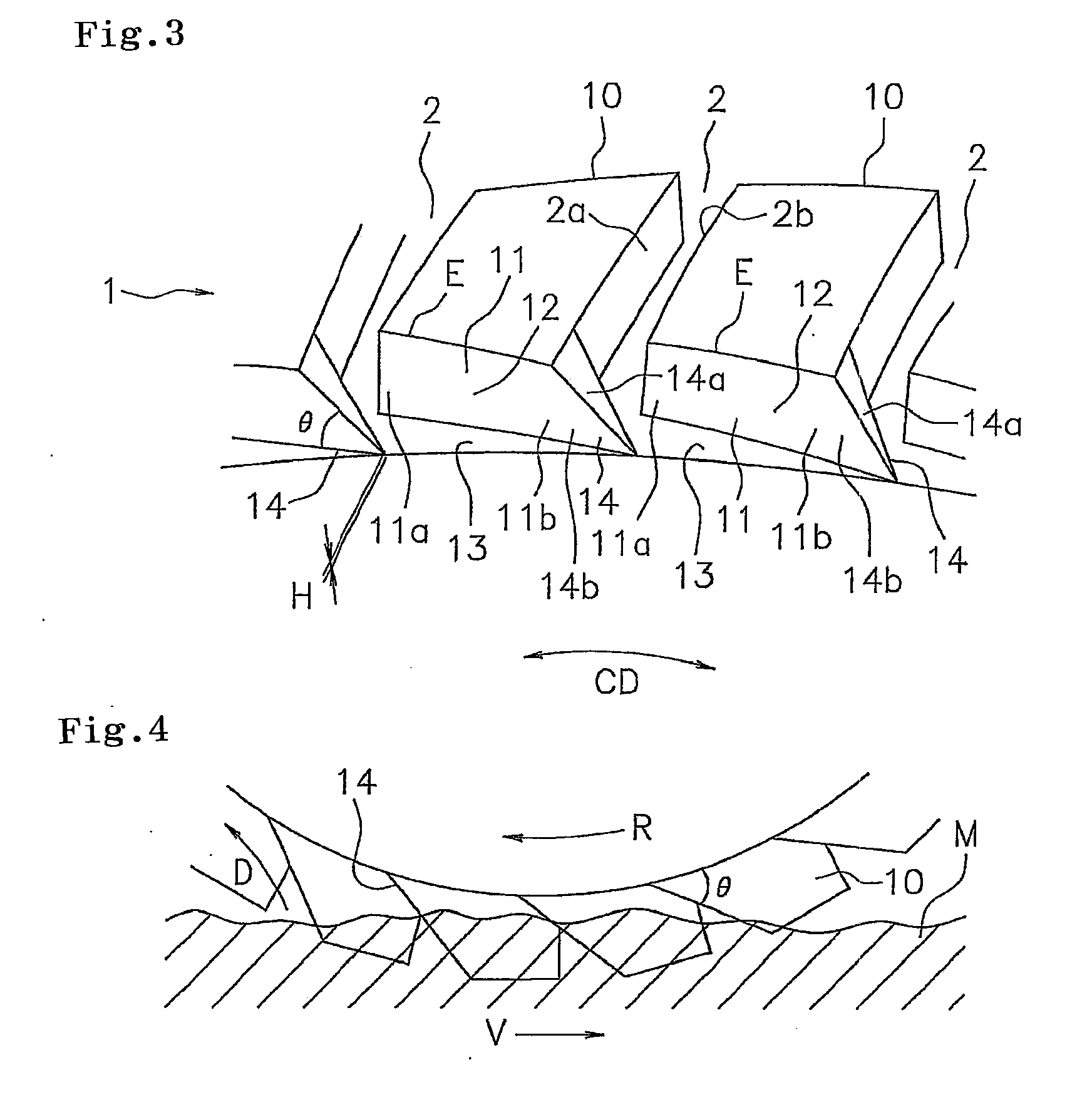

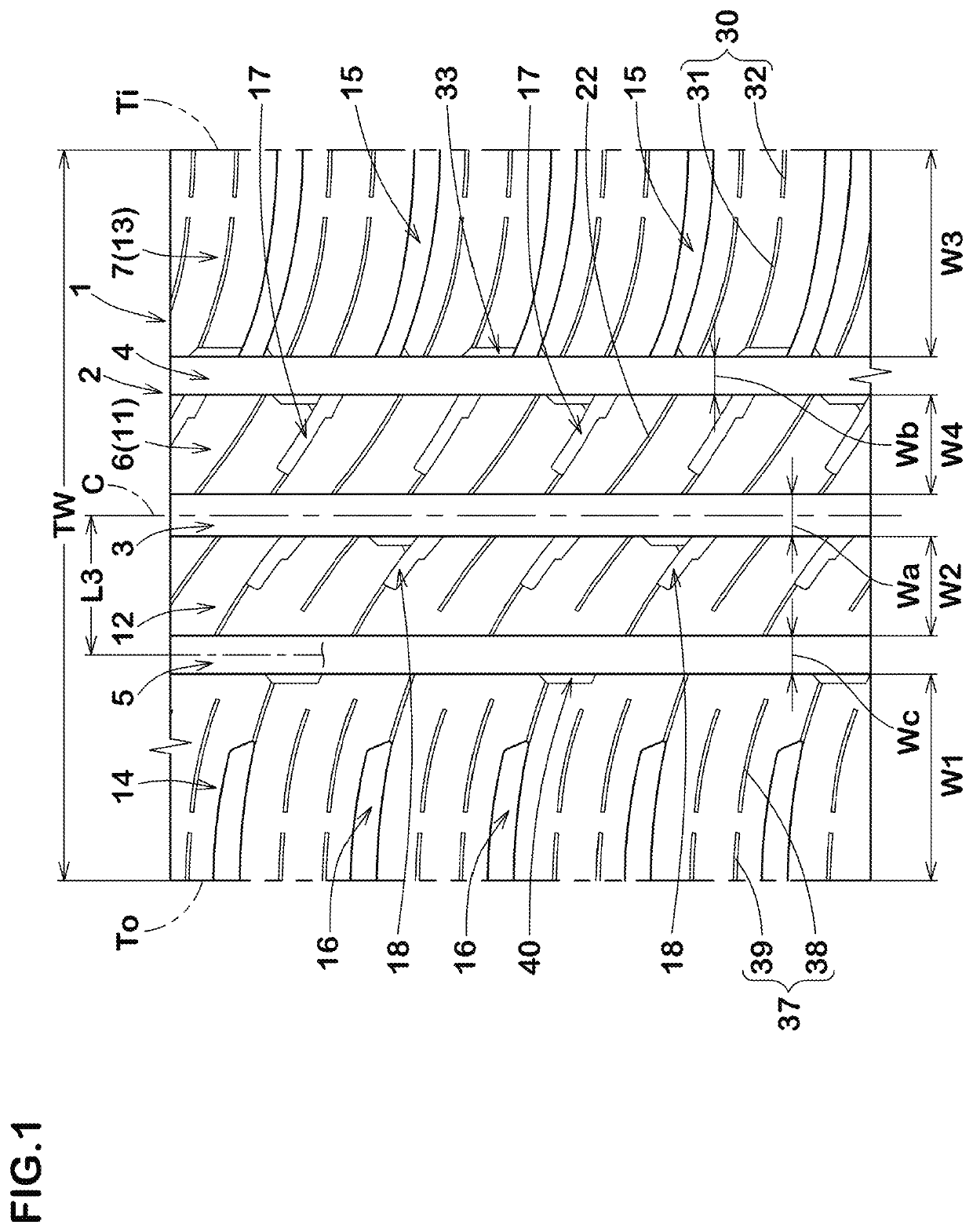

The invention relates to a vehicle tire, in particular for use in winter driving conditions, comprising a tire tread having at least one tread bar row (2) extending all-round in a circumferential direction, the tread bars (4) thereof having tread bar edges (4b) which delimit transverse grooves (6) which separate the individual tread bars (4) from each other within the tread bar row (2), wherein the tread bars (4) each have at least two at least substantially parallel notches (7), the extensions of which in the respective tread bar (4) are oriented on the basis of the progression of the tread bar edges (4b) delimiting the transverse grooves (6) and which notches (7) have a center section and two edge sections, wherein the center section is the deepest and longest section and the two edge sections have differing depths. At least the center section (7b) of those notches (7) which run adjacent to the tread bar edges (4b) that delimit the transverse grooves (6) include an acute angle with said tread bar edge (4b), wherein the edge section having a lower depth connects to the end of the center section which has the smaller distance to the adjacent tread bar edge (4b, 4'b).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

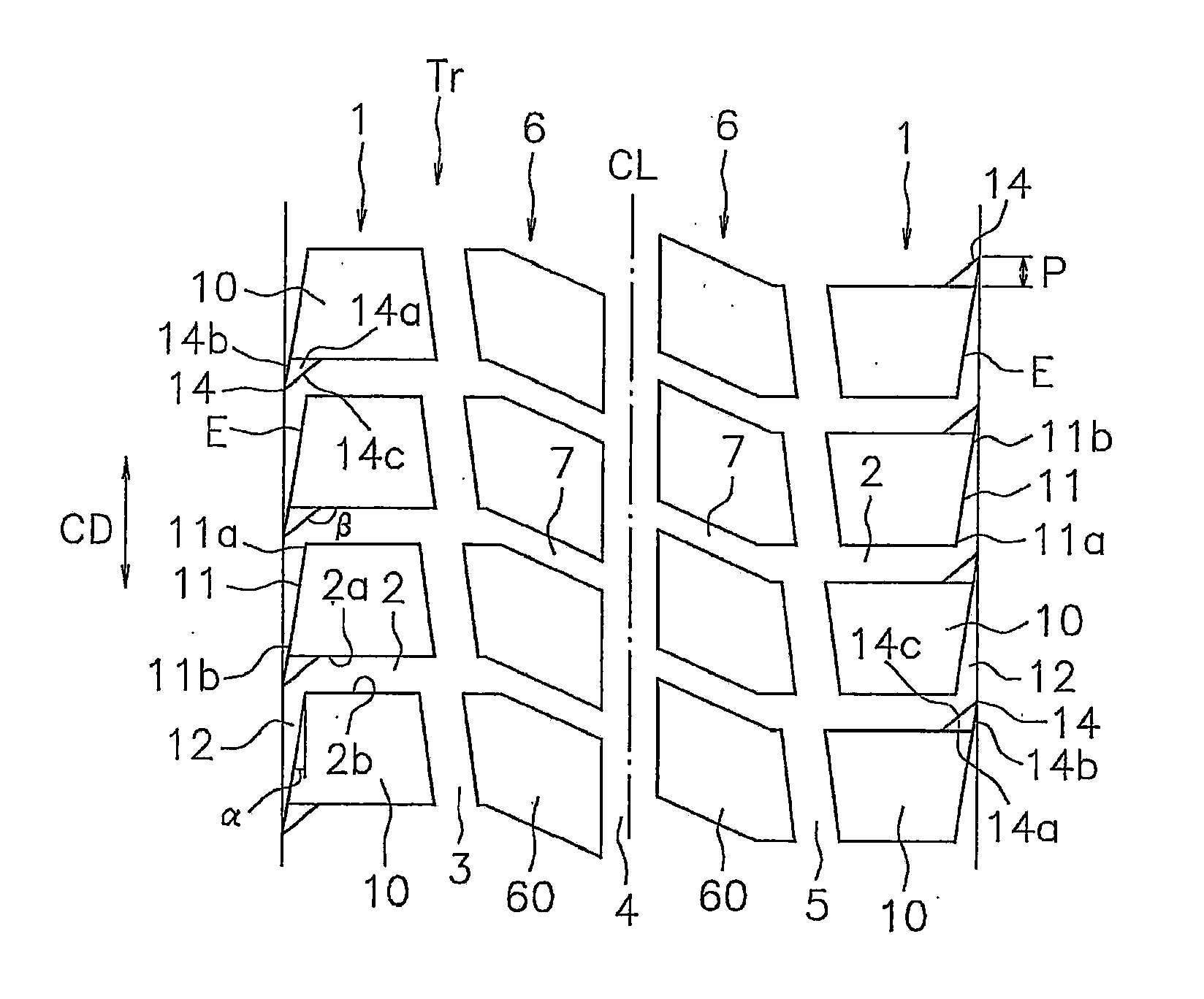

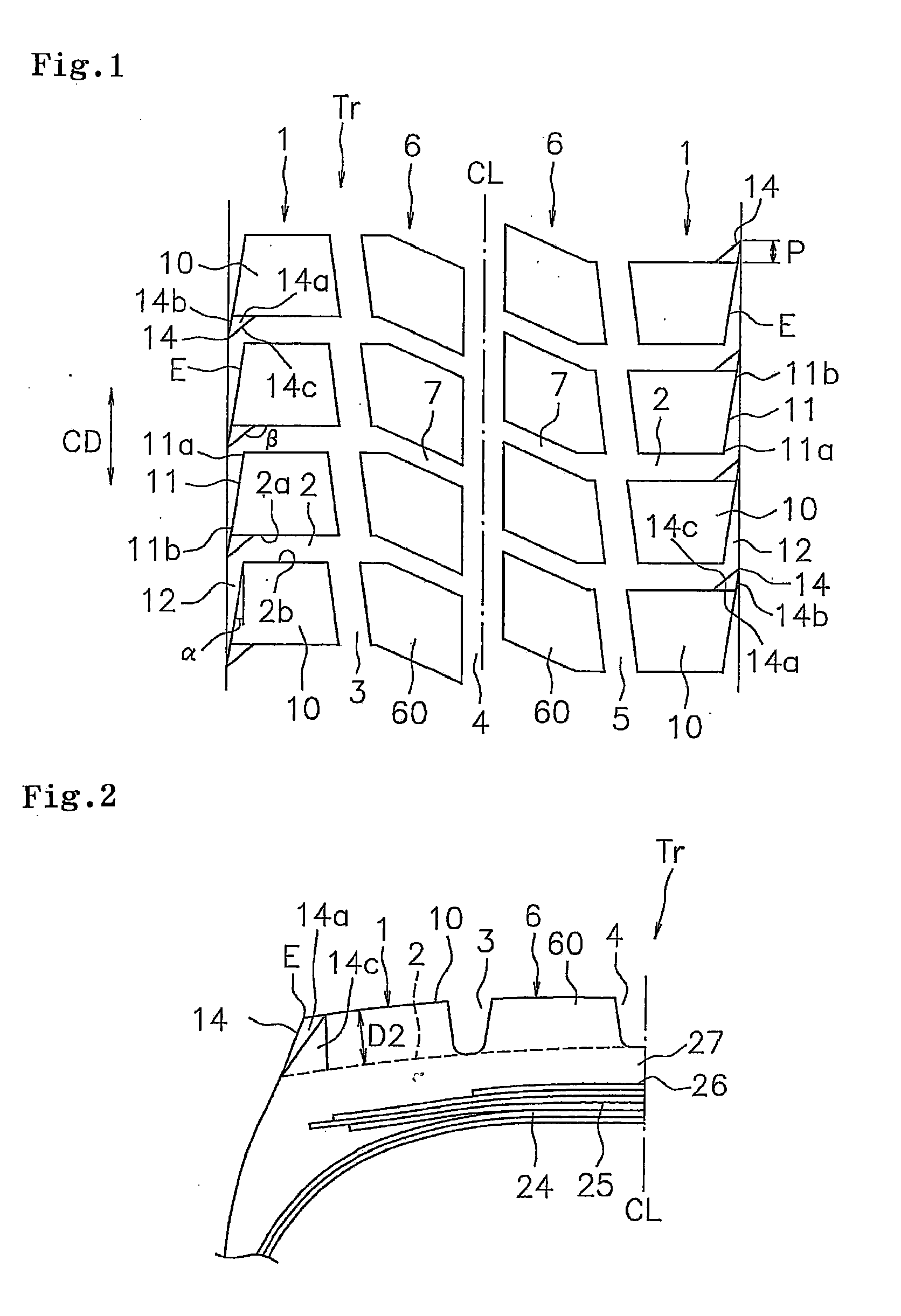

Pneumatic tire with tread having rib portion, sub-grooves and sipes

InactiveUS8714218B2Improve rigidityImprove driving stabilityTyre tread bands/patternsNon-skid devicesGround contactCurve shape

A pneumatic tire is configured such that: paired first main grooves extending in a tire circumferential direction are provided on the two sides of a tire equator line in a tread portion, respectively; a distance between a center position of each first main groove and the tire equator line is set at 8% to 20% of a ground contact width W; a first land portion is defined between these first main grooves; multiple sub-grooves each having a curved shape are formed in each of both edge portions of the first land portion at intervals in the tire circumferential direction; one end of each sub-groove is opened to the corresponding first main groove, and the other end of the sub-groove is terminated inside the first land portion; a rib portion continuously extending in the tire circumferential direction is formed in an area of the first land portion on the tire equator line; and a relation between a length (L) of a center line of each sub-groove and a pitch length (P) of the sub-grooves in the tire circumferential direction satisfies 1.1×P≦L≦2.0×P.

Owner:THE YOKOHAMA RUBBER CO LTD

Tire

ActiveUS10864775B2Improve snow performanceMaintain relatively stableInflatable tyresTyre tread bands/patternsMining engineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

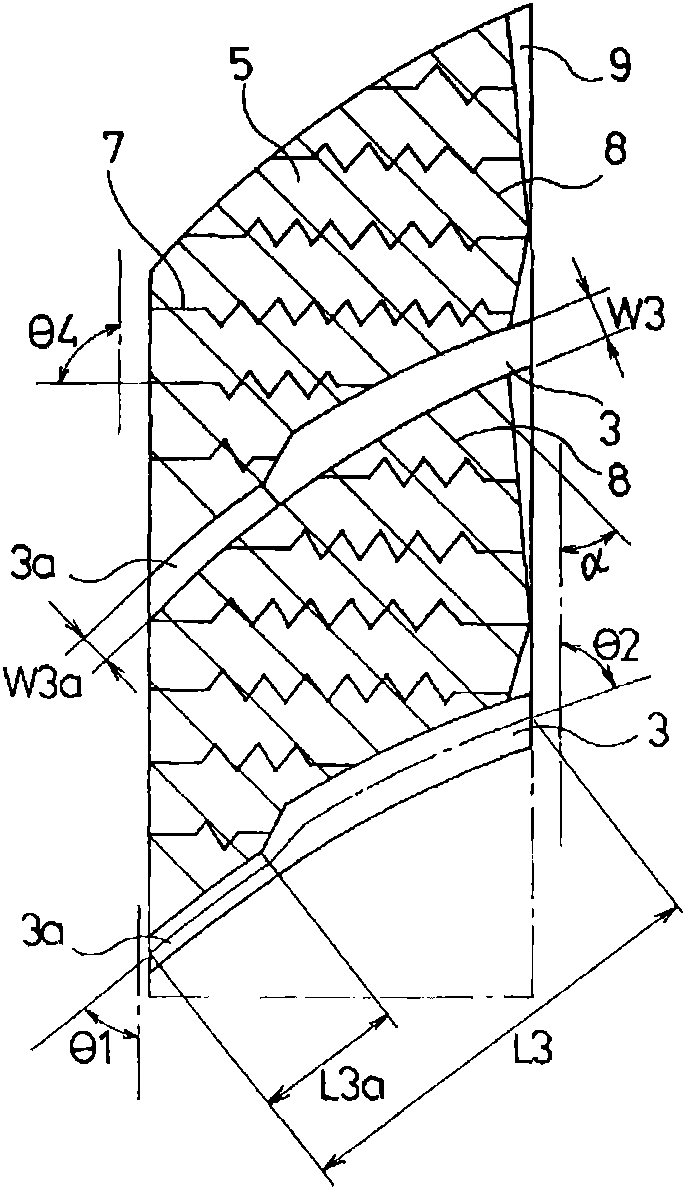

InactiveUS9186937B2Improve snow performanceImprove steering stabilityTyre tread bands/patternsNon-skid devicesStructural engineeringEngineering

On the surface of a tread portion (1), one central main groove (2) extends in a tire circumferential direction (C) at a pattern center, and a pair of outer main grooves (4a, 4b) extend in the tire circumferential direction (C) each at a position between the central main groove (2) and a respective one of two tread ends (3a, 3b). The central main groove (2) and the outer main grooves (4a, 4b) define central land portions (5a, 5b), and the outer main grooves (4a, 4b) and the tread ends (3a, 3b) define outer land portions (6a, 6b). Among the central land portions (5a, 5b) and the outer land portions (6a, 6b), first circumferential narrow grooves (7a, 7b) are provided only in the central land portions (5a, 5b), extend in the tire circumferential direction (C), have a narrower opening width and a shallower depth than those of the central main groove (2), and have a first groove wall (8) on the side of the outer main groove (4a, 4b) and a second groove wall (9) on the side of the central main groove (2) such that an intersection angle (θ1) between a tread surface (10) and the first groove wall (8) is larger than an intersection angle (θ2) between the tread surface (10) and the second groove wall (9).

Owner:BRIDGESTONE CORP

Pneumatic Tire

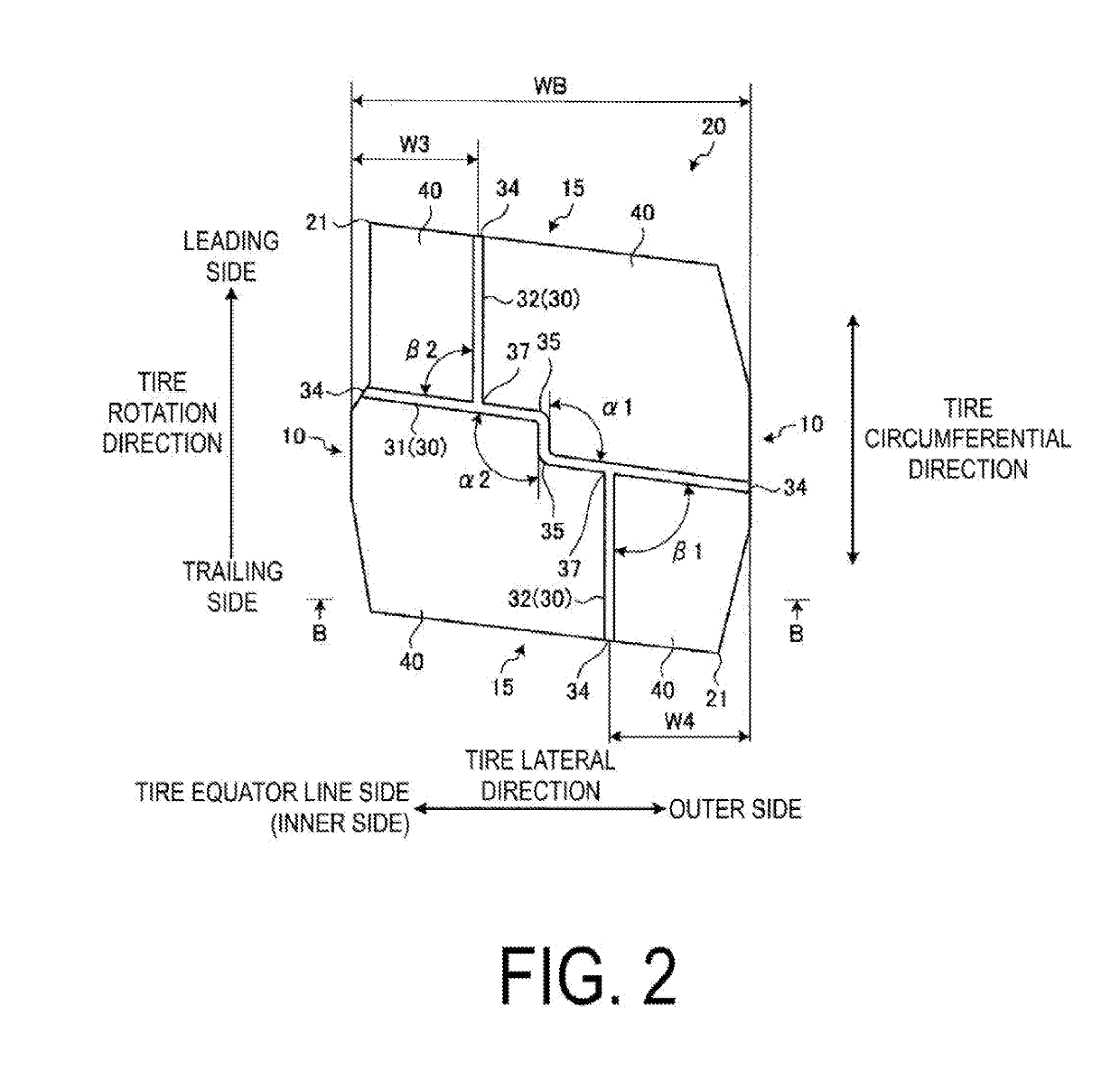

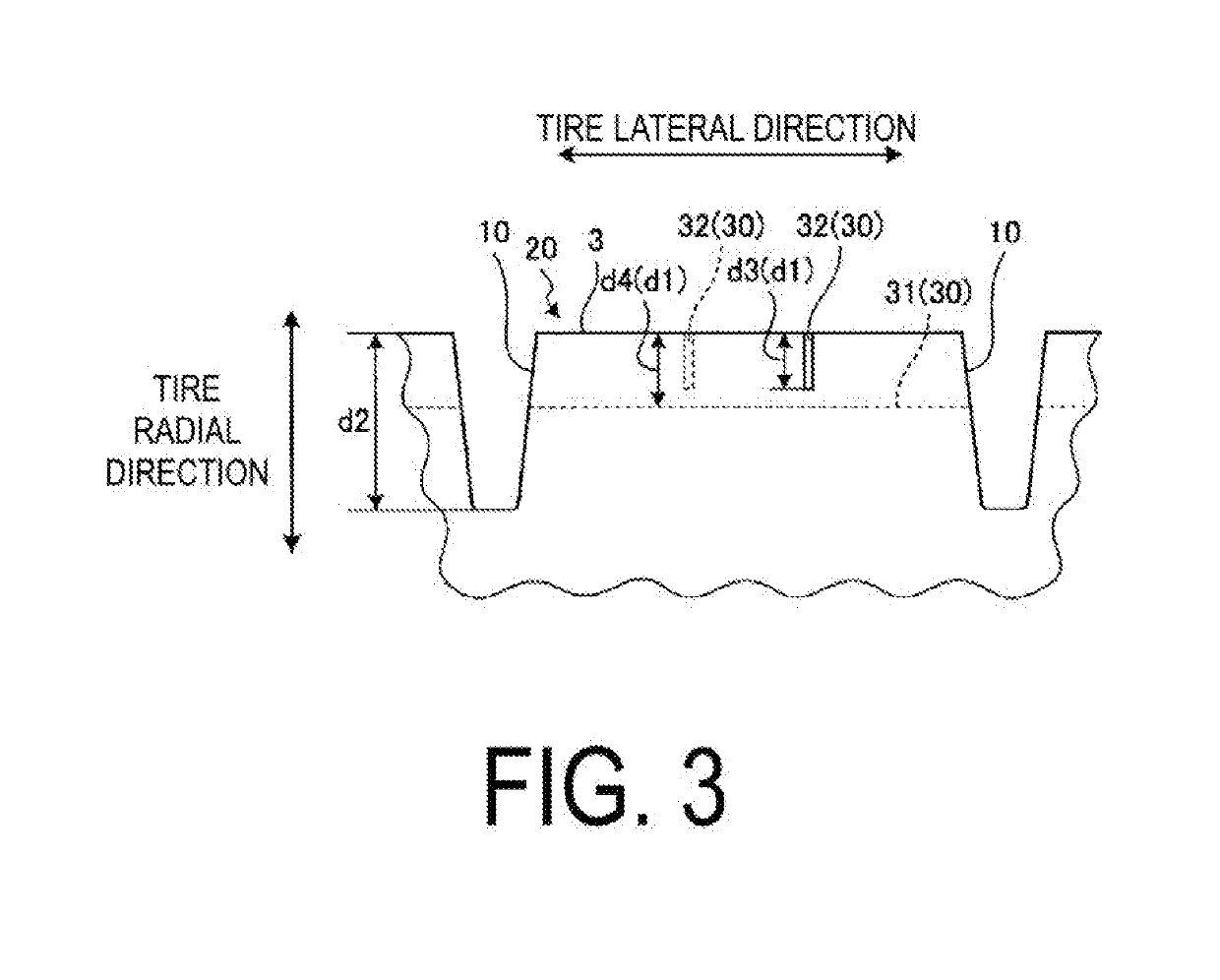

ActiveUS20190225027A1Improve snow performanceImprove steering stabilityTyre tread bands/patternsEngineeringMechanical engineering

A pneumatic tire includes a plurality of main grooves extending in a tire circumferential direction in a tread portion; and a sipe extending in a tire width direction in a rib defined by the plurality of main grooves, the sipe including a leading side edge and a trailing side edge, a chamfered portion shorter than a sipe length of the sipe being formed in each of the leading side edge and the trailing side edge, a non-chamfered region including no other chamfered portion being present in a part facing each chamfered portion of the sipe, and, in a plan view of the tread portion, at least one of the chamfered portions including an outer edge profile line not parallel to a ridge line of the sipe.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS11203234B2Improve wettabilityImprove snow performanceTyre tread bands/patternsEngineeringStructural engineering

Owner:THE YOKOHAMA RUBBER CO LTD

Tire with one or more recesses in the lateral grooves of at least one shoulder portion

PendingUS20220144018A1Improve traction performanceGreat tractionTyre tread bands/patternsMechanical engineeringTread

This invention relates to a tire, such as a pneumatic all-seasons tire, comprising a tread portion extending in a tire width direction and that is divided between an outer shoulder portion, a central portion and an inner shoulder portion; each of the outer shoulder portion and the inner shoulder portion comprises lateral grooves having an internal end and an external end; wherein at least one of the outer shoulder portion and the inner shoulder portion has at least one lateral groove comprising one or more recesses, wherein the cumulated length of the recesses in the lateral groove ranges from 20% to 60% of the total lateral groove length in the footprint, and wherein one or more recesses are placed at a distance from the internal end of the lateral groove.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire

ActiveUS20180297413A1Improve snow performanceMaintain steer stabilityTyre tread bands/patternsEngineeringTread

A tire includes a tread portion being divided into four land portions by one circumferentially extending crown main groove and two circumferentially extending shoulder main grooves arranged one on each side of the crown main groove. The four land portions include two crown land portions disposed one on each side of the crown main groove. Each of the crown land portions is provided with first crown lateral grooves each extending from the crown main groove and terminating within the crown land portion and second crown lateral grooves each extending from the adjacent shoulder main groove and terminating within the crown land portion. In each of the crown land portion, the first crown lateral grooves and the second crown lateral grooves extend at least to an axial center location of the crown land portions.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

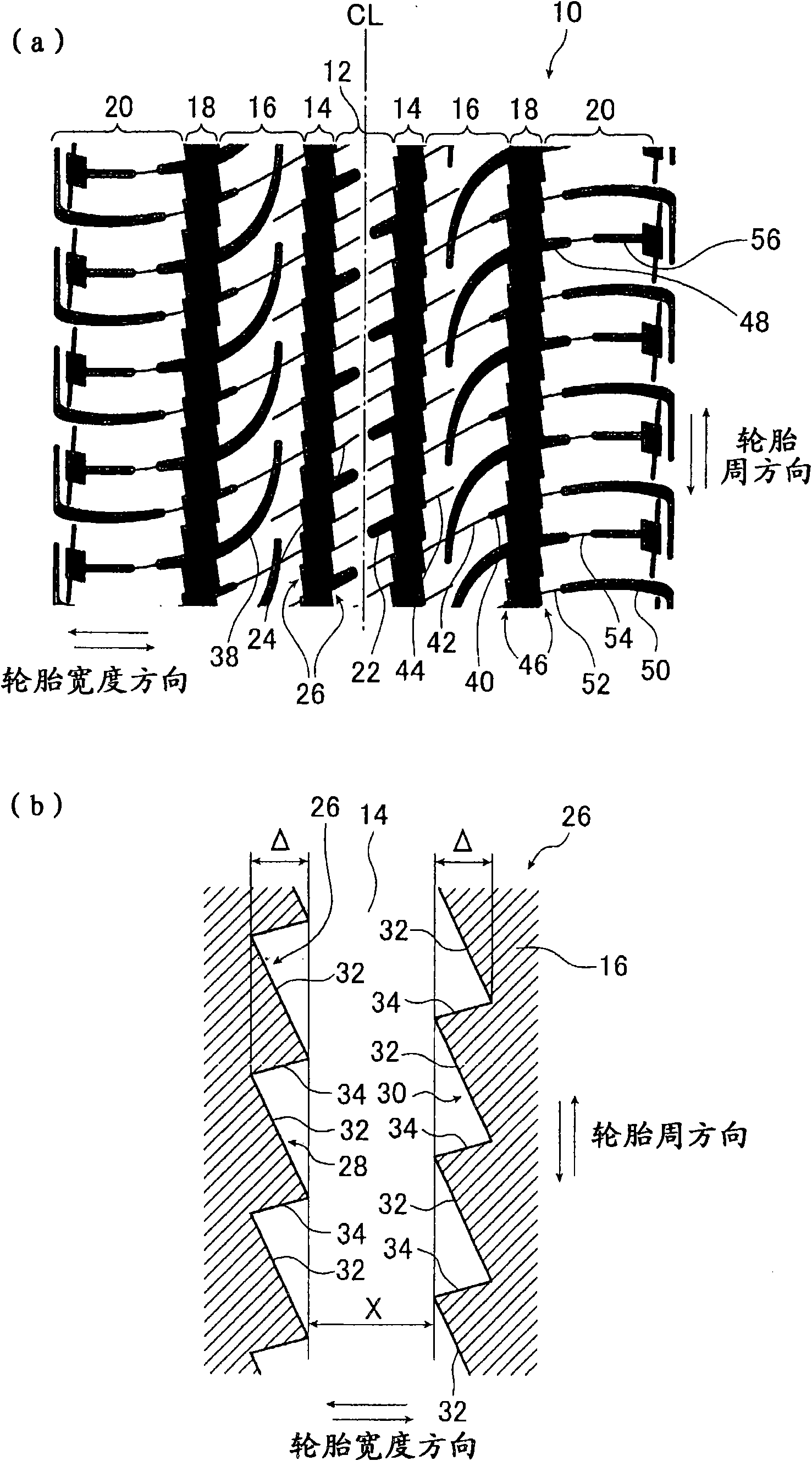

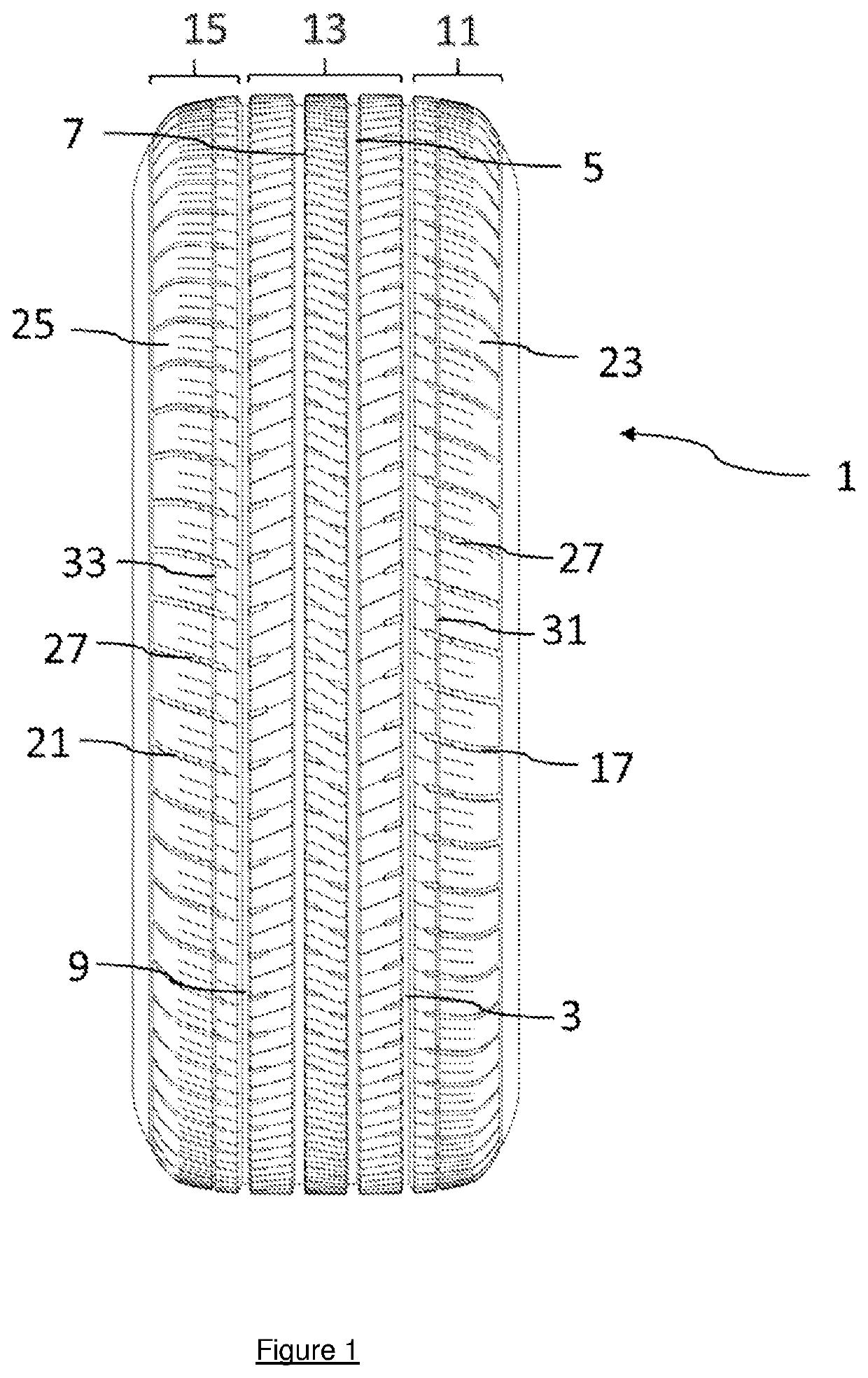

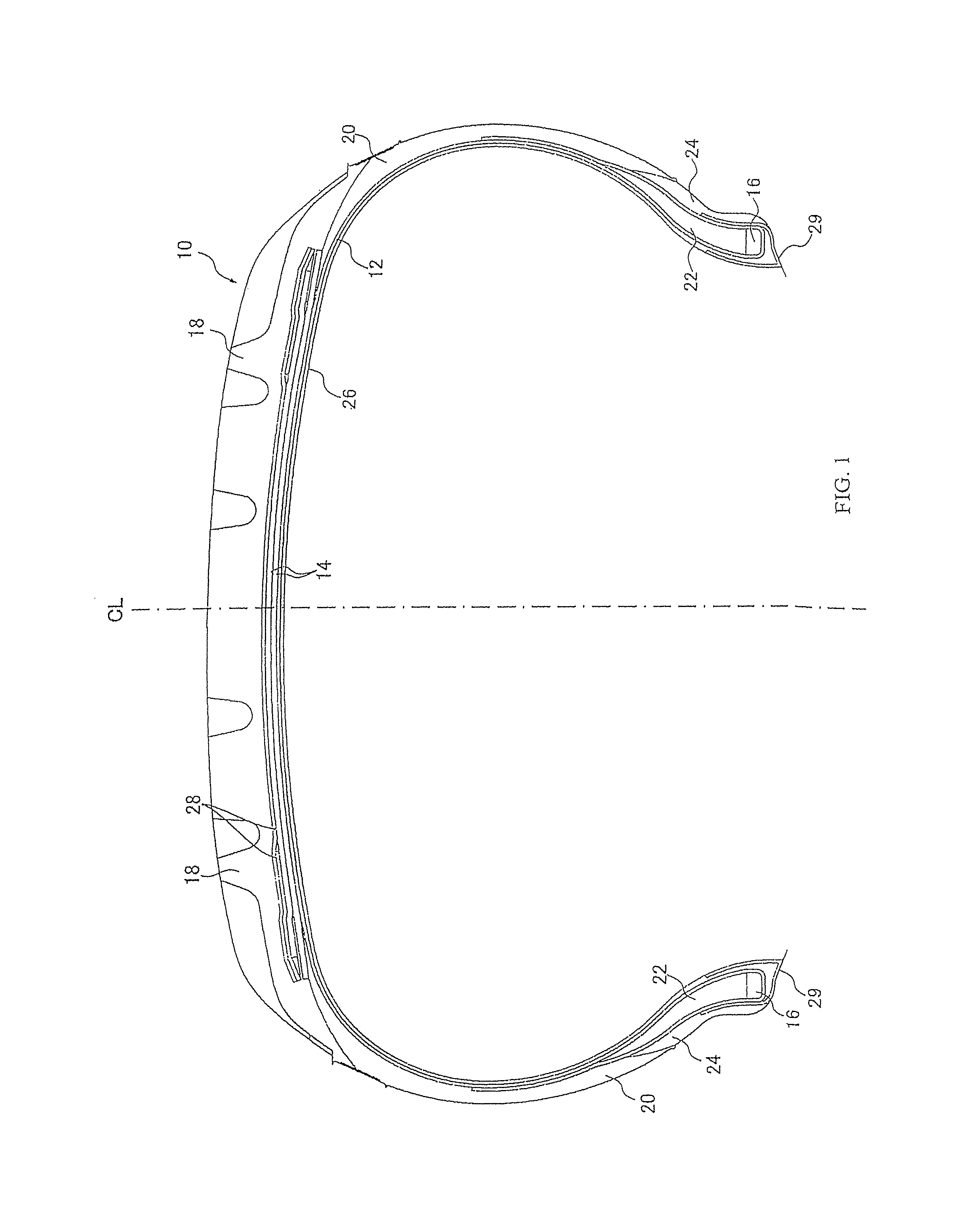

ActiveUS9038680B2Decreasing resistanceResistance to unevenTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

A pneumatic tire includes first and second side members at first and second sides and a tread section between the first and second side members. The tread section has a tread pattern including a pair of main grooves extending linearly in a circumferential direction of the tire and a land section extending in the circumferential direction between the main grooves. The land section includes a sub groove extending in the circumferential direction without connecting to the main grooves, and a first sipe connecting between the sub groove and one of the main grooves. The sub groove includes a first groove section extending diagonally toward the first side at 0 to 30 degrees with respect to the circumferential direction and a second groove section connecting to the first groove section and extending diagonally toward the second side at 10 to 45 degrees with respect to the circumferential direction.

Owner:THE YOKOHAMA RUBBER CO LTD

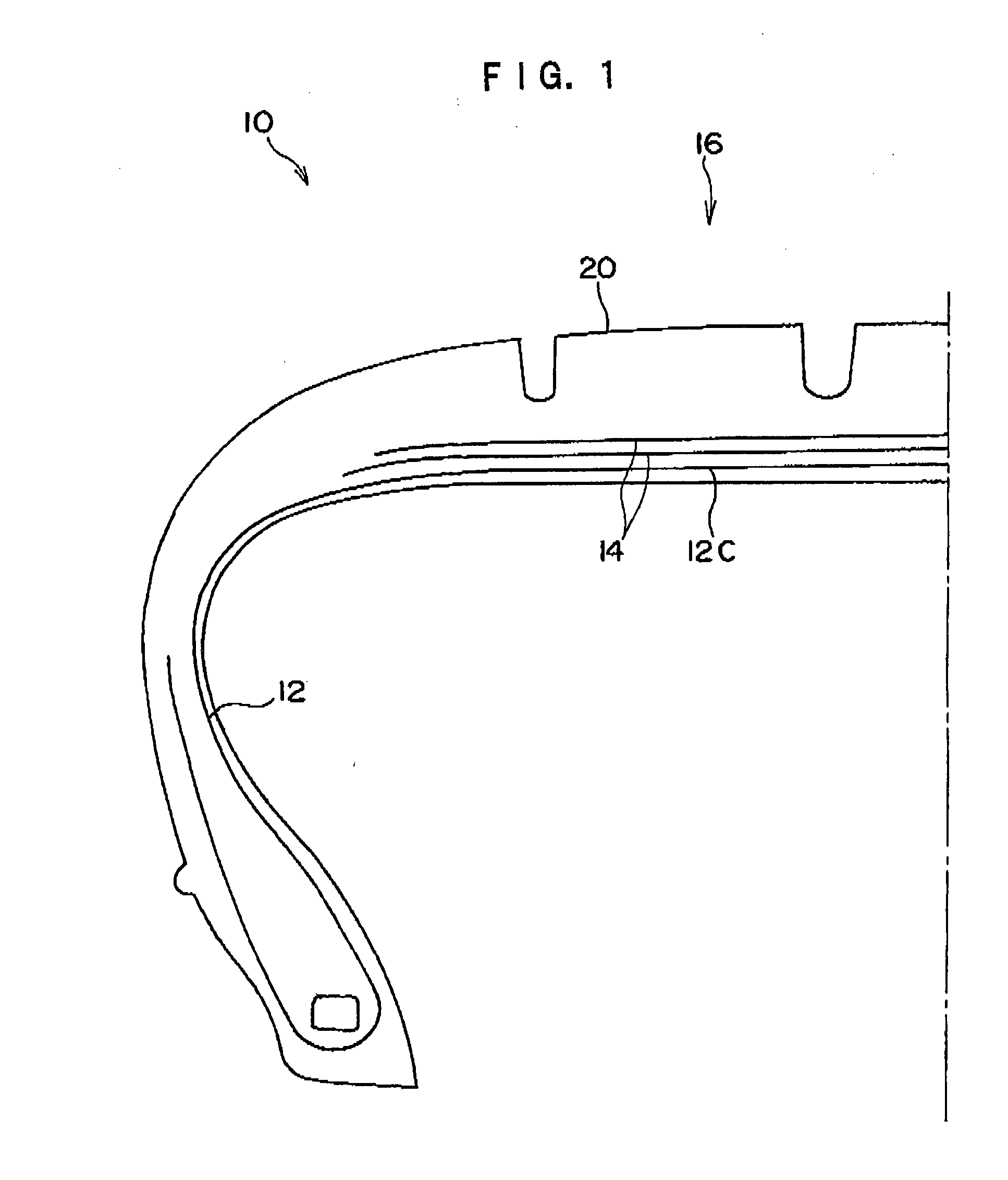

Pneumatic Tire and Method for Manufacturing the Same

PendingUS20200282779A1Reducing cavernous resonanceImprove snow performanceTyresTyre tread bands/patternsEngineeringAcoustics

A pneumatic tire includes a sound absorbing member fixed to an inner surface of a tread portion via an adhesive layer in the tire circumferential direction. A thickness of the sound absorbing member 6 is 20 mm or greater, a hardness of the sound absorbing member is from 80 N / 314 cm2 to 150 N / 314 cm2, a tensile strength of the sound absorbing member 6 is 90 kPa or greater, an elongation at break of the sound absorbing member is 130% or greater, a JIS hardness of the tread rubber of the tread portion is from 50 to 68, and a plurality of sipes are provided in a land portion formed in the tread portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Tire

PendingUS20220111683A1Improve performance on iceImprove snow performanceTyre tread bands/patternsGround contactMechanical engineering

A tire includes a tread portion includes circumferential grooves and a land portion divided by the circumferential grooves. The land portion has a ground contacting surface provided with first blind grooves, second blind grooves, first connecting ,sipes, second connecting sipes, and transverse sipes. The transverse sipes include first portions extending from a first circumferential edge with an inclination, second portions extending from the second circumferential edge and inclined in a same direction as with the inclination of the first portions, and third portions connecting the first and second portions with an inclination at a different angle from that of the inclination the first and second portions. In a plan view of the tread portion, the first portions overlap projection regions in which the respective first connecting sipes or the respective second connecting sipes are expanded parallel to the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic Tire

ActiveUS20210206207A1Improve snow performanceAppropriately maintaining steering stabilityTyre tread bands/patternsTire beadEngineering

A tire includes a tread, sidewalls, beads, and pairs of first and second grooves formed in the tread. A first land is between the first grooves, and second lands are between one of the first and second grooves and between another of the first and second main grooves. First sipes and lateral grooves are in the first land, at the same angle, the first sipes being connected to the lateral grooves. The first sipe and the lateral groove open to one of the first grooves. Second sipes and auxiliary grooves are in a bent shape in the second land. The first and second sipes are oriented the same. The auxiliary groove includes first and second portions. An intersection angle of the first portion with the second sipe is within 45° to 90°. A length a of the first portion and a length b of the second portion satisfy 0.05×a≤b≤0.4×a.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire and method for manufacturing same

PendingCN111094013AReduce cavity resonanceImprove snow performanceTyresInflatable tyresAcousticsUltimate tensile strength

Provided are a pneumatic tire in which snow performance can be improved at the same time that cavernous resonance is reduced on the basis of a sound-absorbing material, and a method for manufacturingthe pneumatic tire. A sound-absorbing material (6) is secured, along a tire circumference direction, to the inner surface of a tread section (1) via an adhesive layer (7). The thickness of the sound-absorbing material (6) is 20 mm or greater, the hardness of the sound-absorbing material (6) is 80 N / 314 cm<2> to 150 N / 314 cm<2>, the tensile strength of the sound-absorbing material (6) is 90 kPa orgreater, and the rupture elongation of the sound-absorbing material (6) is 130% or greater. The JIS hardness of tread rubber (11) in the tread section (1) is 50-68, and a land section formed in the tread section (1) has a plurality of sipes.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com