Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., which can solve the problems of improving snow performance and achieve the effect of improving snow performance and reducing tire noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] In order to investigate the effect of the tread pattern 10 of such a tire, a test tire was produced.

[0105] The tire size was set to 265 / 70R17 115H. The rims are set to 17×8J. Make a tire with the tread pattern below. The vehicle used to investigate the tire performance was an SUV vehicle with an engine displacement of 6 liters. The internal pressure conditions were set to 210 (kPa) for both the front and rear wheels.

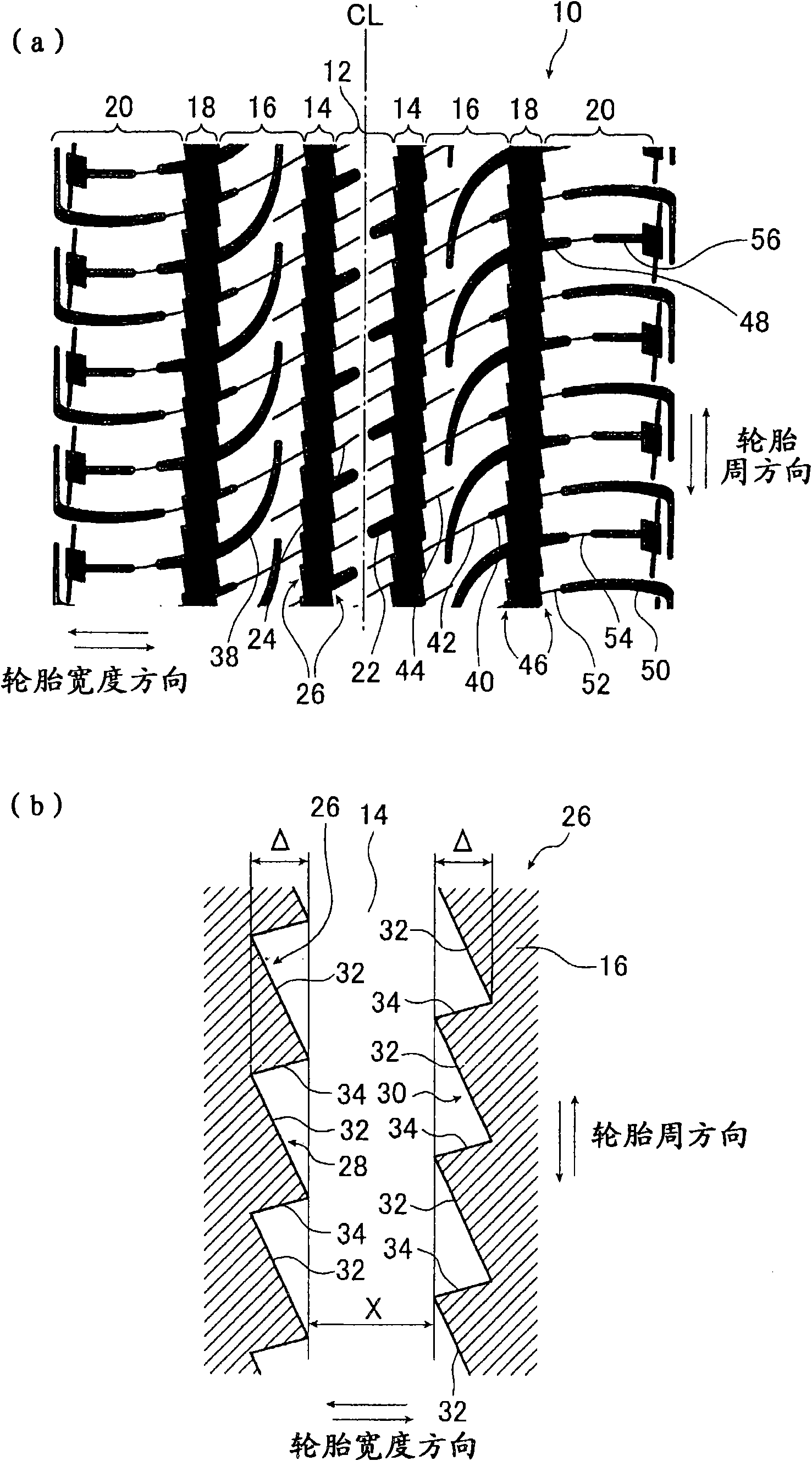

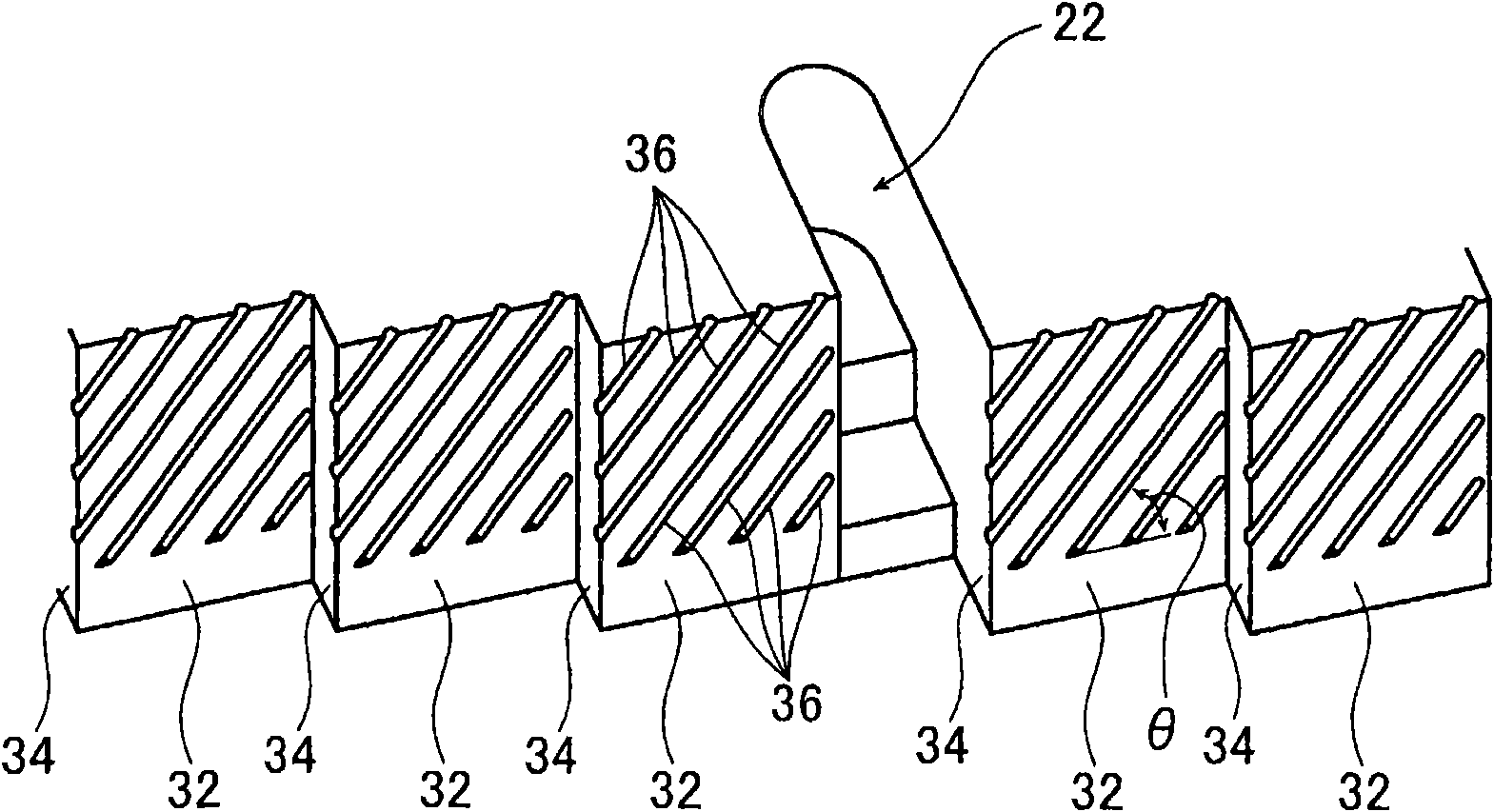

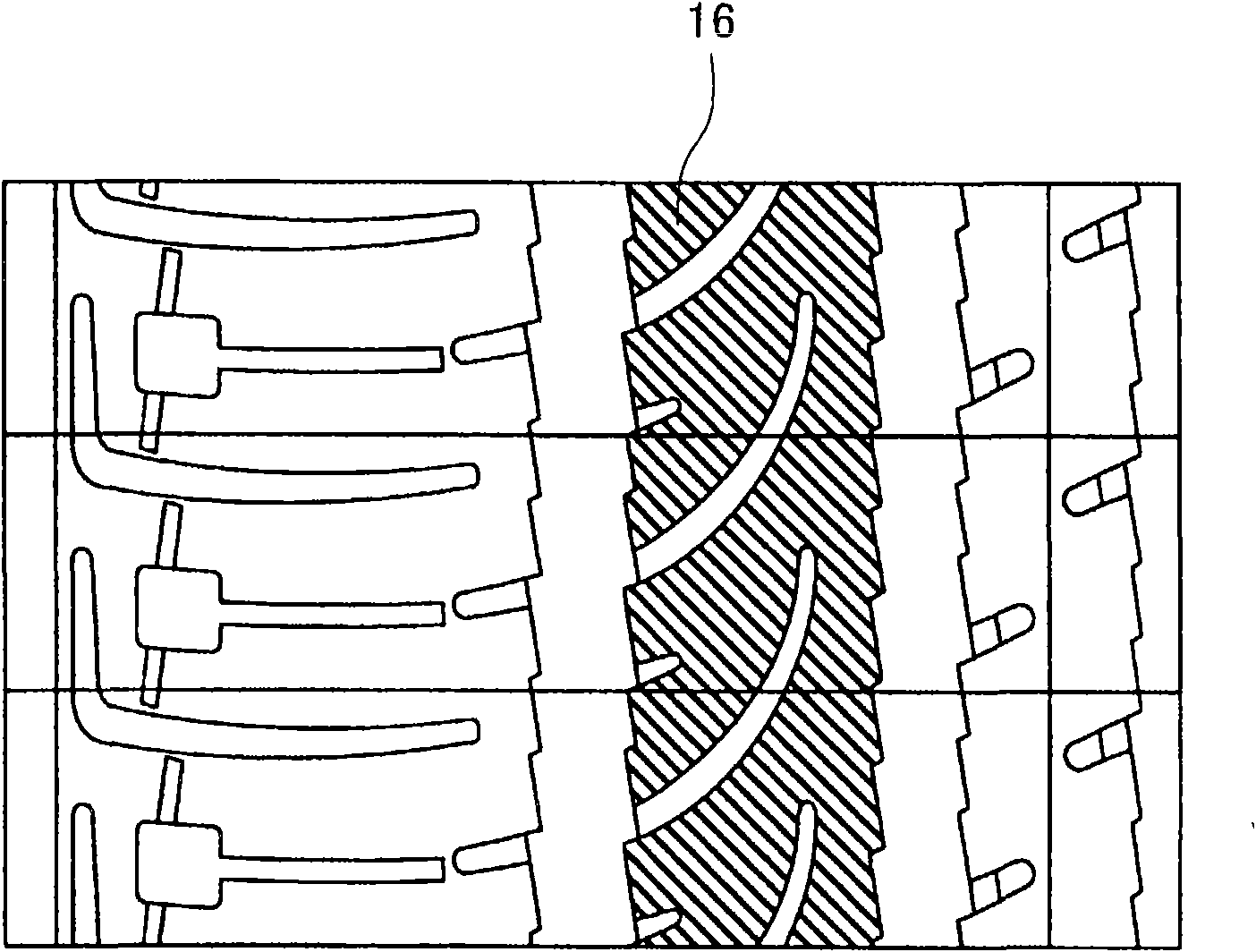

[0106] The tread patterns are the following patterns a to d. Pattern a is figure 1 In the patterns shown in (a), patterns b to d are patterns that have been changed based on the pattern a. In Table 1 below, the specifications of the patterns a to d are summarized. Patterns b~d are as follows Figures 4 to 6 shown.

[0107] Table 1

[0108] 1st Land Department

1st main slot

2nd Land Department

2nd main slot

3rd Land Department

pattern

a: figure

1(a)

with pattern

Slot 22, knife groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com