Vehicle tires

A technology for pneumatic tires and vehicles, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc. It can solve the problems of hard tread blocks and the impact of snow performance, so as to achieve good snow-snow friction and ensure Snow-snow friction, the effect of improving winter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The invention consists of a special arrangement of cut-outs in the tread of passenger car (PKW) tires, which tires are particularly suitable for use in winter driving conditions.

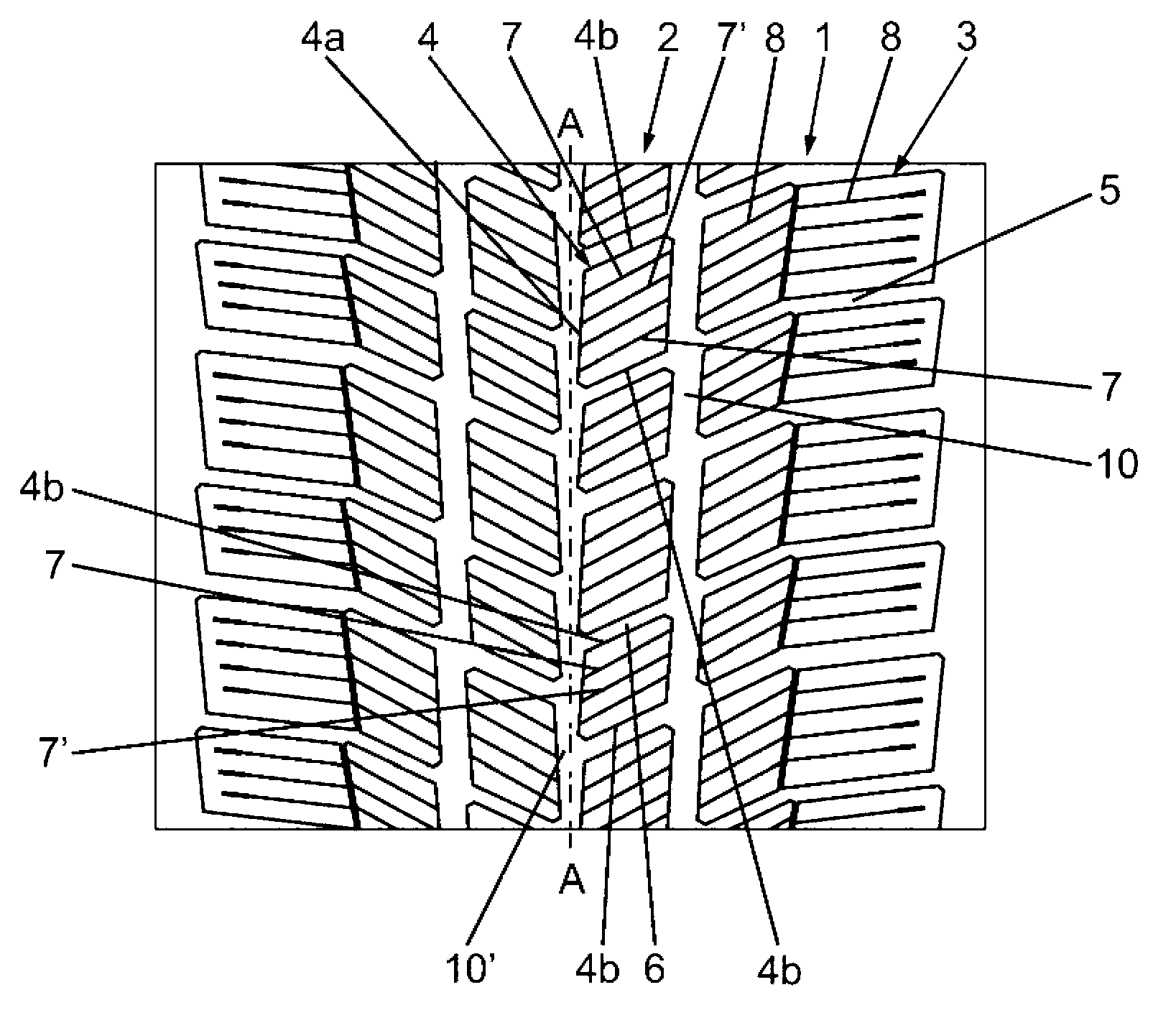

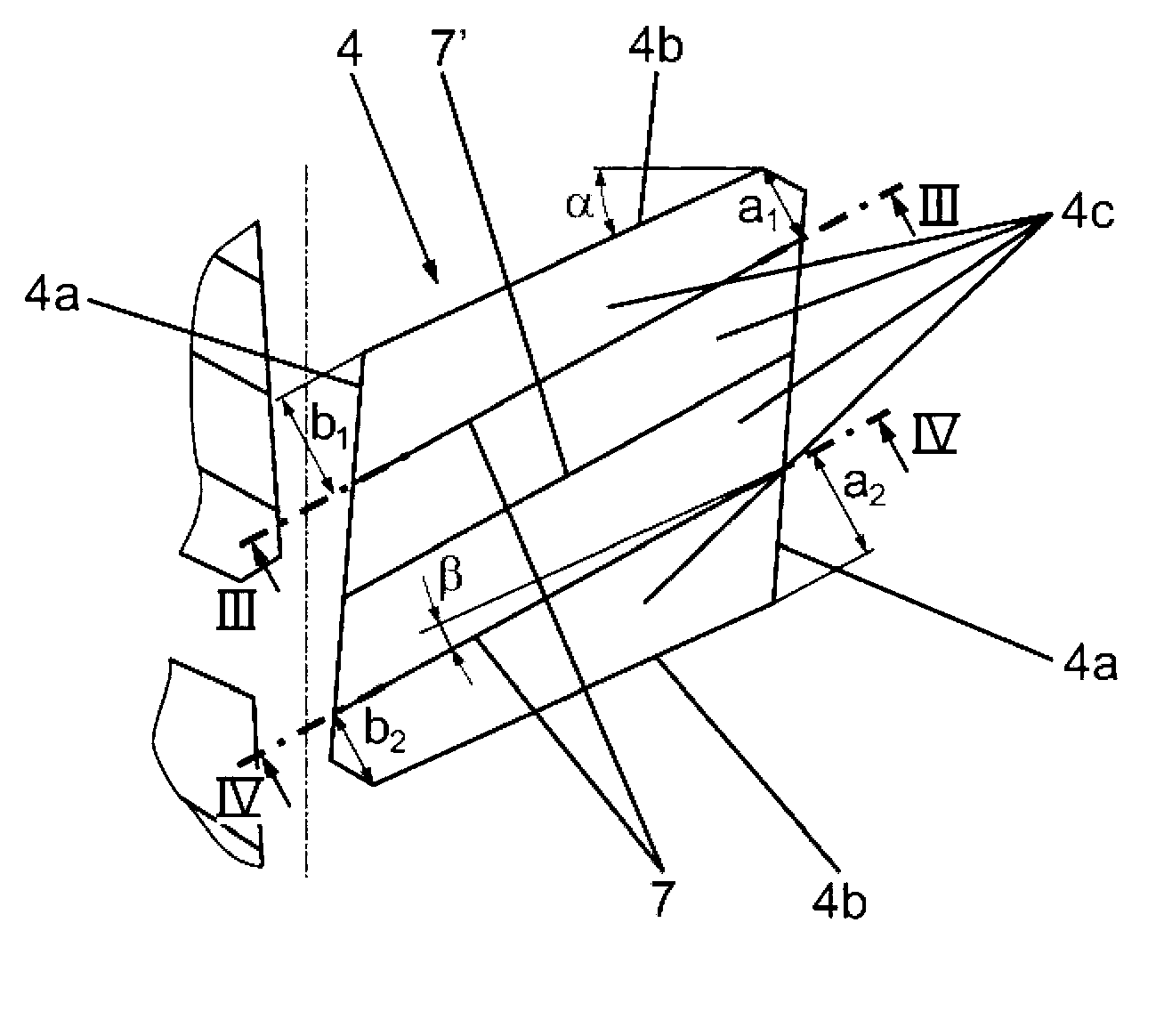

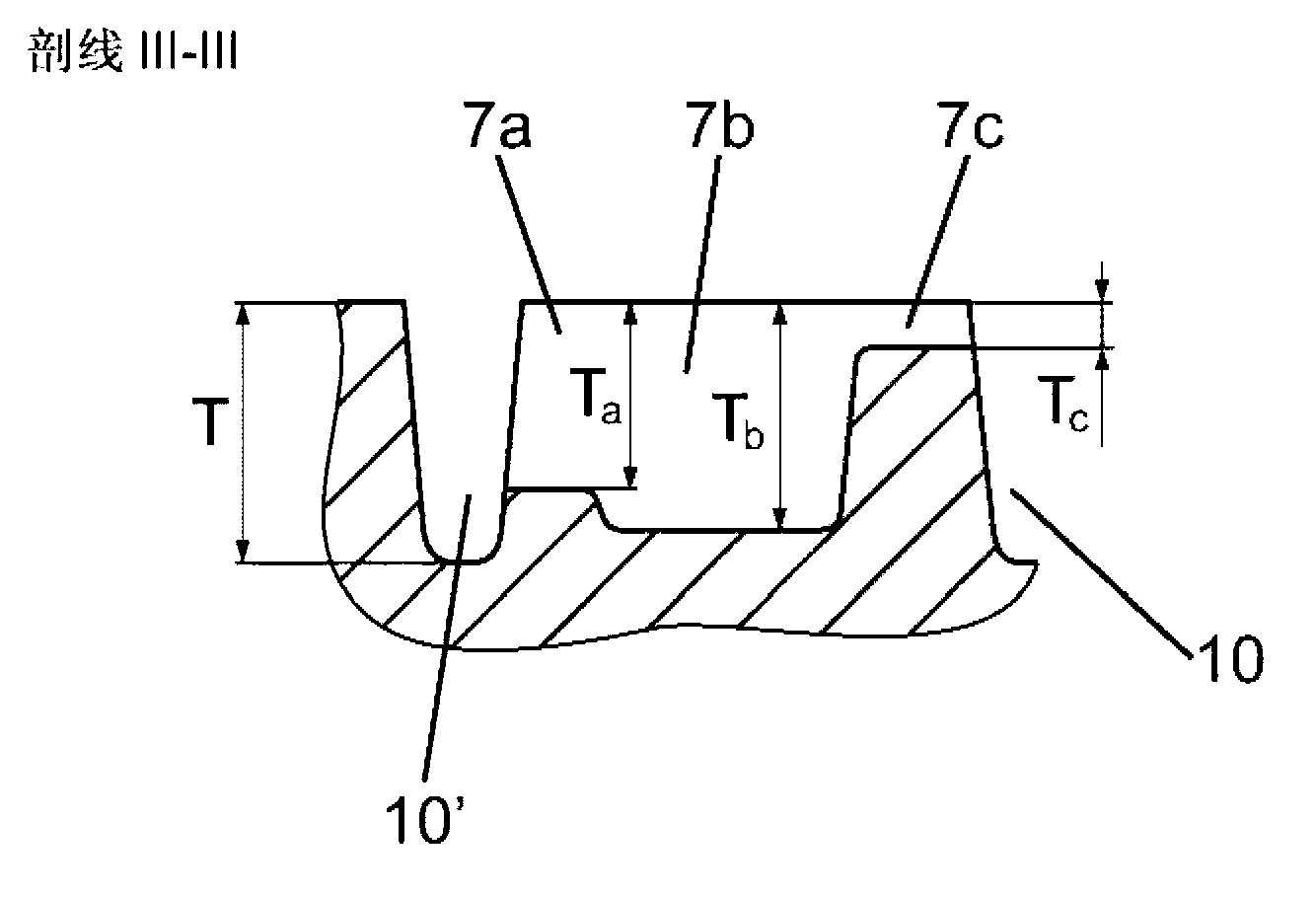

[0050] figure 1 Shows an example, direction-of-travel-bound (laufrichtungsgebunden) of the circumferential section of the realized tread stripe, which is located on each tread half Center, with one wide row of blocks 1 on the shoulder side and two other central rows of blocks 2 in the middle of the tread. Each row 1 of blocks has blocks 3 separated from one another by transverse grooves 5 running substantially transversely of the tread. Each central block row 2 , which is separated from the adjacent shoulder-side row 1 by a circumferentially surrounding circumferential groove 10 , has tread blocks 4 and transverse grooves 6 , which In the embodiment shown, the groove runs in the extension of the transverse groove 5 . The central row of blocks 2 is delimited at a central circumferential gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com