An artificial wetland insulation structure

A technology for artificial wetlands and wetlands, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of difficult to guarantee thermal insulation effect, cumbersome operation, high cost, and improve winter operation effect, Simple production process, good air permeability and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

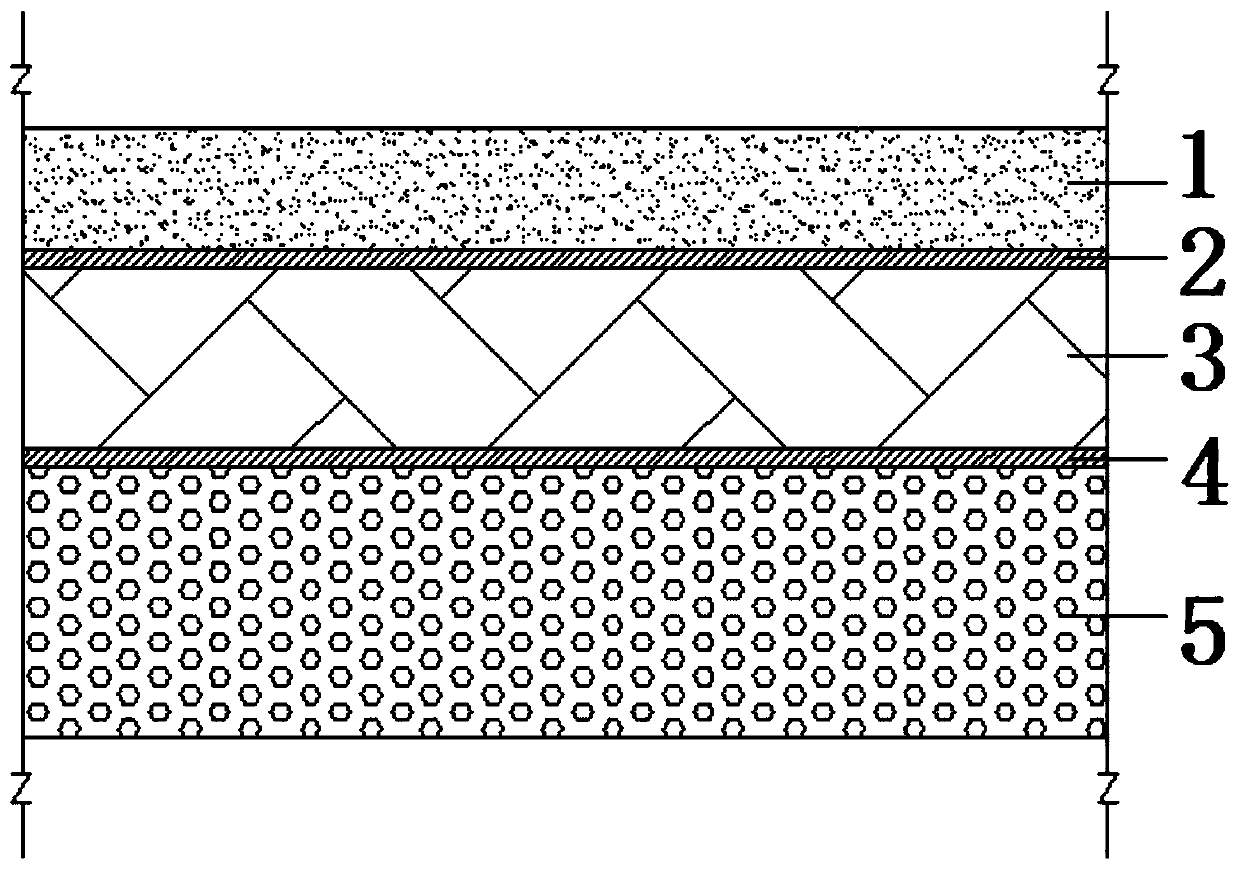

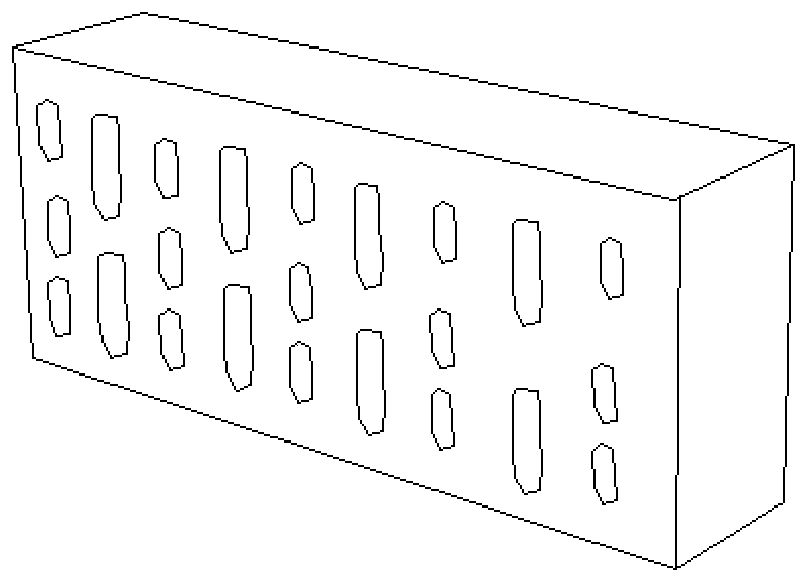

[0029] combine figure 1 and figure 2 , The thermal insulation structure of the constructed wetland in this embodiment includes an upper layer of permeable plastic film 2 , a thermal insulation permeable brick 3 and a lower layer of permeable plastic film 4 . Wherein the upper permeable plastic film 2 is placed under the surface layer 1 of the wetland, the lower permeable plastic film 4 is placed on the artificial wetland matrix 5, and the thermal insulation permeable brick 3 is placed between the upper permeable plastic film and the lower permeable plastic film; the upper permeable plastic film and the lower permeable plastic film are The non-woven mulch; the thermal insulation permeable brick is a high-strength lightweight hollow brick, and the preparation process of the high-strength lightweight hollow brick includes the above five steps of mixing, aging, pressing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com