Pneumatic tire

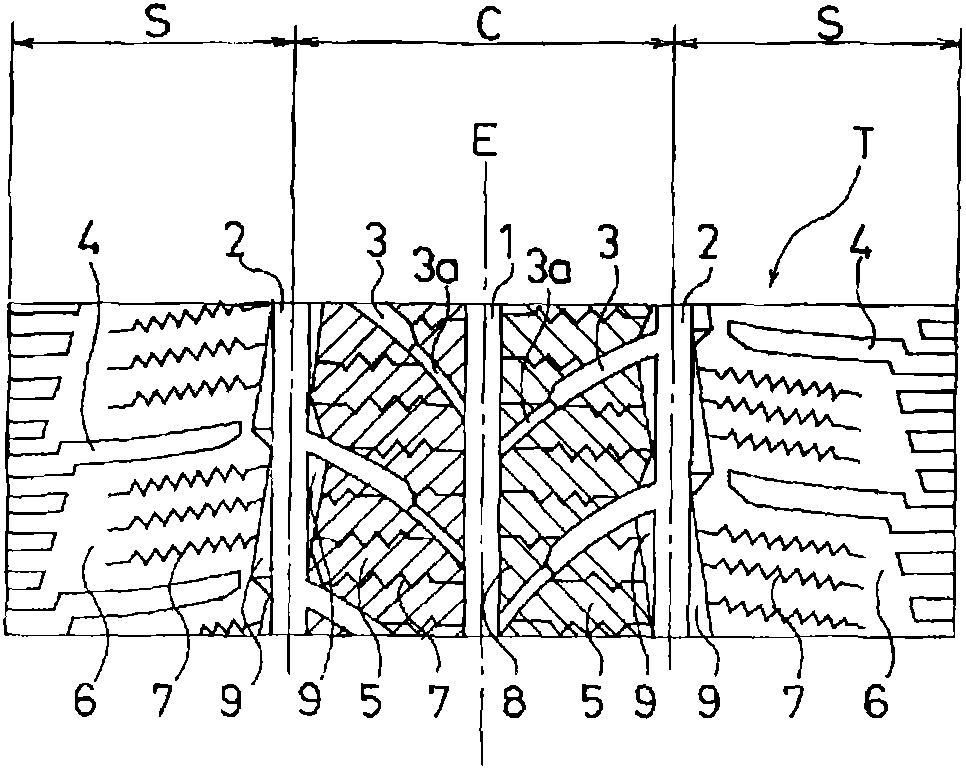

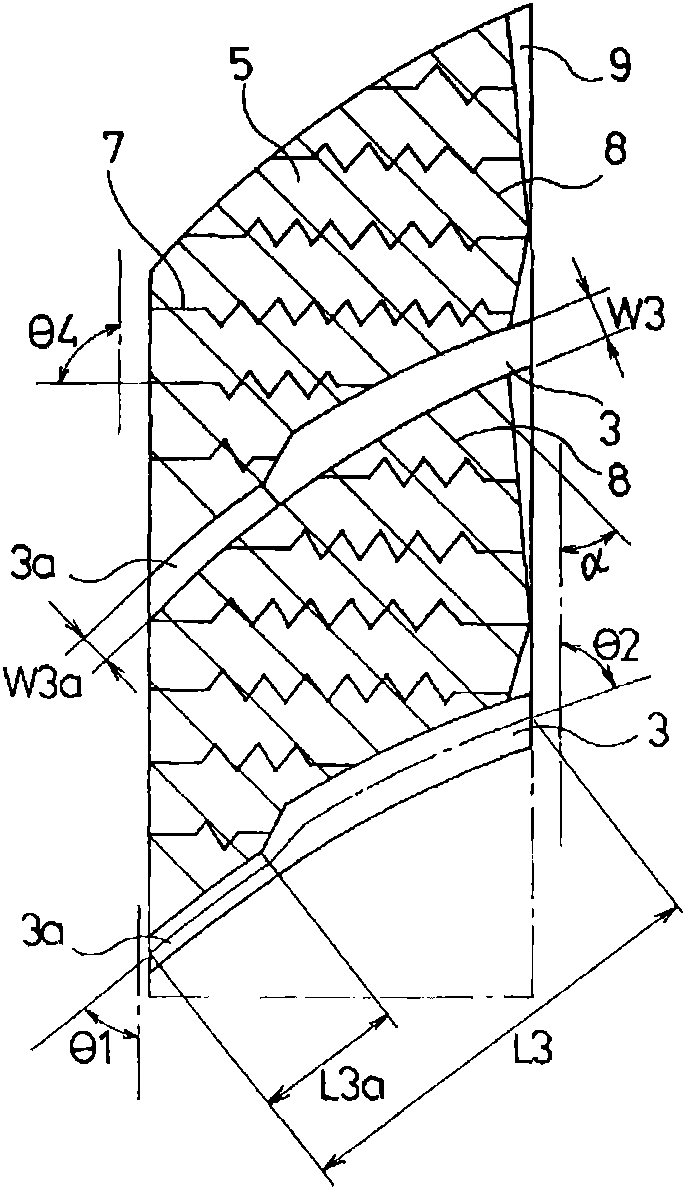

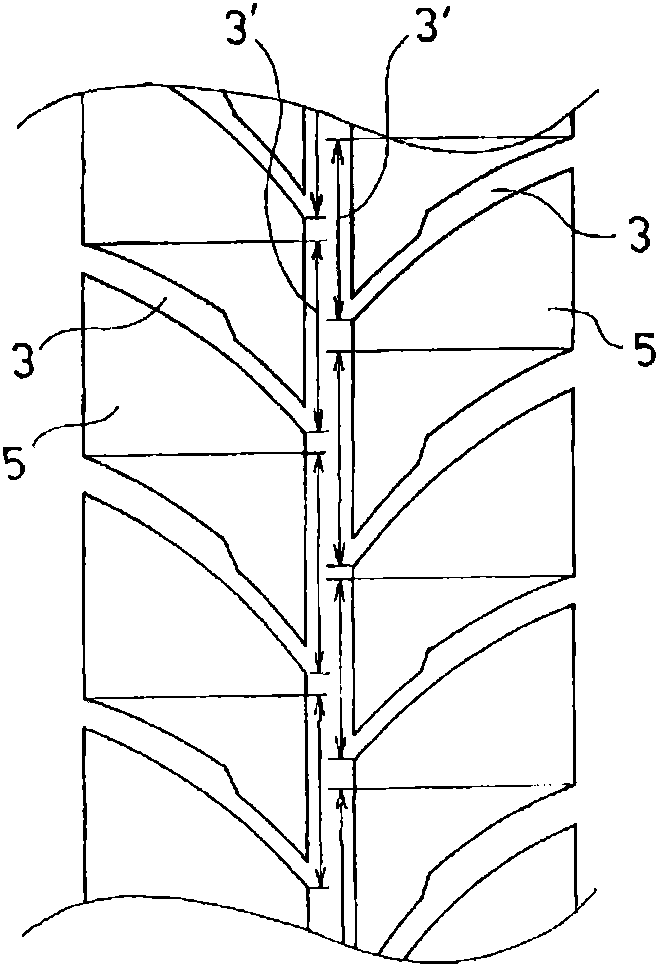

A pneumatic tire and tire technology, applied in special tires, tire parts, tire tread/tread pattern, etc., can solve the problem of wet performance, snow performance, uneven wear resistance, and reduced snow performance, etc. Improve wet performance and snow performance, ensure drainage performance, and improve uneven wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0062] 11 kinds of pneumatic tires of Conventional Example 1, Comparative Examples 1-2, and Examples 1-8 were produced. The tire sizes were 195 / 75R16C and 107 / 105R, and the different specifications were shown in Tables 1 and 2.

[0063] These 11 kinds of tires are assembled on the 16×51 / 2J rim, the front wheel is inflated to 280kPa, and the rear wheel is inflated to 450kPa, and then installed on European trucks with a maximum load capacity of 3.5 tons, and the resistance is measured by the following method Uniform wear, water drainage, wet handling stability, and snow handling stability.

[0064] Uneven wear resistance

[0065] After running 4000 km on an asphalt road with the above-mentioned vehicle, the appearance of the tire was visually evaluated. The evaluation results were expressed with the value of Conventional Example 1 as an index of 100. The smaller the index value, the better the uneven wear resistance.

[0066] Drainage performance

[0067] Use the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com