Guide pillar sealing mechanism for needle machine

A sealing mechanism and technology for acupuncture machines, which are used in acupuncture machines, textiles, papermaking, non-woven fabrics, etc., can solve problems such as affecting the production progress, troublesome replacement of the sealing ring 1, etc., and achieve the effect of preventing the leakage of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

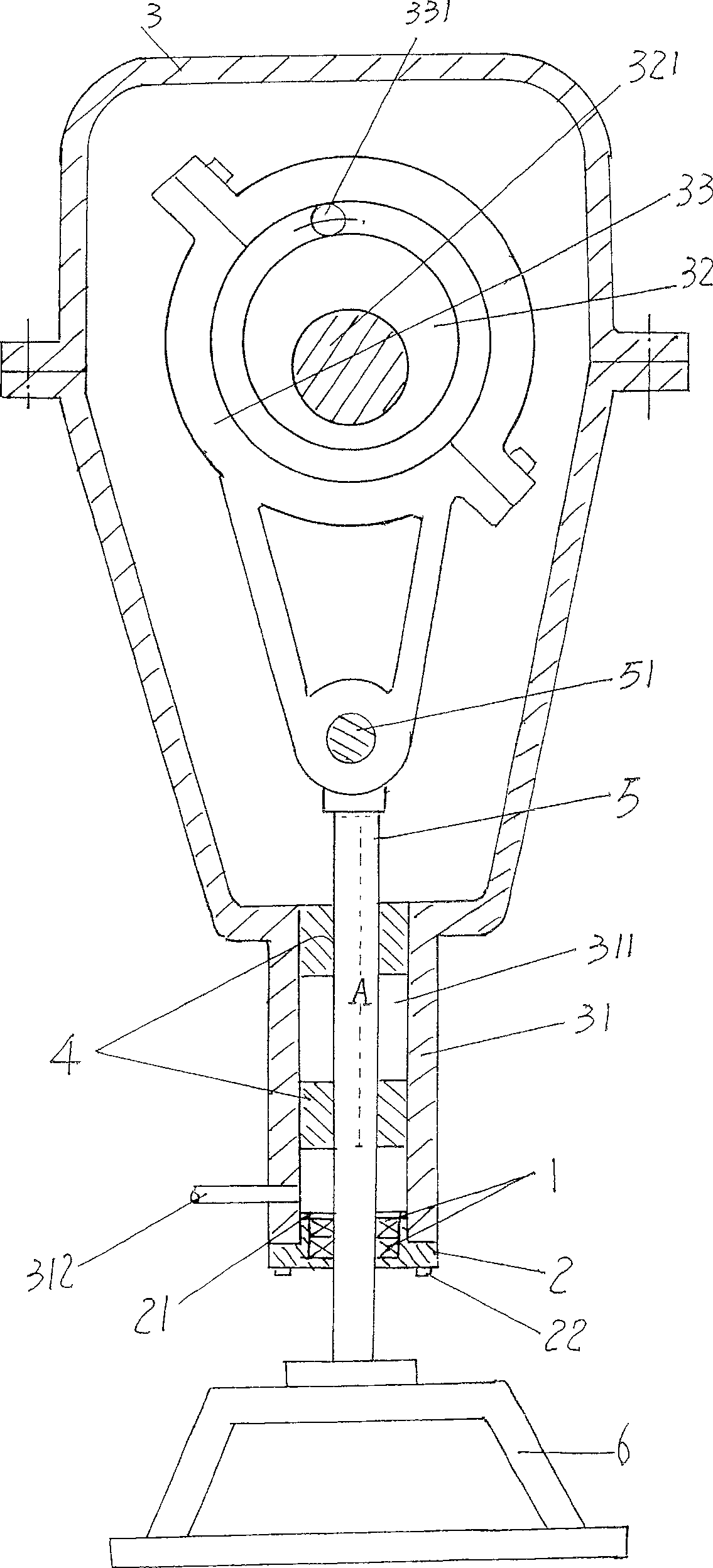

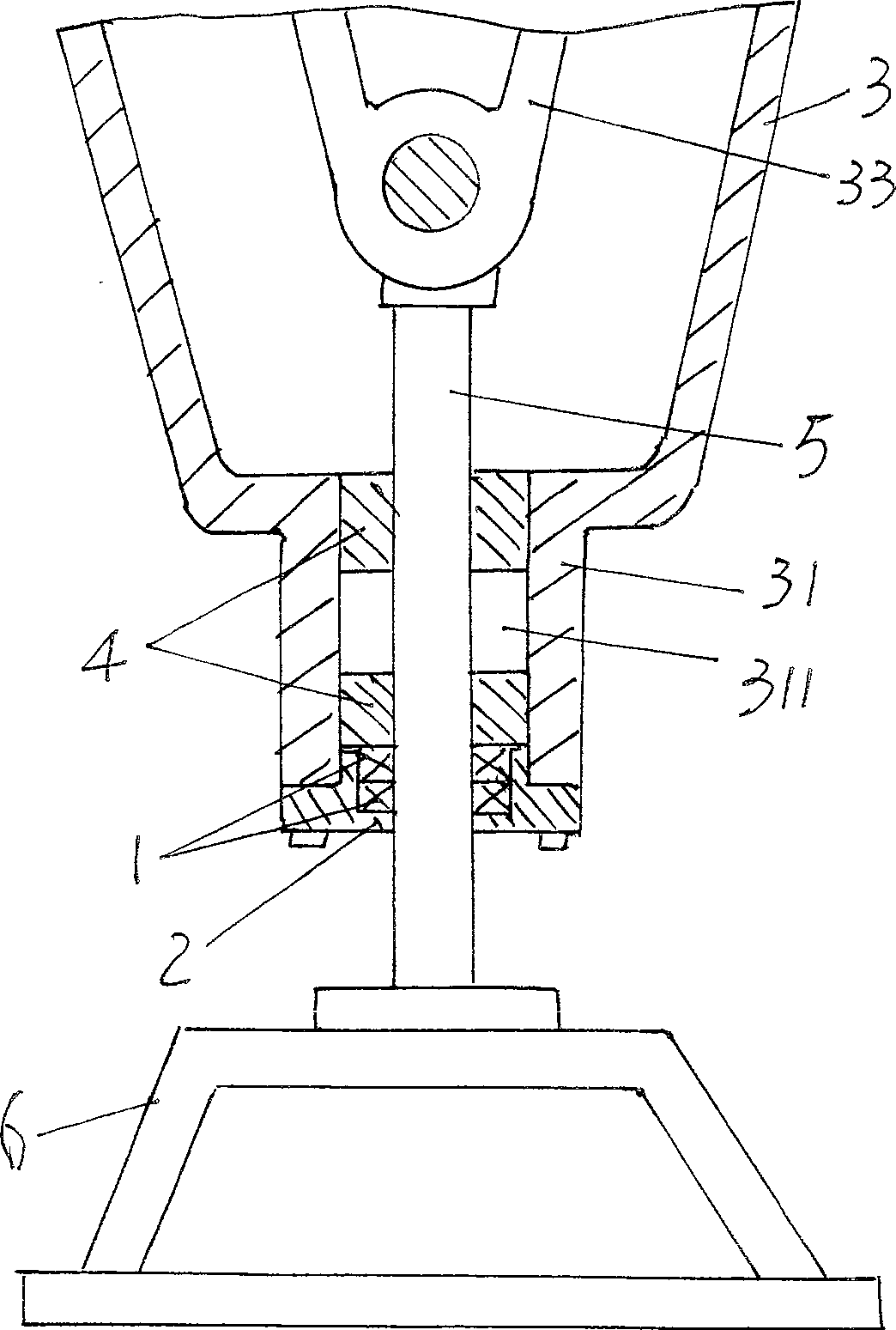

[0022] See figure 1 , as well known in the industry, as the spindle housing 3 of the present invention, the upper part is expanded, while the lower part is narrowed, and an eccentric cam 32 and a connecting rod 33 are equipped in the expanded upper cavity. Specifically: the connecting rod 33 cooperates with the eccentric cam 32 through the bearing 331, and the eccentric cam 32 is installed on the main shaft or the eccentric cam shaft 321 as the transmission power of the acupuncture machine. The lower end of the connecting rod 32 is connected to the upper end of the guide post 5 by a pin shaft 51, and the lower end of the guide post 5 is connected to the needle bed 6 after passing through the guide sleeve 4 (a pair), the sealing ring 1 and the sealing cover 2.

[0023] As clearly shown in the figure, the lower part of the spindle housing 1 is narrowed into a cylindrical tubular body, and the tubular body is formed into a guide post seat 31, and a pair of copper rods preferably...

Embodiment 2

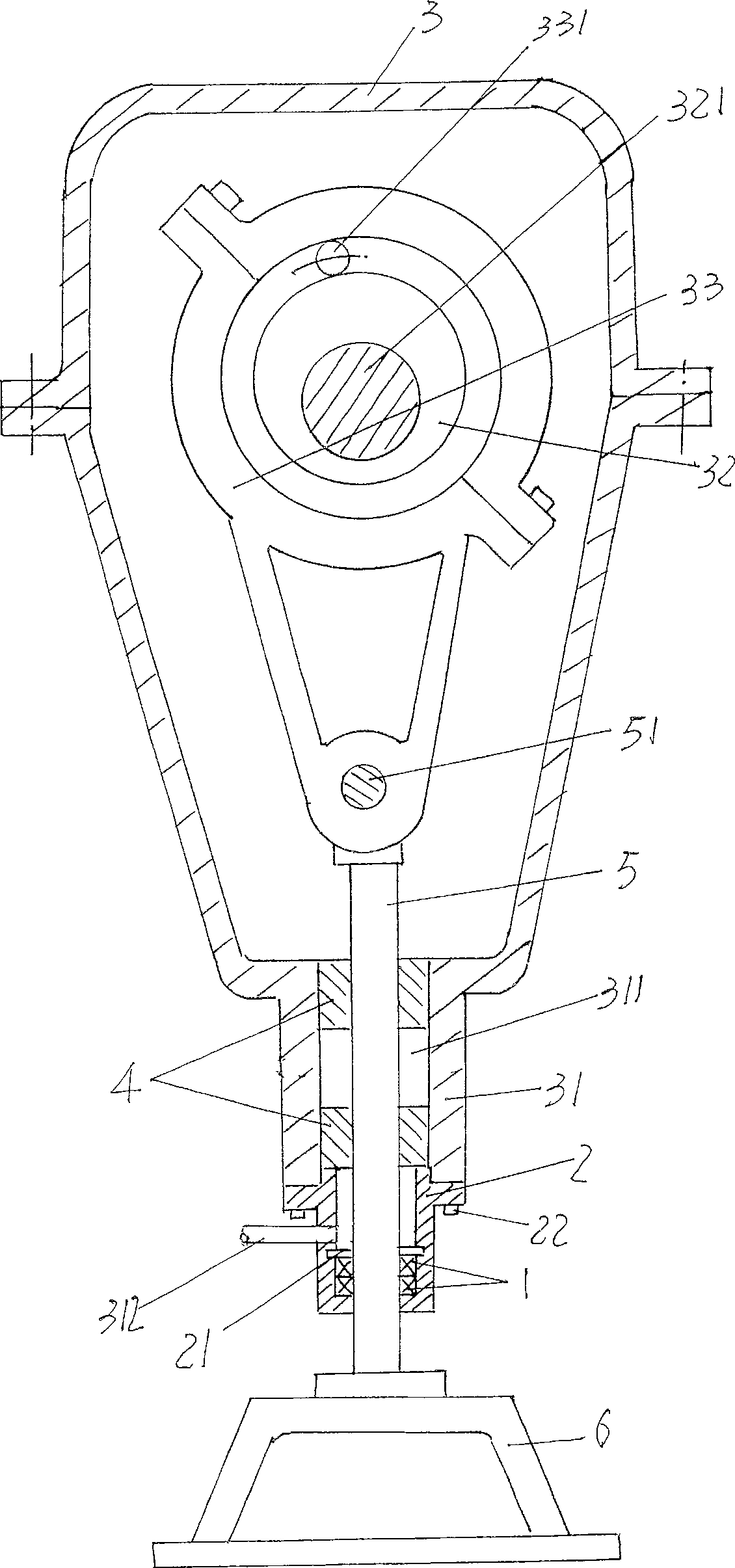

[0025] See figure 2 , for some needle looms with different specifications, for example, the length of the guide post seat 31 is shorter, that is, the stroke of the guide post 5 is small, then in this case, the solution of the present invention can be slightly improved, specifically: the sealing cover 2 lengthened, and the oil outlet pipe 312 is transferred to the sealing cap 2. All the other are the same as the description of embodiment 1.

[0026] applicant based on figure 1 or figure 2 Briefly describe the working principle of the present invention. Driven by the power mechanism of the acupuncture machine, the eccentric camshaft 321 rotates to make the eccentric cam 32 move, driving the connecting rod 33 to move up and down repeatedly. The rod 33 is connected, so the guide post 5 moves up and down on the guide sleeve 4, and the guide post 5 carries the needle bed 6 to move accordingly, and then the needle bed 6 drives and fixes the needle plate covered with needles on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com