Cable foaming insulation layer sampling device

A foam insulation layer and sampling device technology, which is applied in the direction of sampling devices, measuring devices, instruments, etc., can solve the problems of foam insulation layer damage, shear force is difficult to grasp, and detection cannot be carried out, so as to achieve the effect of ensuring thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

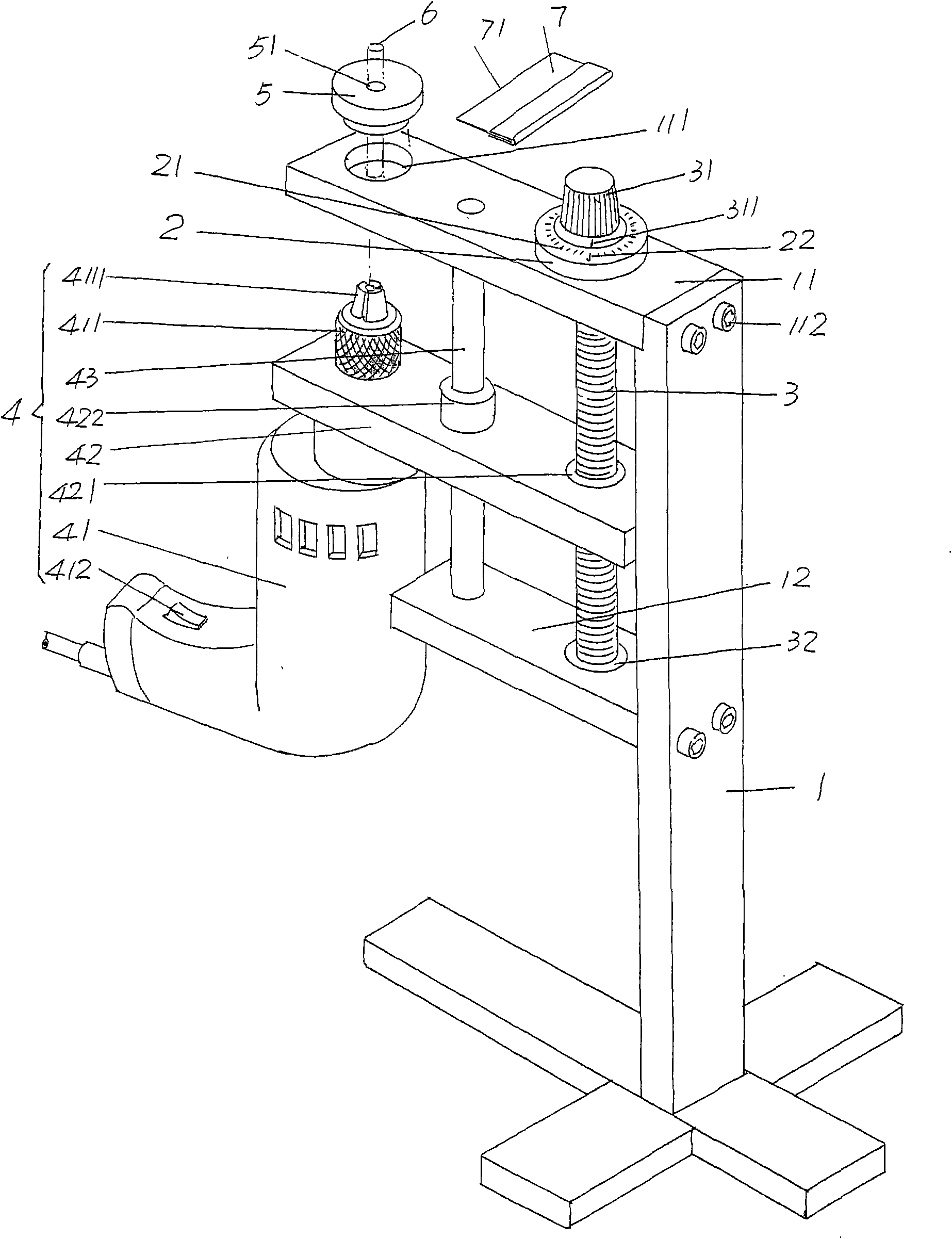

[0014] Please refer to accompanying drawing, have provided the support 1 that specific shape is not restricted by illustration and can have various variations, on the top of support 1 (the present embodiment is the top) fix a first cantilever with first fixing screw 112 plate 11. Of course, the first hanging plate 11 can also be welded or riveted to the top of the bracket 1 . In addition, the first hanging plate 11 and the top of the bracket 1 can also be fixed by mortise and tenon. A second suspension plate 12 is also fixed on the bracket 1. The fixing method is as described for the first suspension plate 11. The second suspension plate 12 corresponds to the bottom of the first suspension plate 11. The two are parallel, but the second suspension plate The length of the plate 12 is shorter than that of the first suspension plate 11, so as to avoid forming an installation obstacle to the cable capture mechanism 4. Of course, if the position of the second suspension plate 12 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com