Yarn cutter for clearing winding yarn

A technology of cutting and wrapping yarn, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of blade cuts, affecting the coiling of the coiling mechanism, affecting the pulling force of the knitted fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

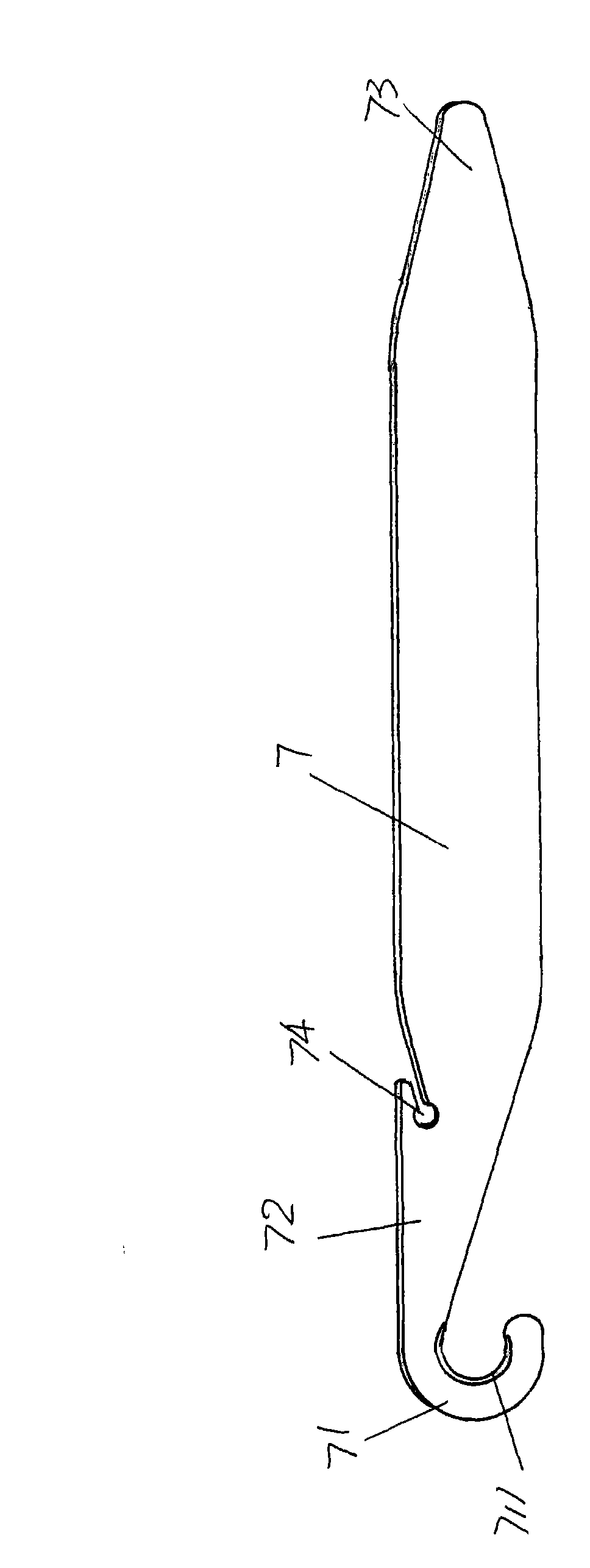

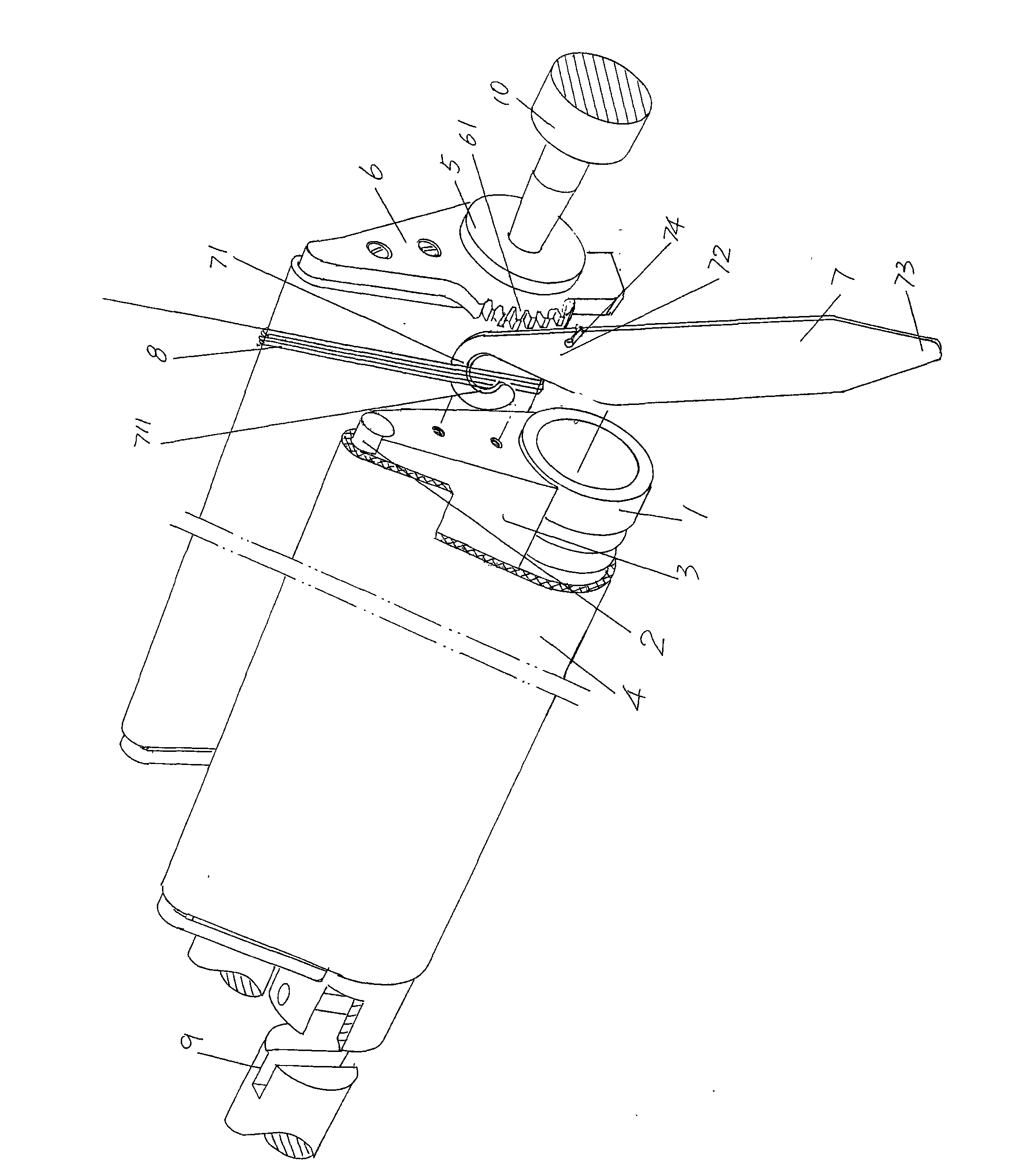

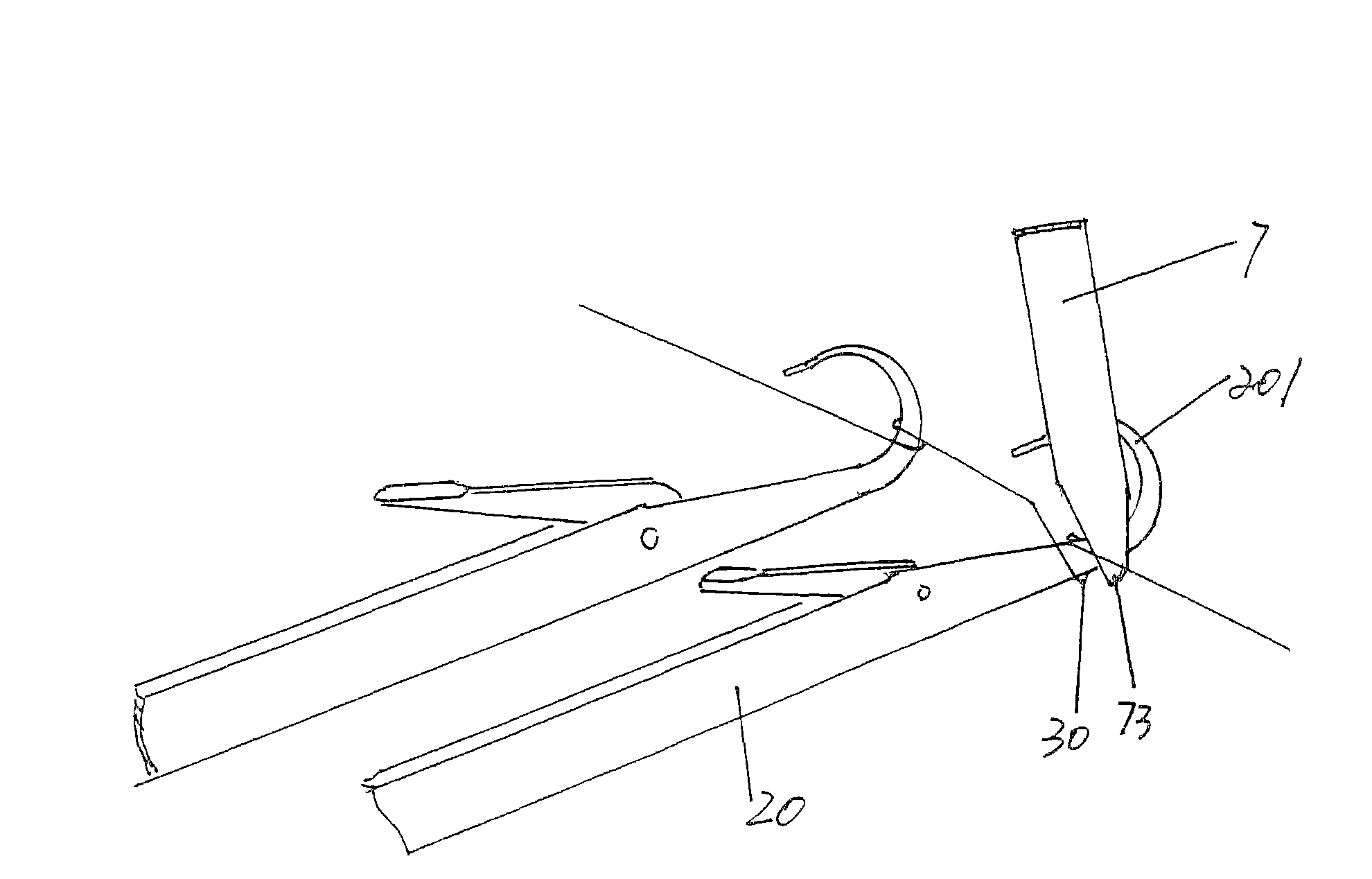

[0019] please see figure 1 , provides a knife bar 7 whose material is preferably made of stainless steel, the knife bar 7 is flat and elongated, and one end of the knife bar 7 is currently figure 1 The left end of the shown position state forms a narrow body 72 whose width is obviously smaller than the middle part of the knife bar 7, that is to say, one end of the knife bar 7 forms a narrow body 72 with a width narrower than the width of the middle part, and the end of the narrow body 72 is bent And constitute cutter head 71, in the present embodiment, the bending of the end of narrow body 72 is U-shaped bending, and the cutting edge 711 on the cutter head 71 is positioned at U-shaped cavity, that is to say, because cutter head 71 It is U-shaped, so the yarn cutting blade 711 is also U-shaped. Form a hanging groove 74 at the junction of the aforementioned narrow body 72 and the cutter bar 7, that is, the junction. At the other end of the knife bar 7 that is figure 1 The ...

Embodiment 2

[0021] The figure is omitted, only the shape of the cutter head 71 is changed into a 7-shape, and the yarn cutting blade 711 is located on the inside of the 7-shape. This scheme is essentially to form the cutter head 71 into a sickle-like effect, that is, in the shape of a sickle. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com