Spanners for automobile tyre

A technology for automobile tires and wrenches, applied in the directions of wrenches, hand-held tools, wrenches, etc., can solve the problems of cumbersome assembly, complex structure, troublesome processing, etc., and achieve the effect of being beneficial to processing and assembly, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

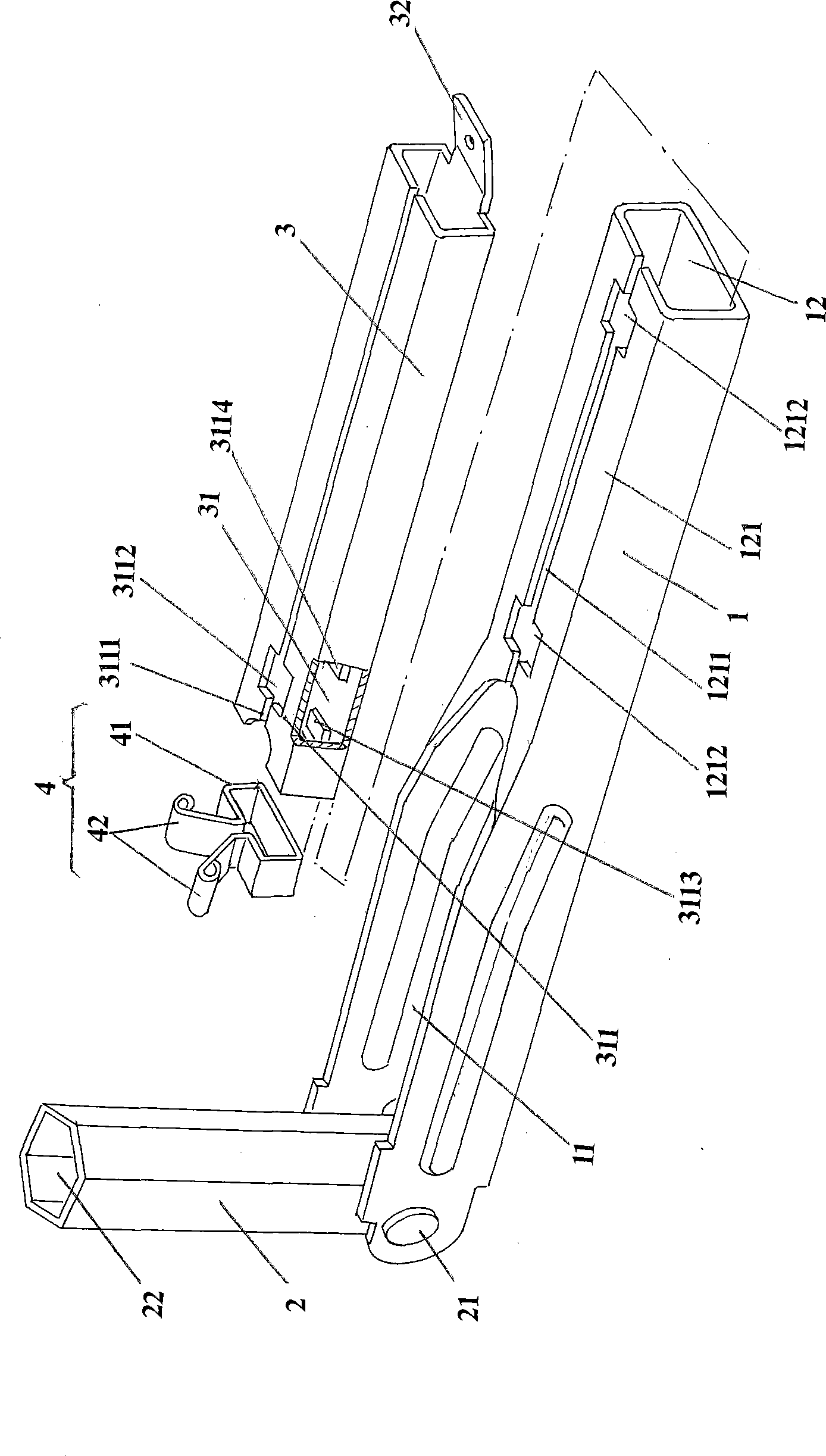

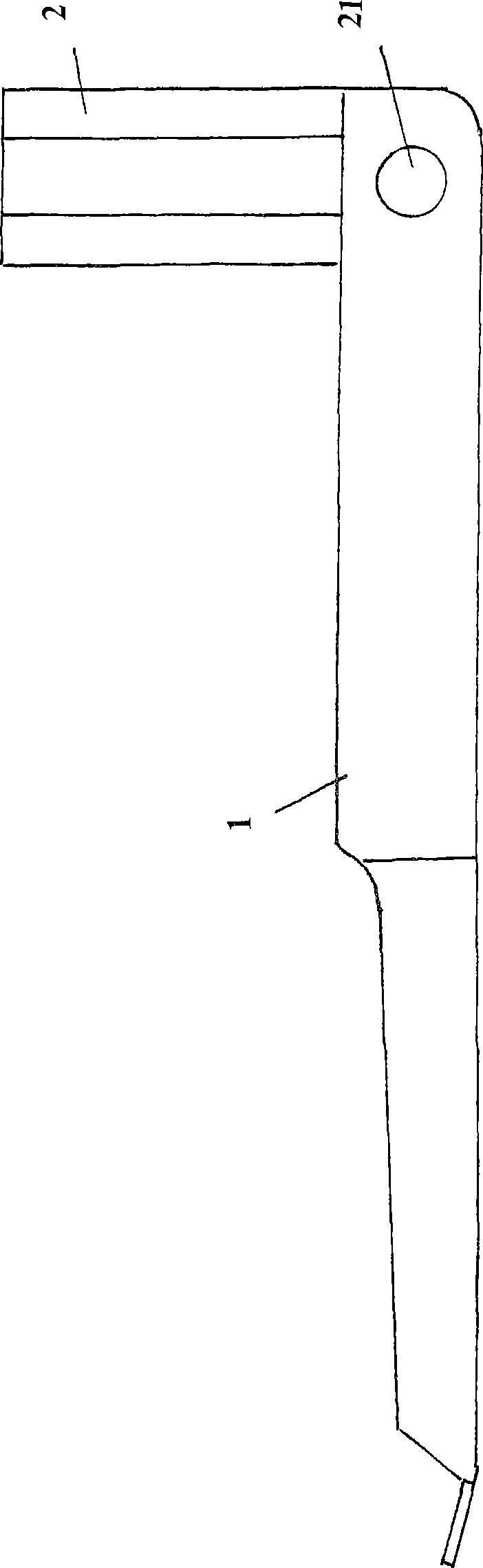

[0020] please see figure 1 , as the overall shape of the handle 1 constituting the automobile tire wrench of the present invention is just like the mallet shape used for cleaning clothes seen in daily life, it is currently made of figure 1 Taking the position shown as an example, one end of the handle 1, namely the left end, is expanded, while the other end, namely the right end, is narrowed, that is to say, the left end is thicker and the right end is thinner. On the left end of handle 1 (with figure 1 The state shown is an example, the same below) constitutes a sleeve housing chamber 11, the base of the sleeve 2 is hinged with the handle 1 through the hinge shaft 21, when the sleeve 2 is pulled toward the direction of the sleeve housing chamber 11, the Currently figure 1 In the state shown, when the sleeve 2 is stretched 90° towards the sleeve accommodation chamber 11, the sleeve 2 is stored in the sleeve accommodation chamber 11, and the sleeve 2 is in a non-use stand...

Embodiment 2

[0024] Figure slightly, in figure 1 A first positioning opening 1212 is formed between the pair of first positioning openings 1212 shown, so that the number of first positioning openings 1212 is increased to three. According to this reasoning, when figure 1 If more than one first positioning opening 1212 is formed between the pair of first positioning openings 1212 shown, then the number of first positioning openings 1212 is increased to more than three. Therefore, the number of first positioning openings 1212 is not subject to specific restrictions. For example, for different types of vehicles, when the length of the handle 1 is longer, the number of first positioning openings 1212 should be increased accordingly, and vice versa. Length adjustment puts 3 degrees of adjustment required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com