Slurry removing method and assembly and system for implementing method

A slurry and component technology, which is applied in the field of systems, slurry removal methods and components to realize the method, can solve the problems of destroying the current collector, reducing the safety performance of the battery cell, operating efficiency, and operating stability to be improved. The effect of simple process, excellent safety performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

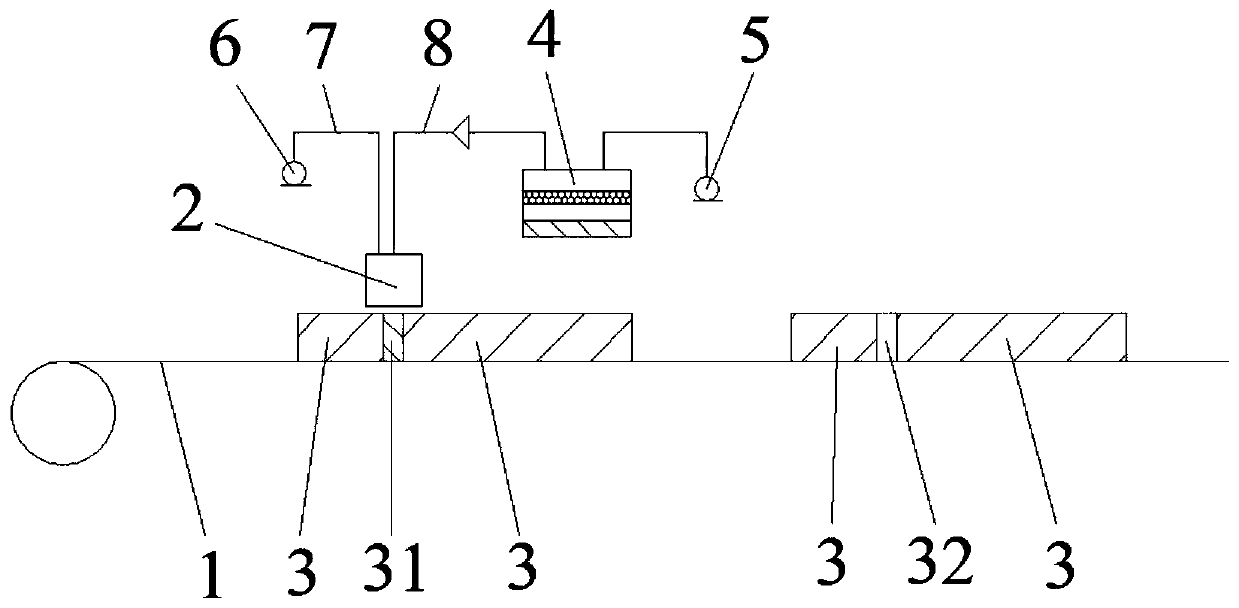

[0029] This embodiment provides a slurry removal method, comprising the following steps:

[0030] Step 1, setting a preliminary empty foil area 31 on the surface of the current collector 1, and coating the slurry on the current collector 1 to obtain the active material layer 3;

[0031] Step 2, setting the upper part of the preparatory empty foil area 31 as a positive pressure, so that the slurry on the surface of the preparatory empty foil area 31 is gathered;

[0032] Step 3: Set the upper part of the preparatory empty foil area 31 as a negative pressure, and suck the slurry accumulated on the surface of the preparatory empty foil area 31 to obtain the empty foil area 32 .

[0033] Further, setting the upper part of the preparatory empty foil area 31 as a positive pressure is specifically to pass compressed air to the preparatory empty foil area 31 . Pass compressed air above the preparatory empty foil area 31, so that the compressed air forms a positive pressure air knife,...

Embodiment 2

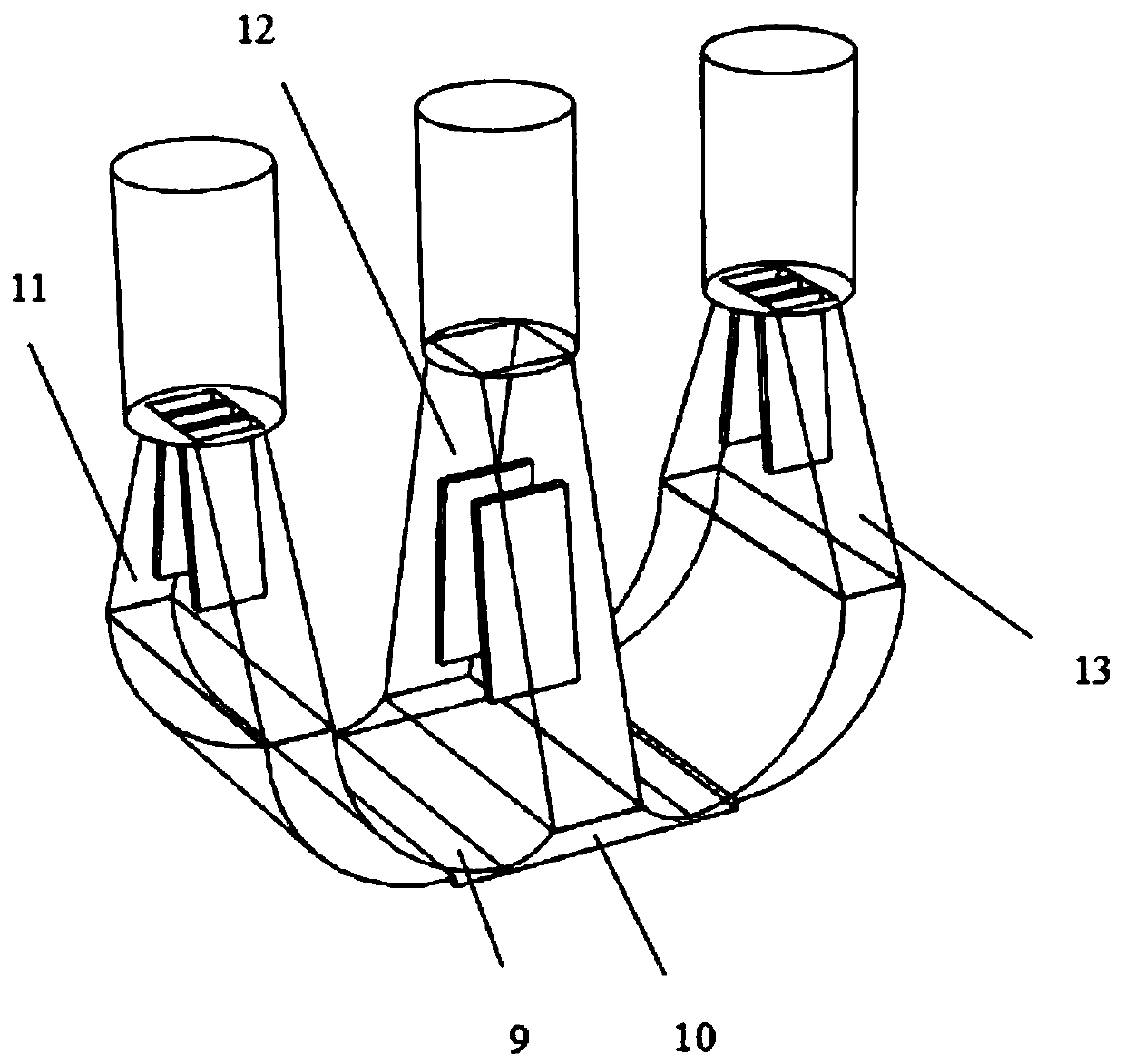

[0039] This embodiment provides a slurry removal assembly 2 for implementing the method of Embodiment 1, including a gas nozzle that can move up and down, and the gas nozzle includes a first positive pressure chamber 11, a negative pressure chamber 12 and a second positive pressure chamber arranged side by side. The bottom of the pressure chamber 13 , the first positive pressure chamber 11 and the bottom of the second positive pressure chamber 13 are respectively provided with a positive pressure slit 9 , and the bottom of the negative pressure chamber 12 is provided with a negative pressure hole 10 . During use, when the slurry removal assembly 2 reaches the top of the preparatory empty foil area 31, the air is blown out from the positive pressure slot 9 to form a positive pressure air outlet knife, and the high-speed air molecules in the positive pressure air outlet air knife impact the coating on the preparatory air foil area. The slurry on the surface of the foil area 31 ma...

Embodiment 3

[0042] This embodiment provides a slurry removal system that implements any one of the methods in Embodiment 1, including a slurry collection bucket 4, a vacuum device, and a slurry removal assembly 2. The slurry removal assembly 2 is the slurry described in Embodiment 2. The slurry removal assembly 2, the slurry removal assembly 2 is connected to the slurry collection bucket 4, and the slurry collection bucket 4 is connected to the vacuum device. Wherein, the vacuuming device includes a vacuum pipeline 8 and a vacuum pump 5 connected with the vacuum pipeline 8. When the vacuum pump 5 is turned on, the negative pressure high-speed air will suck the slurry accumulated on the surface of the preparatory empty foil area 31 into the negative pressure cavity 12, and then the vacuum pipeline will 8 enters the slurry collection bucket 4, realizes the separation of gas and slurry in the slurry collection bucket 4, and the slurry accumulated on the surface of the preparatory empty foil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com