Preparation method of starch adhesive for adhering cartons

A starch adhesive, carton technology, applied in the direction of adhesive types, starch-derived adhesives, non-polymer adhesive additives, etc., can solve the problems of low bonding strength, slow drying speed, unstable storage performance, etc. To achieve the effect of stable storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

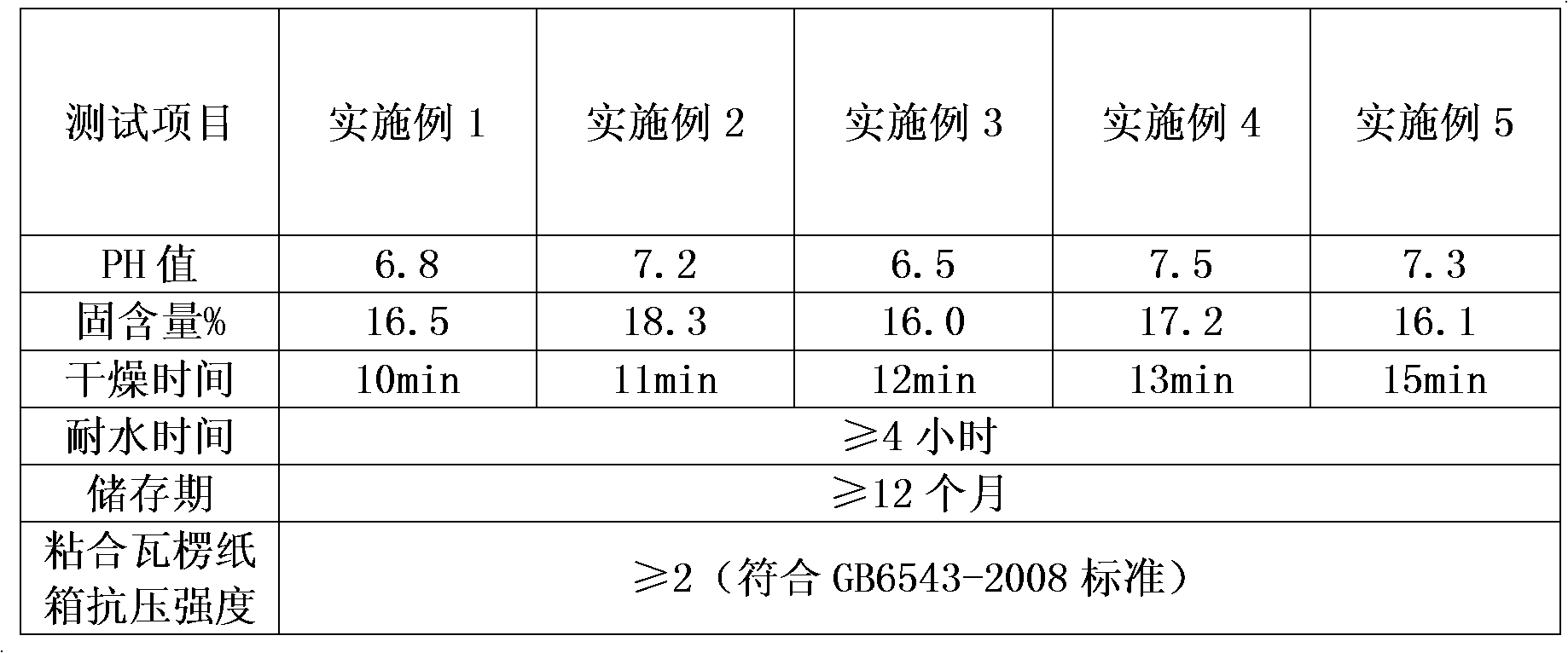

Examples

Embodiment 1

[0017] According to parts by weight, first add 500 parts of water and 100 parts of cornstarch into the reaction kettle, stir evenly, add 5 parts of hydrogen peroxide, react for 30 minutes, then slowly add 10 parts of sodium hydroxide aqueous solution with a mass percentage concentration of 30%, and stir to react 110 minutes, add 0.8 parts of borax, 0.03 parts of ferrous sulfate, 10 parts of polyvinyl alcohol, 18 parts of urea, 0.6 parts of sodium hydroxymethyl cellulose, 0.1 parts of sodium benzoate, 16 parts of inorganic bentonite and 0.6 parts of tributyl phosphate, Then stir and react for 55 minutes to obtain a starch adhesive for carton bonding.

Embodiment 2

[0019] According to parts by weight, first add 450 parts of water and 100 parts of sorghum starch into the reaction kettle, stir evenly, add 3 parts of hydrogen peroxide, react for 60 minutes, then slowly add 5 parts of sodium hydroxide aqueous solution with a mass percentage concentration of 28%, and stir for reaction 130 minutes, add 0.2 parts of borax, 0.01 parts of ferrous sulfate, 9 parts of polyvinyl alcohol, 12 parts of urea, 0.3 parts of sodium hydroxymethyl cellulose, 0.05 parts of sodium benzoate, 15 parts of inorganic bentonite and 0.5 parts of tributyl phosphate, Then stir and react for 60 minutes to obtain a starch adhesive for bonding cartons.

Embodiment 3

[0021] According to parts by weight, first add 550 parts of water and 100 parts of sweet potato starch into the reaction kettle, stir evenly, add 6 parts of hydrogen peroxide, react for 50 minutes, then slowly add 7 parts of sodium hydroxide aqueous solution with a mass percentage concentration of 29%, and stir for reaction 120 minutes, add 0.6 parts of borax, 0.04 parts of ferrous sulfate, 15 parts of polyvinyl alcohol, 17 parts of urea, 0.8 parts of sodium hydroxymethyl cellulose, 0.09 parts of sodium benzoate, 18 parts of inorganic bentonite and 0.7 parts of tributyl phosphate, Then stir and react for 65 minutes to obtain a starch adhesive for carton bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com