Feed lifting device of roll-dividing machine

A technology of separating and feeding materials, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of labor-intensive, vulnerable and large rolls, and safety of workers, so as to avoid interference effects, The effect of reducing work intensity and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

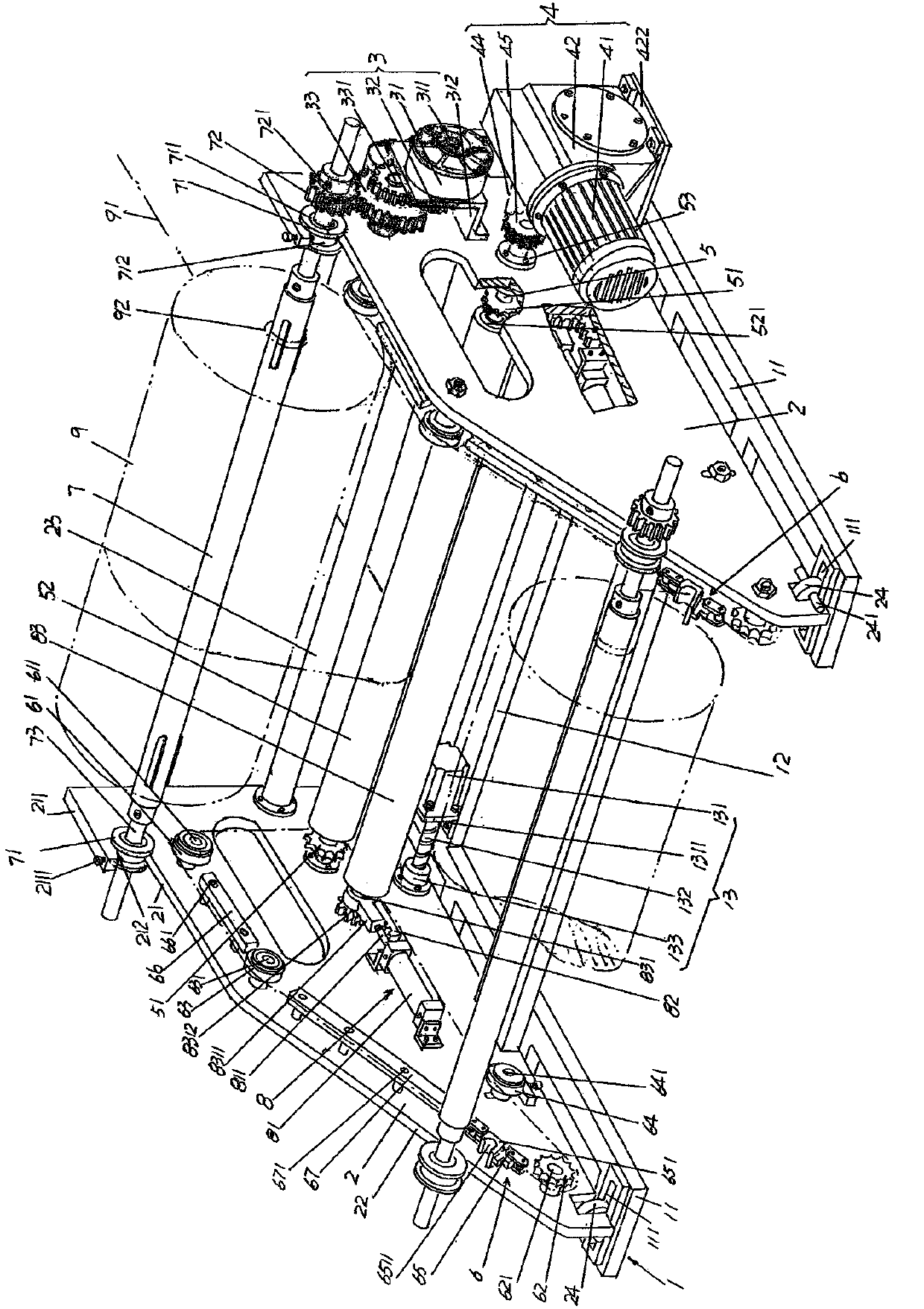

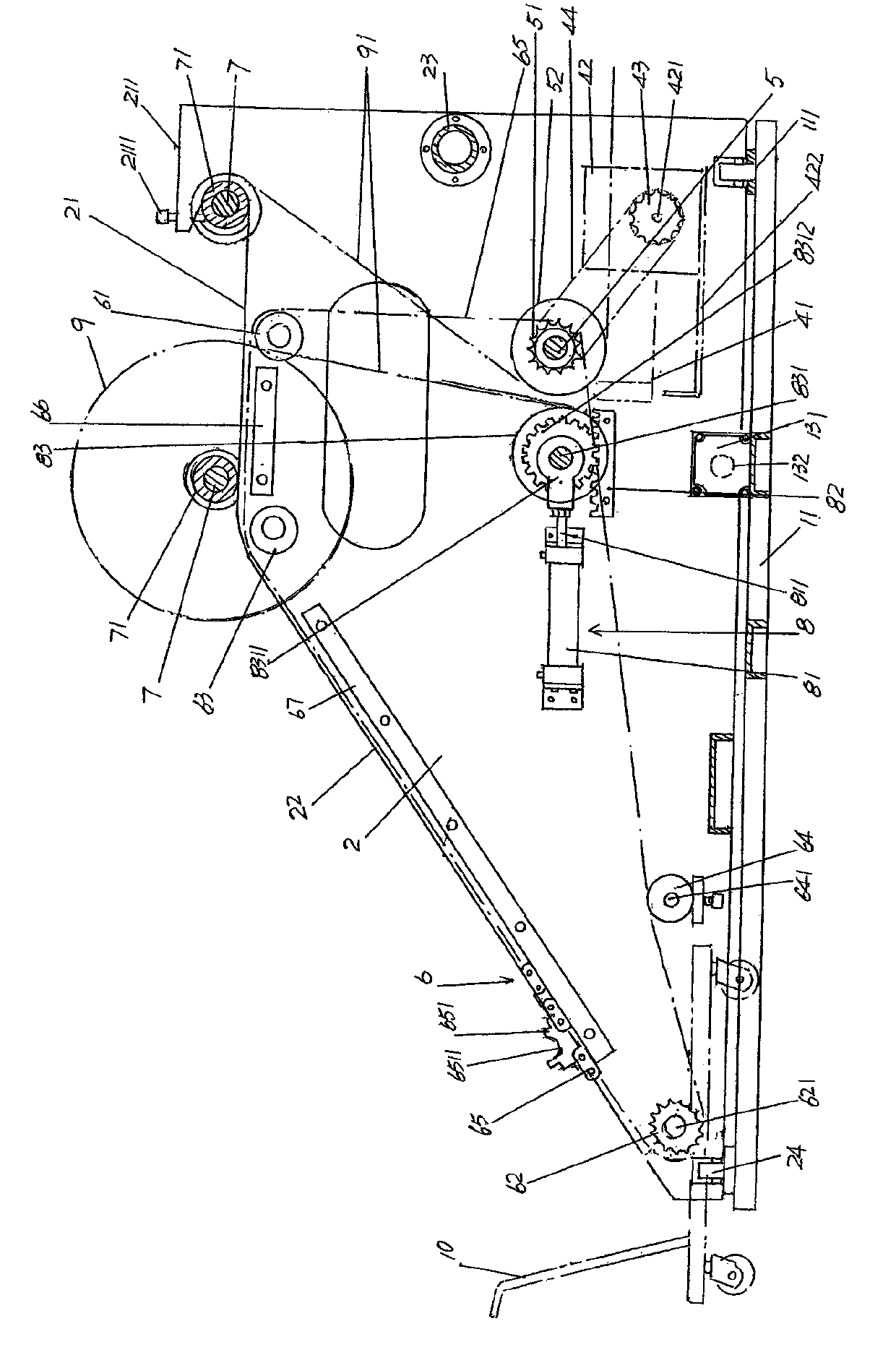

[0023] See figure 1 , A frame 1 belonging to the structural system of the sub-winding machine is given, and the frame 1 can also be called a base or a chassis. by figure 1 It can be seen that the base 1 is composed of a pair of base arms 11 parallel to each other and a base arm connecting beam 12 for connecting the pair of base arms 11 into a solid overall structure. As a preferred solution, a pair of base arms 11 The front and rear ends of the arm 11 ( figure 1 (Shown in the position state) each of the components is to provide a wallboard roller groove 111, and the function of the wallboard roller groove 111 will be described below.

[0024] A pair of wall panels 2 that also belong to the structural system of the sub-winding machine is given. The pair of wall panels 2 are set on the machine base 1 in a state of facing each other and are fixedly connected to each other, specifically: a pair of wall panels One of the wall panels in 2, that is, the wall panel on the left is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com