Ore crusher rotor disk hinge pin dismantling method

A crusher and pin shaft technology, used in welding equipment, gas flame welding equipment, grain processing, etc., can solve the problems of high labor intensity, inability to disassemble, easily damaged discs and rotors, etc., to improve dismantling efficiency and facilitate dismantling. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

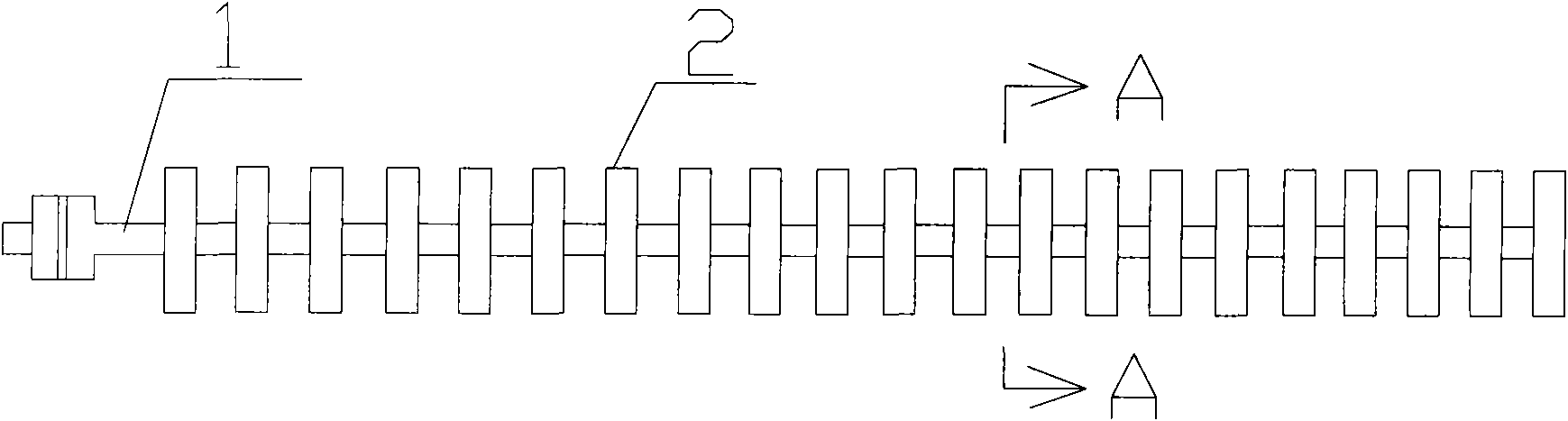

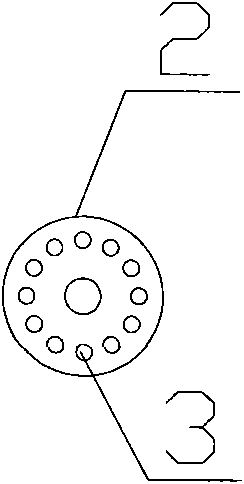

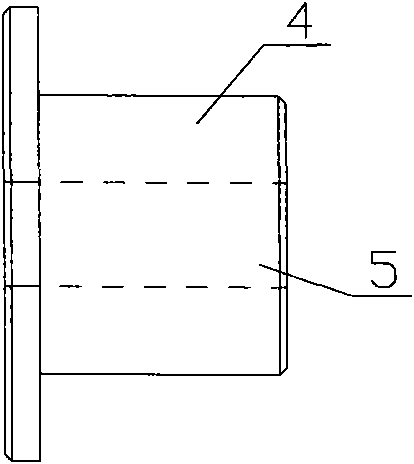

[0016] The method for dismantling the disc pins of the ore crusher rotor of the present invention comprises the rotor, a plurality of discs arranged on the rotor and a plurality of pins located in the holes of the discs. The method includes the following steps:

[0017] Step 1. Prepare an oxygen lance. The oxygen lance is made of thick-walled and small-diameter steel pipe, one end of which is connected to oxygen, and the other end is made into an oxygen injection head. The length of the oxygen lance matches the rotor;

[0018] Step 2. The rotor is placed on the bracket, and low-pressure oxygen is passed through the oxygen lance, and the oxygen lance spray head is ignited, and the oxygen lance spray head is aligned with the pin on the first row of disks to preheat, and the After the pin shaft is preheated, increase the oxygen pressure to cut the pin shaft and use high-pressure oxygen to impact and blow off the cutting residue;

[0019] Step 3, after the through hole is cut out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com