Production method for MEMS air mass flow meter with back-cavity structure

A technology of air mass flow rate and manufacturing method, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problem of affecting chip performance and yield, unstable resistance of thermistor, and poor adhesion of metal film and other problems, to achieve good line width control ability, stable resistance characteristics, and ensure the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

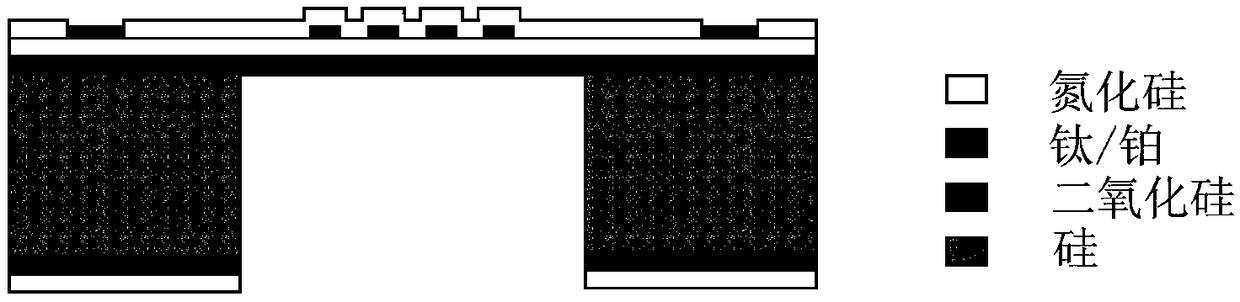

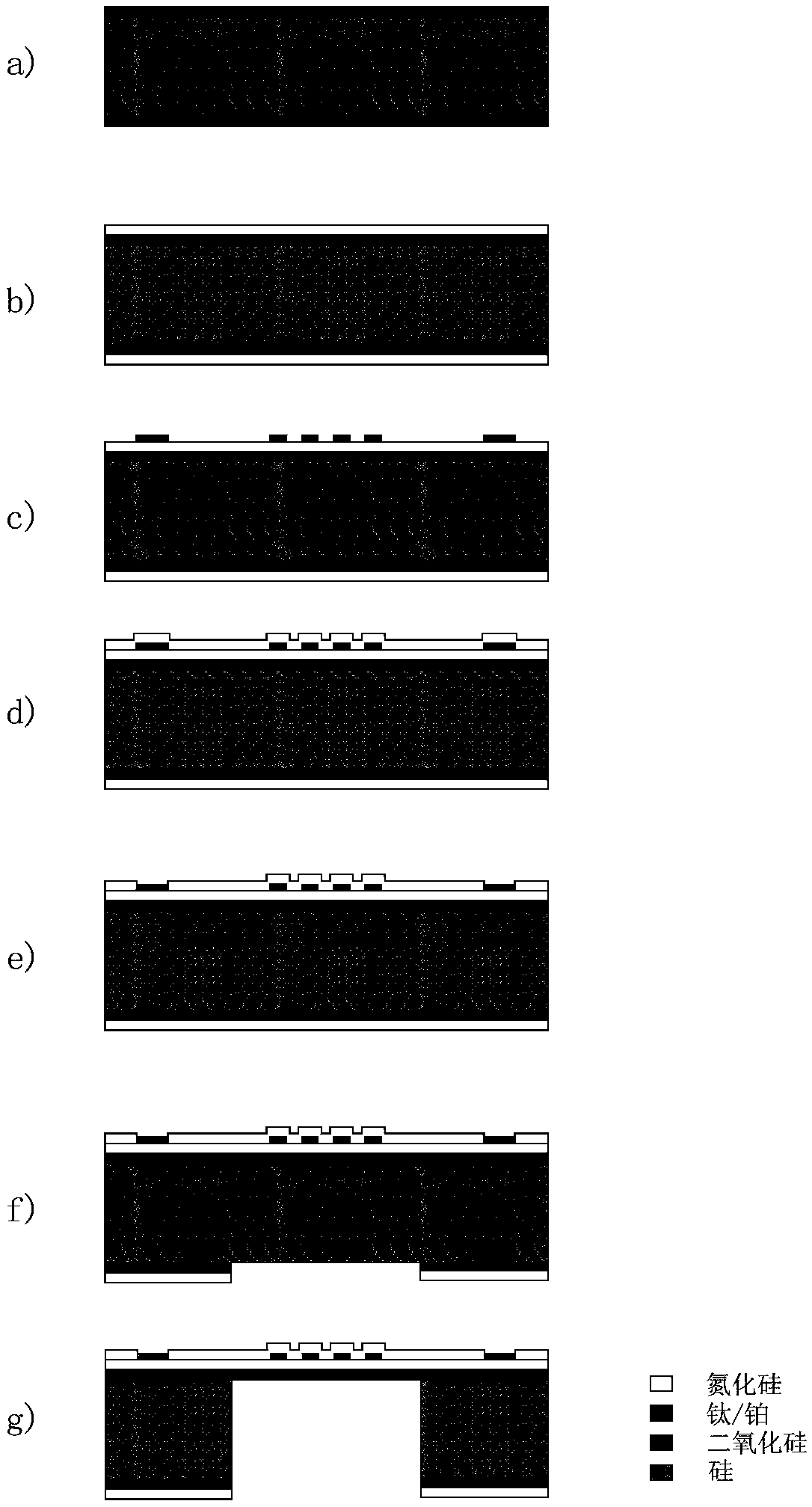

[0027] The method for manufacturing a chip of a silicon-based air mass flowmeter with a back cavity structure mainly includes the following steps: 1) forming a composite dielectric film on the surface of a silicon chip; 2) preparing a metal thermistor film pattern by a stripping method; A protective layer is grown on the surface of the metal thermistor film; 4) high-temperature annealing is performed; 5) the protective layer on the pad is removed by photoetching and corrosion, and the metal layer is exposed; 6) the back is photo-etched and dry-etched to form a back cavity structure; 7) Chip cutting into lobes to complete chip processing. The schematic diagram of the structure of the chip is as follows figure 1 shown.

[0028] Silicon wafers with a thickness of 200um-400um are selected for the processing of silicon-based air mass flowmeter chips, and the crystal orien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com