Nut huller

A nut shelling machine and nut technology, applied in the field of mechanical equipment, can solve the problems of unseparated nut shell and nut, poor shelling effect, easy blockage of the shelling machine, etc., to achieve convenient adjustment, ensure the shelling effect, The effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

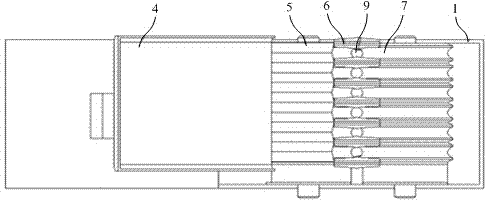

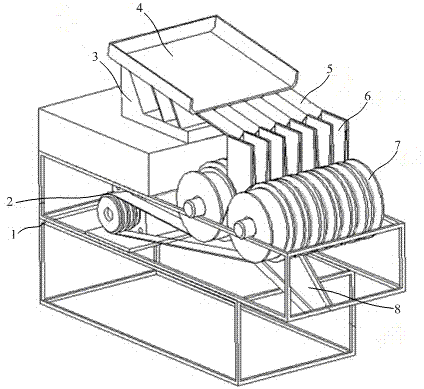

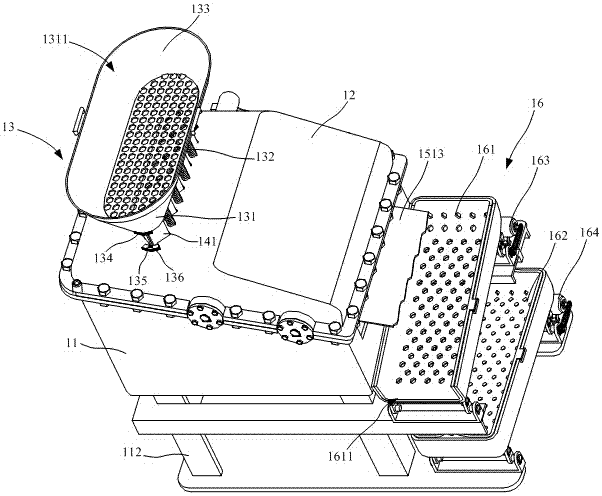

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] The nut sheller of the present invention is suitable for nuts with hard shells, such as pine nuts, hazelnuts, walnuts, chestnuts and other dried fruits. The medium protects the kernels of nuts and avoids the phenomenon that the kernels are crushed during extrusion. The extruding mechanism is used to squeeze the nuts intermittently, effectively ensuring the shelling effect of the nuts. By adjusting the motor of the cam drive device, the extruding frequency of the extruding mechanism on the nuts can be adjusted. For harder nuts, the motor speed can be adjusted. It is fast, realizes the increase of the number of squeezes on nuts per unit time, improves the cracking rate of nuts, and ensures the effect of shelling. Combining with the separation device, the nuts can be easily obtained by filtering the shells and kernels multiple times, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com