Sorghum dehulling method

A sorghum and seed coat technology, which is applied in grain husking, grain processing, application, etc., can solve the problems of sorghum peeling effect, finished product integrity, grain loss, etc., to achieve improved peeling efficiency, small grain loss rate, and grain loss. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A sorghum peeling method, comprising the following steps:

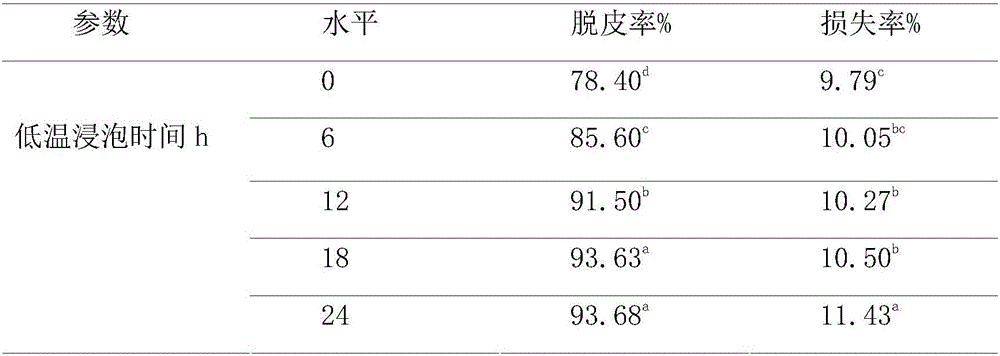

[0077] The first step is to pick clean and free sorghum raw materials, add water (just submerge the sorghum), and soak at 4°C for 12 hours;

[0078] In the second step, after soaking, filter with a sieve, centrifuge at 1000r / min for 10min with a dehydration centrifuge, and dry the sorghum;

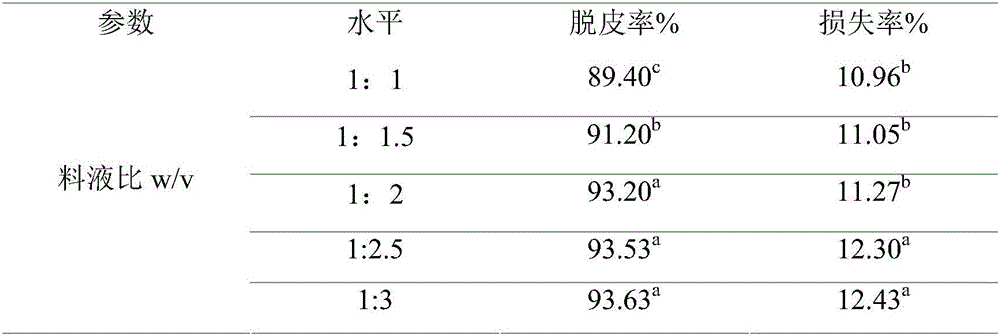

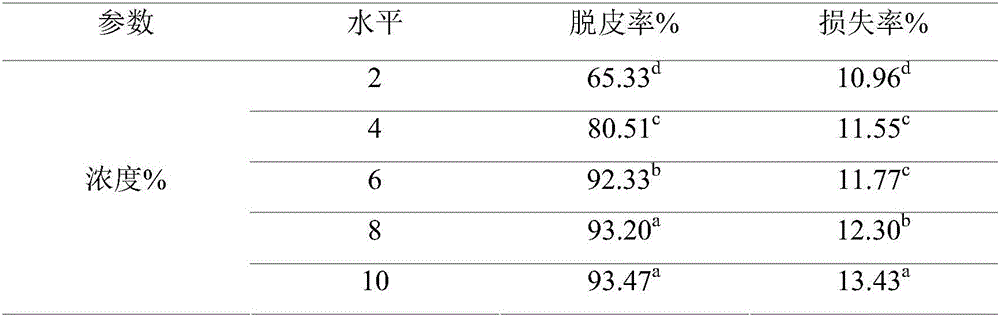

[0079] The third step is to add 1.5 ml of NaOH solution with a concentration of 6% to 1 g of sorghum according to the ratio of material to liquid: 1:1.5;

[0080] The fourth step is to place the mixed solution in a beaker, and use an ultrasonic cleaner to perform ultrasonication under the condition of a water bath. The liquid level of the water bath exceeds the mixed liquid level. During the ultrasonic process, the stirrer stirs the mixed solution synchronously, and the power of the ultrasonic cleaner is set to 80w , The temperature is set to 50°C, the stirring speed of the stirrer is 160r / min, and the ultrasonic and stirr...

Embodiment 2

[0086] A sorghum peeling method, comprising the following steps:

[0087] The first step is to pick clean and free sorghum raw materials, add water (just submerge the sorghum), and soak at 4°C for 18 hours;

[0088] In the second step, after soaking, filter with a sieve, centrifuge at 3000r / min for 10min with a dehydration centrifuge, and dry the sorghum;

[0089] The third step is to add 2ml of NaOH solution with a concentration of 8% to 1g of sorghum according to the ratio of material to liquid: 1:2;

[0090] The fourth step is to place the mixed solution in a beaker, and use an ultrasonic cleaner to perform ultrasonication in a water bath. The liquid level of the water bath exceeds the mixed liquid level. During the ultrasonic process, the stirrer stirs the mixed solution synchronously, and the power of the ultrasonic cleaner is set to 100w. , The temperature is set to 60°C, the stirring speed of the stirrer is 120r / min, and the ultrasonic and stirring time is 10min;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com