Sugarcane peeling brush

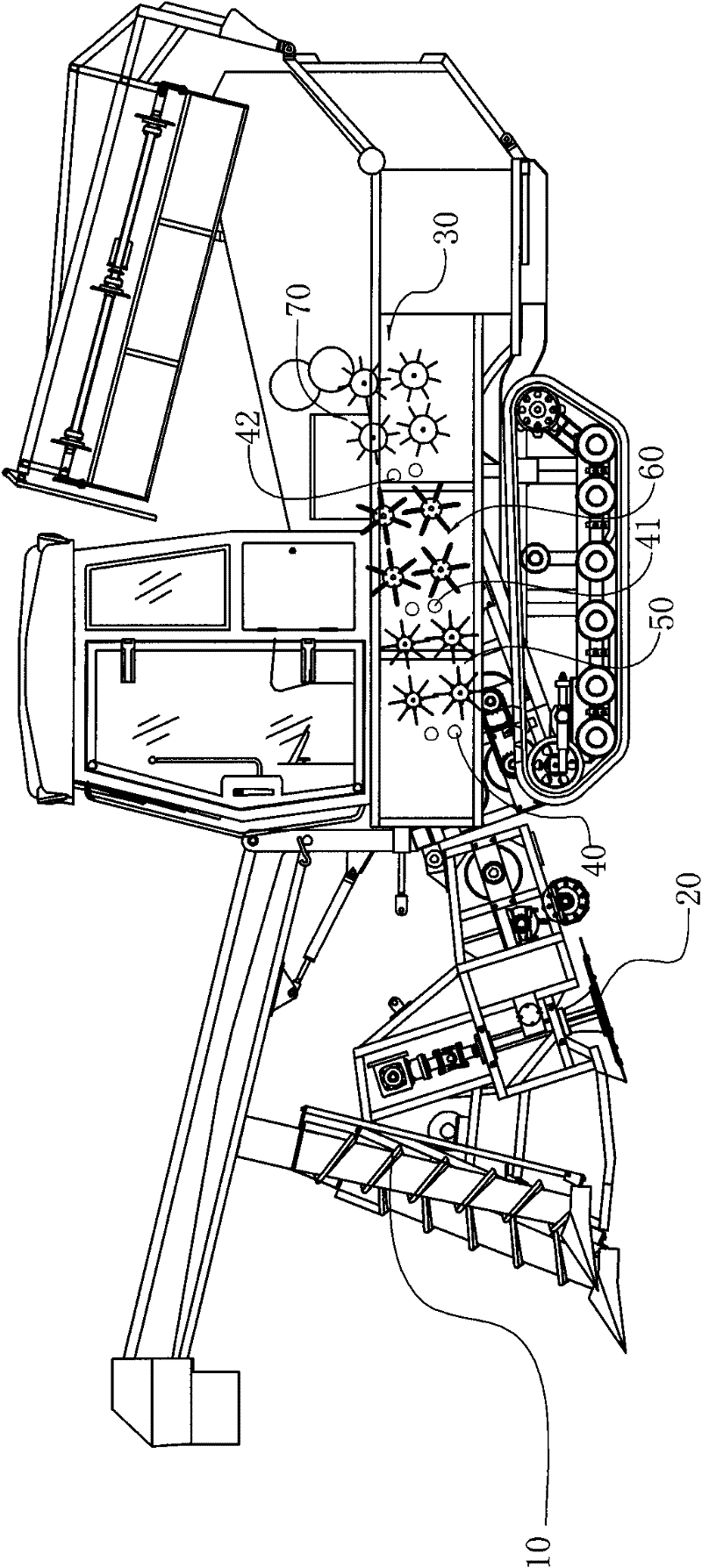

A sugarcane and leaf stripping technology, applied in cutters, agricultural machinery and implements, applications, etc., can solve the problems of unstable transmission speed, dead angle of sugarcane leaf stripping, and blockage of sugarcane in the transmission channel, so as to improve the efficiency and ensure the effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

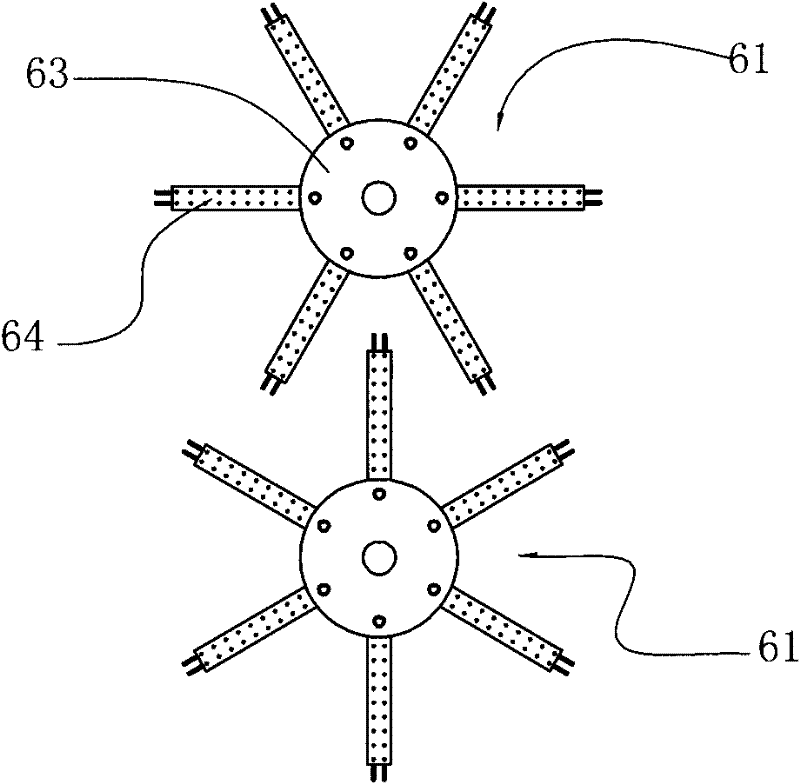

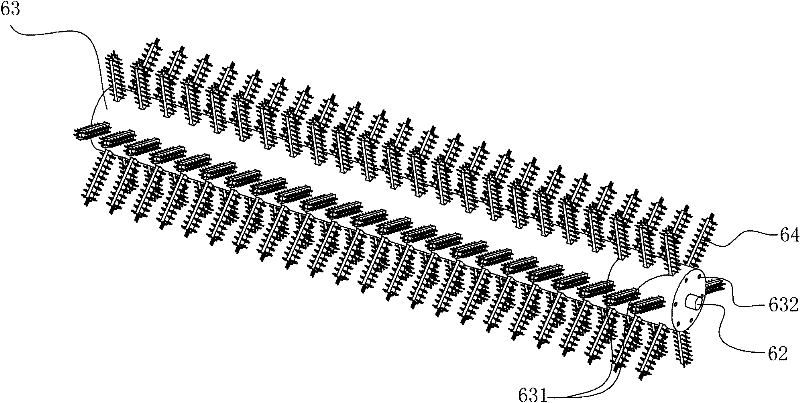

[0020] Such as Figure 2-4 As shown, the stripping device 60 includes at least a pair of stripping wheels 61 correspondingly arranged up and down on the transmission channel. The stripping wheels 61 include a central shaft 62 and a drum 63 for installation. The central shaft 62 is located at the radial center of the drum 63 and is The axis of rotation of the drum 63. The outer peripheral surface of the drum 63 is provided with a plurality of grooves 631 distributed in a matrix, and the drum 63 is also provided with pin holes 632 passing through a plurality of grooves 631 in the same axial direction, and each groove 631 is inserted with a Brush block 64, each brush block 64 also has through hole 642 on the position corresponding to pin hole 632, by inserting pin in pin hole 632 and through hole 642, just brush block 64 can be fixed on the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com