Progressive green walnut peeling equipment with auxiliary feeding function

A technology for auxiliary feeding and green walnuts, which is applied in the field of green walnuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

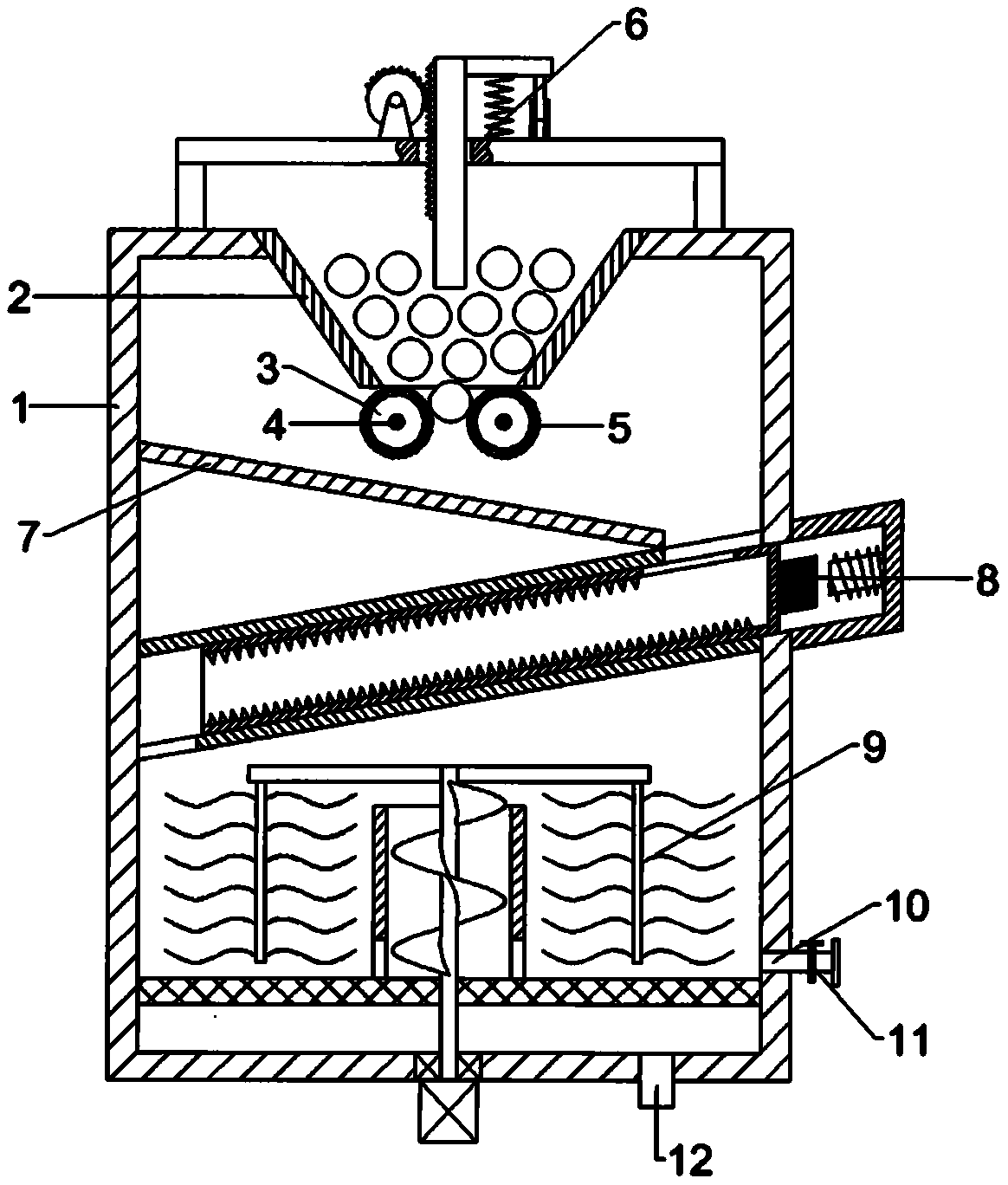

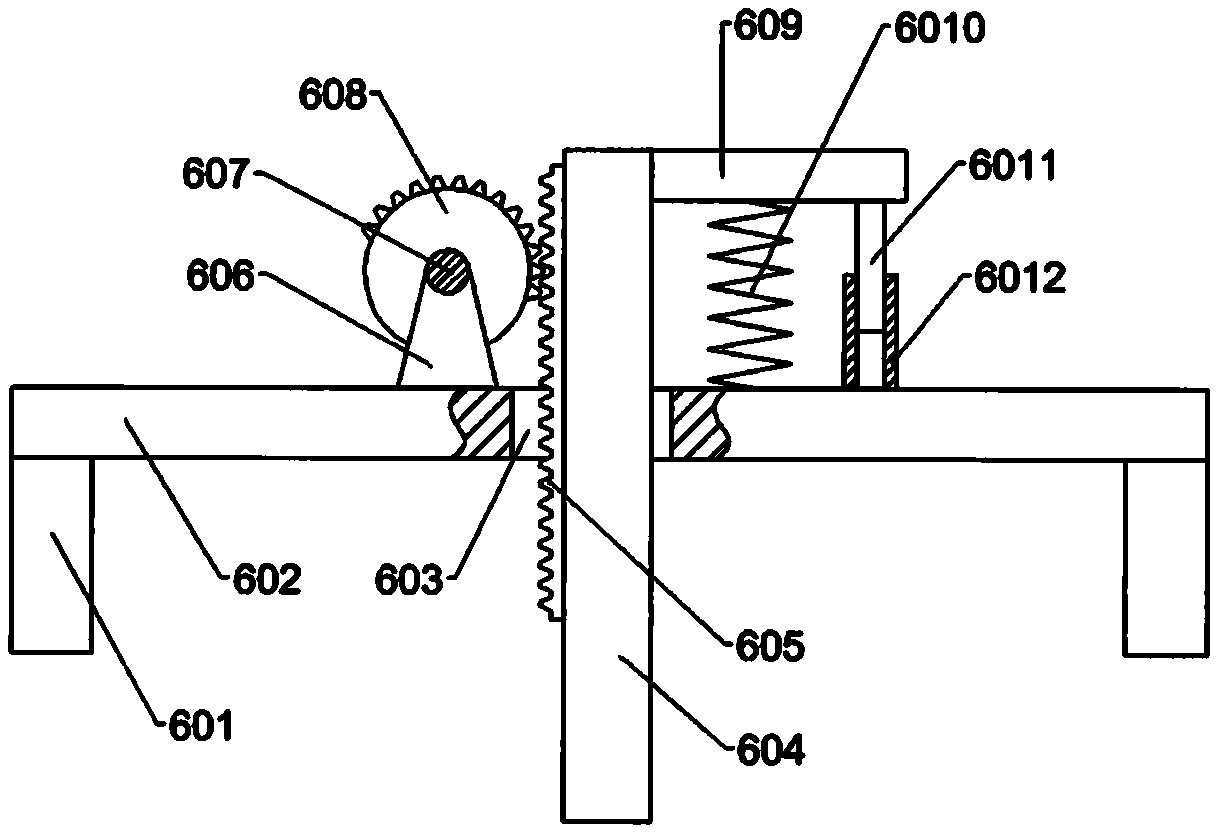

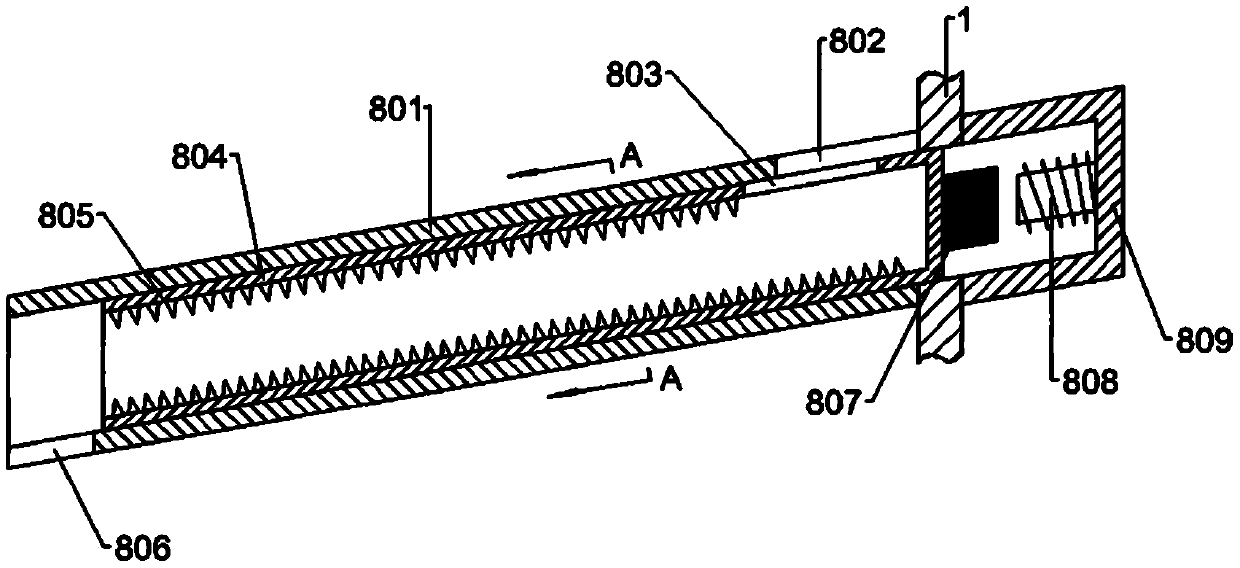

[0029] see figure 1 , in this embodiment, a progressive green walnut peeling device with auxiliary feeding function, including a housing 1, the top of the housing 1 is fixedly connected with a feeding hopper 2, and the feeding hopper 2 is up and down Small inverted circular table shape, a pair of extrusion rollers 3 are arranged at the opening of the lower side of the feed hopper 2, and the middle of the extrusion rollers 3 is fixedly connected with a horizontal shaft 4, and the two ends of the horizontal shaft 4 are erected on the side of the housing 1 On the wall, and the outer end of the horizontal rotating shaft 4 is connected with a driving device, and the outer surface of the squeeze roller is arranged with a layer of rubber layer 5, and green walnut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com