Method and device for stripping loose bodies of optical fiber preform rod

A technology of optical fiber preform and loose body, which is applied in the field of optical fiber, can solve the problems of high density of optical fiber preform loose body, high labor intensity of workers, time-consuming and laborious, etc., to improve stripping efficiency, reduce labor intensity, and ensure stripping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

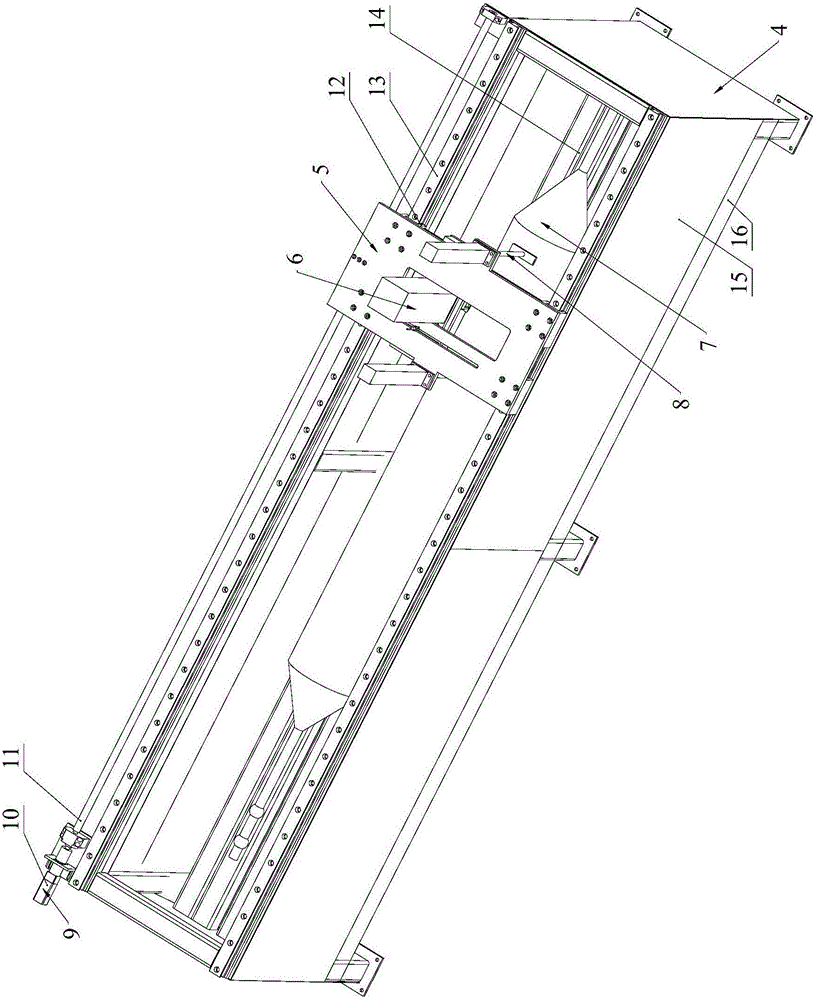

[0070] Below in conjunction with each accompanying drawing, the present invention is described in detail.

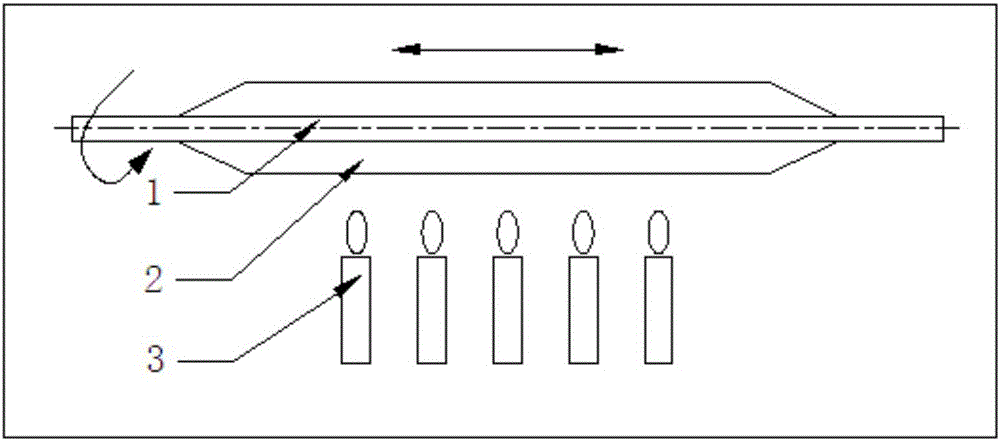

[0071] The loose body of the optical fiber preform mentioned in this application does not refer to the finished optical fiber preform, and the loose body of the optical fiber preform in this application includes a core rod and a loose body that needs to be stripped.

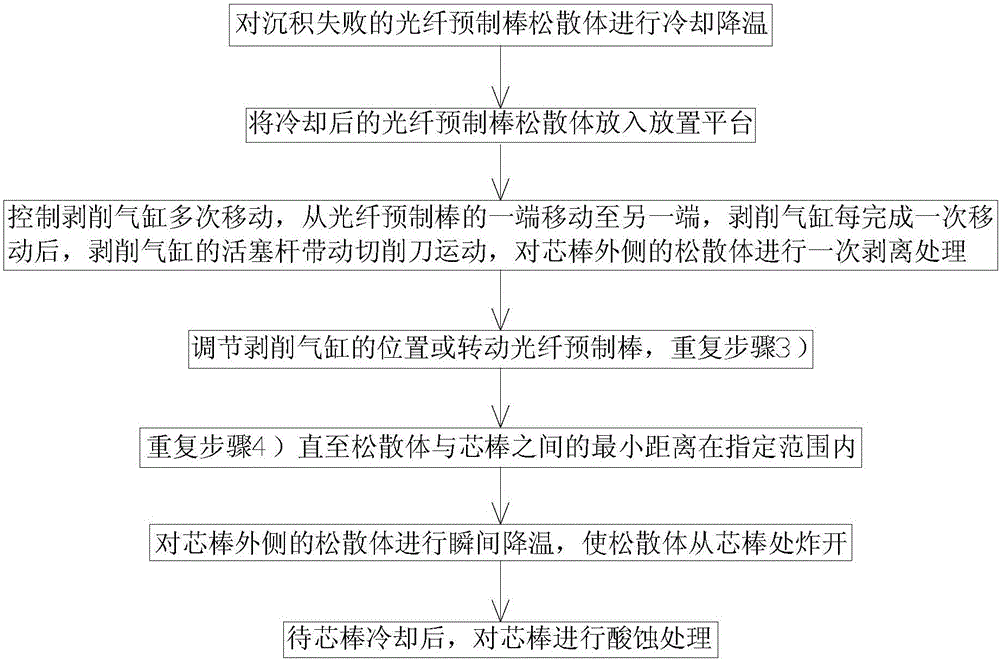

[0072] Such as figure 2 Shown, a kind of stripping method of optical fiber preform loose body, comprises the following steps:

[0073] 1) cooling down the loose body of the optical fiber preform that failed to deposit;

[0074] 2) Put the cooled optical fiber preform loose body into the placement platform;

[0075] 3) Control the multiple movements of the stripping cylinder, from one end of the loose body of the optical fiber preform to the other end. After each movement of the stripping cylinder is completed, the piston rod of the stripping cylinder drives the cutting knife to perform a stripping of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com