Tool equipment for stripping sleeve rod and sleeve based on machining

A technology of mechanical processing and tooling equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficult clamping and fixing, poor universality, and pinching sleeve rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

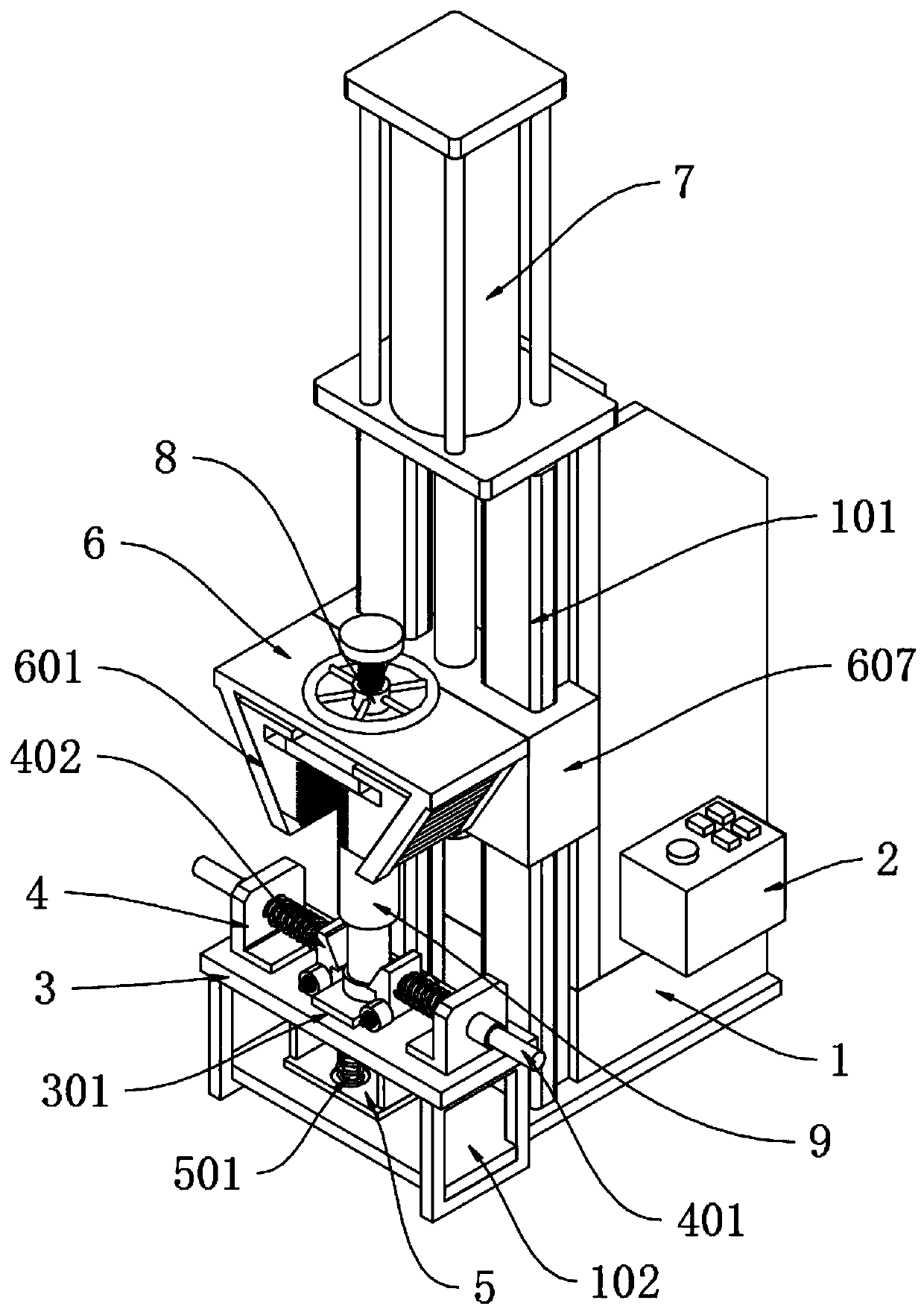

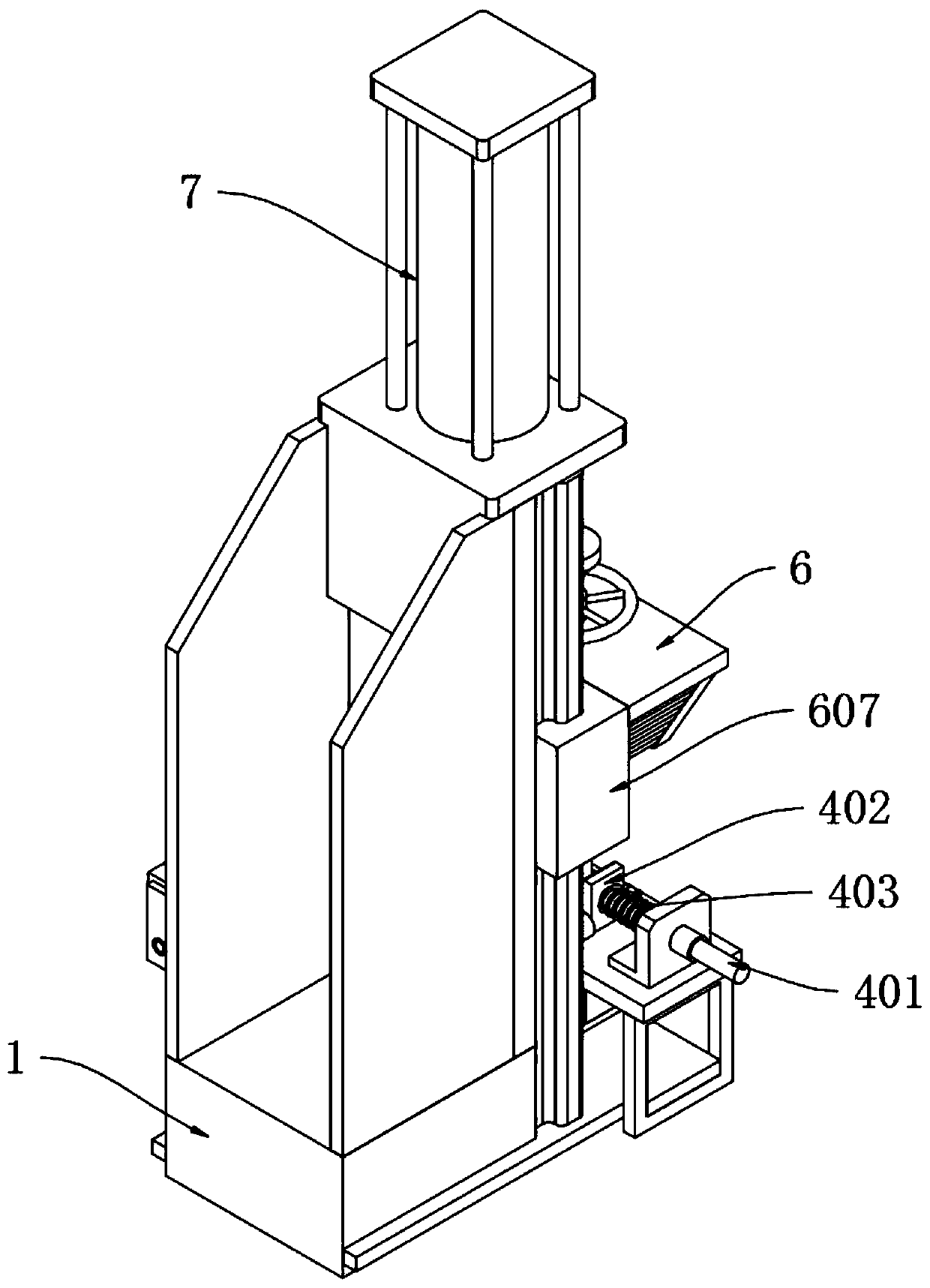

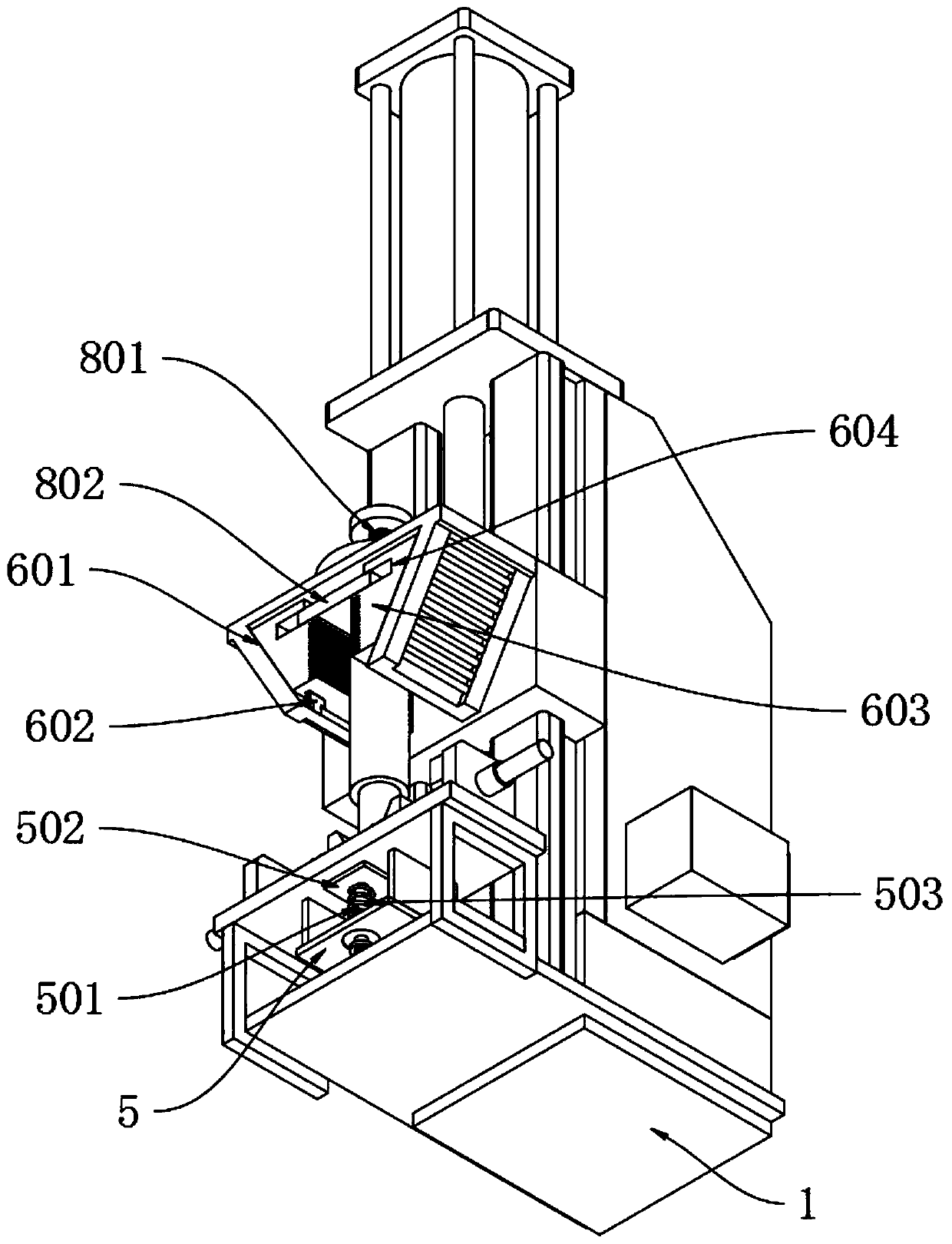

[0035] as attached figure 1 To attach Figure 8 Shown:

[0036] The present invention provides a tooling device based on the stripping of sleeve rods and sleeves for mechanical processing, including a tooling body 1; an adapter box 2 is fixedly installed on the right side wall of the tooling body 1; the lower end of the tooling body 1 is fixed vertically forward Stripping platform 3 is installed; The top plane of stripping platform 3 is symmetrically fixedly installed with horizontal clamping mechanism 4; In the stripping platform 3 between two clamping mechanisms 4, stripping seat 5 is vertically installed, and its stripping seat 5 is fixed. Installed on the bottom plane of the peeling table 3; the upper end of the peeling seat 5 is vertically inserted with a sleeve rod sleeve assembly 9;

[0037] The peeling table 3 includes an adaptive hole 301, and the middle part of the peeling table 3 is provided with a rectangular adaptive hole 301 that penetrates up and down, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com