Low-temperature photoresist reworking stripping liquid and application thereof

A stripping solution and photoresist technology, applied in the field of photoresist heavy industry stripping solution and its preparation, can solve the problems of inability to reduce costs, high cost, easy volatility, etc., and achieve improved service life, reduced harm, and stable system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

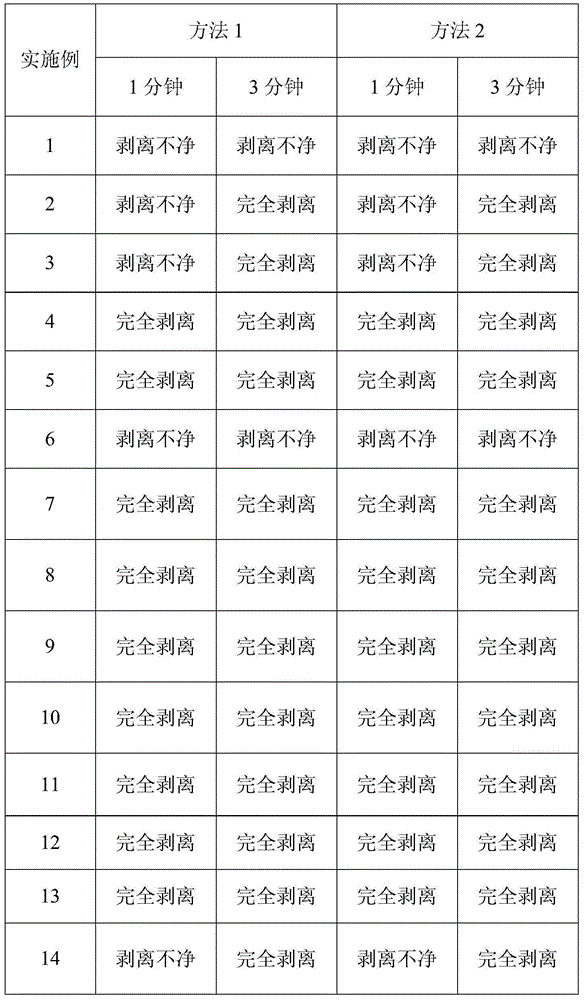

Examples

Embodiment Construction

[0025] The problem to be solved by the present invention is to provide a stripping solution with stability, compatibility, stripping effect, excellent stripping speed, low cost, long service life (large processing capacity) under the premise of not corroding the stripping substrate. After the stripping liquid is used, it can be recycled after being filtered to save cost. The comprehensive design of the formula of the stripping solution is the key to solving this problem. Specifically, each component that makes up the stripping solution and the specific type and dosage of the components will have an impact on the performance and cost of the final stripping solution.

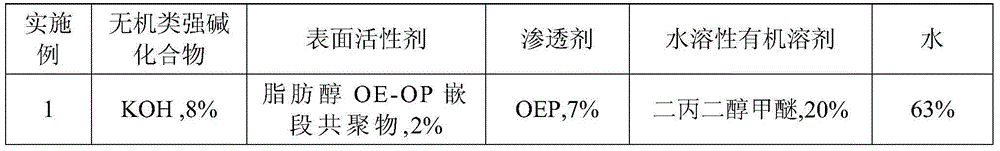

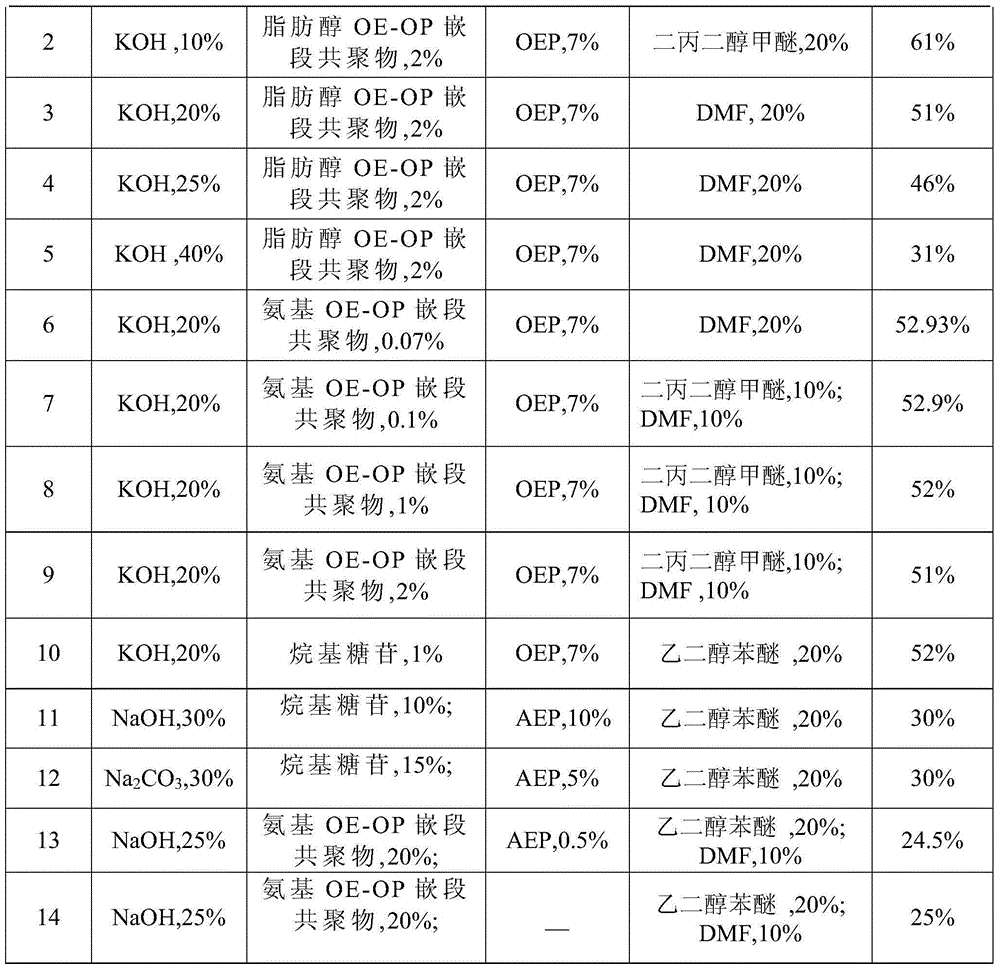

[0026] In the present invention, the stripping solution is composed of inorganic strong base compound, surfactant, penetrating agent, water-soluble organic solvent and water. Wherein, the existence of an effective amount of inorganic strong base compound can make the molecular bonds of the photoresist layer and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com