Fresh corn bract peeling apparatus

A technology of fresh corn and stripping device, which is applied in the field of agricultural machinery, can solve the problems of increased corn crushing rate, low efficiency, waste of manpower, etc., and achieves the effects of low cost, improved economic benefits, and saved manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

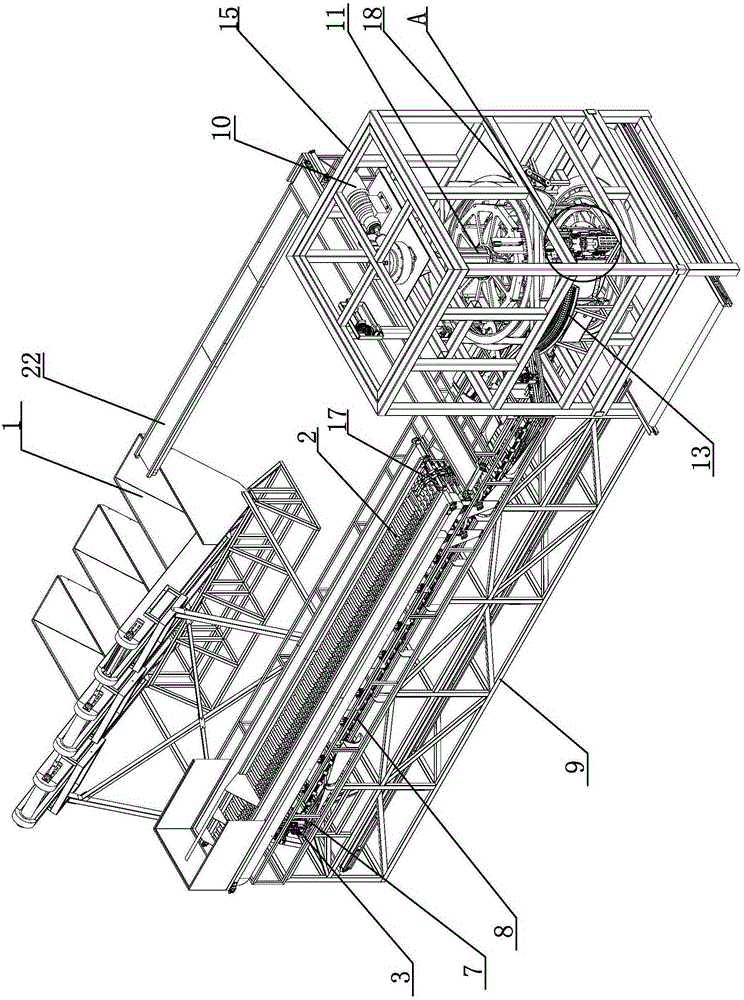

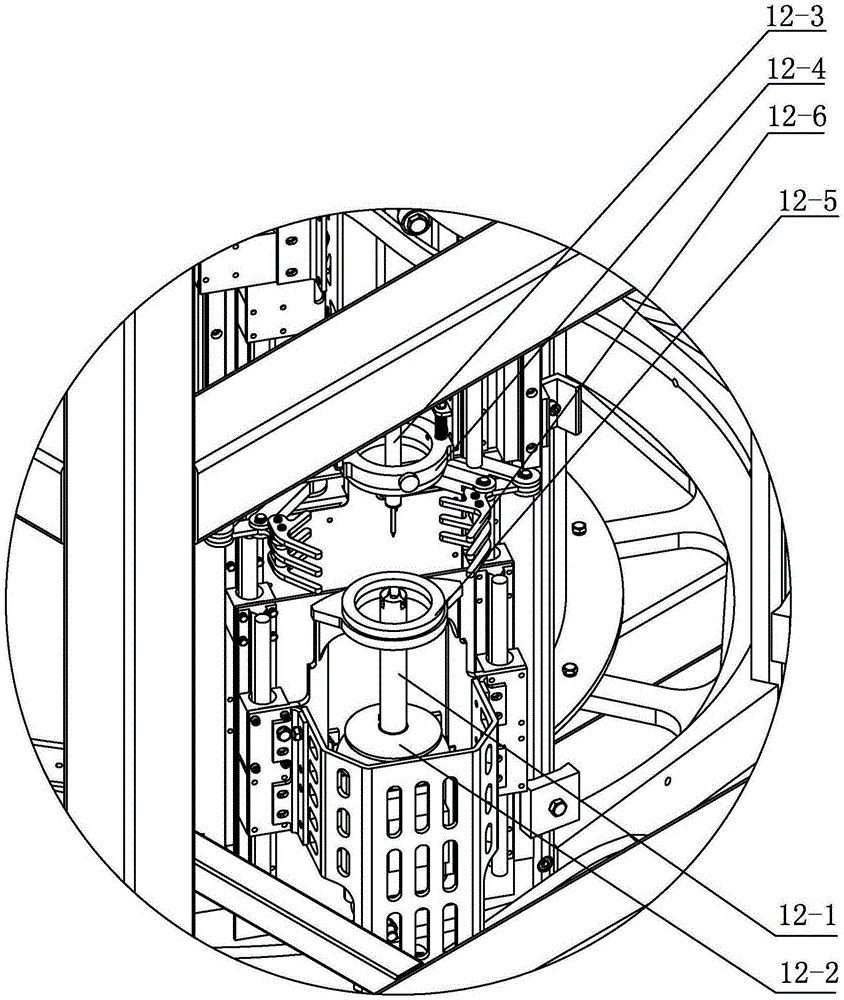

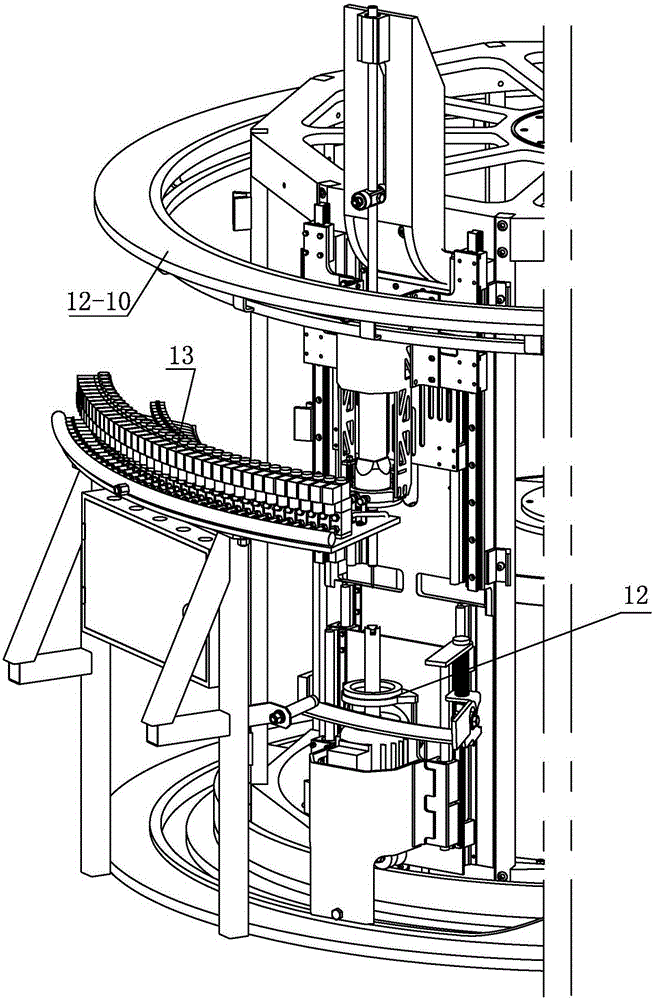

[0016] Specific implementation mode one: combine Figure 1-Figure 20 Illustrate that a fresh corn husk stripping device in this embodiment includes a main power motor 10, a main engine 11, an air blowing mechanism 13, a main engine frame 15, a residual corn leaf removal mechanism 18 and a plurality of corn clamping units 12;

[0017] The main frame 11 is installed in the main frame 15, the main power motor 10 is installed on the top of the main frame 15, the main power motor 10 is connected with the main frame 11, the blowing mechanism 13 is installed on the main frame 15, and a plurality of corn clamping units 12 along the circumference The direction is uniformly installed on the outer wall of the main machine 11, and the residual corn leaf removal mechanism 18 is installed on the main machine frame 15;

[0018] Blowing mechanism 13 comprises high-pressure gas bottle 13-1, support 13-2, main pipe 13-5, a plurality of electromagnetic valves 13-3 and a plurality of outlet air p...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 7 Note that the circular closed air curtain or arc-shaped air curtain in this embodiment is in the shape of outward expansion, straight beam or narrowing. In this way, the blowing width at the bottom of the externally expanded air curtain is 6-10 cm, which is convenient for effectively blowing all the gas onto the corn. When the circular closed air curtain or arc-shaped air curtain is in the shape of a straight beam, the width of the air curtain is 5-7cm, and a plurality of air outlet ducts 4 are arranged in one or more rows in an arc shape, thereby ensuring When the shape of the air curtain is a straight beam, it is convenient to blow off the ears of corn that are close to the corn kernels and the gaps between the corn kernels. The width of the lower end of the closing-shaped air curtain is 3-6cm, which is convenient for blowing and blowing together. In addition to the shape of the circular closed air curtain or a...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 8 Note that one end of the plurality of air outlet ducts 13 - 4 in this embodiment is an air outlet duct bent downward. Such setting is convenient for ensuring downward blowing and blowing effect. When this embodiment is in use, the shape of the air outlet duct is divided into: a horizontal pipe section, an inclined pipe section and a vertical pipe section. The horizontal pipe section is easy to connect with the solenoid valve, the inclined pipe section plays a transitional role for blowing air, and the vertical pipe section realizes downward blowing. The structure is simple, the connection is smooth, and the gas can be blown out smoothly. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com