Method for stripping laminated inorganic material

A technology of inorganic materials and layers of inorganic materials, applied in inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve the problems of long time required, weakened bonding force, reduced particle size, etc., to achieve faster reaction rate, heating Fast, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Preparation of kaolin-urea intercalation complex

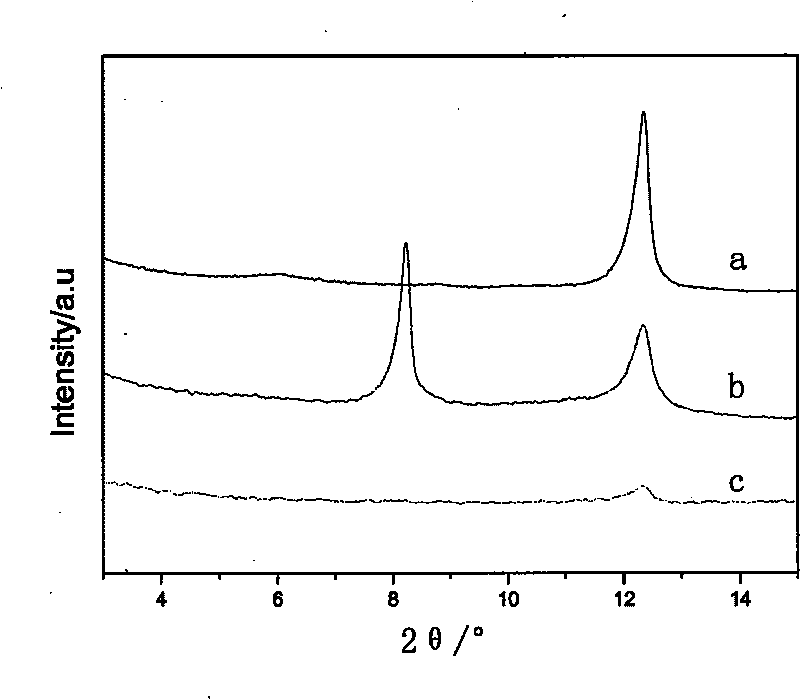

[0023] Weigh 5g of kaolin, put it in a flask, then add 50ml of saturated urea solution (concentration is about 13M), stir for 3d under 65°C water bath condition, after centrifugation, wash the urea remaining on the surface of kaolin with absolute ethanol, and then After centrifugal separation, dry under vacuum at 60°C to obtain the urea-kaolin intercalation complex with an intercalation rate of 65%.

[0024] The second step: rapid stripping of kaolin by ultrasonic acid leaching decomposition method

[0025] Add 1 g of the kaolin-urea intercalation complex prepared above into the acidic solution, and immediately perform ultrasonic treatment for 5 minutes after mixing to make the kaolin flake off naturally.

[0026] Step Three: Finished Product

[0027] The kaolin obtained above was repeatedly washed with absolute ethanol for 2 to 3 times, and then dried at 60° C. to obtain an exfoliated product of kaolin. It i...

Embodiment 2

[0029] Step 1: Preparation of hydrotalcite-OBSH intercalation complex

[0030] (1) Take 2 g of hydrotalcite and evenly disperse it in 20 ml of deionized water, add hydrochloric acid dropwise to adjust the pH of the liquid to 4.

[0031] (2) Dissolve 2 g of OBSH solid in 40 ml of DMSO to form a clear solution.

[0032] (3) Mix the two solutions prepared in steps 1 and 2 with each other, stir in a constant temperature water bath at 40°C for 24 hours, centrifuge and dry the resulting precipitate for 24 hours to obtain the final white product, which is the hydrotalcite-OBSH intercalation complex .

[0033] Step 2: Quickly peel off the hydrotalcite

[0034] Heat 1 g of the hydrotalcite-OBSH intercalation compound prepared above in a microwave oven to rapidly decompose the OBSH and naturally peel off the hydrotalcite.

[0035] Step Three: Finished Product

[0036] The hydrotalcite obtained above was repeatedly washed with absolute ethanol for 2 to 3 times, and then dried at 60° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com