Water-dispersed acrylic acid series sticker composition and adhesion sheet and preparation method thereof

An acrylic emulsion, acrylic technology, applied in the directions of non-polymer adhesive additives, adhesives, ester copolymer adhesives, etc., can solve the balance of undisclosed fixing effect, adhesion, surface adhesion, and re-peelability Good adhesive sheet and other problems, to achieve the effect of easy re-peelability, good adhesion to curved surfaces, and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

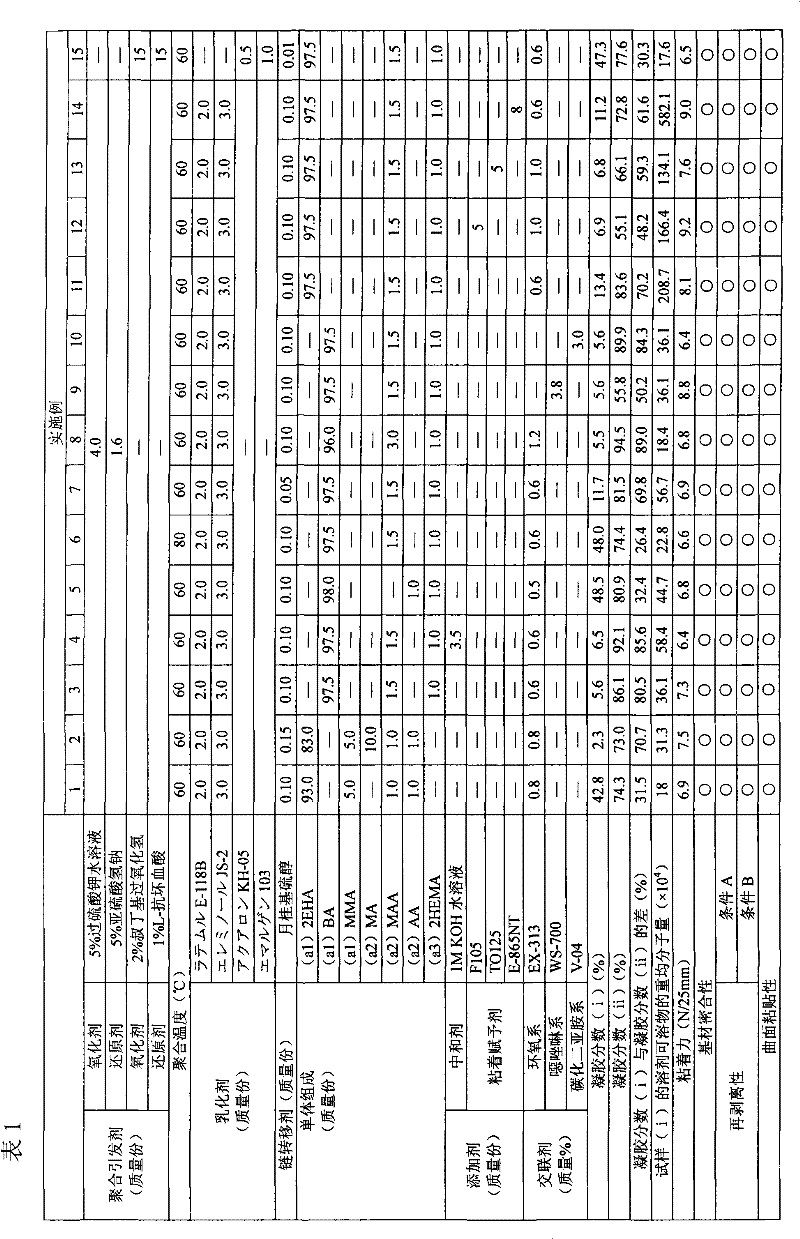

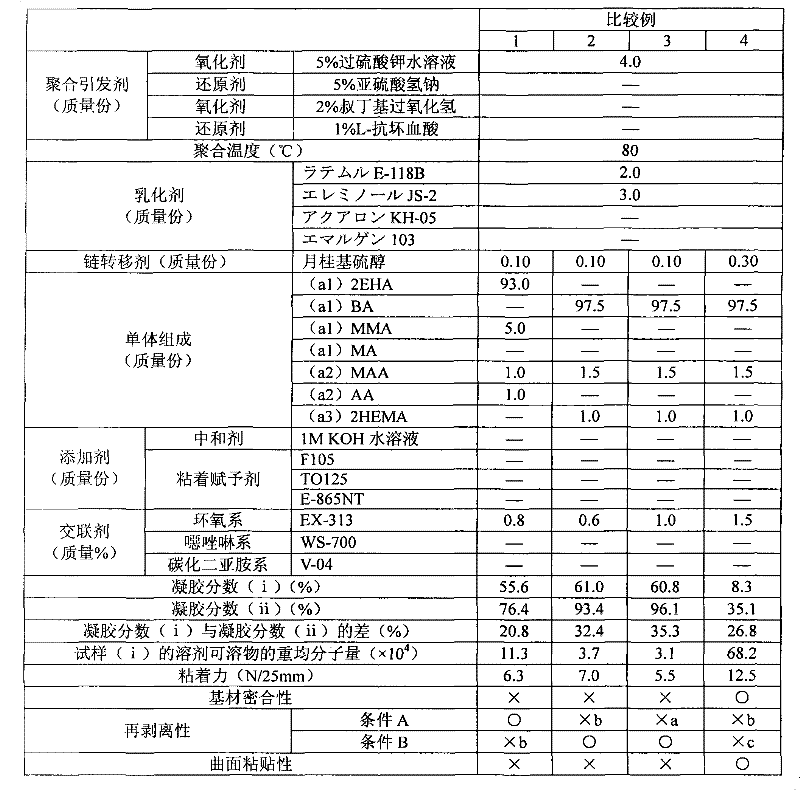

Embodiment 1

[0167] 93 parts by mass of 2-ethylhexyl acrylate (2EHA) and 5 parts by mass of methyl methacrylate (MMA) as components of (a1) were added to a container with a stirrer, a thermometer, and a dropping funnel, and as (a2) 1.0 parts by mass of methacrylic acid (MAA), 1.0 parts by mass of acrylic acid (AA), 0.1 part by mass of lauryl mercaptan as a chain transfer agent, and sodium alkylpolyoxyethylene ether sulfate [anion type non-reactive emulsifier "Latemol E-118B", manufactured by Kao Corporation] 2 parts by mass, sodium allyl alkyl sulfosuccinate [anionic non-reactive emulsifier "Eleminol JS-2", Sanyo Kasei Co., Ltd.] 3 parts by mass and 56 parts by mass of ion-exchanged water were stirred at room temperature to prepare an emulsion of an unsaturated monomer mixture in advance.

[0168] In addition, 28 parts by mass of ion-exchanged water was added to a reaction device having a stirrer, a reflux condenser, a thermometer, a nitrogen gas introduction pipe, and a dropping funnel, n...

Embodiment 2

[0173] Except that the amount of 2EHA is 83 parts by mass, the amount of lauryl mercaptan is 0.15 parts by mass, and 10 parts by mass of methyl acrylate (MA) is added as the component (a1), the operation is carried out according to Example 1 to produce baseless Adhesive sheets and adhesive sheets were used for the same measurement and evaluation.

Embodiment 3

[0175] In addition to 97.5 parts by mass of n-butyl acrylate (BA) as the component (a1), 1.0 parts by mass of 2-hydroxyethyl methacrylate (2-HEMA) as the component (a3), and 1.5 parts by mass of MAA as the unsaturated mono The composition of the body mixture, and make relative to 100 mass parts of the emulsion polymerization composition, the consumption of epoxy-based crosslinking agent is 0.6 mass parts, operate according to Example 1, make no substrate adhesive sheet and adhesive sheet, carry out Same measurement and evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com