Carbon nanotube assembly

a carbon nanotube and assembly technology, applied in the direction of manufacturing tools, transportation and packaging, coatings, etc., can solve the problems of difficult insertion of cnts into other structures, difficulty in manipulating individual cnts, and problematic use of cnts as structural components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

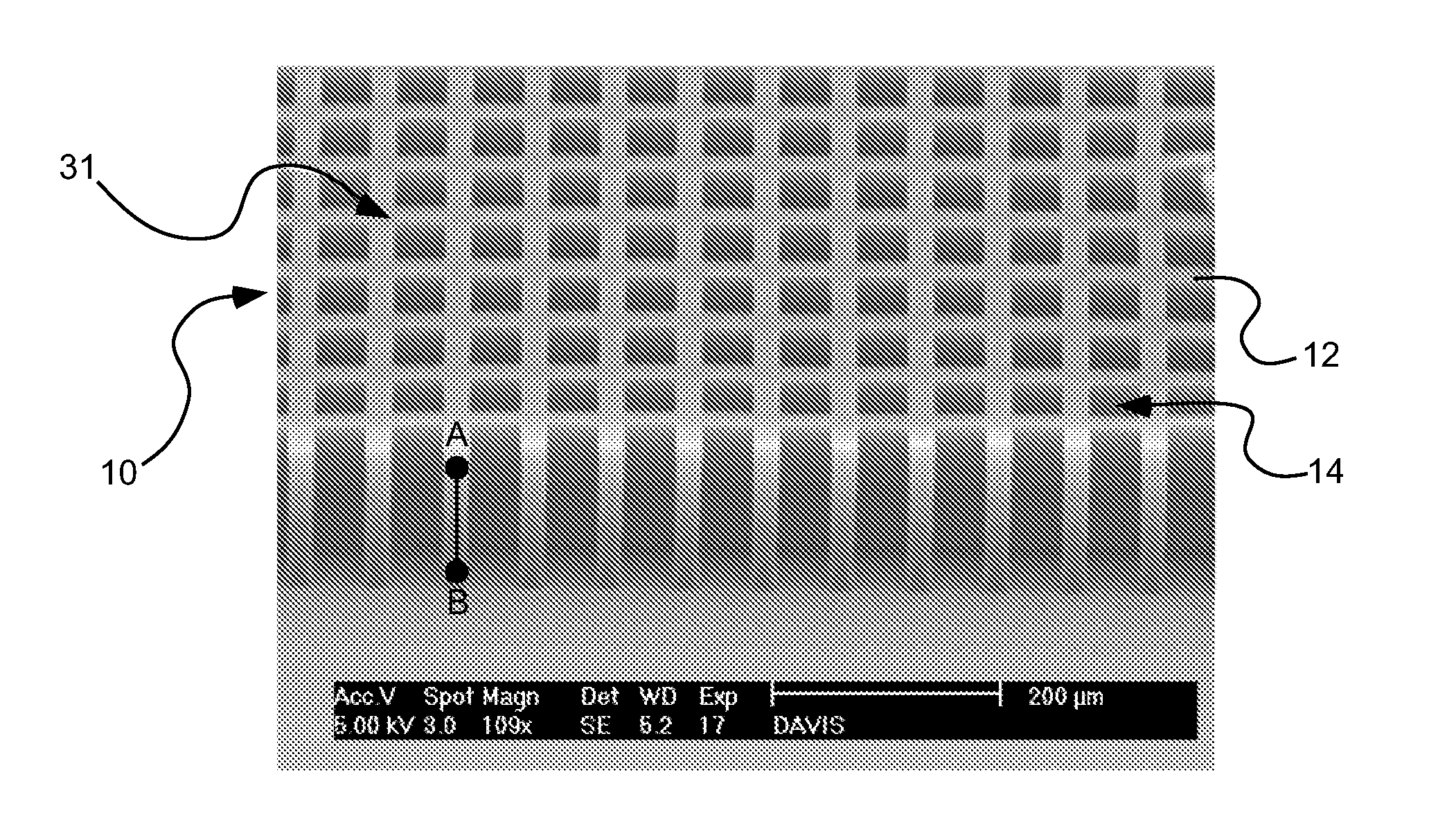

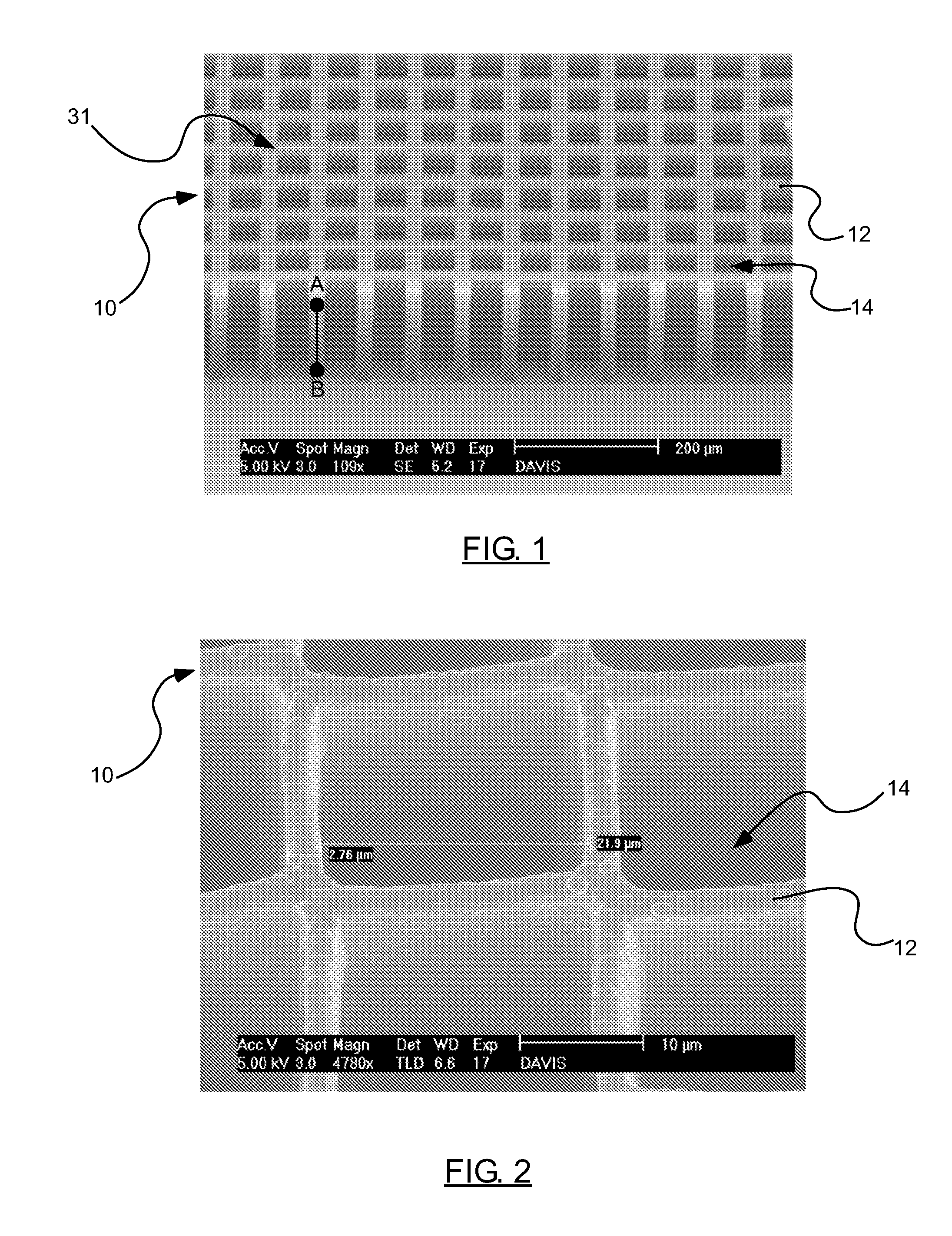

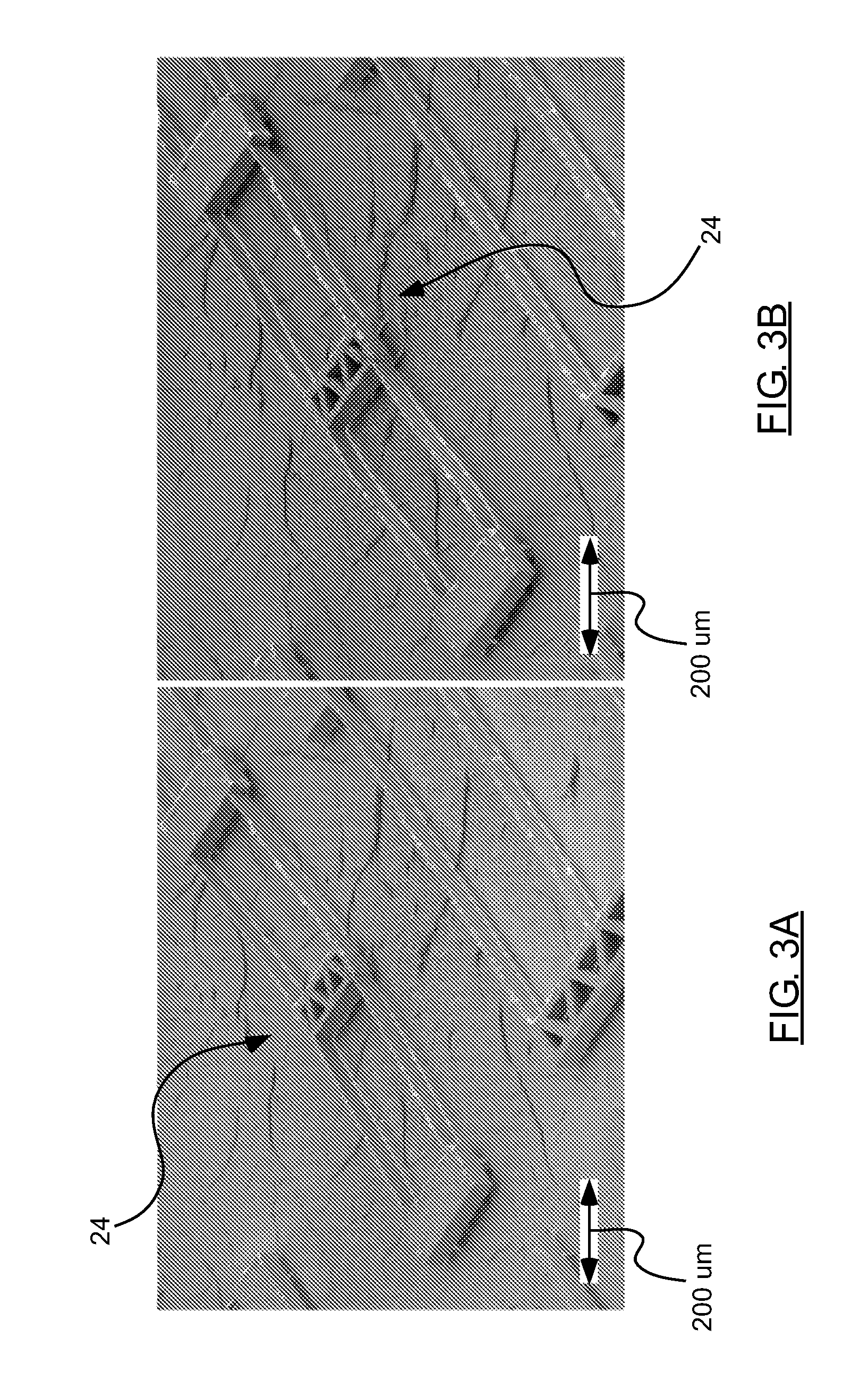

[0018]The following detailed description of exemplary embodiments of the invention makes reference to the accompanying drawings, which form a part hereof and in which are shown, by way of illustration, exemplary embodiments in which the invention may be practiced. While these exemplary embodiments are described in sufficient detail to enable those skilled in the art to practice the invention, it should be understood that other embodiments may be realized and that various changes to the invention may be made without departing from the spirit and scope of the present invention.

[0019]In describing and claiming the present invention, the following terminology will be used.

[0020]As used here, the term “vertically grown” is used to describe nanotubes that are generally grown upward from a substrate or catalyst material. While such nanotubes exhibit a generally vertical attitude, it is to be understood that such tubes are not necessarily perfectly straight or perfectly upright, but will te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com