Biomass glycol refining method

A biomass ethylene glycol and refining method technology, applied in the field of biomass ethylene glycol refining, can solve the problems of cumbersome process, high energy consumption, and low adsorption capacity of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

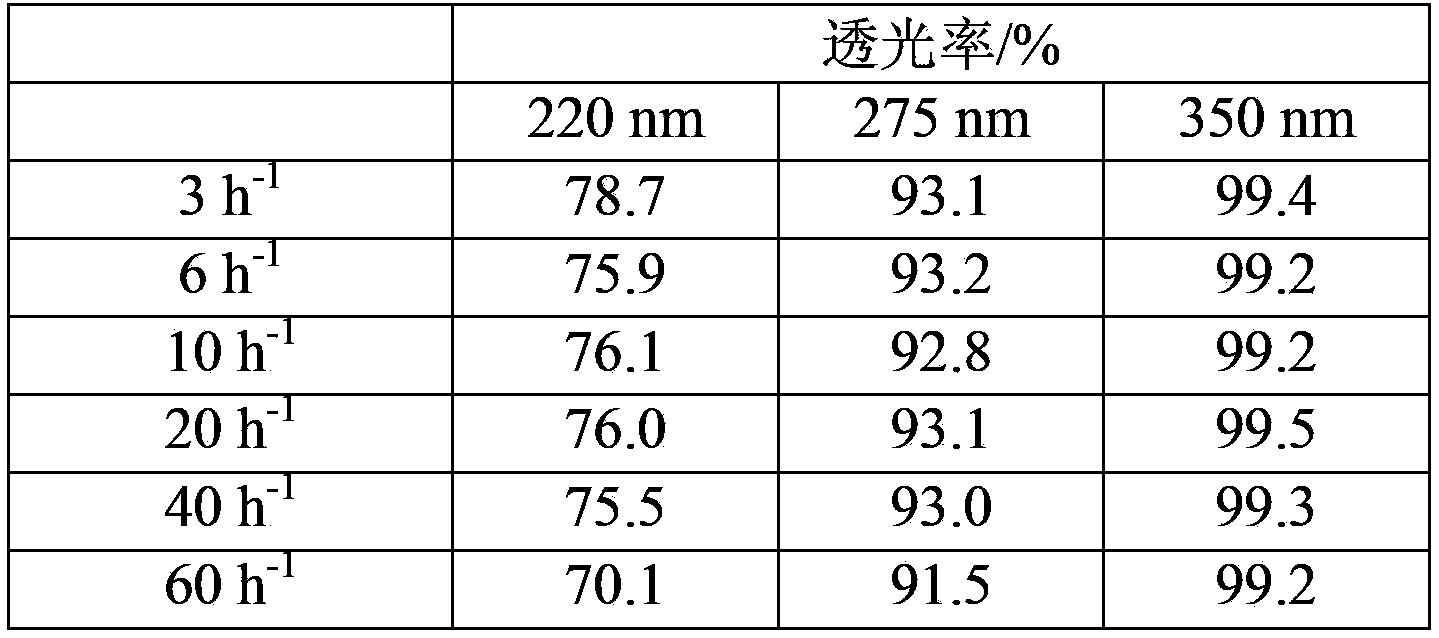

[0022] Catalytic conversion experiment: put 5g of catalyst into a fixed-bed reactor, in situ reduction with hydrogen at 200-500°C for 1 hour, then lower the temperature to 60-150°C, stabilize for 30 minutes, and then use a high-pressure pump to feed crude biomass ethylene glycol raw materials , mass space velocity WHSV is controlled at 0.1-100h -1 , the hydrogen air velocity GHSV is controlled at 100-10000h -1 . The reacted ethylene glycol was separated by gas and liquid, and then taken out for ultraviolet light transmittance analysis, and the light transmittance at 220nm, 275nm and 350nm was detected.

Embodiment 2

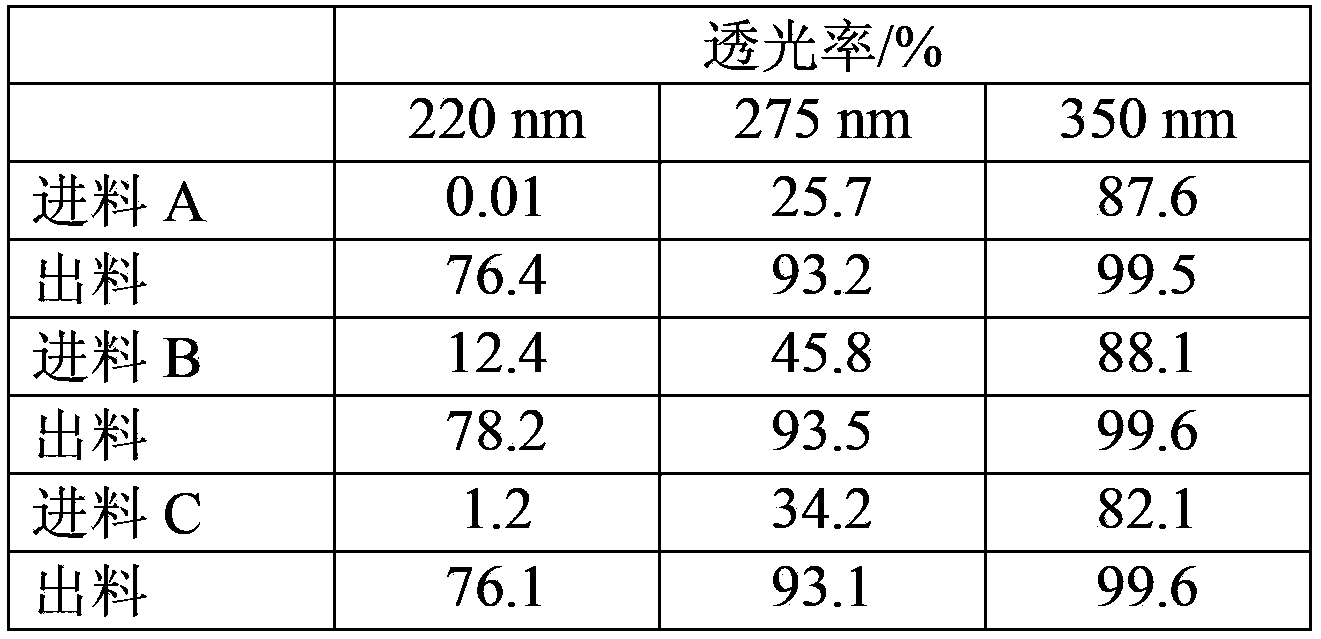

[0024] The refining results of different biomass ethylene glycol (Table 1), the reaction conditions are the same as in Example 1, the catalyst is 2% Ru / AC, and the volume space velocity of crude biomass ethylene glycol is 6h -1 , 90°C, hydrogen pressure is 5MPa, hydrogen volume flow rate is 1000h -1 .

[0025] Raw material A is derived from ethylene glycol obtained by catalytic hydrocracking of sorbitol.

[0026] Raw material B is derived from ethylene glycol obtained by catalytic hydrocracking of glucose.

[0027] Raw material C is derived from ethylene glycol obtained by catalytic hydrocracking of cellulose.

[0028] Table 1 Refining results of crude biomass ethylene glycol from different sources

[0029]

[0030] As shown in Table 1, although the initial light transmittance of biomass ethylene glycol varies greatly, the ultraviolet light transmittance of ethylene glycol after catalytic hydrogenation refining is significantly improved, and the light transmittance meets...

Embodiment 3

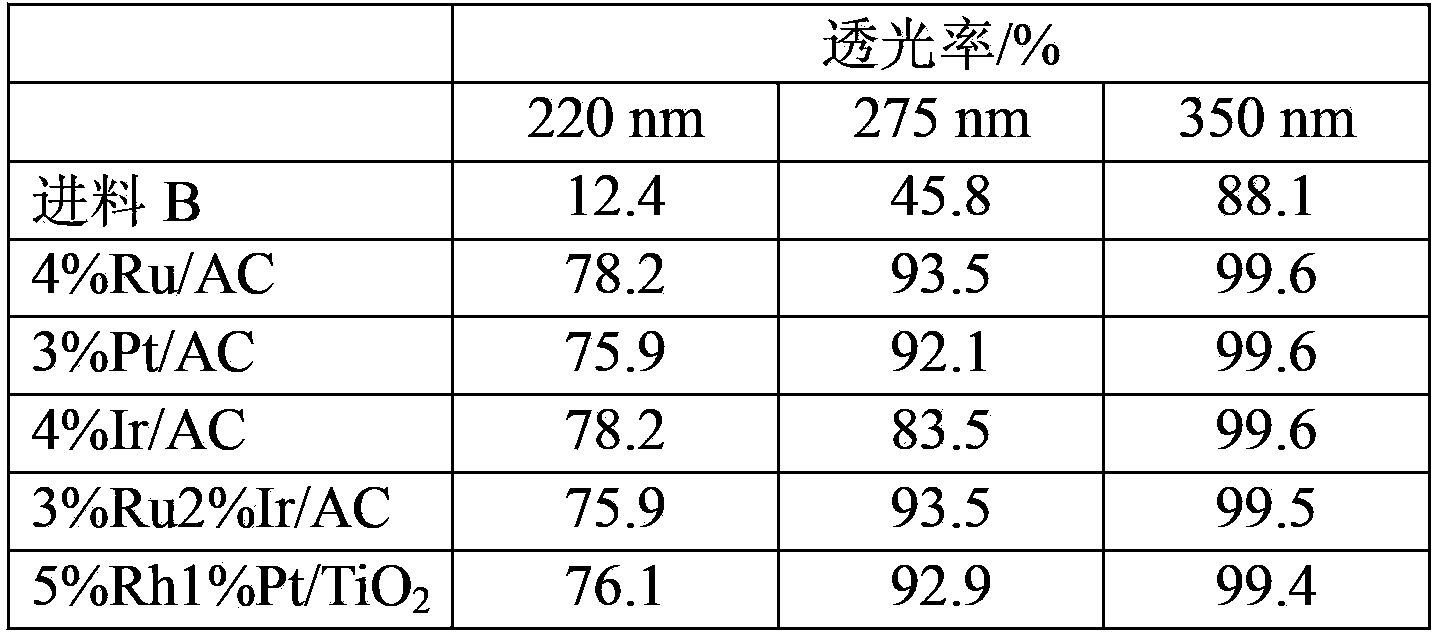

[0032] The results of catalytic purification of crude biomass ethylene glycol on different catalysts (Table 2), the reaction conditions are the same as in Example 1.

[0033] Table 2 The purification results of crude ethylene glycol on different catalysts (crude ethylene glycol volume space velocity is 10h -1 , 100℃, hydrogen pressure is 4MPa, hydrogen volume space velocity is 1200h -1 ):

[0034]

[0035] As shown in Table 2, on different catalysts, the UV light transmittance of crude ethylene glycol has been significantly improved, respectively meeting the requirements of polymerization grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com