Method for preparing iso-butyl aldehyde by using isobutene or tert-butyl alcohol as raw material

A technology for isobutene and isobutyraldehyde is applied in the field of preparing isobutyraldehyde, can solve the problems of low space-time yield, low production cost, poor catalyst selectivity, etc., and achieves high space-time yield, high reaction conversion rate and high product selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

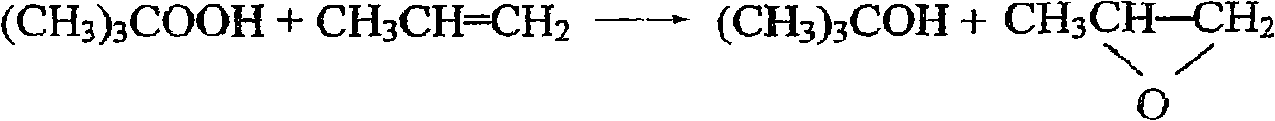

Method used

Image

Examples

Embodiment 1

[0042] After the mixture of isobutene, water vapor and air is preheated, it is passed through the catalyst 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb 0.2 Yb 0.1 W 0.5 Ce 0.5 ) / 20TiO 2 In a fixed bed reactor, at 370°C, normal pressure, O 2 The molar ratio of water vapor to isobutene is 2, the molar ratio of water vapor to isobutene is 4, and the total space velocity of raw material mixture is 890h -1 The selective oxidation reaction is carried out under the conditions, the conversion rate of isobutene is 95.9%, and the selectivity of methacrolein is 87.6%.

[0043] The obtained methacrolein is separated and purified, and diluted with isobutanol until the mass concentration of methacrolein is 60%, and after preheating with hydrogen, the catalyst Ru-Sn / γ-Al 2 o 3 fixed bed reactor, at a reaction temperature of 50°C, a pressure of 1.0MPa, and a mass space velocity of methacrolein of 2.0h -1 、H 2The hydrogenation reaction is carried out under the condition that the molar...

Embodiment 2

[0045] After the mixture of tert-butanol, water vapor and air is preheated, it is passed through the catalyst 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb 0.2 Yb 0.1 W 0.5 Ce 0.5 ) / 20TiO 2 fixed-bed reactor, at 450°C, normal pressure, O 2 The molar ratio of water vapor to isobutene is 6, the molar ratio of water vapor to isobutene is 6, and the total space velocity of raw material mixture is 2000h -1 The selective oxidation reaction is carried out under the conditions, the conversion rate of isobutene is 96.1%, and the selectivity of methacrolein is 84.2%.

[0046] The obtained methacrolein is separated and purified, and diluted with isobutanol until the mass concentration of methacrolein is 80%, and after preheating with hydrogen, the catalyst Ru-Fe / γ-Al 2 o 3 fixed bed reactor, at a reaction temperature of 50°C, a pressure of 0.5MPa, and a mass space velocity of methacrolein of 3.0h -1 、H 2 The hydrogenation reaction is carried out under the condition that the molar...

Embodiment 3

[0048] After the mixture of isobutene, water vapor and air is preheated, it is passed through the catalyst 80 (Mo 12 Bi 1.8 Fe 2.0 co 7.0 Sb 0.3 Pb 0.2 Yb 0.1 W 0.5 Ce 0.5 ) / 20TiO 2 fixed-bed reactor, at 460°C, normal pressure, O 2 The molar ratio of water vapor to isobutene is 6, the molar ratio of water vapor to isobutene is 7, and the total space velocity of raw material mixture is 2400h -1 The selective oxidation reaction is carried out under the conditions, the conversion rate of isobutene is 95.9%, and the selectivity of methacrolein is 86.2%.

[0049] Separation and purification of the obtained methacrolein to a mass content of 98%, after preheating with hydrogen, passing through the catalyst Ru-Co / γ-Al 2 o 3 fixed bed reactor, at a reaction temperature of 40°C, a pressure of 0.5MPa, and a methacrolein mass space velocity of 7.6h -1 、H 2 The hydrogenation reaction is carried out under the condition that the molar ratio of methacrolein is 8, the conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com