Catalyst for preparing methyl alcohol from syngas as well as preparation method and application of catalyst

A catalyst and methanol production technology, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of great influence, poor catalytic activity and stability, etc., so as to reduce the activation energy barrier, The effect of accelerating the catalytic reaction rate and improving the single-pass conversion rate of CO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 10ml C302 catalyst in the crucible, add an equal volume of 0.5mol / L Rh(NO 3 ) 3 Solution, soak for 12h, then dry at 100℃ for 12h, and roast at 350℃ for 4h to obtain CuO-Rh 2 O 3 / ZnO / Al 2 O 3 catalyst. In terms of metal elements, the composition molar ratio is Cu:Zn:Al:Rh=55.7:35.8:6.6:1.9.

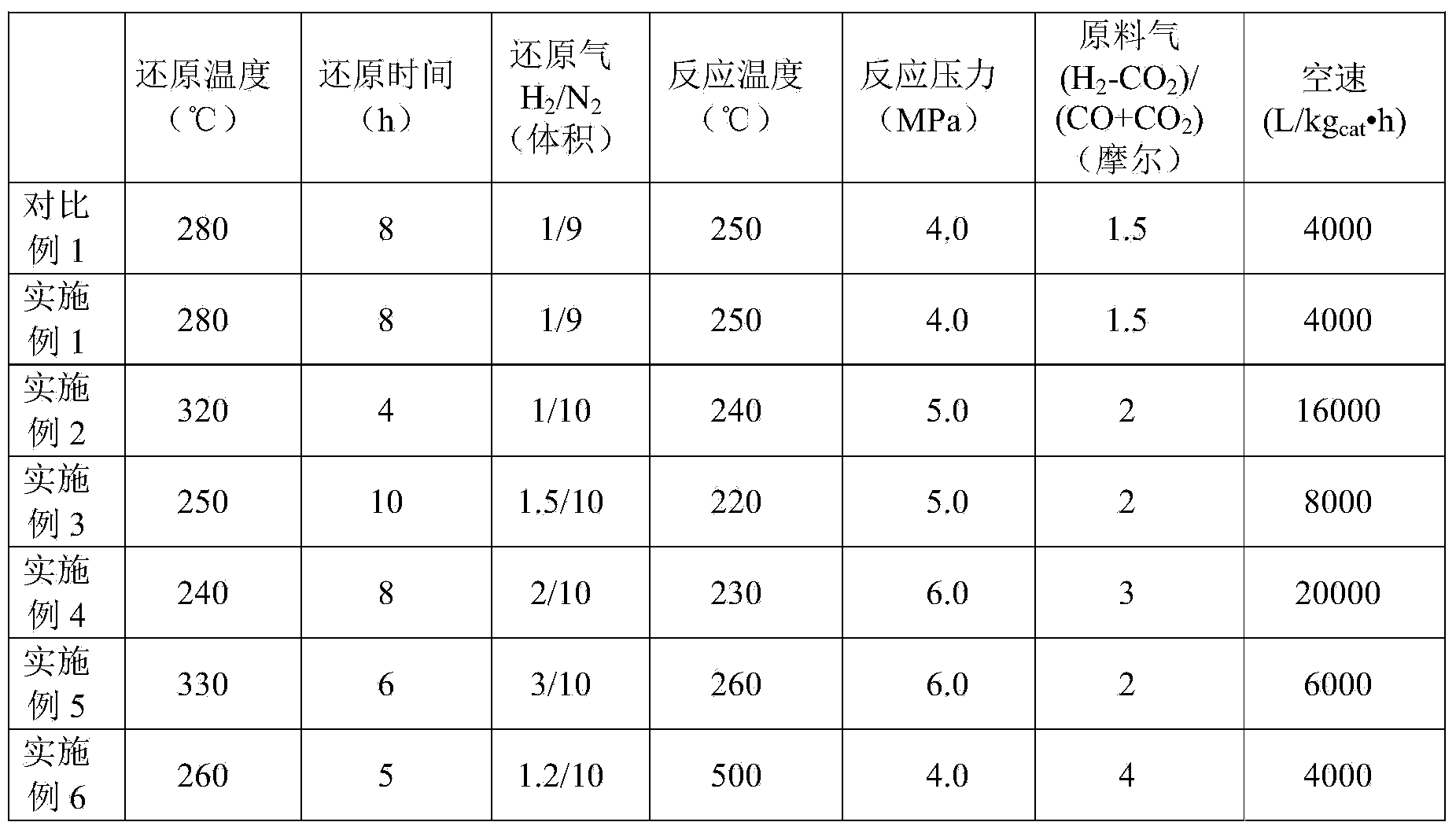

[0022] The catalyst reduction and evaluation conditions are shown in Table 1, and the catalyst activity results are shown in Table 2.

Embodiment 2

[0024] Add 10ml of LG104 catalyst from Lurgi, Germany (CuO-V 2 O 5 / ZnO / Al 2 O 3 , In terms of metal elements, its composition molar ratio is Cu: Zn: Al: V = 55.4: 34.8: 4.3: 5.5) Put it in a crucible and add an equal volume of 0.4mol / L RhCl 3 Solution, immerse for 6h, then dry at 110℃ for 10h, and roast at 380℃ for 3h to obtain CuO-Rh 2 O 3 -V 2 O 5 / ZnO / Al 2 O 3 catalyst. In terms of metal elements, the composition molar ratio is Cu:Zn:Al:V:Rh=54.5:34.1:4.3:5.3:1.8.

[0025] The catalyst reduction and evaluation conditions are shown in Table 1, and the catalyst activity results are shown in Table 2.

Embodiment 3

[0027] Put 20ml of C301 catalyst from the Research Institute of Nanjing Chemical Industry Group of China (in terms of metal elements, its composition molar ratio is Cu:Zn:Al=62.5:31.2:6.3) into the crucible, and add an equal volume of 0.42mol / LRh(NO 3 ) 3 Solution, soak for 12h, then dry at 110℃ for 14h, and roast at 400℃ for 4h to obtain CuO-Rh 2 O 3 / ZnO / Al 2 O 3 catalyst. In terms of metal elements, the composition molar ratio is Cu:Zn:Al:Rh=62.0:30.9:6.3:0.8.

[0028] The catalyst reduction and evaluation conditions are shown in Table 1, and the catalyst activity results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com