Jet flow fluidized bed reaction device and olefin polymerization method thereof

A fluidized bed reaction and fluidized bed technology, applied in the field of polymerized olefins, can solve the problems of increasing gas flow rate and increasing the production cost of polymerized olefins, so as to improve the space-time yield, strengthen the forced heat transfer ability, and precisely control product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

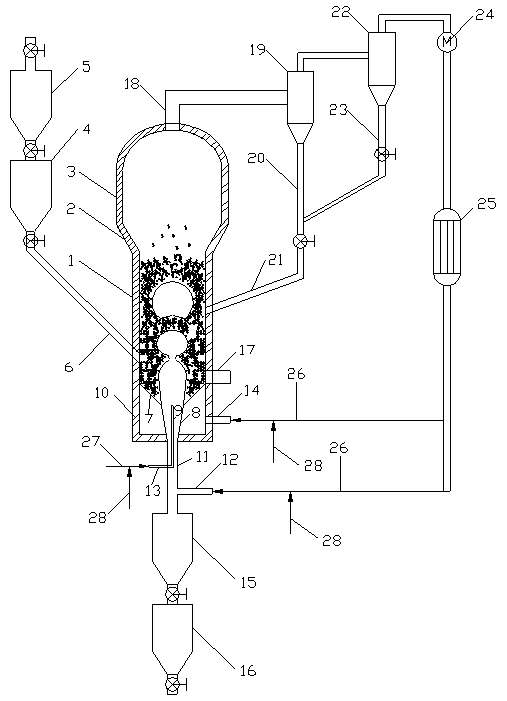

[0041] use as figure 1 The shown jet fluidized bed polymerization reaction device of the present invention has been operated in a cold state and computer simulation in a laboratory, and has been operated in a hot state on a hot state device to investigate the polymerization effect of the jet fluidized bed.

[0042] 1) Laboratory cold operating data

[0043] Materials: polyethylene particles with wide particle size distribution, air / nitrogen (nitrogen was used in pressurized experiments).

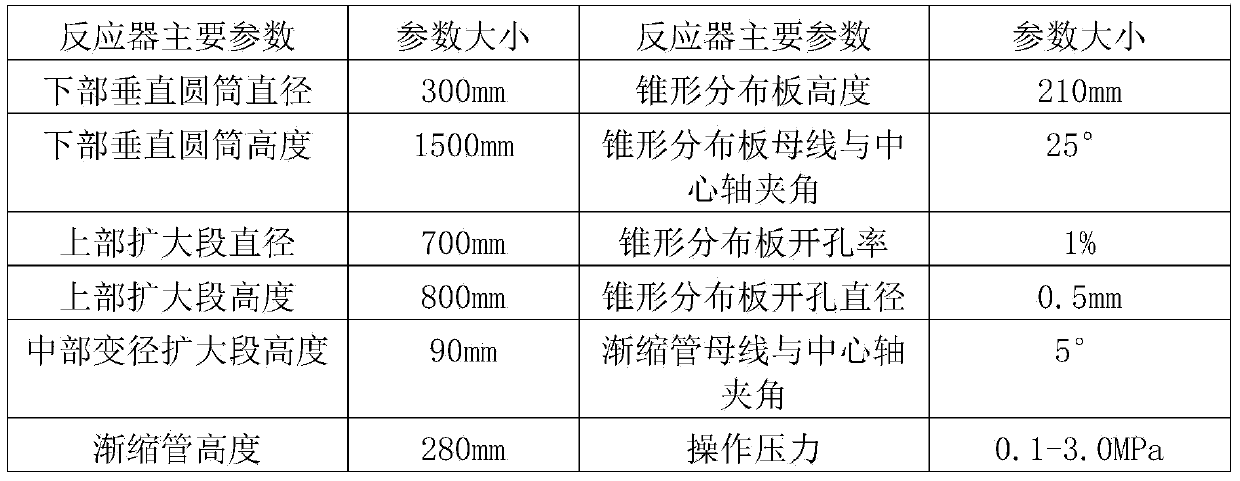

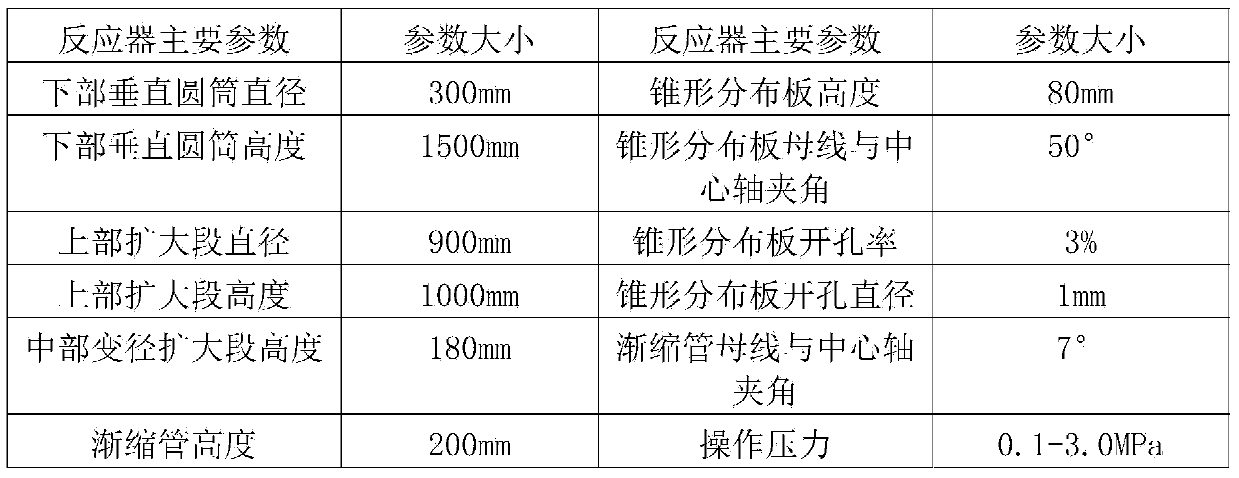

[0044] The main parameters of the cold experimental device are listed in Table 1, Table 2, and Table 3.

[0045] Running data: adopt the present invention as figure 1 The main parameters of the jet fluidized bed reactor are shown in Table 1, Table 2, and Table 3. Using an ultra-high-speed image analyzer, particle dynamic imaging analysis system, fiber optic particle velocimeter, and differential pressure sensor, it was found that the reaction Particle movement in the side wall area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com