Mixing granulation equipment and process for production of granulated mineral fiber cotton for hard spray coating

A mineral fiber, mixed granulation technology, used in manufacturing tools, granulation in static tanks/tanks, ceramic molding machines, etc., to achieve the effects of high output, reduced manufacturing costs, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

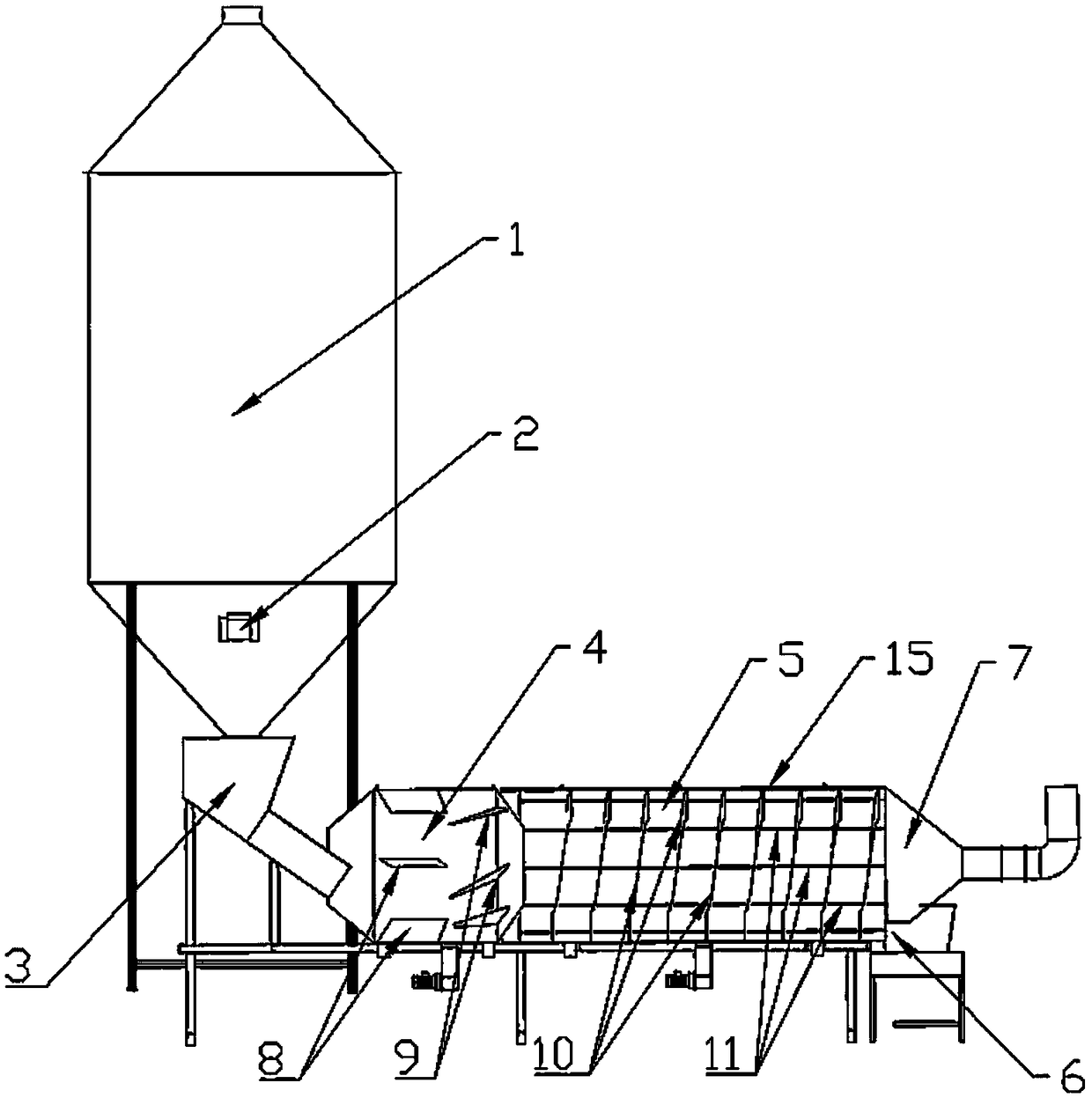

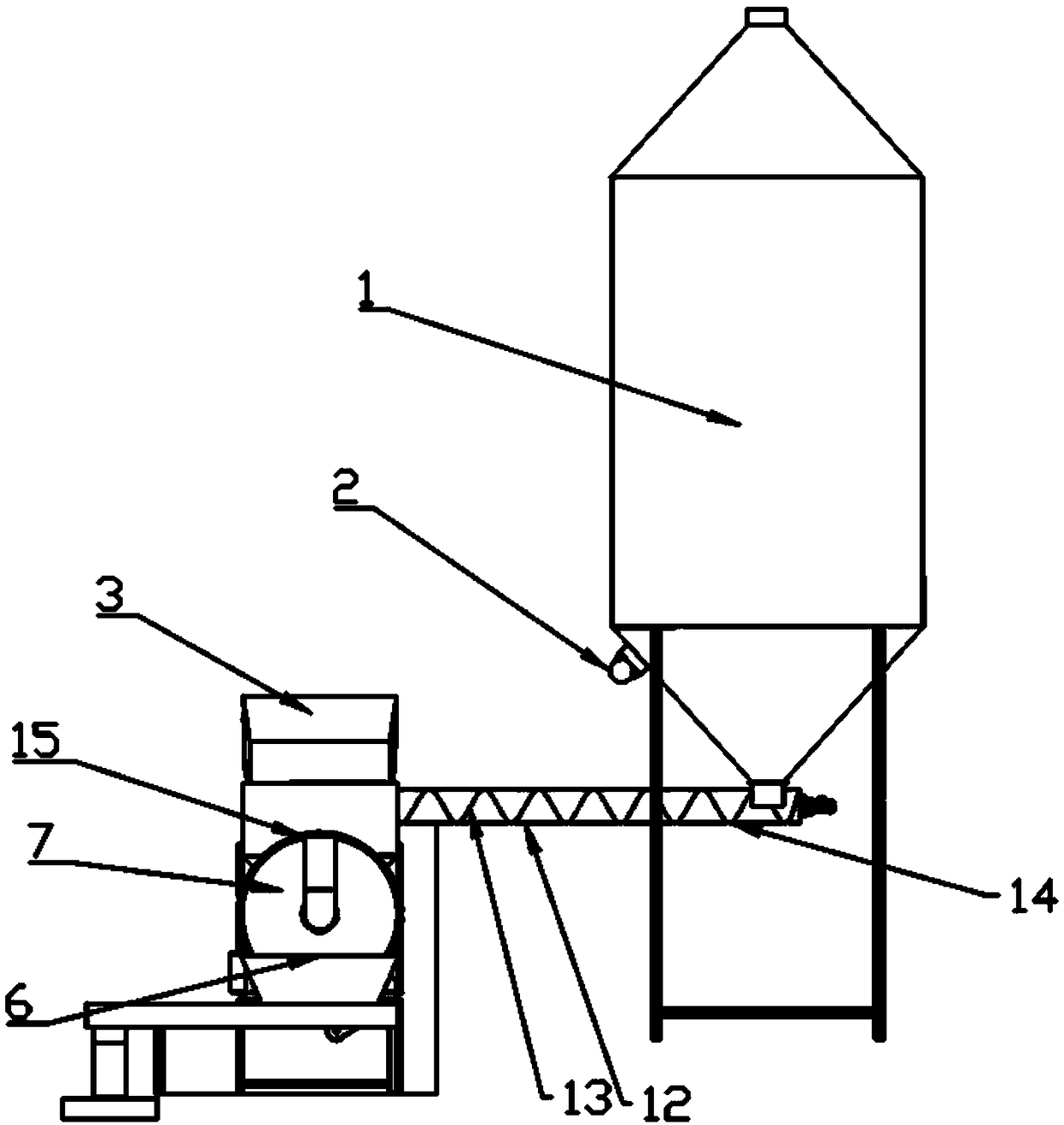

[0033] The invention provides a mixing and granulation equipment, see Figure 1~2 , the present invention provides a mixing and granulating equipment for producing mineral fiber granular cotton for hard spraying, comprising a powder storage tank 1, a powder discharger 12 positioned below the powder storage tank 1, and a powder discharger connected with the powder discharger 12 a mixing granulator 15 at the lower end, the powder discharger 12 includes a powder discharge port 14 and a linear screw propeller 13 connected to the discharge port 14;

[0034] The mixing and granulating machine 15 is an integrated non-destructive mixing and granulating machine, comprising a feed hopper 3 located at the front end of the mixing and granulating machine 15, a premixing drum 4 connected to the lower end of the feeding hopper 3, and a premixing drum 4 located at the front end of the mixing granulator 15 The mixing and granulating drum 5 at the tail of the drum 4, and the product outlet 6 an...

Embodiment 2

[0049] According to the mixing and granulating equipment in embodiment 1, the present invention also provides a kind of preparation technology of hard spraying mineral fiber granular cotton, comprising the following steps:

[0050] (1) Mineral wool with an acidity coefficient of 1.3, a WT value of 55 and an average fiber diameter of 4.5 μm is selected, and the silica sol is atomized and evenly sprayed on the mineral surface during the fiber-forming process of the mineral wool. 0.25% by weight, and the bulk density of the mineral wool is 138Kg / m 3 ;

[0051] (2) the mixing and granulating equipment described in claim 1 is provided;

[0052] (3) 40 parts by weight of powder in the powder storage tank 1 is pushed into the feed hopper 3 through the powder discharger 12, and the mineral wool in 60 parts by weight of step (1) is added through the feed hopper 3 In the mixing and granulating machine 15, the powder and mineral wool are fully mixed and secondary granulated through the...

Embodiment 3

[0057] According to the mixing and granulating equipment in embodiment 1, the present invention also provides a kind of preparation technology of hard spraying mineral fiber granular cotton, comprising the following steps:

[0058] (1) Select mineral wool with an acidity coefficient of 1.3, a WT value of 55 and a fiber diameter of 5 μm, and the mineral wool is sprayed evenly on the surface of the mineral after the water glass is atomized during the fiber forming process, and the water glass accounts for 0.25% of the weight of the mineral wool %, while the bulk density of the mineral wool is 145Kg / m 3 ;

[0059] (2) the mixing and granulating equipment described in claim 1 is provided;

[0060] (3) 54 parts by weight of powder in the powder storage tank 1 is pushed into the feed hopper 3 through the powder discharger 12, and the mineral wool in 46 parts by weight of step (1) is added through the feed hopper 3 In the mixing and granulating machine 15, the powder and mineral wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com