Method for manufacturing jun porcelain bottle mouths of various shapes

A production method and technology of Jun porcelain, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the needs of integrated cutting and molding of Jun porcelain bottle mouths of various shapes, consume manpower, material resources and costs , roughness of the bottle mouth forming device, etc., to achieve the effect of reducing equipment operating power consumption, improving production efficiency and yield, and accelerating cutting and forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

[0034] A method for making Jun porcelain bottle mouths satisfying various shapes, comprising the following steps:

[0035] S1: Prepare the production models of Jun porcelain bottle mouths of different shapes;

[0036] S2: Carving the model prepared in step S1 into a mold;

[0037] S3: Grouting molding: inject the slurry into the mold carved in step S2, and solidify to form a green body;

[0038] S4: Dry at a temperature of 25°C-120°C, and the moisture content of the dried green body is less than 3%;

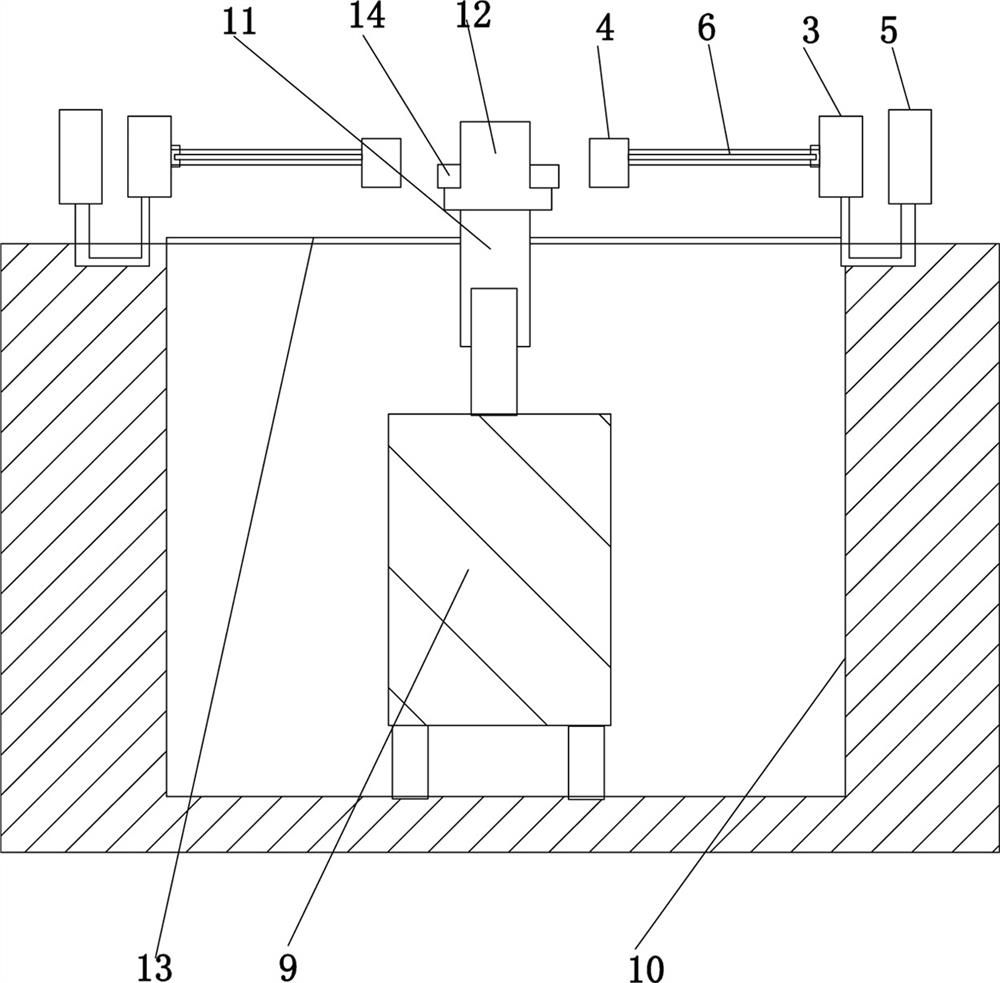

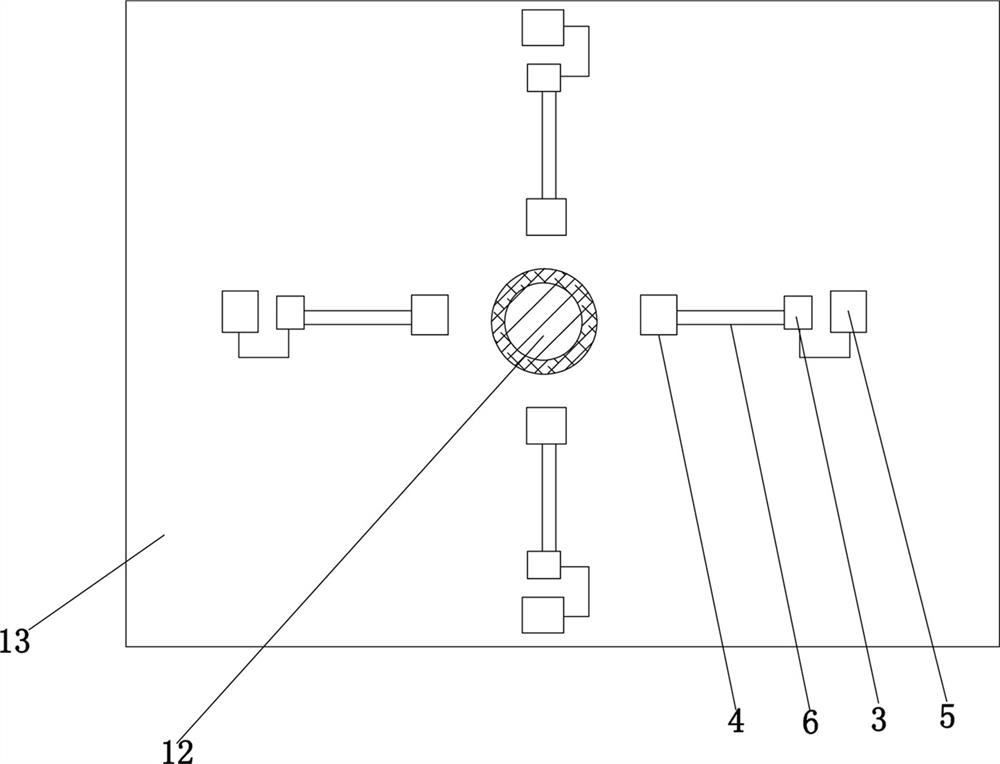

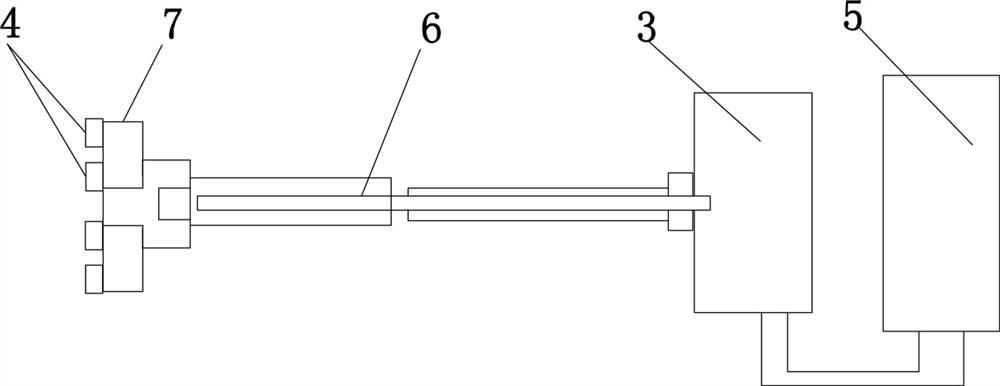

[0039] S5: Turn on the processing control system, the air box 5 supplies air to the cylinder 3, and enters the normal working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com