Wide cone angle atomization oil flinger structure

An oil slinger and cone angle technology, which is applied in the field of wide cone angle atomization oil slinger structure, can solve the problems of affecting the uniformity of the temperature field in the flame tube, difficult to adapt to the outlet mode, uneven oil supply of the flame tube, etc. Improve the uniformity of temperature field, good atomization effect and stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

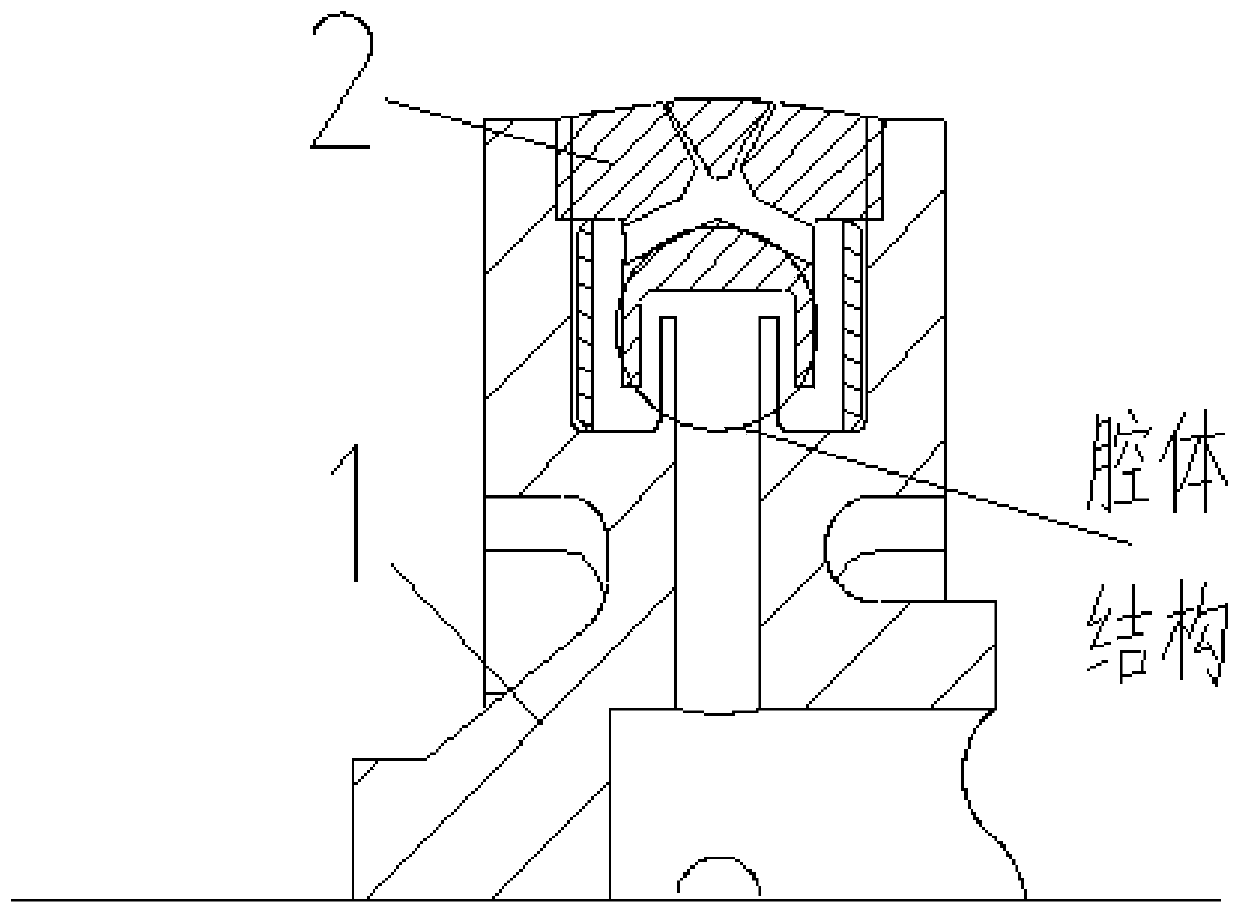

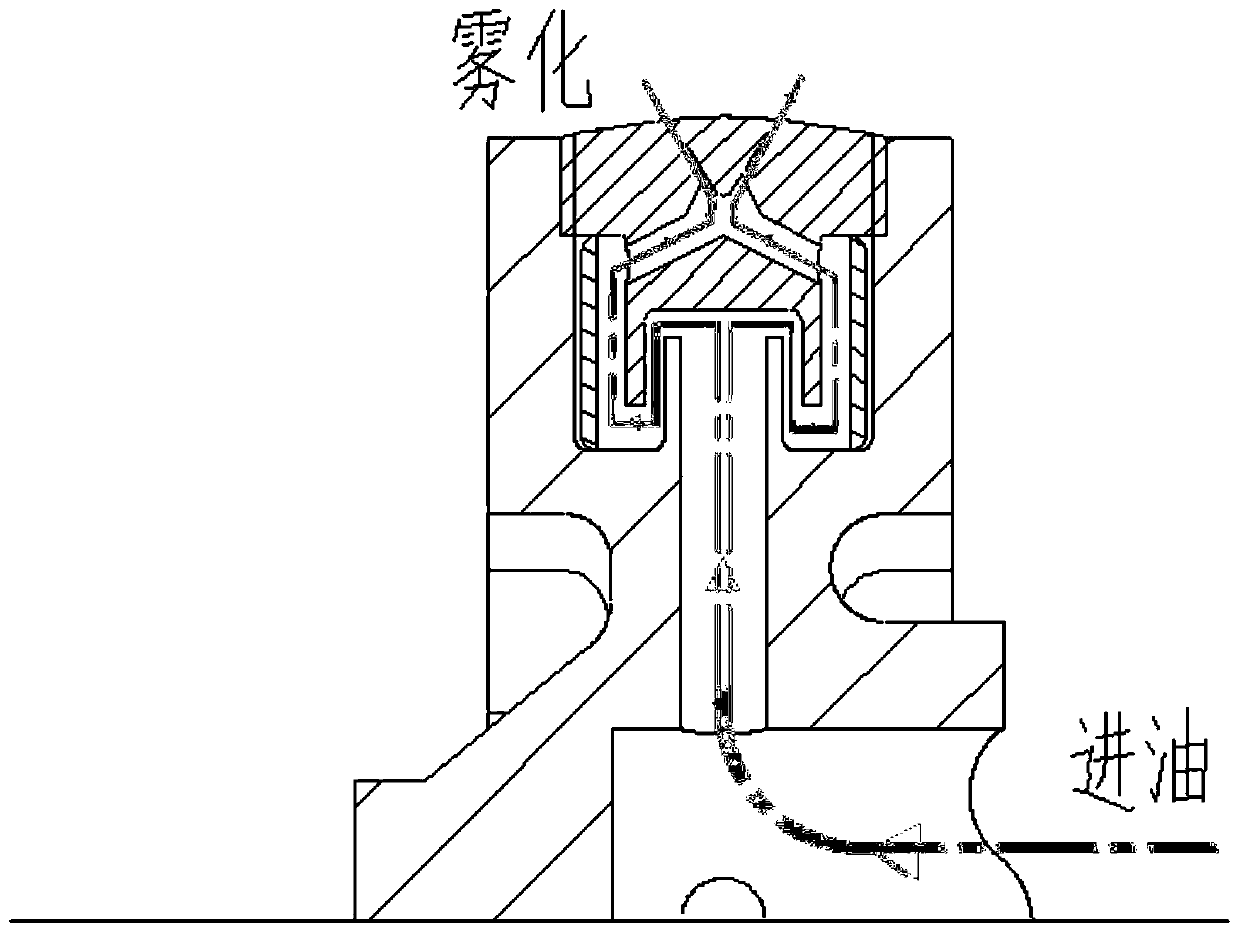

[0016] Such as figure 1 As shown, the present invention provides a wide cone angle atomization oil thrower structure, including the oil thrower body 1 and the nozzle 2; the oil thrower body 1 and the nozzle 2 are connected together by threaded connection, each The nozzle 2 is connected to the rotating shaft of the oil thrower body 1 by means of threaded connection. The oil thrower body 1 is provided with four internal threads, corresponding to the positions of the external threads of the four nozzles 2 distributed at intervals of 90° in the circumferential direction. The flow pipeline in the nozzle 2 and the flow pipeline in the oil slinger body 1 form a cavity structure; each nozzle 2 is provided with a plurality of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com