Manufacturing process of large pressurized vessel pipe plate forging

A pressure vessel and manufacturing process technology, which is applied in the field of manufacturing process of large pressure vessel tube sheet forgings, can solve the problems of easy forging, low qualification rate, uneven internal deformation, etc. , the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

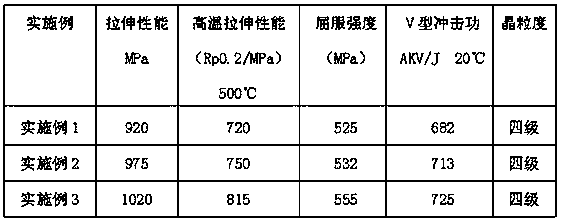

Examples

Embodiment 1

[0032] Before forging, place the forging billet in a heating furnace, heat it at a rate of 20°C / hour, so that the forging billet is slowly heated to 350°C, and heat it at a speed of 45°C / hour, so that the forging billet is slowly heated to 600°C ℃, the heating time is not less than 5 hours, and then heated at a speed of 60°C / hour, so that the forging billet is slowly heated to 910°C, and the heating time is not less than 3.5 hours, and then heated at a speed of 100°C / hour, so that the forging billet is slowly heated Rapidly heat to 1240°C to reach the forging temperature, and keep at this forging temperature for 16 hours.

[0033] The initial forging temperature during forging is 1250°C, and the final forging temperature is 800°C. The forging blank is forged by two times of upsetting + WHF method of drawing. The two times of upsetting and drawing are carried out on a 500-ton forging press. After reaching the initial forging temperature, start The first upsetting forging, that ...

Embodiment 2

[0036] Before forging, place the forging billet in a heating furnace and heat it at a rate of 25°C / hour to slowly heat the forging billet to 400°C. After heating to 400°C, heat the billet at a speed of 50°C / hour to slowly Heating rapidly to 650°C, the heating time is not less than 5 hours, and then heating at a speed of 80°C / hour, so that the forging billet is slowly heated to 930°C, the heating time is not less than 3.5 hours, and then heating at a speed of 100°C / hour , make the forging billet slowly heated to 1250°C, the heating time is not less than reaching the forging temperature, and keep at this forging temperature for 16 hours.

[0037] During the forging process, the initial forging temperature is 1250°C, and the final forging temperature is 800°C. The forging billet is forged by two times of upsetting + WHF method of drawing. The two times of upsetting and drawing are carried out on a 500-ton forging press. After reaching the initial forging temperature, Start the fi...

Embodiment 3

[0040] Before forging, place the forging billet in a heating furnace and heat it at a rate of 30°C / hour to slowly heat the forging billet to 450°C and heat it at a speed of 55°C / hour to slowly heat the forging billet to 700°C , the heating time is not less than 5 hours, and then heated at a speed of 100°C / hour, so that the forging billet is slowly heated to 950°C, the heating time is not less than 3.5 hours, and then heated at a speed of 100°C / hour, so that the forging billet is slowly heated Heating to 1260°C, the heating time is not less than reaching the forging temperature, and keeping at this forging temperature for 16 hours;

[0041] During the forging process, the initial forging temperature is 1250°C, and the final forging temperature is 800°C. The forging billet is forged by two times of upsetting + WHF method. The two upsetting and drawing processes are carried out on a 500-ton forging press. After reaching the initial forging temperature, Start the first upsetting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com