High-density LAS microcrystalline glass fiber and preparation method thereof

A technology of glass fiber and density, applied in the field of high-density LAS glass-ceramic fiber and its preparation, can solve the problem that it is difficult to guarantee the light transmission performance of LAS glass ceramics, the influence of semi-permeability is not clearly mentioned, and the fiber does not consider the transmission of light. Light and other problems, achieve the effect of uniform and controllable diameter, low cost, and increase solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

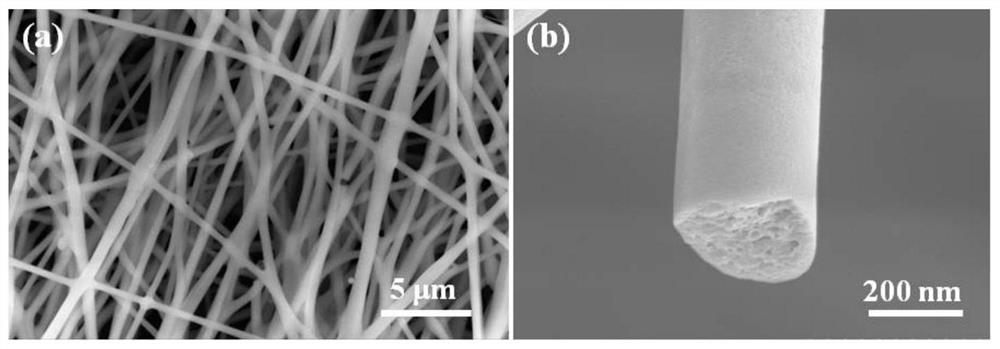

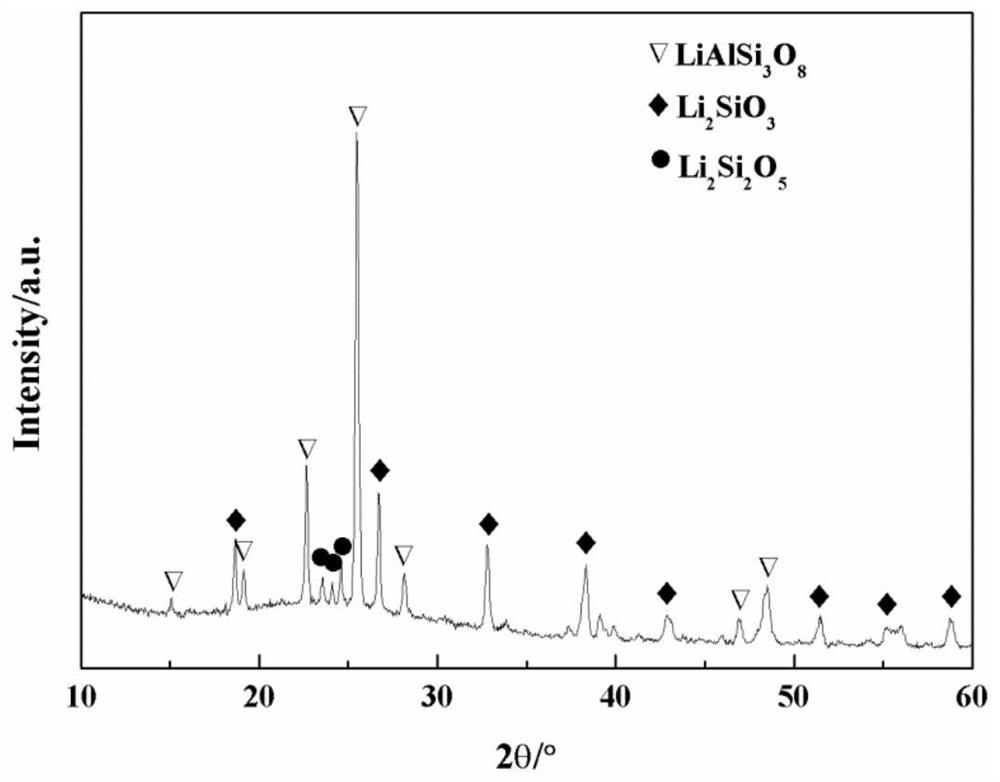

Image

Examples

preparation example Construction

[0026] A preparation method of high-density LAS glass-ceramic fibers, comprising the following steps:

[0027] (1) Preparation of aqueous precursor solution: Dissolve ethyl tetrasilicate in ethanol, add nano silicon dioxide powder, stir evenly to obtain solution A; dissolve lithium nitrate in water to obtain solution B; dissolve aluminum nitrate in water to obtain solution C; mix solution A and solution B, stir evenly, and add it to solution C, stir evenly to obtain an aqueous precursor solution;

[0028] (2) Preparation of polyvinyl alcohol (PVA) aqueous solution: take a certain amount of polyvinyl alcohol powder and soak in deionized water, stir for a certain period of time under water bath heating conditions to obtain PVA aqueous solution;

[0029] (3) Preparation of the spinnable LAS precursor: mixing the aqueous solution of the precursor and the aqueous solution of PVA, and aging for a certain period of time to obtain a spinnable LAS precursor with a certain viscosity;

...

Embodiment 1

[0035] (1) Preparation of aqueous precursor solution: Dissolve 9.36 g of ethyl orthosilicate in 4.4 g of ethanol, add 1 wt % (0.094 g) of nano-silica powder, and stir magnetically at room temperature for 0.5 h to obtain A solution; Take 10.35g of lithium nitrate as a lithium source and dissolve it in 10.26g of deionized water, and stir it with a magnetic stirrer for 10 minutes to obtain solution B; take 31.95g of aluminum nitrate and dissolve it in 10.26g of deionized water, heat to 70°C and continuously process the solution Mechanical stirring promotes Al in aluminum nitrate solution 3+ Hydrolysis and polymerization reaction to obtain C solution. The molar ratio of ethyl orthosilicate, ethanol, water, nitric acid, lithium nitrate, and aluminum nitrate is 3:6.4:7.6:0.1:1:1. Add solution B to C to form a lithium-aluminum sol, mix well and then add solution A to obtain an aqueous solution of the LAS precursor;

[0036] (2) Preparation of polyvinyl alcohol (PVA) aqueous solutio...

Embodiment 2

[0041] (1) Preparation of aqueous precursor solution: Dissolve 12.48 g of ethyl orthosilicate in 4.4 g of ethanol, add 15 wt % (1.87 g) of nano-silica powder, and stir magnetically at room temperature for 0.5 h to obtain A solution; Take 10.35g of lithium nitrate as a lithium source and dissolve it in 10.26g of deionized water, and stir it with a magnetic stirrer for 10 minutes to obtain solution B; take 31.95g of aluminum nitrate and dissolve it in 10.26g of deionized water, heat to 70°C and continuously process the solution Mechanical stirring promotes Al in aluminum nitrate solution 3+ Hydrolysis and polymerization reaction to obtain C solution. The molar ratio of ethyl orthosilicate, ethanol, water, nitric acid, lithium nitrate, and aluminum nitrate is 4:6.4:7.6:0.1:1:1. Add solution B to C to form a lithium-aluminum sol, mix well and then add solution A to obtain an aqueous solution of the LAS precursor;

[0042] (2) Preparation of polyvinyl alcohol (PVA) aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com