Perovskite solar cell prepared based on acetic acid-methylamine room-temperature molten salt as green solvent and method and application of perovskite solar cell

A technology of solar cells and methylamine acetate, which is applied in the field of optoelectronic materials, can solve the problems of difficult control of the crystallization process and increase of production costs, and achieve the effects of low cost, reduced toxicity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] In this example, an inverted planar heterojunction perovskite solar cell is prepared using methylamine acetate as a solvent of the present invention, so as to fully understand the present invention. It mainly includes the following steps:

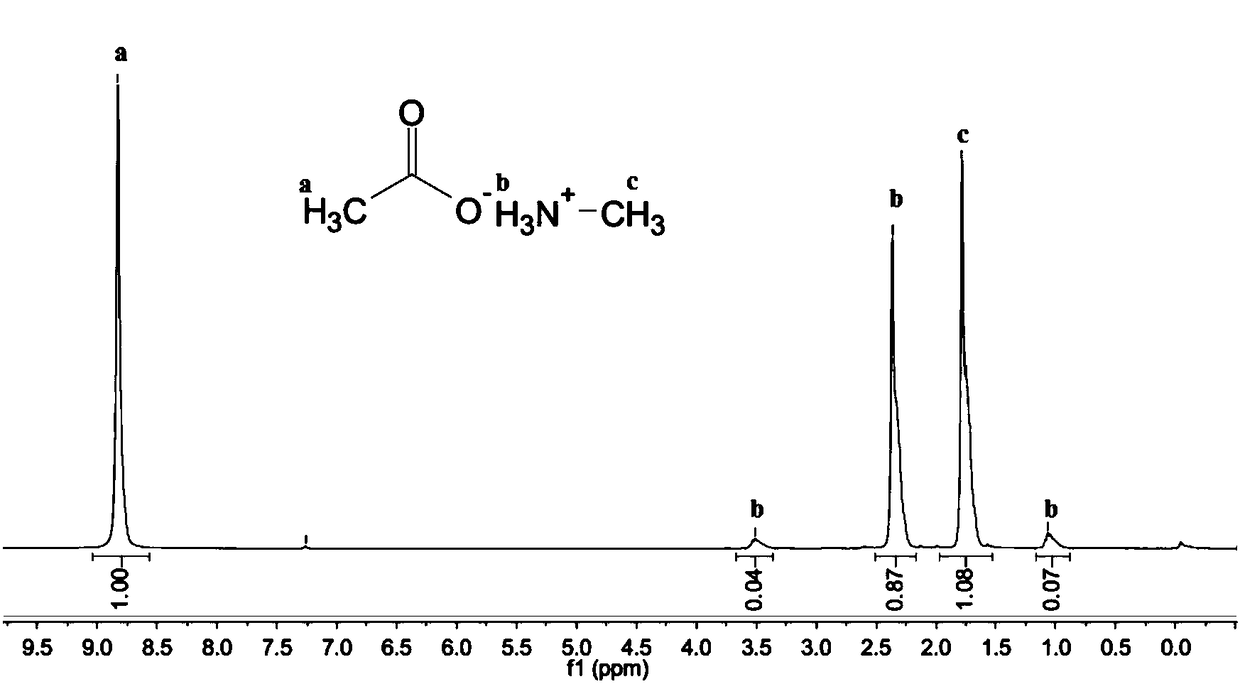

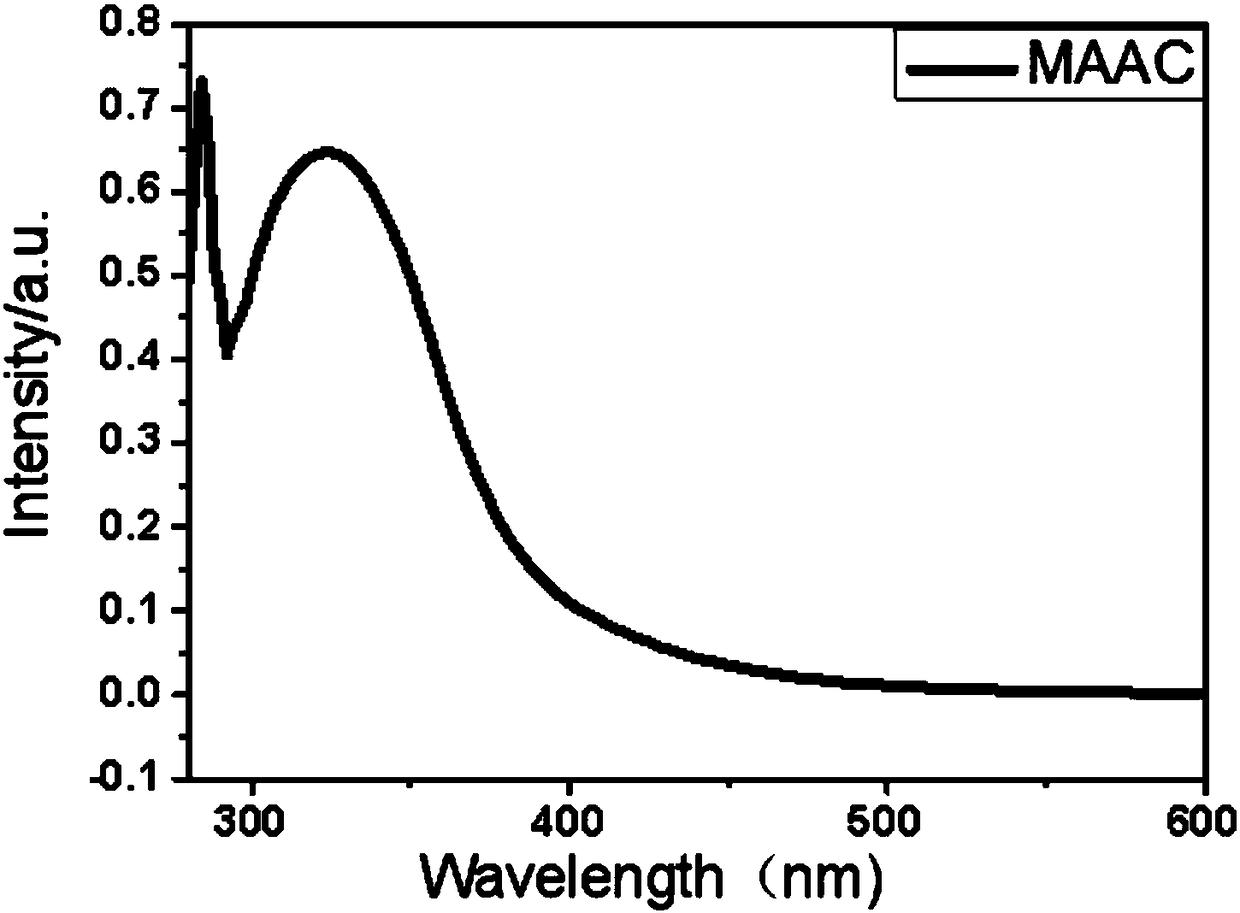

[0045] Step 1) Take 90ml of methylamine and place it in an ice-water bath in a round-bottomed flask, and slowly add 27.6ml of glacial acetic acid dropwise therein. After 2 hours in the ice-water bath, spin-evaporate at 55°C until there is no droplet, and prepare methylamine acetate for use.

[0046] Step 2) Clean the cut ITO conductive glass, the sequence is ethanol, ultrapure water, cleaning agent, ultrapure water, and ethanol, respectively, sonicating for 10 minutes. And blow dry with nitrogen to obtain a clean conductive glass substrate.

[0047] Step 3) Weigh 261.6mg of lead iodide and 38.31mg of methylamine chloride, dissolve them in 1ml of the methylamine acetate solvent prepared in step 1), stir at 60°C for 2 hours until comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com