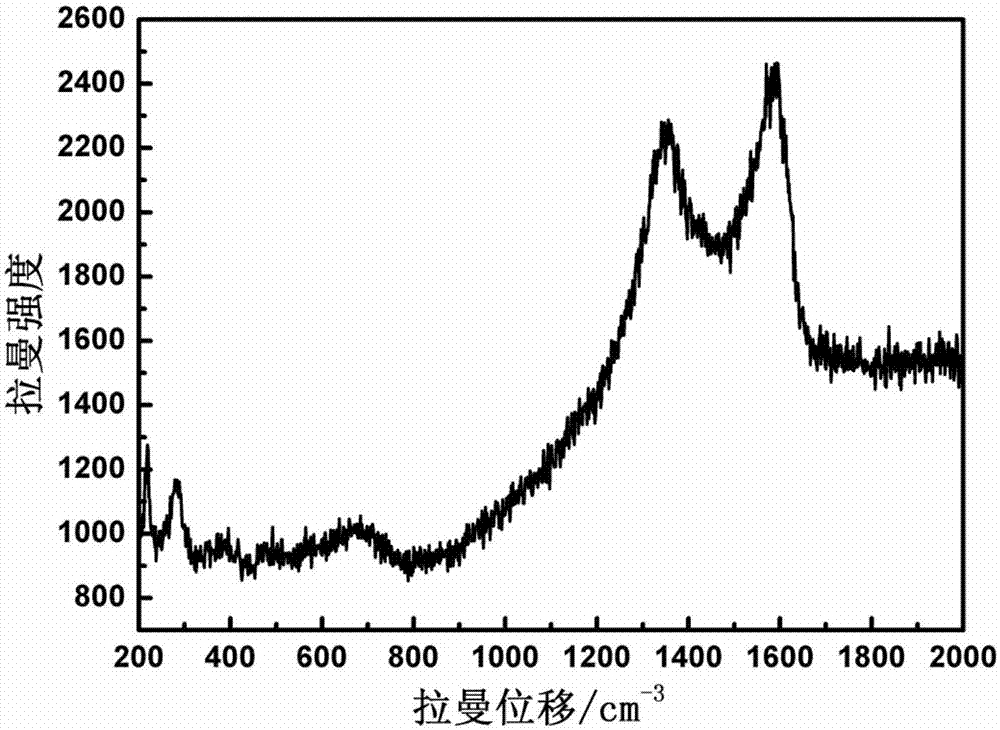

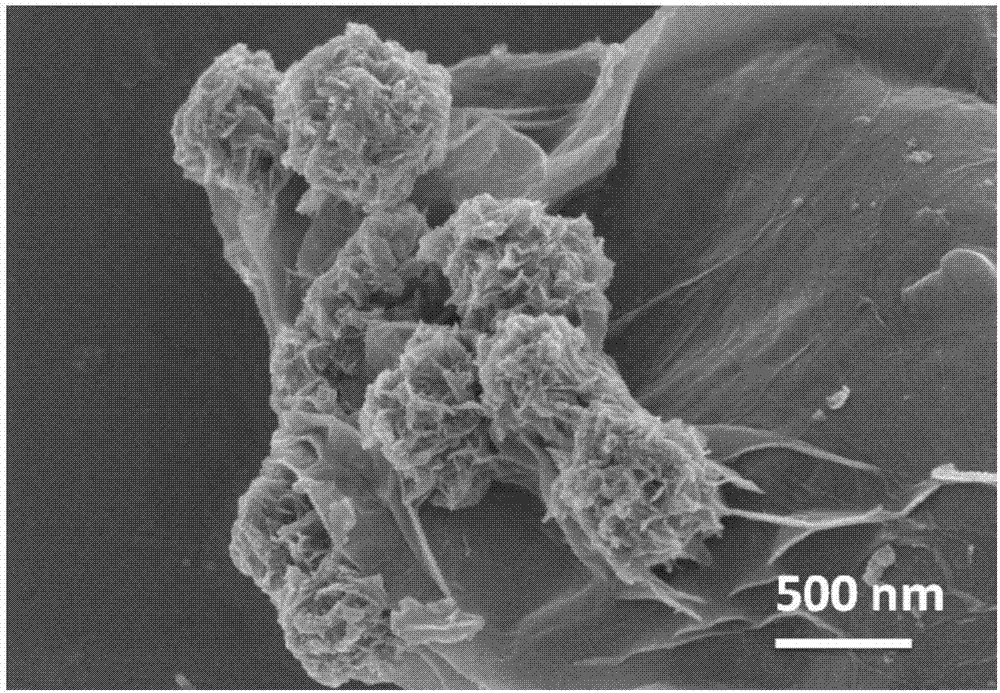

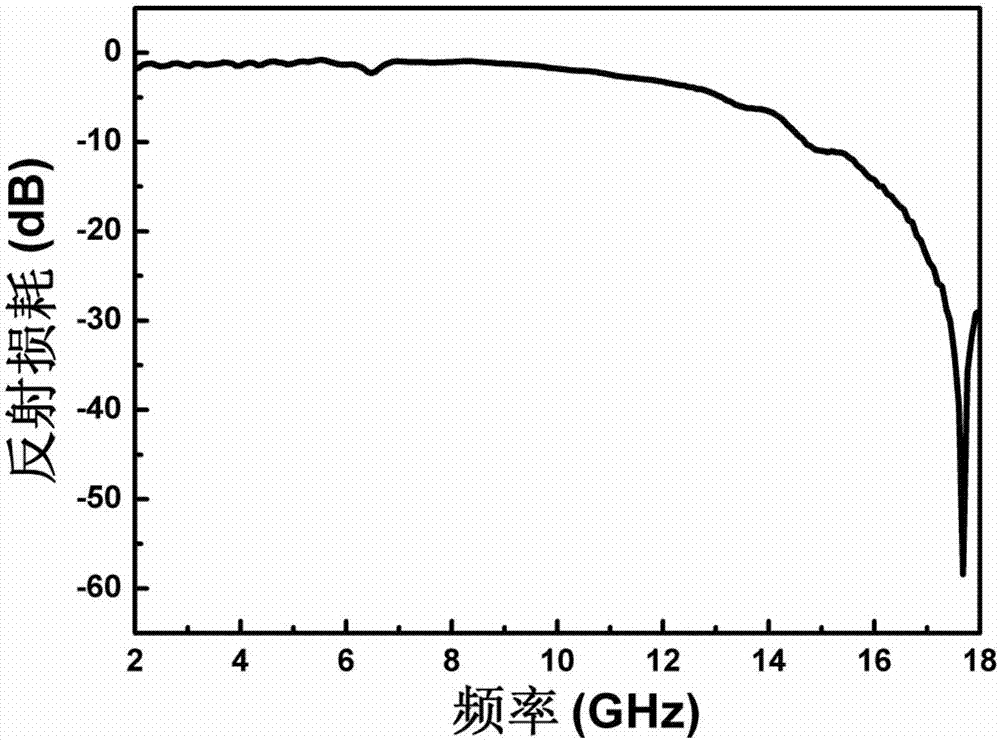

Preparation method for graphene/three-dimensional flower-shaped bismuth ferrite composite absorbing material

A composite wave absorbing material, three-dimensional flower-like technology, applied in the field of material science, can solve the problem of little research, and achieve the effects of good crystallinity, low energy consumption and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation steps of the medium-thick flaky bismuth ferrite powder of the present invention comprise:

[0034] (a) Take Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O and dilute nitric acid are mixed and then magnetically stirred to fully dissolve to obtain a mixed solution B; among them, Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 The ratio of O and dilute nitric acid is 1mmol: 2mmol: (12-15)mL;

[0035] (b) Slowly add NaOH solution dropwise to the mixed solution B, and stir to obtain a reddish-brown suspension C;

[0036] (c) Pour the suspension C into the reaction kettle and seal it, carry out a homogeneous hydrothermal reaction, and generate a precipitate;

[0037] (d) After the reaction kettle is cooled to room temperature, the precipitate obtained by the homogeneous hydrothermal reaction is washed and dried to obtain thick flake bismuth ferrite powder.

[0038] The mass fraction of nitric acid in the step (a) is 65%; the concentration of the NaOH solution in t...

Embodiment 1

[0044] A preparation method of graphene / three-dimensional flower-shaped bismuth ferrite composite absorbing material, comprising the following steps:

[0045] 1) According to Bi 2 Fe 4 o 9 Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, dissolved in 15mL of dilute nitric acid with a volume fraction of 5vol% and magnetically stirred to fully dissolve to obtain mixed solution A; Bi(NO 3 ) 3 ·5H 2 The ratio of O to dilute nitric acid is 1mmol: 12mL;

[0046] 2) Add 45 mL of 12 mol / L NaOH solution dropwise at a rate of two drops per second to the mixture A, and stir to precipitate Bi 3+ and Fe 3+ , to obtain a reddish-brown suspension B;

[0047] 3) Pour the suspension B into a polytetrafluoroethylene reactor, place it in a homogeneous reactor and seal it, and perform a homogeneous hydrothermal reaction. The reaction conditions for the homogeneous reaction: the reaction temperature is controlled at 190°C, and the reaction time is controlled at 6h;

[0048] 4) After the rea...

Embodiment 2

[0061] A preparation method of graphene / three-dimensional flower-shaped bismuth ferrite composite absorbing material, comprising the following steps:

[0062] 1) According to Bi 2 Fe 4 o 9 Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, dissolved in 15mL of dilute nitric acid with a volume fraction of 7vol% and magnetically stirred to make it fully dissolved to obtain mixed solution A; Bi(NO 3 ) 3 ·5H 2 The ratio of O to dilute nitric acid is 1mmol: 12mL;

[0063] 2) Add 45 mL of 10 mol / L NaOH solution dropwise at a rate of two drops per second to the mixture A to precipitate Bi 3+ and Fe 3+ , stirring to obtain a reddish-brown suspension B;

[0064] 3) Pour the suspension B into a polytetrafluoroethylene reactor, place it in a homogeneous reactor and seal it, and perform a homogeneous hydrothermal reaction. The reaction conditions for the homogeneous reaction: the reaction temperature is controlled at 180°C, and the reaction time is controlled at 12h;

[0065] 4) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com