Graphene-based FeS2 nano-material and preparation and application thereof

A nanomaterial, graphene-based technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as long reaction time, achieve low cost, good cycle performance, good structural stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

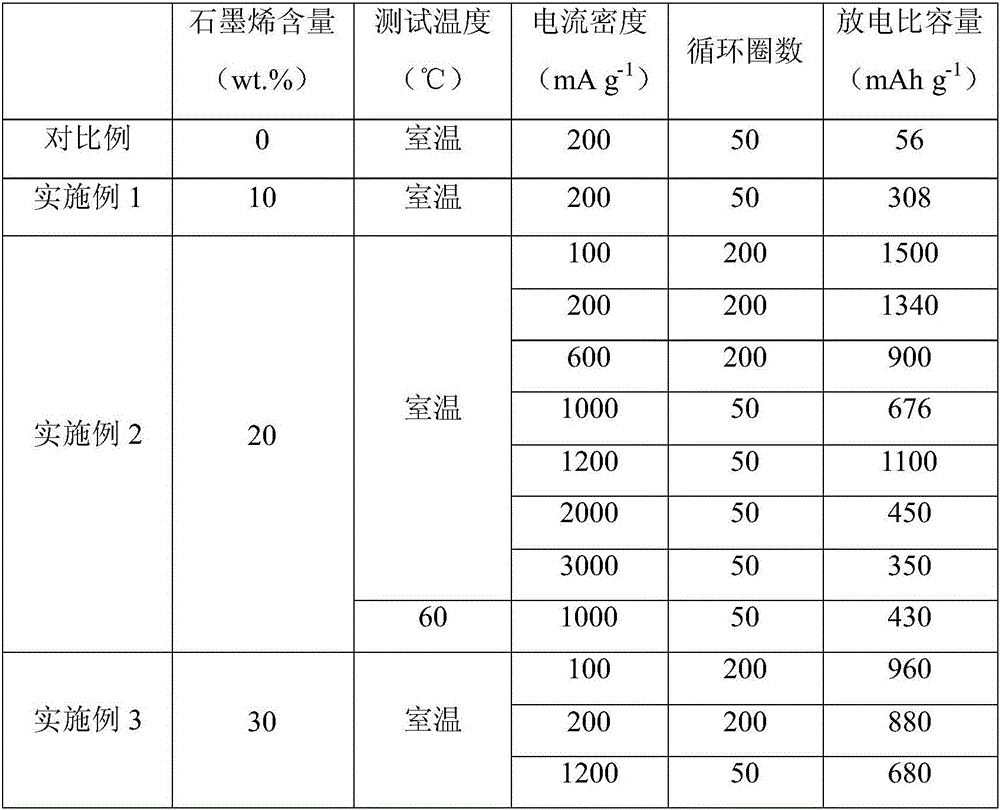

Embodiment 1

[0033] (1) Put 0.0408g of graphene oxide in 30ml of water and ultrasonically disperse for 3 hours to obtain a graphene oxide suspension, then add 0.0401g of vitamin C to dissolve it, and then ultrasonically disperse it for 10 minutes to obtain a graphene suspension;

[0034] (2) Na 2 Add 3mmol each of S and sublimated sulfur into water, heat and stir until the sulfur is completely dissolved to obtain yellow-brown Na 2 S 2 solution;

[0035] (3) Add 3mmol FeSO 4Dissolve in 20ml of water and mix with the graphene suspension in step (1), then add the Na obtained in step (2) 2 S 2 solution, heated up to 100°C, refluxed for 2 hours under an inert gas atmosphere, cooled to room temperature after the reaction, centrifuged with water and ethanol, dried the separated product at 60°C, and ground to obtain 10wt% GNs@FeS 2 Powder, graphene coating amount was determined by thermogravimetric analysis (TGA).

Embodiment 2

[0037] (1) Put 0.0910g of graphene oxide in 30ml of water and ultrasonically disperse for 3 hours to obtain a graphene oxide suspension, then add 0.0900g of vitamin C to dissolve and ultrasonically 10min to obtain a graphene suspension;

[0038] (2) Na 2 Add 3mmol each of S and sublimated sulfur into water, heat and stir until the sulfur is completely dissolved to obtain yellow-brown Na 2 S 2 solution;

[0039] (3) Add 3mmol FeSO 4 Dissolve in 20ml of water and mix with the graphene suspension in step (1), then add the Na obtained in step (2) 2 S 2 Solution, heated up to 100°C, reflux reaction for 1h under an inert gas atmosphere, cooled to room temperature after the reaction was completed, centrifuged with water and ethanol, dried the separated product at 60°C, and ground to obtain 20wt% GNs@FeS 2 Powder, graphene coating amount was determined by thermogravimetric analysis (TGA).

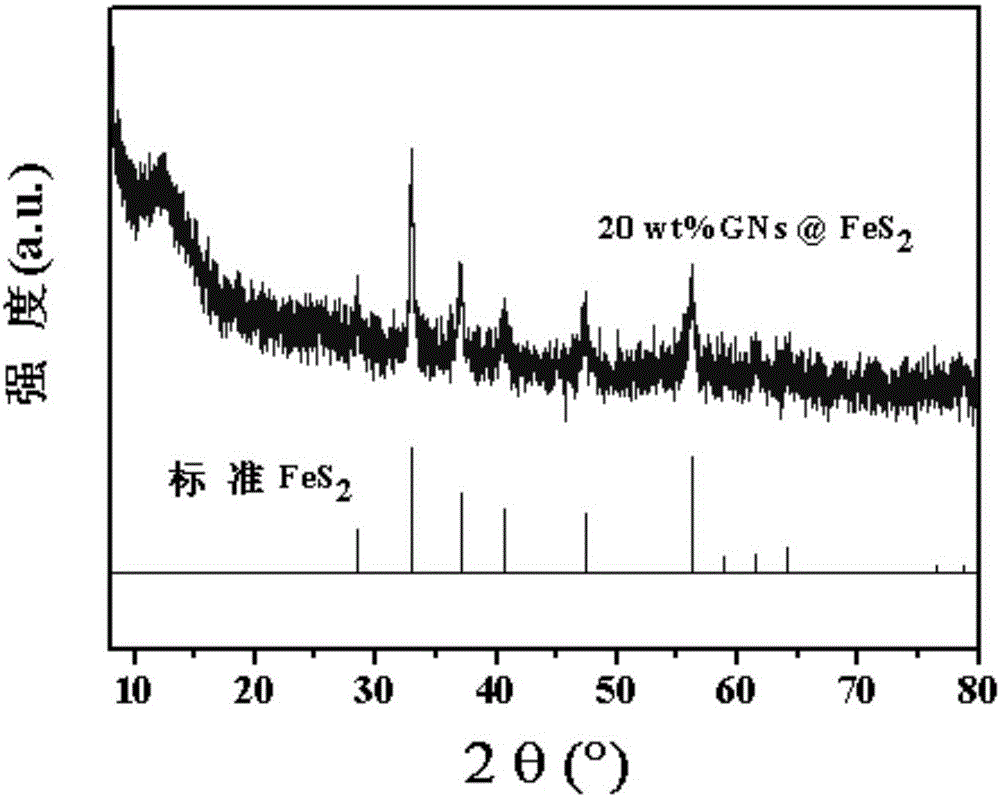

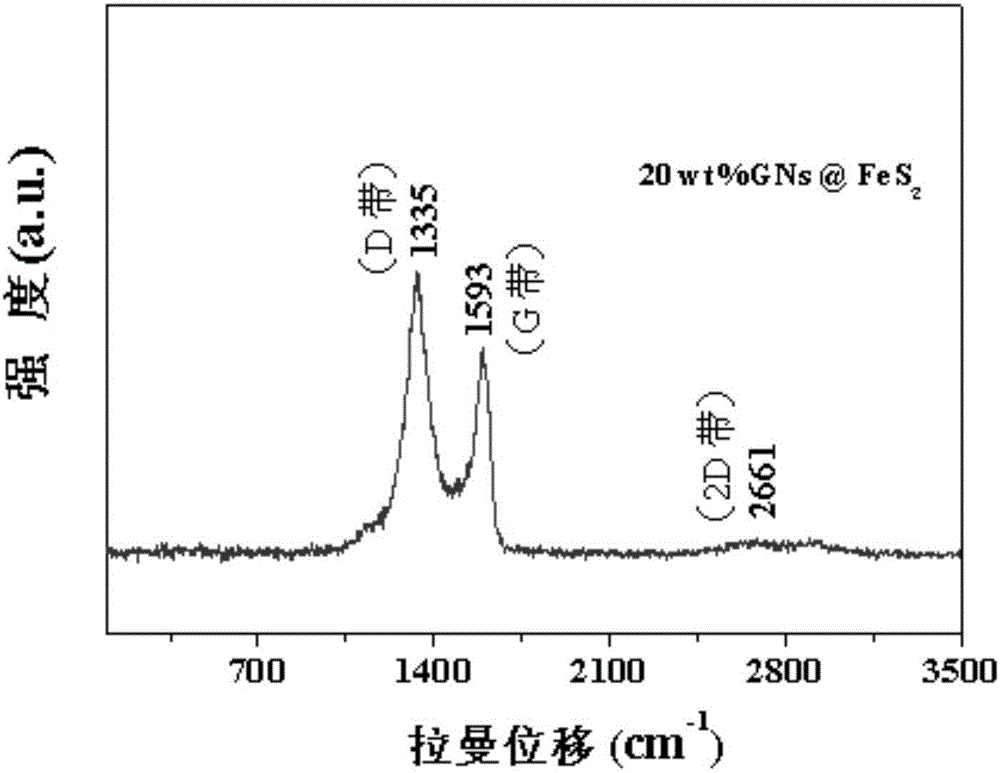

[0040] The products prepared in this example use X-ray diffraction (XRD) and Raman spectr...

Embodiment 3

[0042] (1) Put 0.1538g of graphene oxide in 30ml of water and ultrasonically disperse for 3 hours to obtain a graphene oxide suspension, then add 0.1538g of vitamin C to dissolve and ultrasonically 10min to obtain a graphene suspension;

[0043] (2) Na 2 Add 3mmol each of S and sublimated sulfur into water, heat and stir until the sulfur is completely dissolved to obtain yellow-brown Na 2 S 2 solution;

[0044] (3) Add 3mmol FeSO 4 Dissolve in 20ml of water and mix with the graphene suspension in step (1), then add the Na obtained in step (2) 2 S 2 Solution, heated up to 100°C, reflux reaction for 3h under an inert gas atmosphere, cooled to room temperature after the reaction was completed, centrifuged with water and ethanol, dried the separated product at 60°C, and ground to obtain 30wt% GNs@FeS 2 Powder, graphene coating amount was determined by thermogravimetric analysis (TGA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com