Thin-wall deep diving pontoon capable of automatically realizing internal and external pressure balance

A technology of internal and external pressure and floating tanks, which is applied to underwater operation equipment, transportation and packaging, ships, etc., and can solve problems such as increasing structural strength, reducing net buoyancy, and losing the buoyancy function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

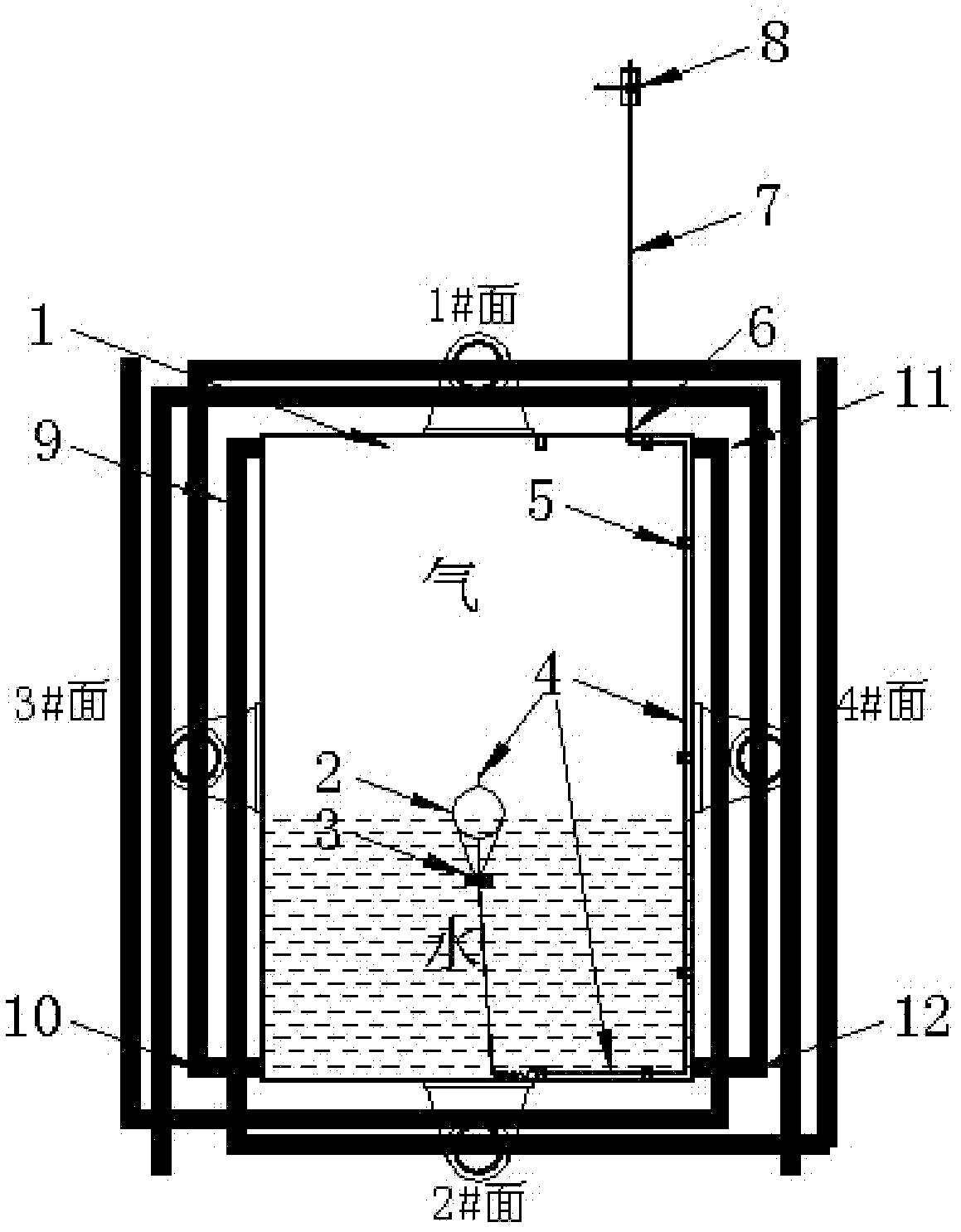

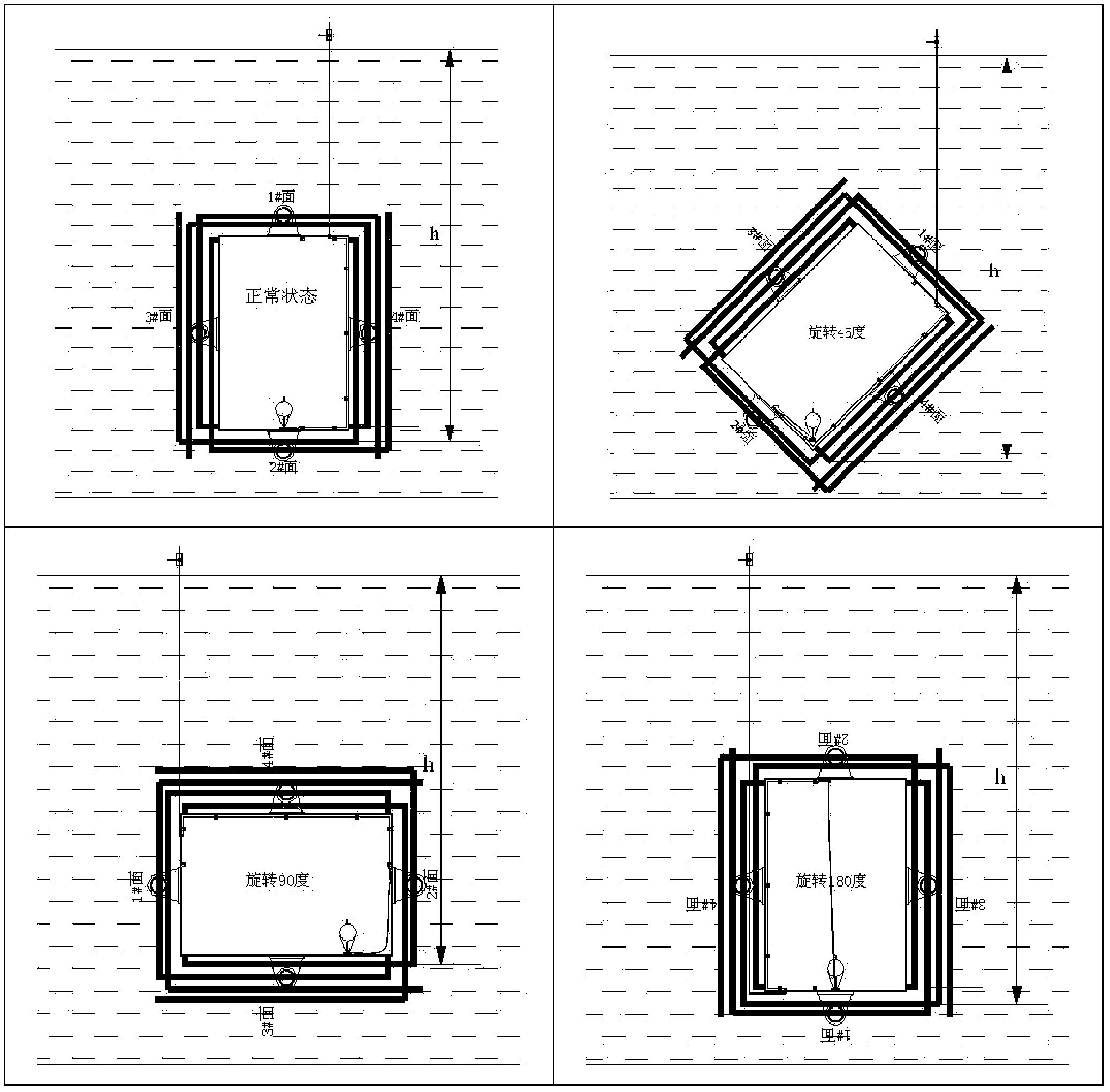

[0026] The thin-walled deep-submersible buoyant tank of the present invention can be designed into any shape according to needs, but its basic composition and working principle are the same. Firstly, the structure introduction and function description will be given by taking the square buoy working under two-dimensional conditions as an example.

[0027] Such as figure 1 As shown, the four faces of the buoyancy tank main body 1 are shown in the figure as side 1#, side 2#, side 3# and side 4#, and these 4 faces can be installed with lugs 13 as required, so as to facilitate the integration with other needs. Structural connections to aid buoyancy. Floating ball 2 is placed inside the main body of the buoyancy tank 1, and the weight 3 is fixedly connected to the bottom of the buoyant ball 2. The gravity of the weight 3 is less than the buoyancy of the buoyant ball 2 in the water. 3 Pull down the floating ball 2, and the buoyancy of the floating ball 2 is greater than the gravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com