Hydraulic power jet system for eliminating bottom sitting adsorption effect of submersible

A technology of hydrojet and adsorption effect, which is applied in the direction of underwater ships, special-purpose vessels, underwater operation equipment, etc. It can solve problems such as being stuck in mud, submersibles threatening the life safety of internal operators, and being unable to extricate themselves, so as to eliminate adsorption effect, enhancing deep-diving capabilities, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below.

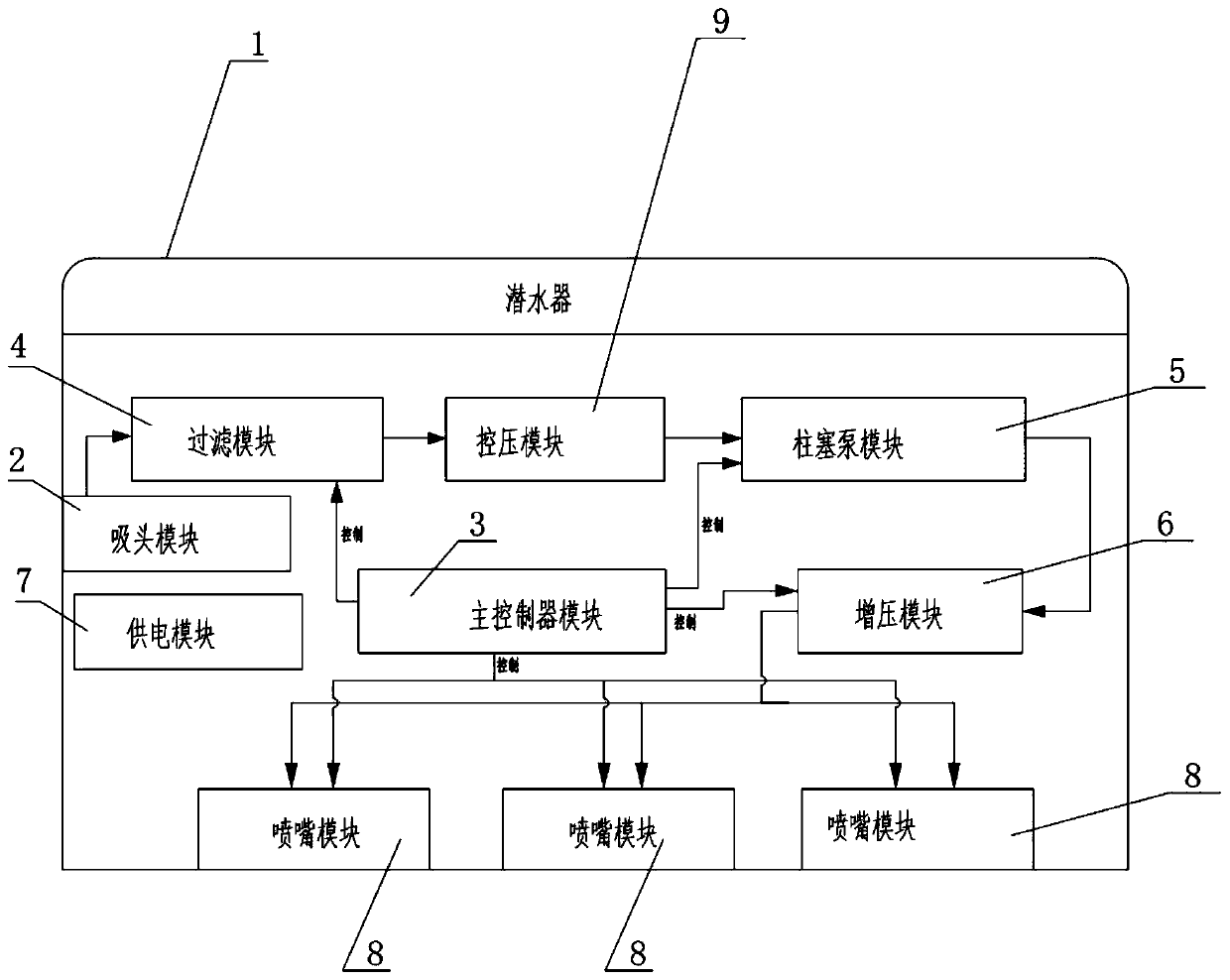

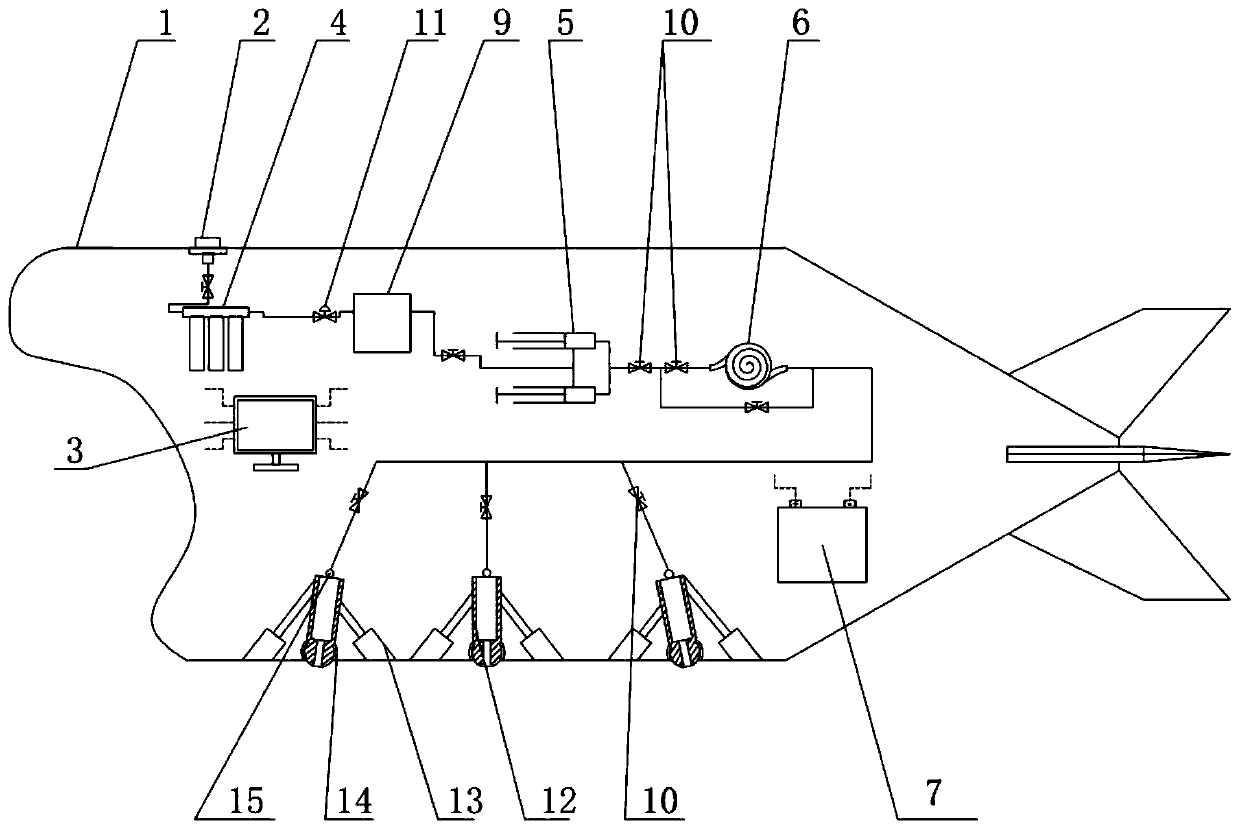

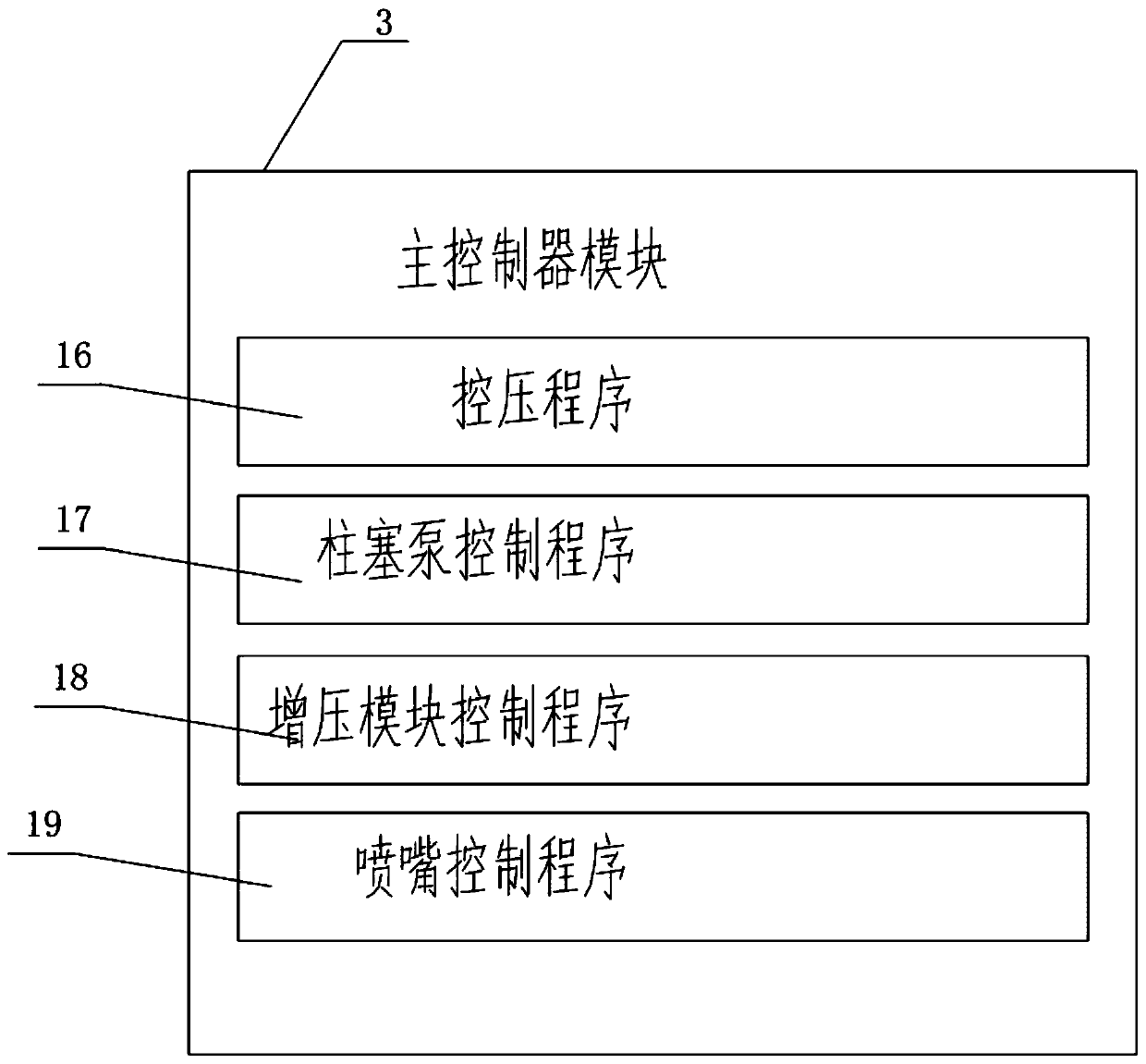

[0024] like figure 1 , figure 2 As shown, the hydrojet system used for submersibles to eliminate the absorption effect of sitting on the bottom includes a main controller module 3 located inside the submersible 1, a suction head module 2, a pressure control module 9, a plunger pump module 5, a booster module 6 and A plurality of nozzle modules 8; wherein the main control module 1 controls the entire hydrojet system through a preset program, such as image 3 As shown, the preset programs include a pressure control program 16 , a plunger pump control program 17 , a booster module control program 18 and a nozzle control program 19 . The pressure control module 9 is used to adjust the inlet pressure of the plunger pump module 5; the plunger pump module 5 and the booster module 6 are used to provide pressure compensation for the hydraulic jet; the nozzle module 8 is used to spray jet water.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com