Double-shaft-shoulder friction stir welding stirring head with four sets of auxiliary devices and method for welding curve butt welds of medium-thickness steel parts through double-shaft-shoulder friction stir welding stirring head

A technology of friction stir welding and auxiliary equipment, which is applied in the direction of welding equipment, non-electric welding equipment, process efficiency improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

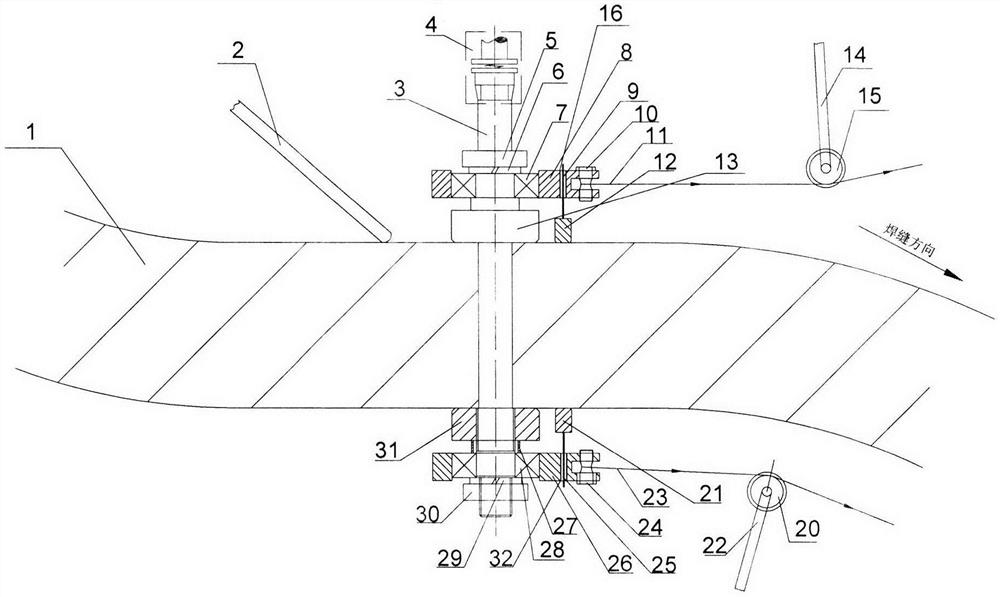

[0021] Install and fix the two parts to be welded or segmented parts that have been machined in cross-section. The height displacement should be minimized in the thickness direction of the weld and made less than 1mm or the trial value, and the gap should be eliminated by pressing in the width direction. If there are occasional or rare gaps, the value is not greater than 0.2mm or the value of the trial trial production, and the two directions should be clamped and fixed. For the assembly and welding process of devices such as stirring head and pull rope, the steps are as follows:

[0022] (1) Please refer to figure 1 , at the beginning of the stay rope 11 and the stay rope 23, pass through the fixed pulley 15 and the fixed pulley 20 respectively, according to the size of the two terminal posts 10 and 24 with a small circular arc in the middle and threads at the ends to make one for easy removal and the inserted joint sleeve (the present invention suggests equal), and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com