Titanizing technology for aluminum welding wire

A technology of aluminum welding wire and titanium plating, applied in welding medium, manufacturing tools, welding equipment, etc., can solve the problems of limiting titanium content, deteriorating the quality of molten aluminum, and interrupting production, so as to increase the amount of plating and eliminate uncertain influences Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) The titanium powder is adjusted into a paste with aviation kerosene, the cotton thread is passed through the paste, the paste is coated on the cotton thread, and the cotton thread coated with titanium is obtained after the aviation kerosene volatilizes;

[0022] (2) The titanium-containing cotton thread obtained in step (1) is controlled by the equipment, and one end is released and the other end is taken up. It is wound on the surface of the ER5087 aluminum welding wire in a tense state and is in a state of being twitched. The tension is 10N, the back tension is 15N, and the speed of twitching the cotton thread is 25 cm / min; the welding wire is also controlled by the equipment, one end is unwound and the other end is taken up, and it is in the state of being twitched.

[0023] Add aviation kerosene dropwise on it to make the aviation kerosene adhere to the surface of the aforementioned aluminum welding wire wound with titanium-containing cotton wire, adjust the twit...

Embodiment 2

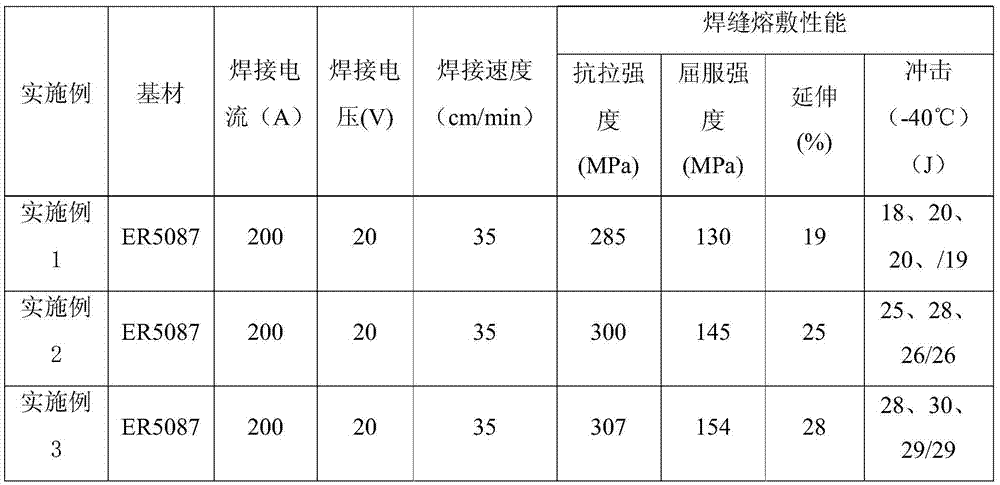

[0025] Use "alcohol" instead of aviation kerosene in Example 1 to add dropwise as an auxiliary agent, and through process adjustment, control the conversion of titanium contained on the surface of the final titanium-coated aluminum welding wire into TiO 2 The weight accounts for 0.10% of the total weight of the welding wire after titanium plating, and the rest of the steps are the same as in Example 1, and the deposition test results are shown in Table 1.

Embodiment 3

[0027] Use "isobutanol" instead of aviation kerosene in Example 1 to add dropwise as an auxiliary agent, and through process adjustment, control the conversion of titanium contained on the surface of the final titanium-coated aluminum welding wire into TiO 2 The weight accounts for 0.15% of the total weight of the welding wire after titanium plating, and the rest of the steps are the same as in Example 1, and the deposition test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com