Follow-up Method for Improving Al/cu Friction Stir Welding Seam Microstructure

A friction stir welding, follow-up technology, applied in the field of forging and metallurgy, can solve the problems of weld defects, low heat input, micro-cracks, etc., to remove holes and tunnel defects, enhance application adaptability, and refine welding. The effect of slit grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

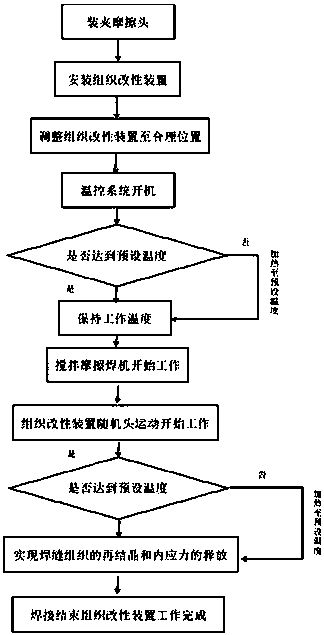

[0013] Such as figure 1 Shown, the present invention is the method that follow-up type improves Al / Cu friction stir welding weld seam structure, and its steps are:

[0014] (1) Step 1: Adjust the minimum working pressure and adjust the minimum pressing force of the tissue modification mechanism;

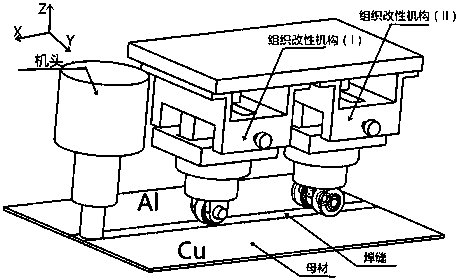

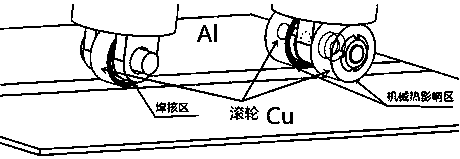

[0015] (2) Step 2: Use the control mechanism to adjust the position of the tissue modification mechanism. In the structure modification mechanism I with a single roller, the roller covers the entire weld nugget area and a part of the mechanical heat-affected zone; in the structure modification mechanism II with two rollers, two The two rollers correspond to the entire mechanical heat-affected zone on the Al / Cu side and a part of the heat-affected zone of the weld and the nugget zone;

[0016] (3) Step 3: Turn on the temperature control system, set the modification temperature, set the roller temperature T1=290~315℃ in the tissue modification mechanism I; preset the Al side roller te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com