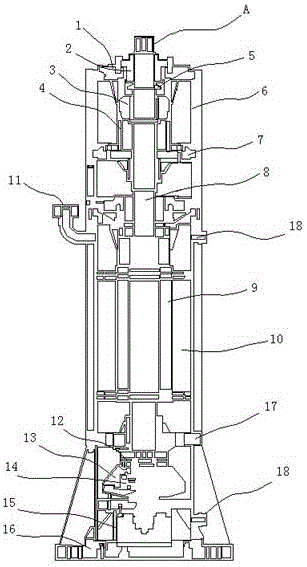

High-power oil-filled deep-diving underwater motor

An underwater motor and oil-filled technology, which is applied in the direction of electrical components, electromechanical devices, and electric components, can solve the problems that deep-sea oil and gas cannot be exploited, and achieve the effects of reducing mining costs, reducing dependence, and avoiding bottleneck constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

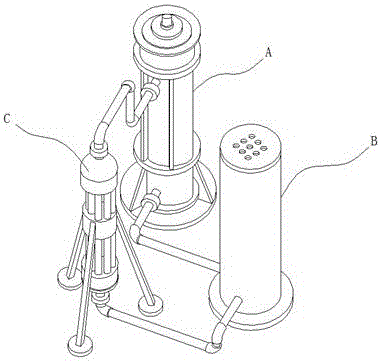

[0036] refer to figure 2 , when the motor A starts to work, the temperature of the motor oil inside the system gradually rises, and the heated volume of the motor oil gradually expands to push the volume of the capsule of the compensator B to become larger to balance the pressure difference between the inside and outside of the system; when the heat generated by the motor A decreases or stops , the temperature of the motor oil inside the system gradually decreases, and the volume of the motor oil gradually shrinks to push the volume of the capsule in the compensator B to shrink to balance the pressure difference between the inside and outside of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com