Ocean floating body structure

A technology for offshore floating bodies and structures, applied to floating structures, hulls, hull decks, etc., can solve the problems of the hull not being able to keep up with loading, prolong the FPSO manufacturing period, and achieve the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below with reference to embodiments shown in the drawings.

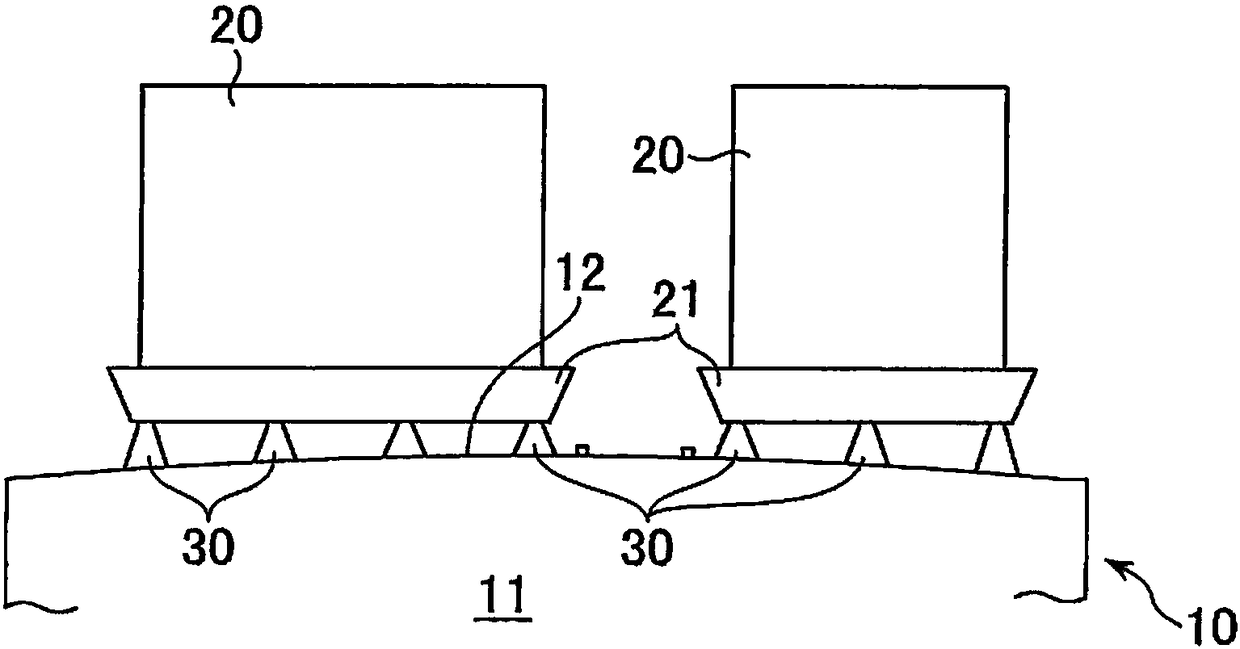

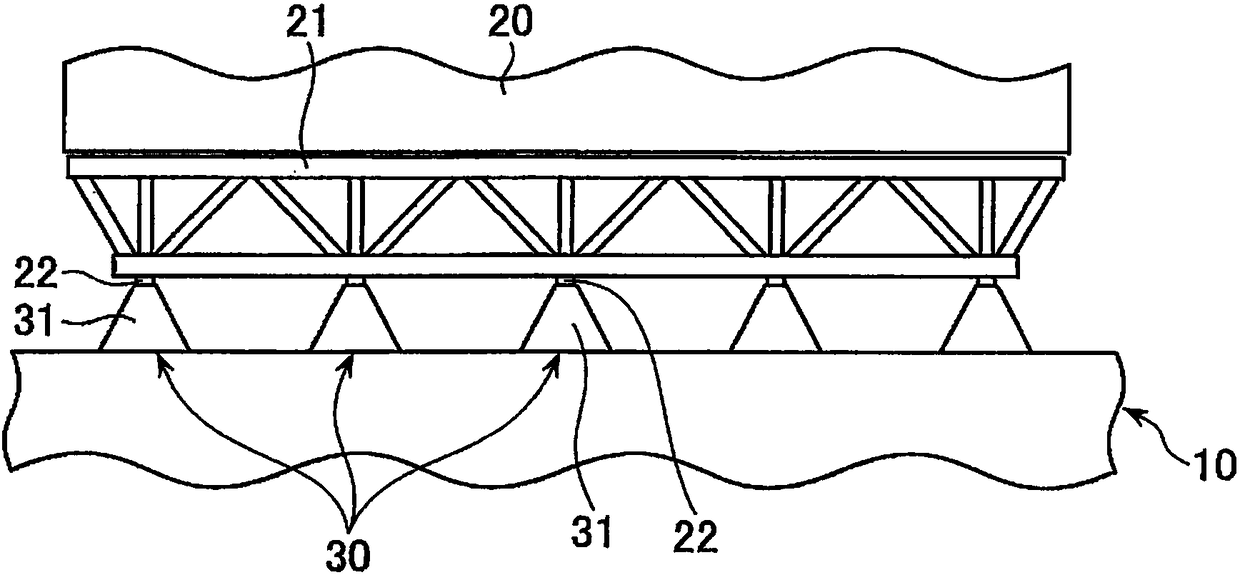

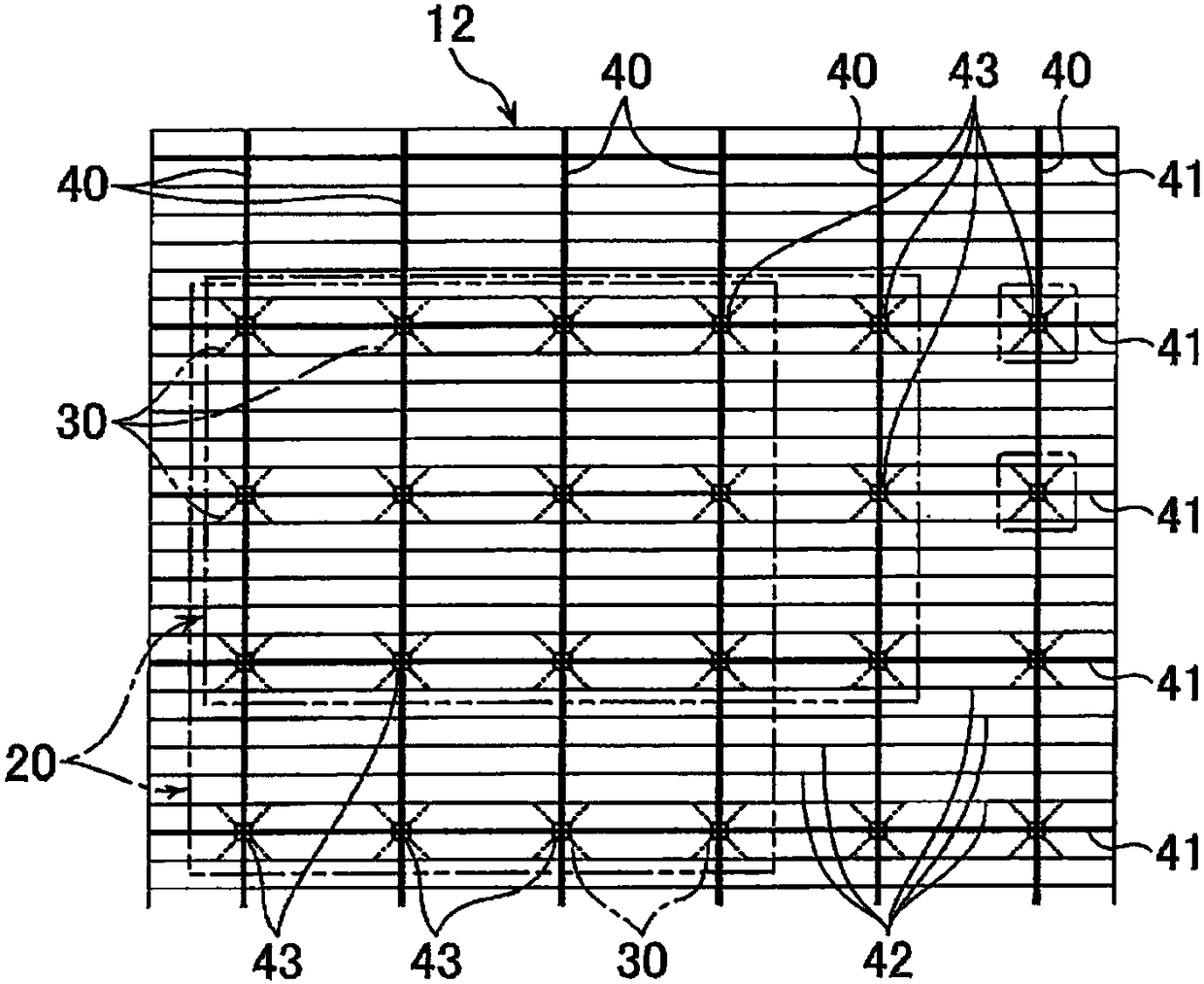

[0027] figure 1 A schematic structure on the upper deck of the FPSO applied to the first embodiment of the present invention is shown. A tank 11 is formed at the floating body 10 , and a plurality of production equipment 20 is arranged on the upper deck 12 . The production equipment 20 includes, for example, natural gas separation equipment, dehydration equipment, metering equipment, and power generation equipment, etc., and is fixed on the base 21 and installed on the bracket base 30 , wherein the bracket base 30 is installed on the upper deck 12 . The bracket base 30 is arranged in a grid shape as will be described later.

[0028] figure 2 is said to be figure 1 An enlarged view of the base 21 and the bracket seat 30 in the shown structure viewed from the side. The bracket base 30 has an inverted V-shaped main body 31 whose width becomes narrower upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com