Welded structure excellent in brittle-cracking propagation stopping characteristics

A technology of brittle crack propagation and welding structure, which is applied in welding equipment, hull, ship construction, etc., can solve the problem of reduced fracture toughness and achieve the effect of reducing the total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

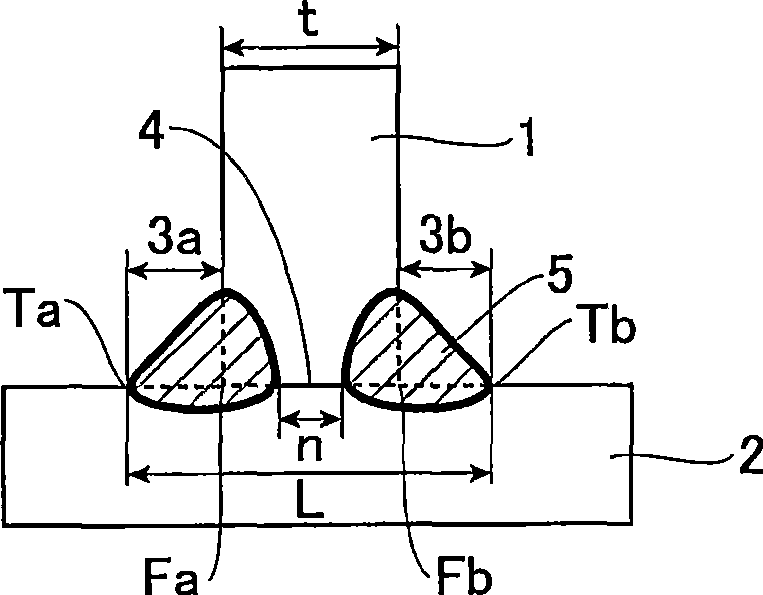

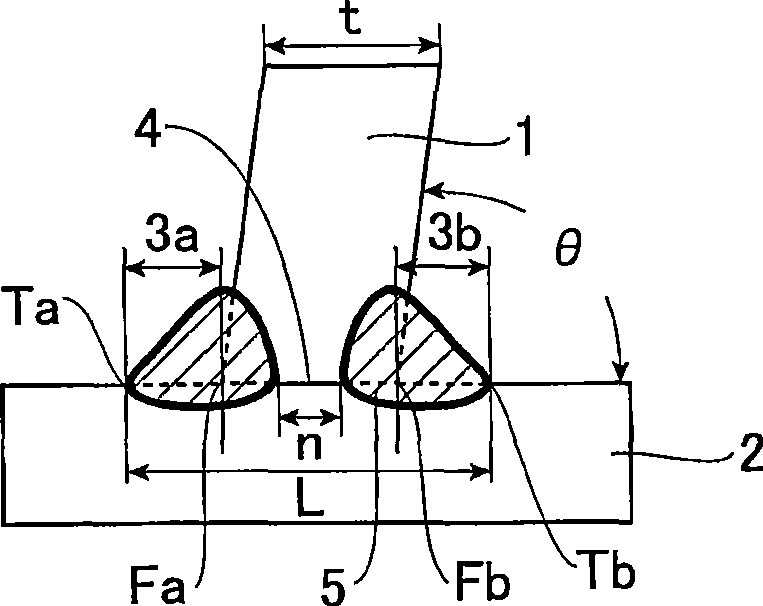

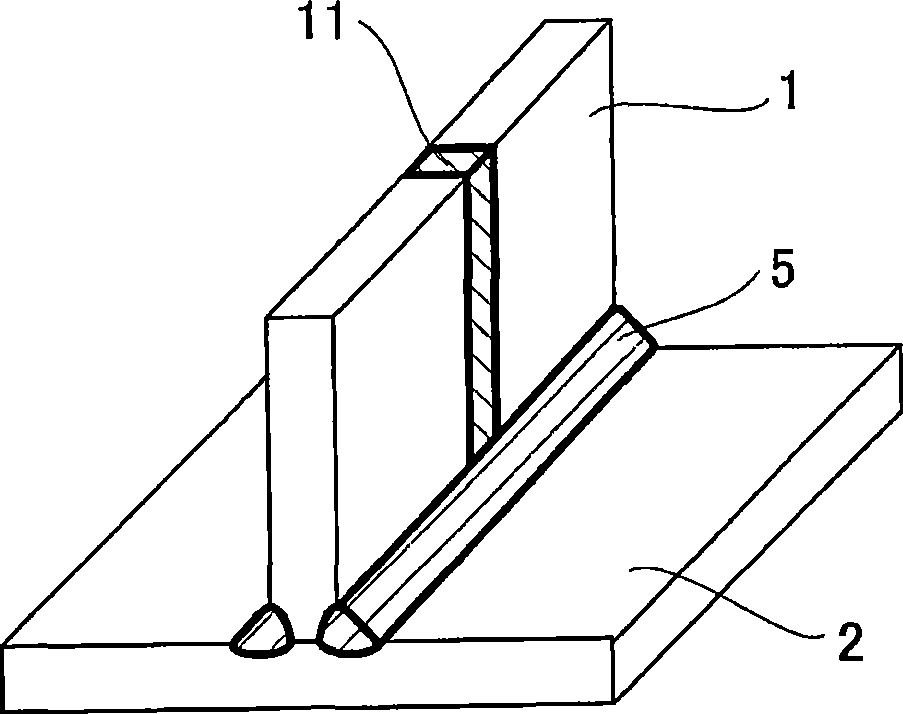

[0074] Using steel plates with various plate thicknesses and brittle crack propagation stopping toughness (Kca at -10°C), various unwelded portion ratios X (width n of unwelded portion to the plate thickness of web 1 The ratio of t to the sum L of the leg lengths 3 (3a, 3b) of the left and right fillet welds of the web 1) is a T-shaped fillet weld joint 9. The T-shaped fillet welded joint 9 is manufactured when the web 1 is only a steel plate base material and when the web 1 has a butt welded joint 11 . In addition, the butt weld joint 11 is welded by single-pass high-energy input (in Table 2, it is expressed as EGW (electro gas arc) or 2-electrode EGW) or multi-layer CO 2 Welding (multi-layer carbon-dioxide welding) production.

[0075] Manufactured using the obtained T-shaped fillet weld joint 9 Figure 3A , Figure 3B The cross-shaped ESSO test piece shown is for the brittle crack arrestability test (ESSO test). For the cross-shaped ESSO test piece, the web 1 and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com