Welding structural body

A technology for structural bodies and welding parts, which is applied in the direction of connecting components, welding equipment, thin plate connections, etc., can solve problems such as high cost, and achieve the effect of simple processing and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

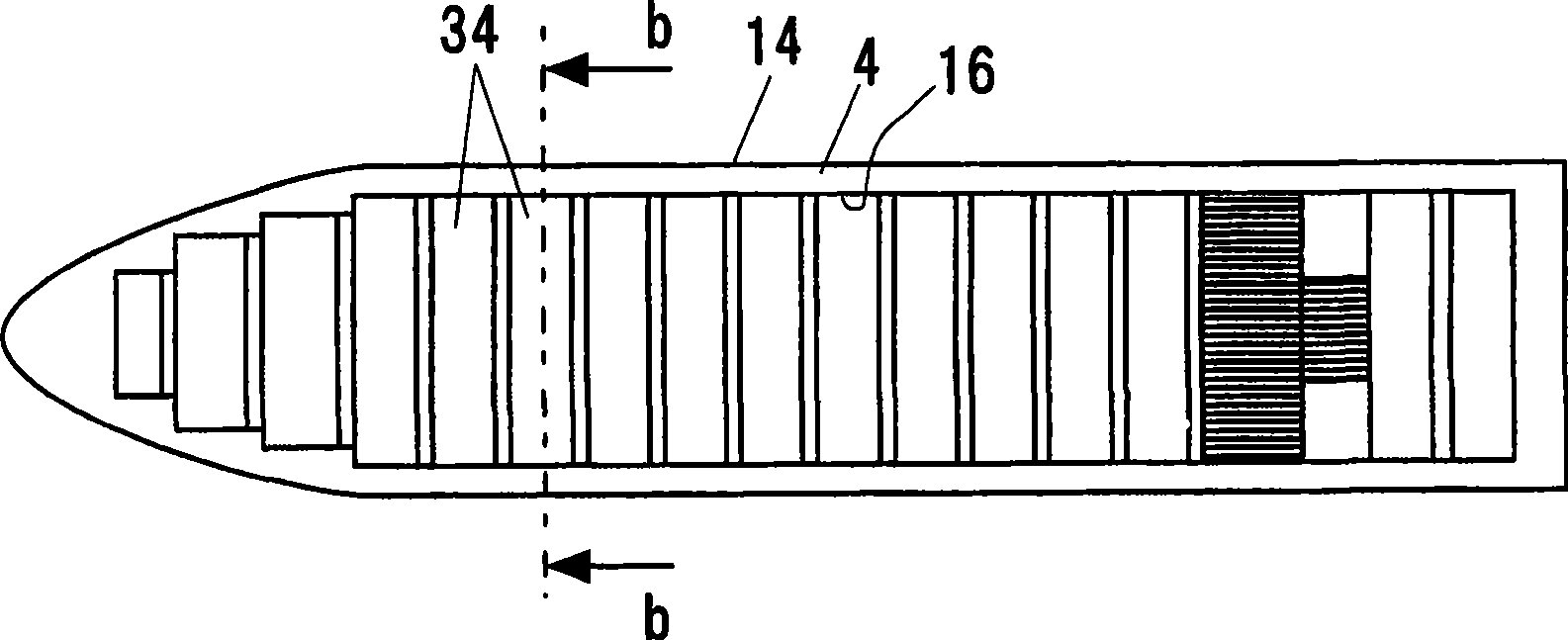

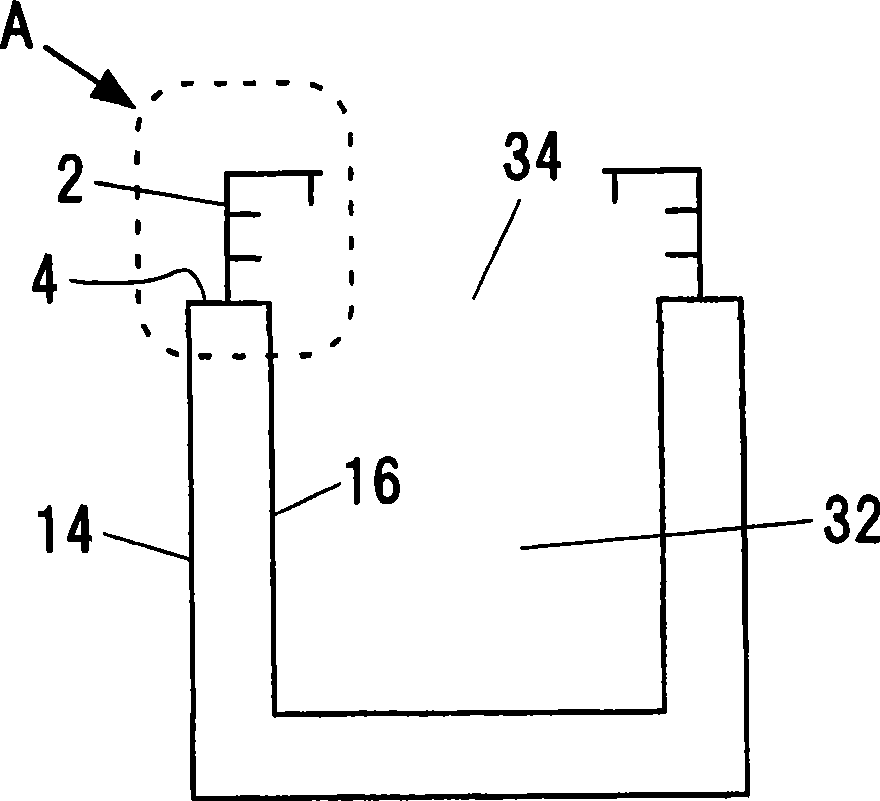

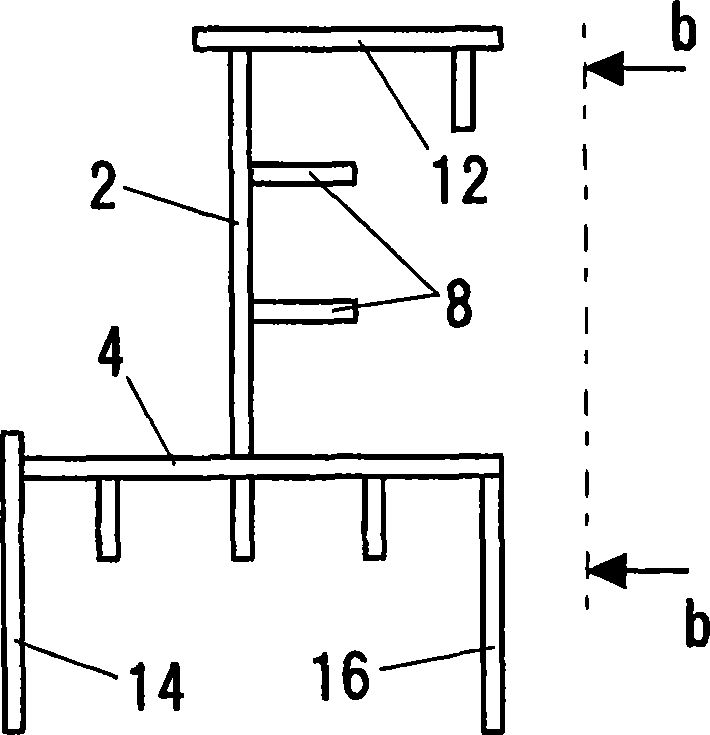

[0066] Figure 3A It is an enlarged view of the part indicated by the arrow A in FIG. 1B, showing the case where the welded structure according to the first embodiment of the present invention (corresponding to the first invention) is applied to the hatch coaming and upper deck of a container ship .

[0067] Such as Figure 3A As shown, the welded structure of the first embodiment is a structure in which the hatch coaming 2 is welded to the upper deck 4 .

[0068] Figure 3B yes Figure 3A b-b line arrow direction view. Such as Figure 3B As shown, the hatch coaming 2 is formed by butting the end surfaces of two or more metal plates 2a (in this example, steel plates) together by welding. In addition, a bone member (aggregate) 8 as a reinforcement member extending in a direction perpendicular to the welded joint portion 6 is joined to the side surface of the hatch coaming 2 by fillet welding. In addition, a top plate 12 arranged in the horizontal direction is welded to the ...

no. 2 Embodiment approach

[0084] Next, a welded structure according to a second embodiment of the present invention will be described. Configurations other than those described below may be the same as those of the first embodiment.

[0085] Figure 6A express Figure 3B The enlarged view of the portion indicated by the arrow C shows the welded structure of the second embodiment. also, Figure 6B yes Figure 6A b-b line arrow direction view.

[0086] Such as Figure 6A , Figure 6B As shown, near the joint position of the welded joint 6 and the upper deck 4 , a contact prevention member 28 is interposed between the welded joint 6 and the upper deck 4 so that the welded joint 6 does not touch the upper deck 4 . The contact protection member 28 can be formed, for example, from relatively tough mild steel. In addition, the shape of the contact preventing member 28 may be such as Figure 6A , Figure 6B As shown, the corners of the four corners of the upper surface are formed into smooth curved f...

no. 3 Embodiment approach

[0099] Figure 9A yes Figure 3A The view in the direction of the arrow of line b-b shows the application of the welded structure according to the third embodiment of the present invention (corresponding to the second technical solution) to the hatch coaming of a container ship. Such as Figure 9A As shown, the welded structure according to the third embodiment includes a structure in which two or more metal plates 2 a (steel plates in this example) are butted against each other with their end faces welded together.

[0100] Figure 9B By Figure 9A The enlarged view of the part indicated by the arrow b in . Such as Figure 9B As shown, according to the third embodiment, a hole 29 penetrating through the welded joint 6 is formed in the thickness direction of the hatch coaming 2 so that the welded joint 6 extending between the two metal plates 2a is cut off in the middle. open.

[0101] In this way, in the welded structure according to the third embodiment, since the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com